Patents

Literature

68results about How to "Cool down thoroughly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

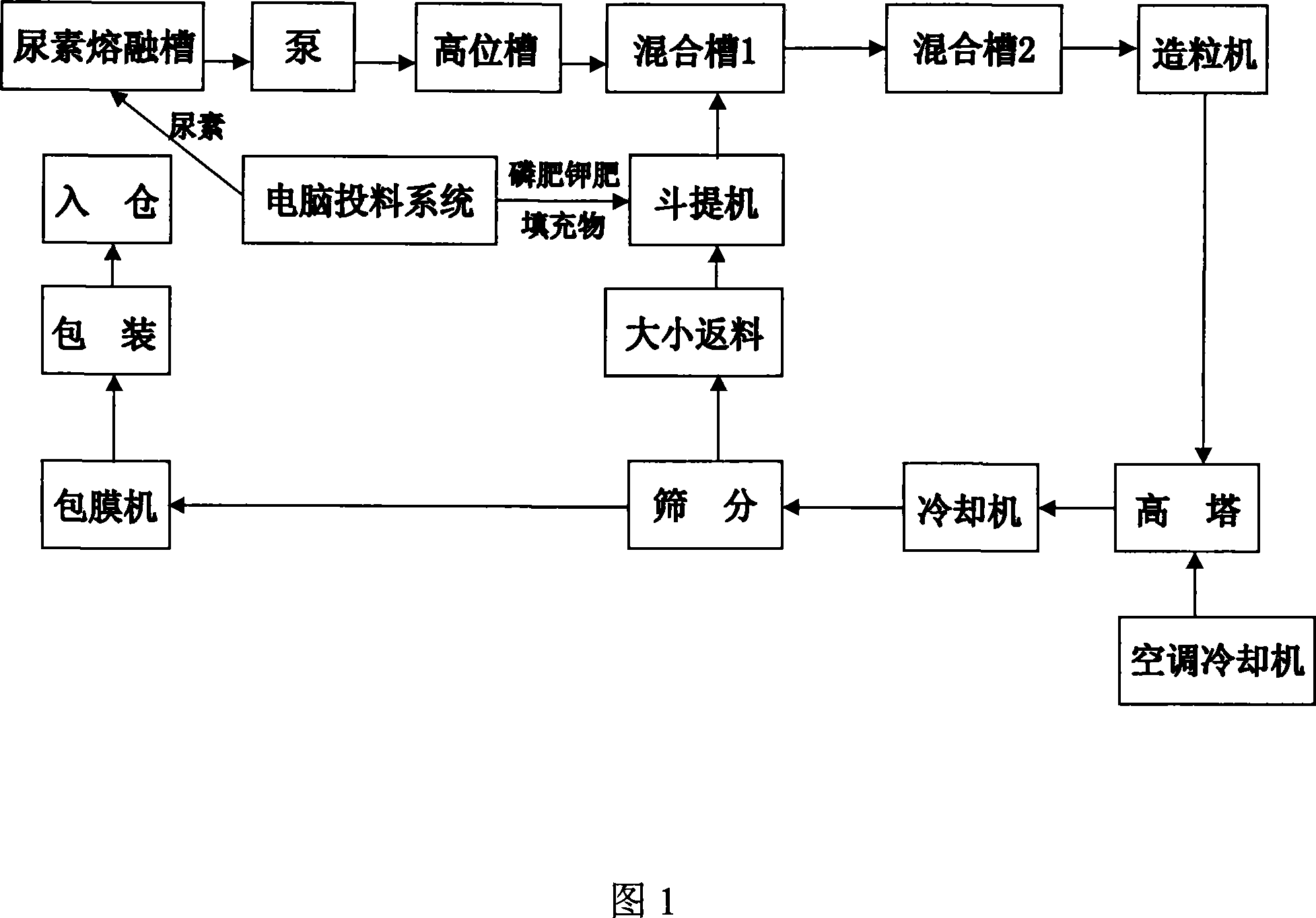

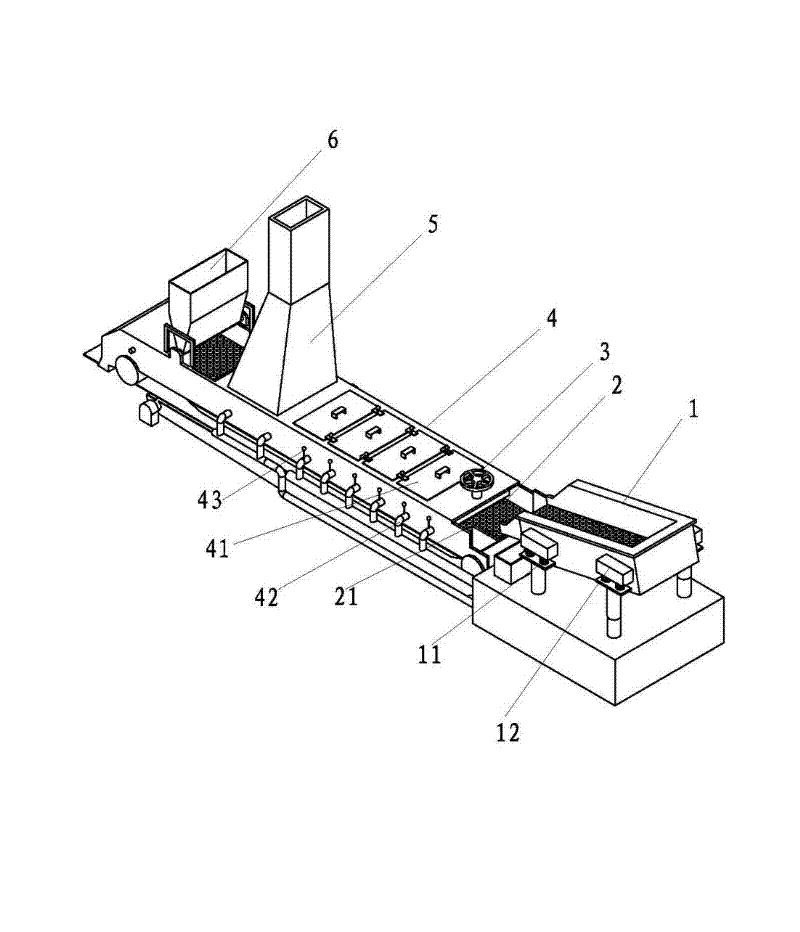

Process for producing compound fertilizer by tower granulation

The invention discloses a high tower making grain technics for producing compound fertilizer, which is characterized in that the urea saltpeter ammonium phosphorus is smelted under the tower through measuring, then enters the mixing reacting groove on the tower top by a pump, then is mixed with measured monoammonium phosphate, potassium chloride, lemery, filler, middle microelement and paint, finally, enters the granulator to be granulated. The invention makes use of the pump to put the urea (saltpeter ammonium phosphorus) material serum to the top of the tower, thereby, saving energy, decreasing investment, being convenient for service and saving cost.

