Underground direct plug of conductive cylinder glue injection type

A conductive cylinder and plug technology, which is applied in the direction of circuits, electrical components, bases/shells, etc., can solve the problems of plug seal failure, no solution, and unsatisfactory temperature and pressure resistance of the plug, and achieve good sealing performance and simple structure , the effect suitable for promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

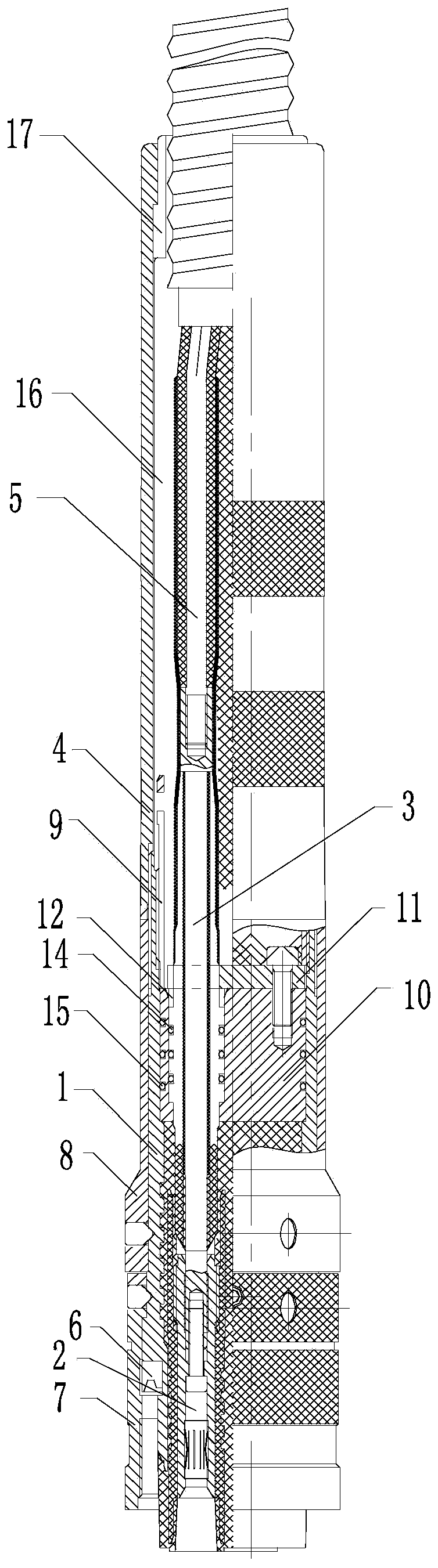

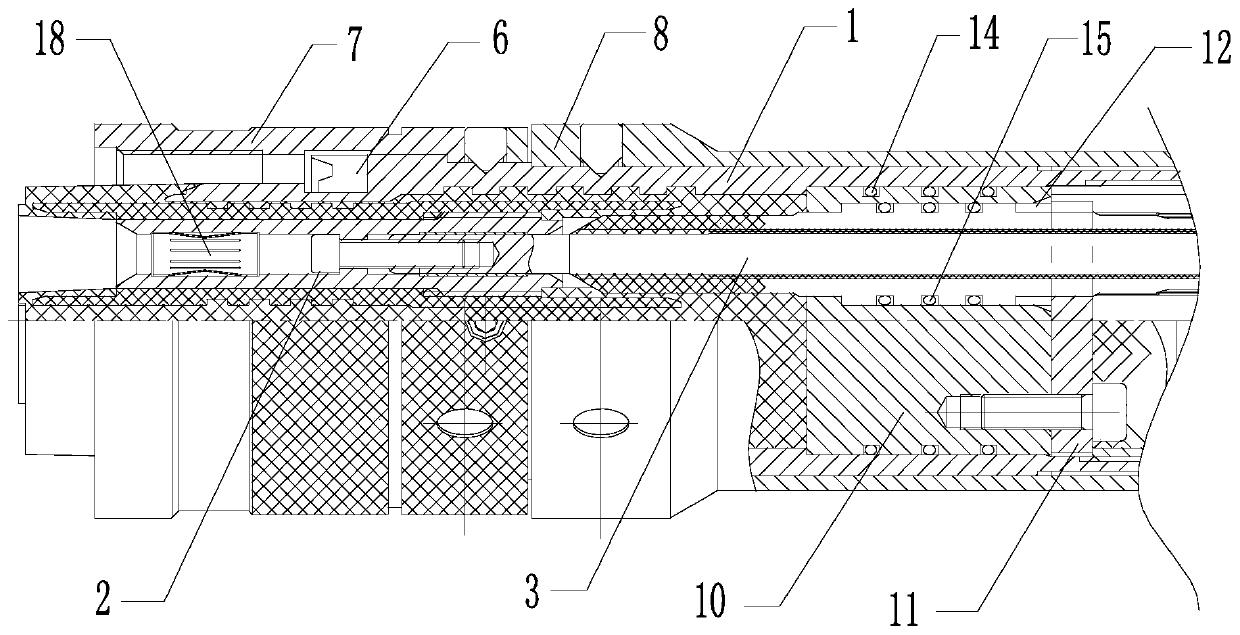

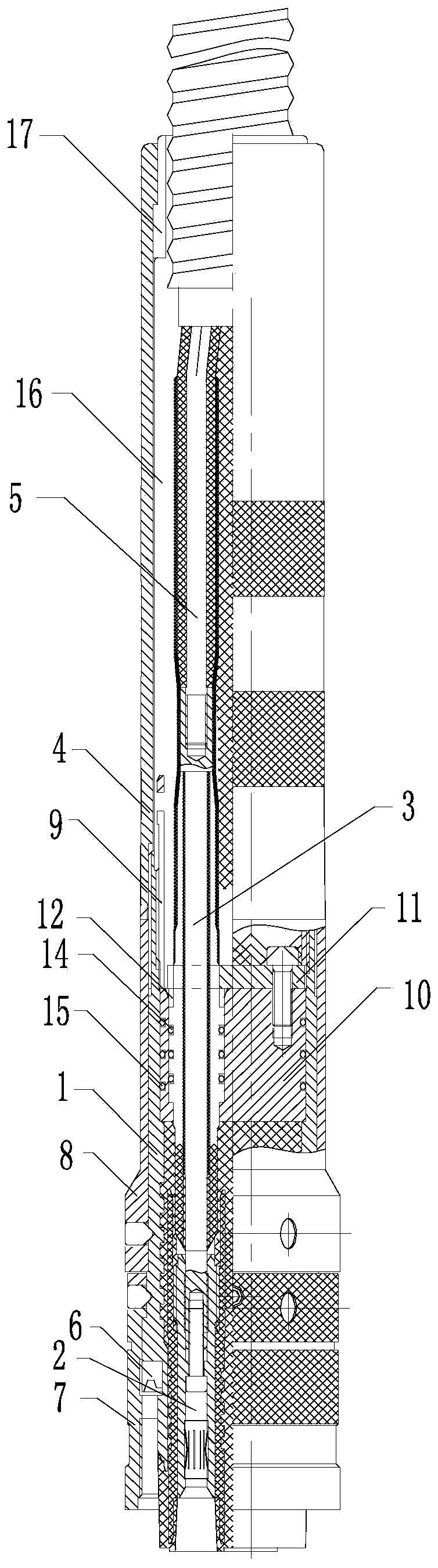

[0013] The present invention will be described in further detail below in conjunction with specific embodiments and accompanying drawings.

[0014] a kind of like figure 1 and figure 2 The conductive cylinder glue injection type downhole straight plug shown includes a straight plug housing 1, a conductive cylinder 2 with an insulating layer arranged in the front of the straight plug housing 1, and a conductive cylinder with an insulating sleeve in the middle of the straight plug housing. Insulated pins 3, and a spring leaf 18 is arranged in the conductive cylinder 2, a straight plug tail shell 4 adapted to it is arranged at the tail of the straight plug shell 1, and a cable stripping head 5 is arranged in the straight plug tail shell 4 , the cable stripping head 5 is connected to the insulating pin 3, a lip sealing ring 6 is provided at the front end of the straight plug housing 1, and a straight plug connecting screw cover 7 and a straight plug positioning sleeve 8 are arra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com