Round block hole type multi-path graphite heat exchanger

A graphite heat exchanger, multi-process technology, applied in the direction of heat exchanger type, heat exchanger shell, indirect heat exchanger, etc., can solve the problems of low heat exchange efficiency, short service life, poor durability, etc., and achieve material flow Smooth, simple structure, the effect of improving heat exchange efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

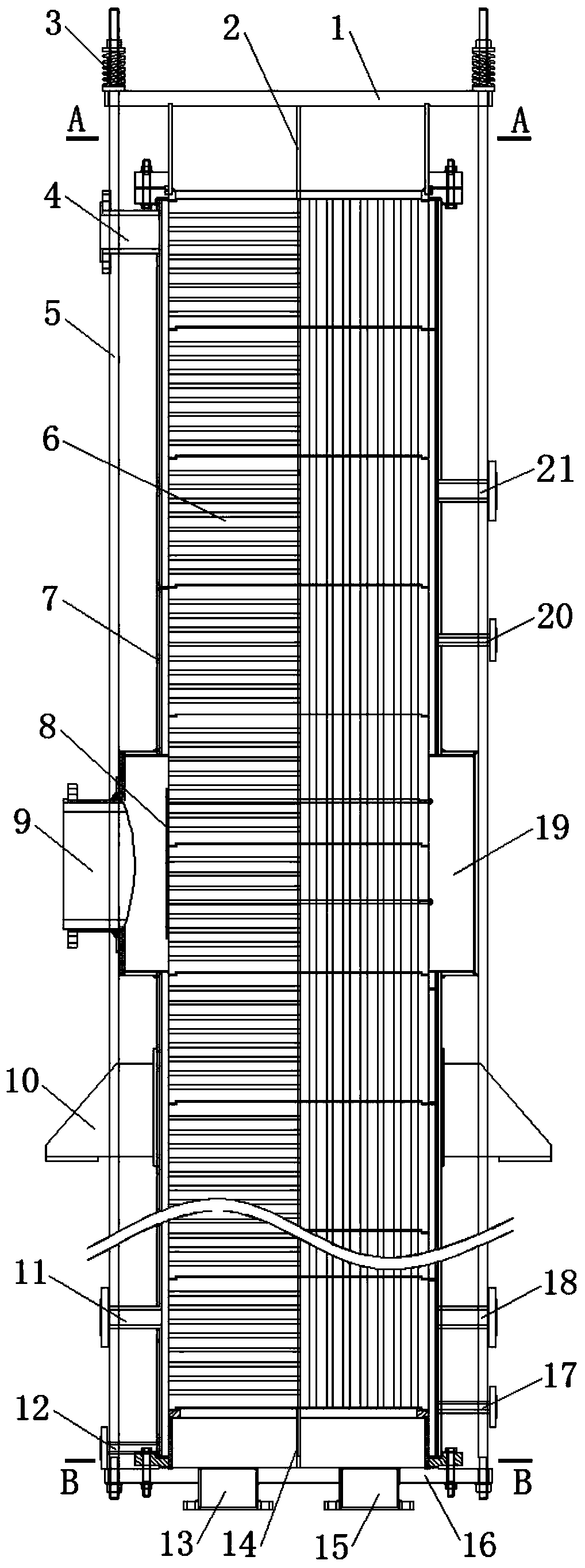

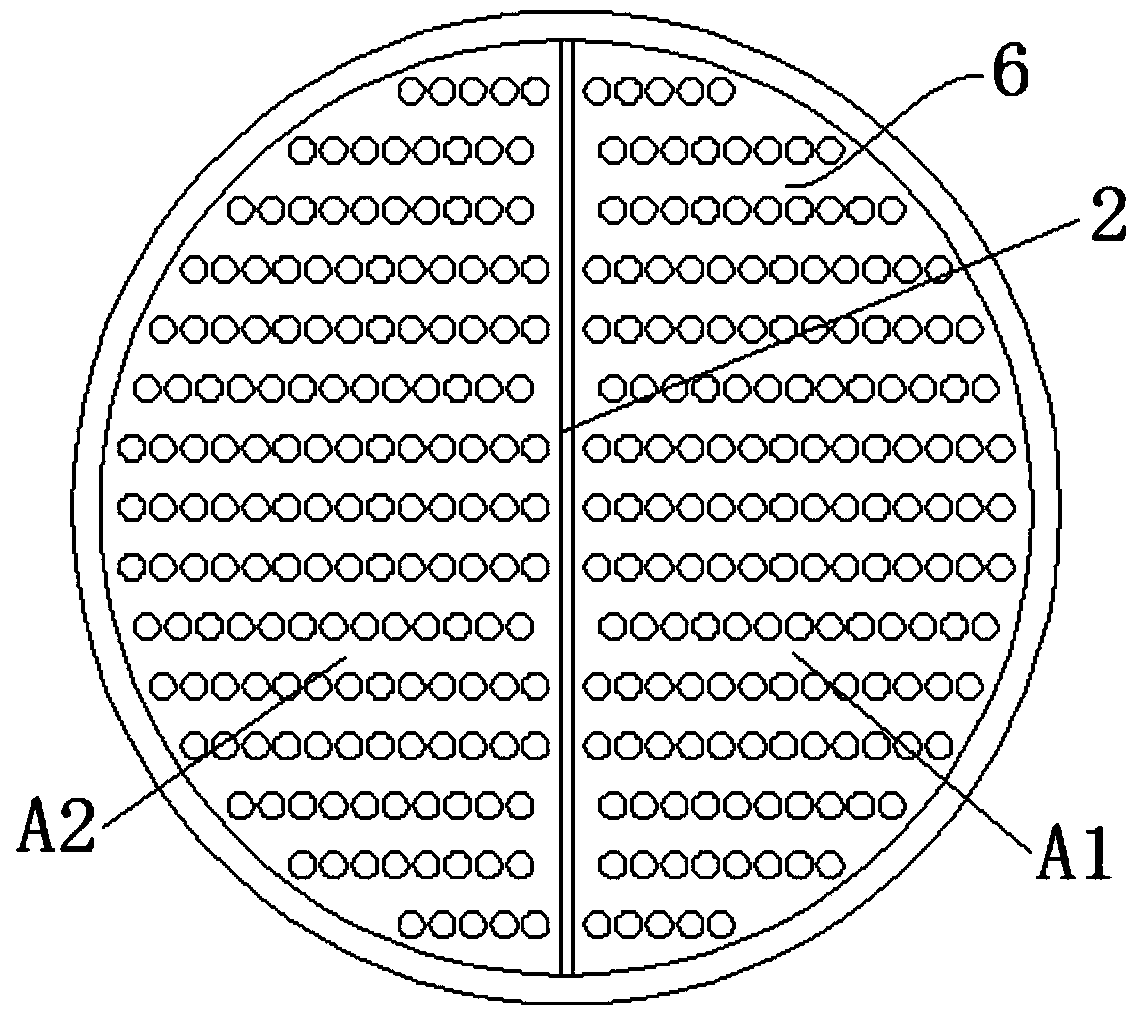

[0039] to combine figure 1 , a round block hole type multi-flow graphite heat exchanger of the present embodiment, comprising a shell 7, a combined graphite block 6 arranged inside the shell 7, a steam inlet 9 set in the middle of the shell 7, and a steam inlet 9 set in the lower part of the shell 7 Condensate outlet 17, water outlet 13, water inlet 15, upper partition 2, lower partition 14, upper pressing plate 1, lower pressing plate 16 and pull rod 5, the gap between shell 7 and graphite block 6 forms the graphite heat exchanger The shell side, the steam inlet 9 and the condensate outlet 17 are respectively connected with the shell side, and the upper partition 2 is arranged on the upper end of the shell 7, and divides the upper tube side of the graphite heat exchanger into a plurality of upper partitions; the lower partition 14 It is located at the lower end of the shell 7, and divides the lower tube side of the graphite heat exchanger into multiple lower partitions; the l...

