Midsole and its forming method

A molding method and shoe shape technology, applied to shoe soles, other household utensils, clothing, etc., can solve the problems of low adhesion and strength, prone to defective products, low production efficiency, etc., and achieve uniform density distribution, not easy to open glue, The effect of improving flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

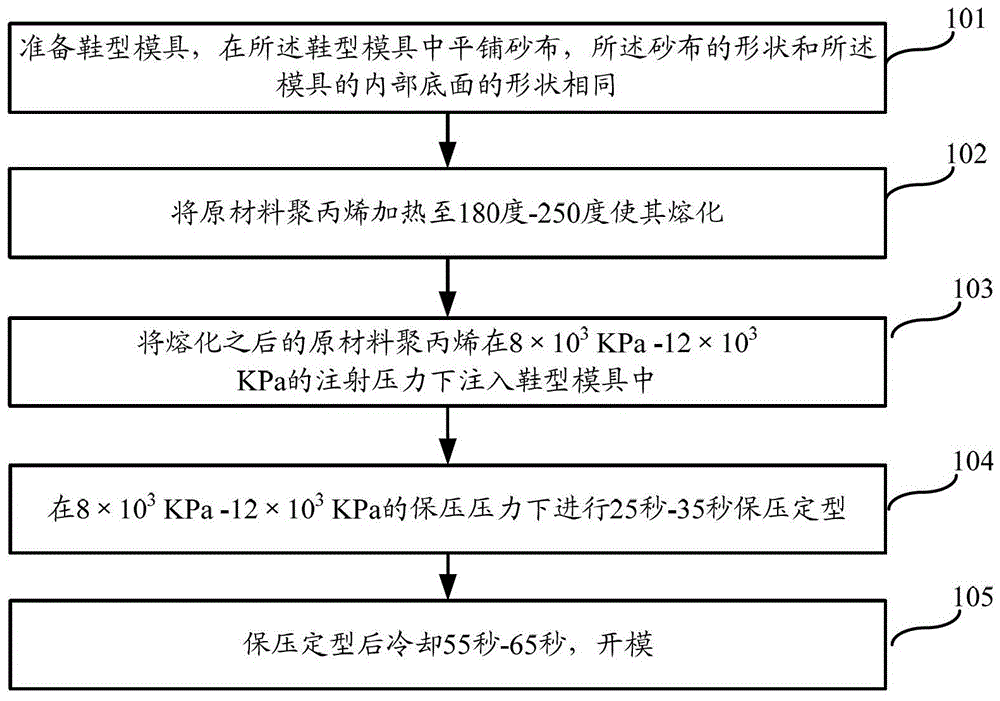

[0043] according to figure 1 Shown, the molding method of midsole, this method comprises the following steps:

[0044] 101. Prepare a shoe mold, lay emery cloth in the shoe mold, and the shape of the emery cloth is the same as the shape of the inner bottom surface of the mould;

[0045] 102. Heating the raw material polypropylene to 180-250 degrees to melt it;

[0046] 103. Put the melted raw material polypropylene in 8×10 3 KPa-12×10 3 Inject into the shoe mold under the injection pressure of KPa;

[0047] 104. In 8×10 3 KPa-12×10 3 Under the holding pressure of KPa, carry out 25-35 seconds holding pressure setting;

[0048] 105. Cool for 55-65 seconds after holding the pressure and shaping, then open the mold.

[0049]Compared with the prior art, in this molding method, the inner bottom surface of the mold refers to the projection on the horizontal plane, which is the same surface as the projection of the horizontal plane of the midsole. In the temperature range of 1...

