Water-blocking foam and its preparation method and application

A technology of water foam and foam, which is applied in the field of foam, can solve problems such as damage, unsatisfactory water resistance and cushioning performance, and failure of mobile phones and other equipment, so as to improve mechanical strength, excellent transparency and dimensional stability, and save energy. the effect of time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

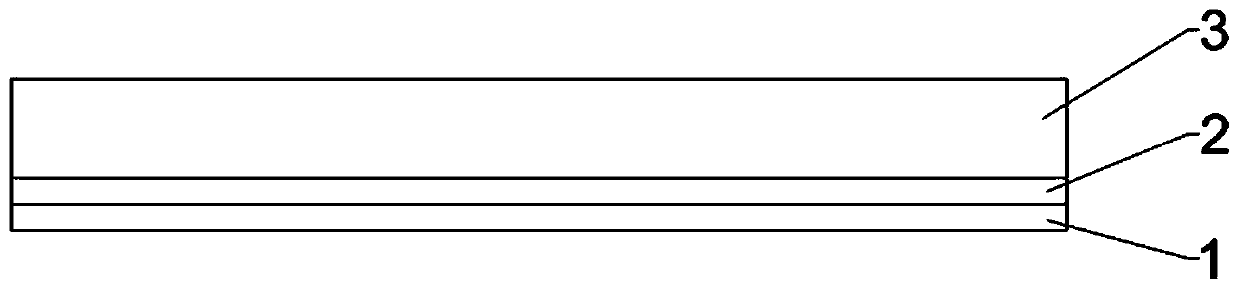

[0060] see figure 1 , which is a schematic structural view of the water-blocking foam of the embodiment of the present invention. The water-blocking foam of this embodiment includes a PET layer 1 , a PVDC layer 2 and a foam layer 3 in contact with each other in sequence. The thicknesses of the PET layer 1 , the PVDC layer 2 and the foam layer 3 are 10 μm, 10 μm and 80 μm respectively. The water-blocking foam is 0.1mm thick.

[0061] In this embodiment, the foam layer 3 is prepared by blending polyethylene and additive masterbatch at a mass ratio of 10:1. The auxiliary agent masterbatch is prepared from polyethylene, carbon nanotubes and azodicarbonamide in a mass ratio of 100:1:1. The average molecular weight of described polyethylene is 80000, and density is 0.965g / cm 3 , The melt index is 1.5g / 10min. The carbon nanotubes are single-wall carbon nanotubes (the model is XFQ045, and the manufacturer is Nanjing Xianfeng Nano Material Technology Co., Ltd.).

[0062] The avera...

Embodiment 2

[0074] The water-blocking foam of this embodiment includes a PET layer, a PVDC layer and a foam layer in contact with each other in sequence. The thicknesses of the PET layer, PVDC layer and foam layer are 5 μm, 15 μm and 80 μm respectively. The water-blocking foam is 0.1mm thick.

[0075] In this embodiment, the foam layer is prepared by blending polyethylene and additive masterbatch at a mass ratio of 10:0.8. The auxiliary agent masterbatch is prepared from polyethylene, carbon nanotubes and azodicarbonamide in a mass ratio of 80:1.2:1.2. The average molecular weight of the polyethylene is 100000, and the density is 0.975g / cm 3 , The melt index is 1.2g / 10min. The carbon nanotubes are single-wall carbon nanotubes (the model is XFQ045, and the manufacturer is Nanjing Xianfeng Nano Material Technology Co., Ltd.).

[0076] The average molecular weight of the PET masterbatch of the PET layer is 10000, and the density is 1.25g / cm 3 , The melt index is 13g / 10min.

[0077] The...

Embodiment 3

[0087] The water-blocking foam of this embodiment includes a PET layer, a PVDC layer and a foam layer in contact with each other in sequence. The thicknesses of the PET layer, PVDC layer and foam layer are 15 μm, 5 μm and 80 μm respectively. The water-blocking foam is 0.1mm thick.

[0088] In this embodiment, the foam layer is prepared by blending polyethylene and additive masterbatch at a mass ratio of 10:1.2. The auxiliary agent masterbatch is prepared from polyethylene, carbon nanotubes and azodicarbonamide in a mass ratio of 120:0.8:0.8. The average molecular weight of described polyethylene is 200000, and density is 1.0g / cm 3 , Melt index is 1g / 10min. The carbon nanotubes are single-walled carbon nanotubes.

[0089] The average molecular weight of the PET masterbatch of the PET layer is 20000, and the density is 1.32g / cm 3 , The melt index is 10g / 10min.

[0090] The PVDC masterbatch of the PVDC layer has an average molecular weight of 70,000 and a density of 0.78g / c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com