Temperature-controllable high-pressure environmental mechanical test box

A technology of environmental mechanics and test chambers, applied in the direction of applying stable tension/pressure to test material strength, scientific instruments, measuring devices, etc., can solve the problem of inability to achieve precise control of test temperature, increase equipment manufacturing costs, limit environmental test pressure, etc. problems, to achieve the effect of good temperature and pressure resistance, good sealing performance, flexible and convenient loading and unloading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

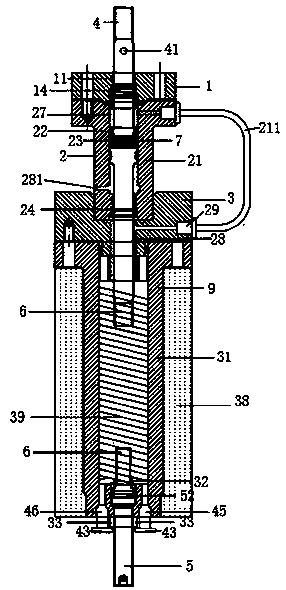

[0053] Embodiment 1: First, unscrew the 8 bolts between the lower kettle body and the middle kettle body, and separate the lower kettle body from the middle kettle body. Put the double-helix heating tube into the upper port of the lower kettle body and lead the two tubes out from the liquid inlet and the liquid outlet respectively; open the fixing nut at the bottom of the lower kettle body, push the lower stretching rod into the lower kettle body, And take out the lower stretch rod from the upper opening of the lower kettle body;

[0054] Install the two ends of the tested sample to the lower end of the upper stretching rod and the upper end of the upper stretching rod respectively, then reinstall the lower stretching rod from the upper opening of the lower kettle body and pull it out from the lower opening, and reinstall and fix it nut, and tighten the fixing nut. If it is necessary to carry out a high-pressure liquid experiment, fill the liquid into the hollow cavity at thi...

Embodiment 2

[0059] Embodiment 2: first unscrew the 8 bolts between the lower kettle body and the middle kettle body, and separate the lower kettle body from the middle kettle body. Put the double-helix heating tube into the upper port of the lower kettle body and lead the two tubes out from the liquid inlet and the liquid outlet respectively; open the fixing nut at the bottom of the lower kettle body, push the lower stretching rod into the lower kettle body, And take out the lower stretch rod from the upper opening of the lower kettle body;

[0060] Install the two ends of the tested sample to the lower end of the upper stretching rod and the upper end of the upper stretching rod respectively, then reinstall the lower stretching rod from the upper opening of the lower kettle body and pull it out from the lower opening, and reinstall and fix it Nut, and fasten the fixing nut, and connect the upper kettle body and the lower kettle body with 8 bolts and fasten them, and then put on the heat ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com