Embodiment 2

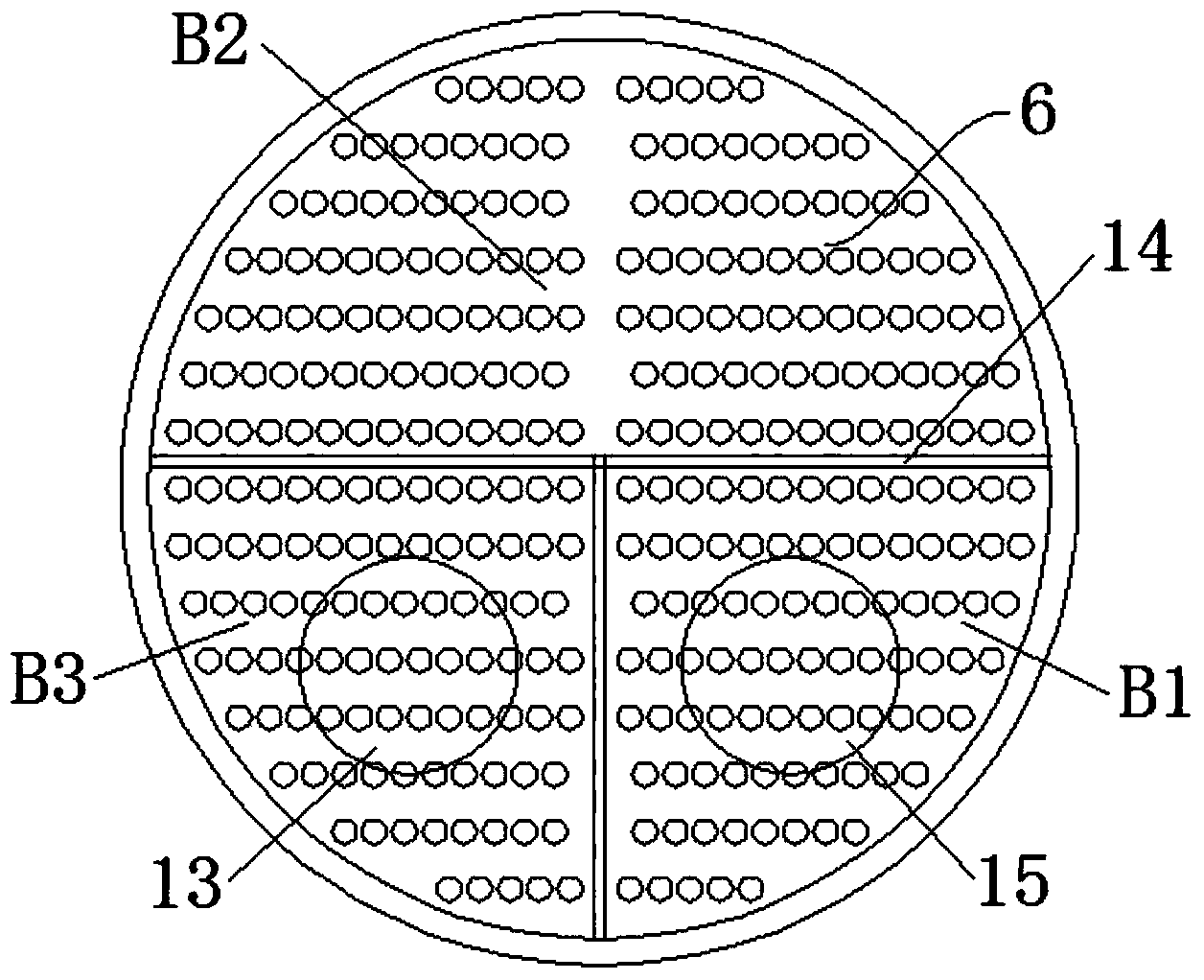

[0043] to combine Figure 4 , Figure 5 with Image 6 , the basic structure of a kind of round hole type multi-flow graphite heat exchanger of the present embodiment is the same as that of the embodiment 1, the difference is that: the upper partition 2 in the present embodiment separates the upper tube side of the graphite heat exchanger into The first upper partition C1, the second upper partition C2 and the third upper partition C3; the lower partition 14 divides the lower tube side of the graphite heat exchanger into the first lower partition D1, the second lower partition D2, and the third lower partition D3 and the lower partition D4; the lower partition D1, the upper partition C1, the lower partition D2, the upper partition C2, the lower partition D3, the upper partition C3 and the lower partition D4 in series It is a six-flow channel bent up and down, the water inlet 15 is located in the first lower partition D1, and the water outlet 13 is located in the fourth lower ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com