Embodiment 2

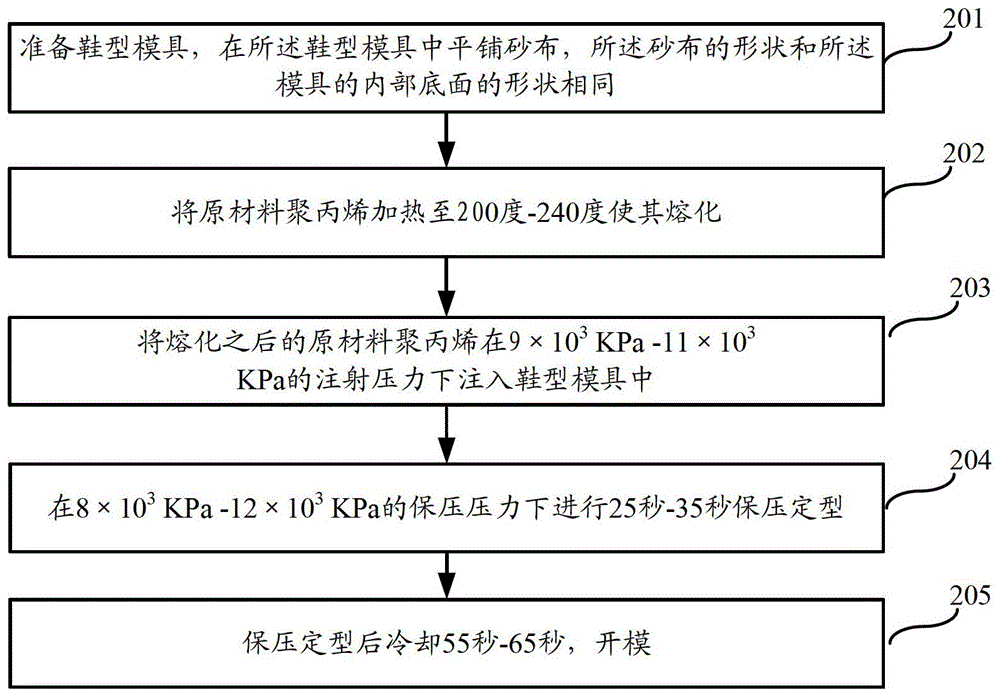

[0053] Such as figure 2 Shown, the molding method of midsole, this method comprises the following steps:

[0054] 201. Prepare a shoe mold, lay emery cloth in the shoe mold, and the shape of the emery cloth is the same as the shape of the inner bottom surface of the mould;

[0055] 202. Heating the raw material polypropylene to 200-240 degrees to melt it;

[0056] 203. Put the melted raw material polypropylene in 9×10 3 KPa-11×10 3 Inject into the shoe mold under the injection pressure of KPa;

[0057] 204. In 9×10 3 KPa-11×10 3 Under the holding pressure of KPa, carry out 25-35 seconds holding pressure setting;

[0058] 205. Cool for 55-65 seconds after holding the pressure and setting the mold, then open the mold.

[0059] Wherein, the melting temperature of the raw material polypropylene may also be 200-240 degrees. The melting temperature is between 200°C and 240°C. Within this temperature range, polypropylene can be fully and well melted, the density distribution...

Embodiment 3

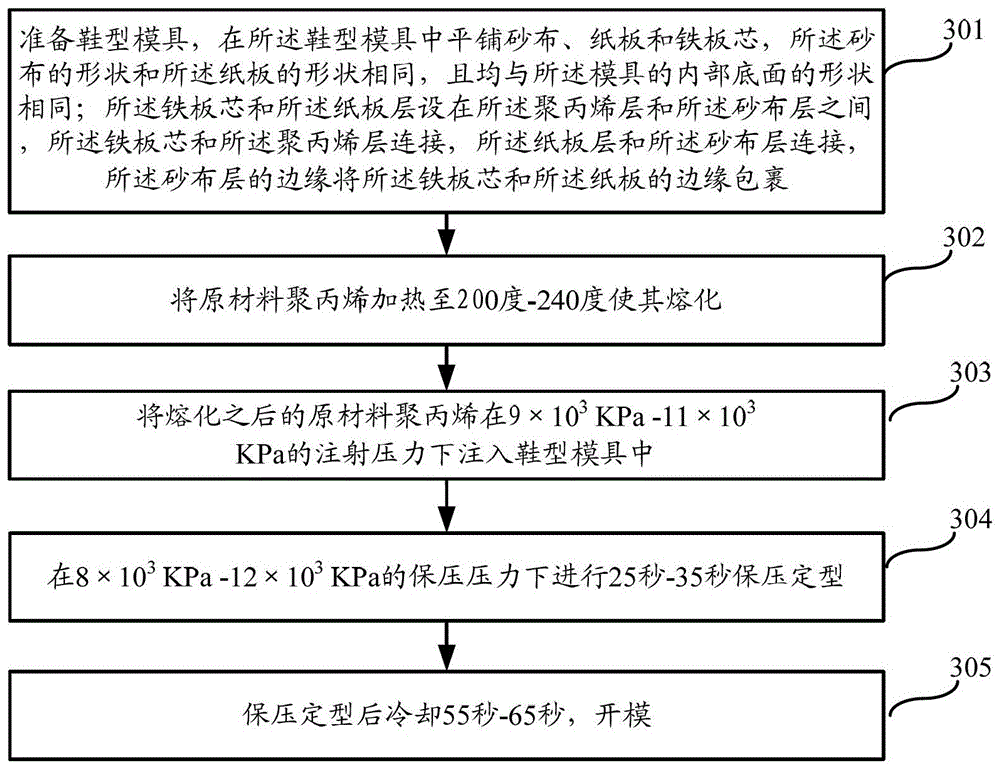

[0067] Such as image 3 Shown, the molding method of midsole, this method comprises the following steps:

[0068] 301. Prepare a shoe mold, lay emery cloth, cardboard and iron core in the shoe mold, the shape of the emery cloth is the same as that of the cardboard, and the shape of the inner bottom surface of the mold is the same; The iron core and the cardboard layer are arranged between the polypropylene layer and the emery cloth layer, the iron core is connected to the polypropylene layer, the cardboard layer is connected to the emery cloth layer, and the The edges of the emery cloth layer wrap the edges of the iron core and the cardboard;

[0069] 302. heating the raw material polypropylene to 200-240 degrees to melt it;

[0070] 303. The raw material polypropylene after melting is in 9×10 3 KPa-11×10 3 Inject into the shoe mold under the injection pressure of KPa;

[0071] 304. In 9×10 3 KPa-11×10 3 Under the holding pressure of KPa, carry out 25-35 seconds holding...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com