Owner:GUANGDONG DAZHONG AGRI SCI CO LTD

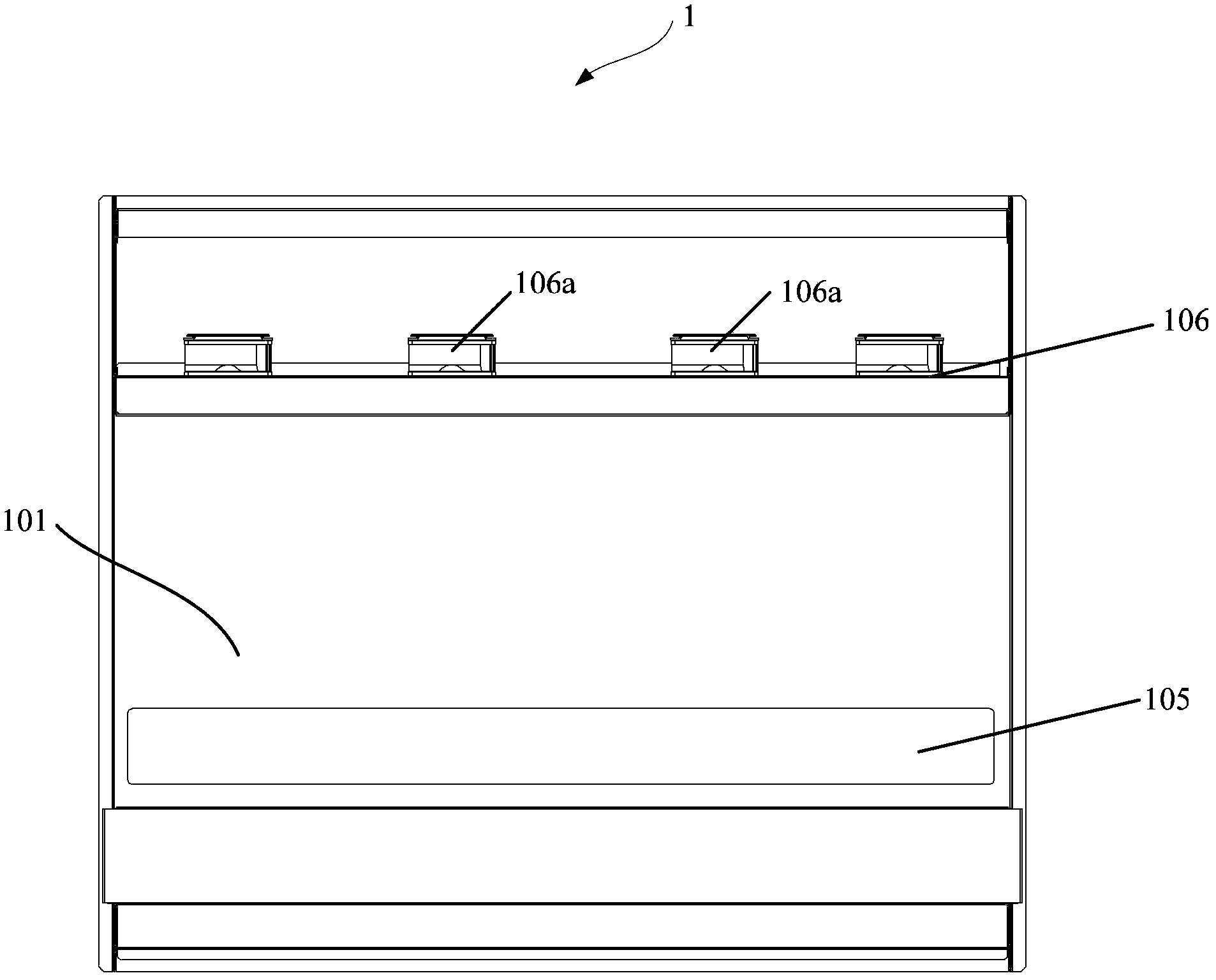

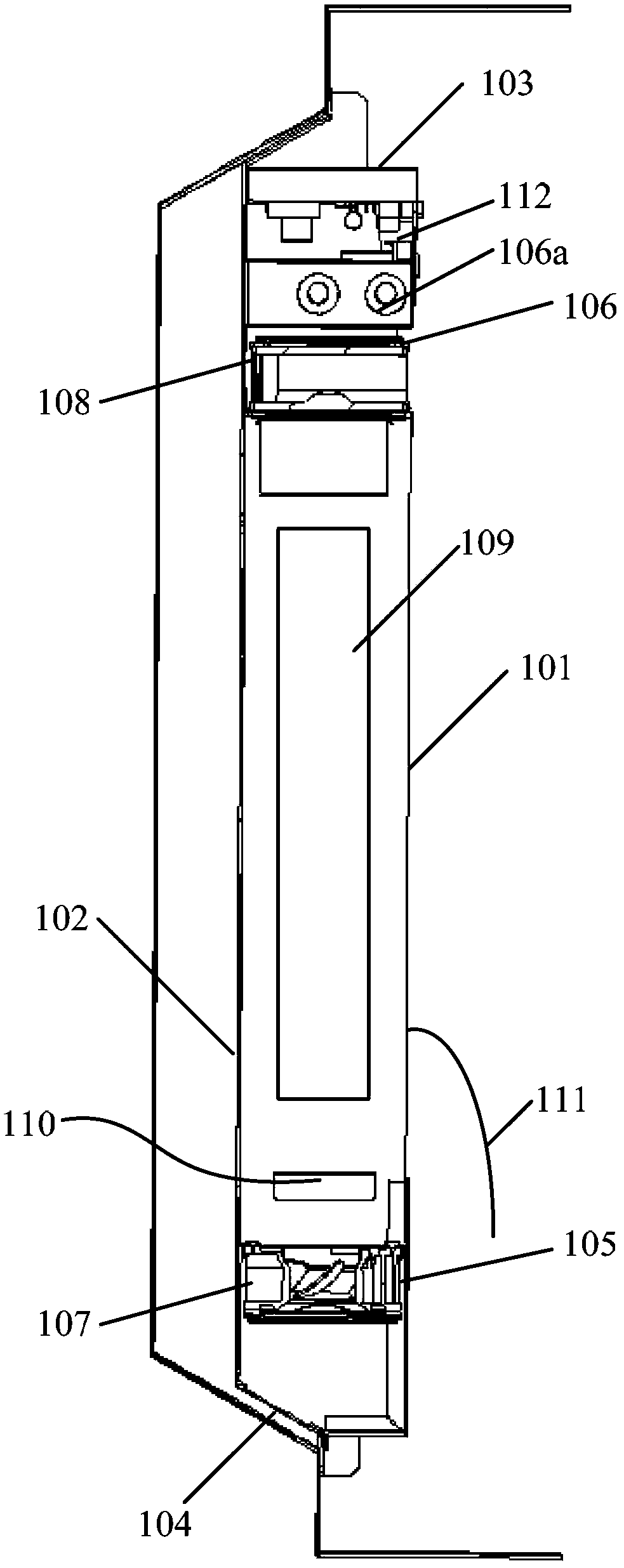

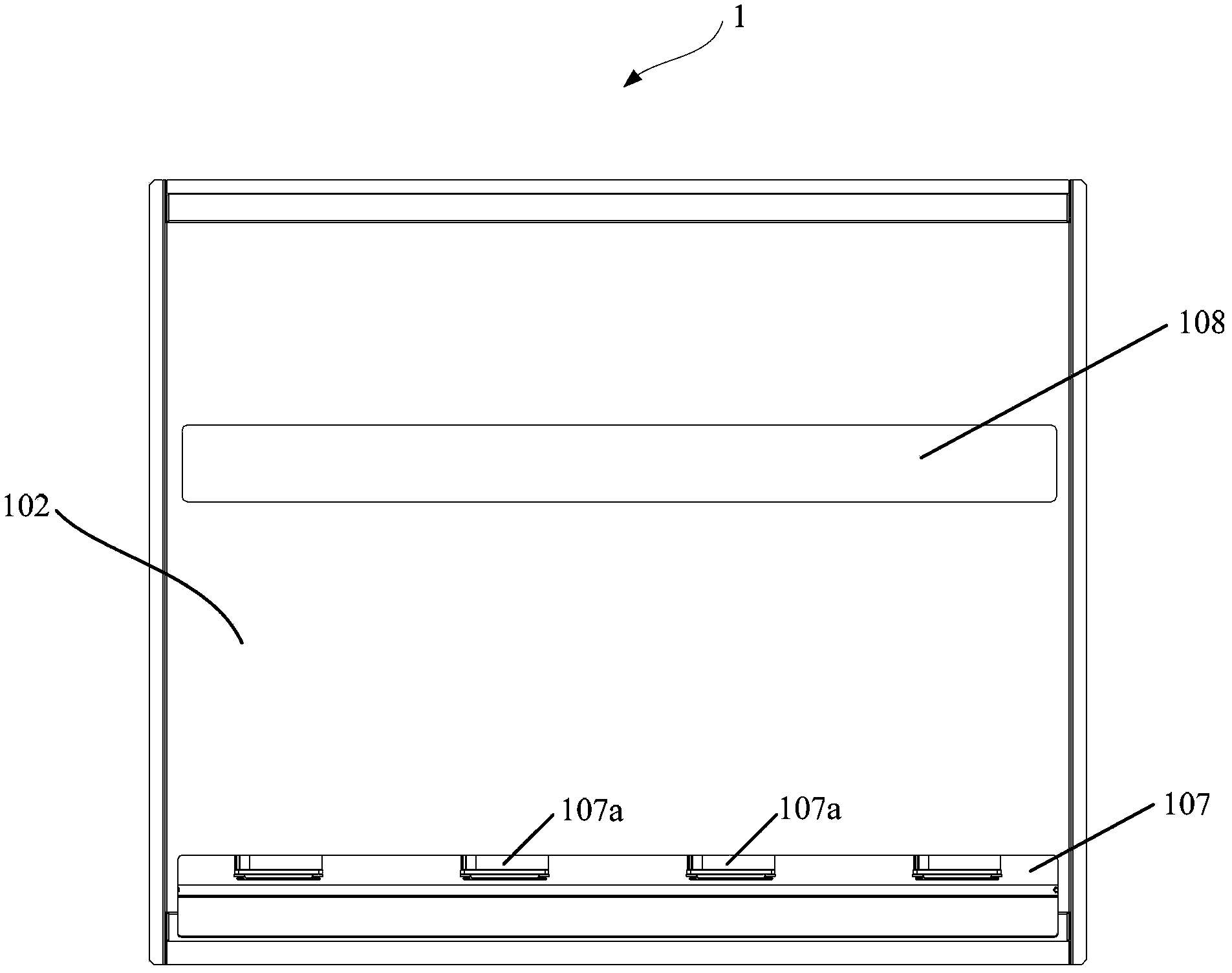

Outdoor electronic newspaper stand and fast cooling device thereof

ActiveCN103582385AIncrease cooling areaImprove cooling effectAdvertisingCooling/ventilation/heating modificationsEngineeringElectronic equipment

Provided are an outdoor electronic newspaper stand and a fast cooling device of the outdoor electronic newspaper stand. The cooling device comprises a first face plate, a second face plate, a third face plate, a fourth face plate, an air supply opening, an air return opening, an air inlet, an air outlet and a heat exchange component. The first face plate and the second face plate are opposite, the third face plate and the fourth face plate are opposite, and the third face plate and the fourth face plate are adjacent to the first face plate and the second face plate. The air supply opening is formed in the first face plate and is close to the fourth face plate, the air return opening is formed in the first face plate and is close to the third face plate, the air inlet is formed in the second face plate and is close to the fourth face plate, the air outlet is formed in the second face plate, and the heat exchange component is arranged between the first face plate and the second face plate. According to the technical scheme, the fast cooling device is low in power consumption and low in cost, and a condensation phenomenon cannot occur when electronic equipment is cooled.

Owner:上海申龙可信数字科技股份有限公司

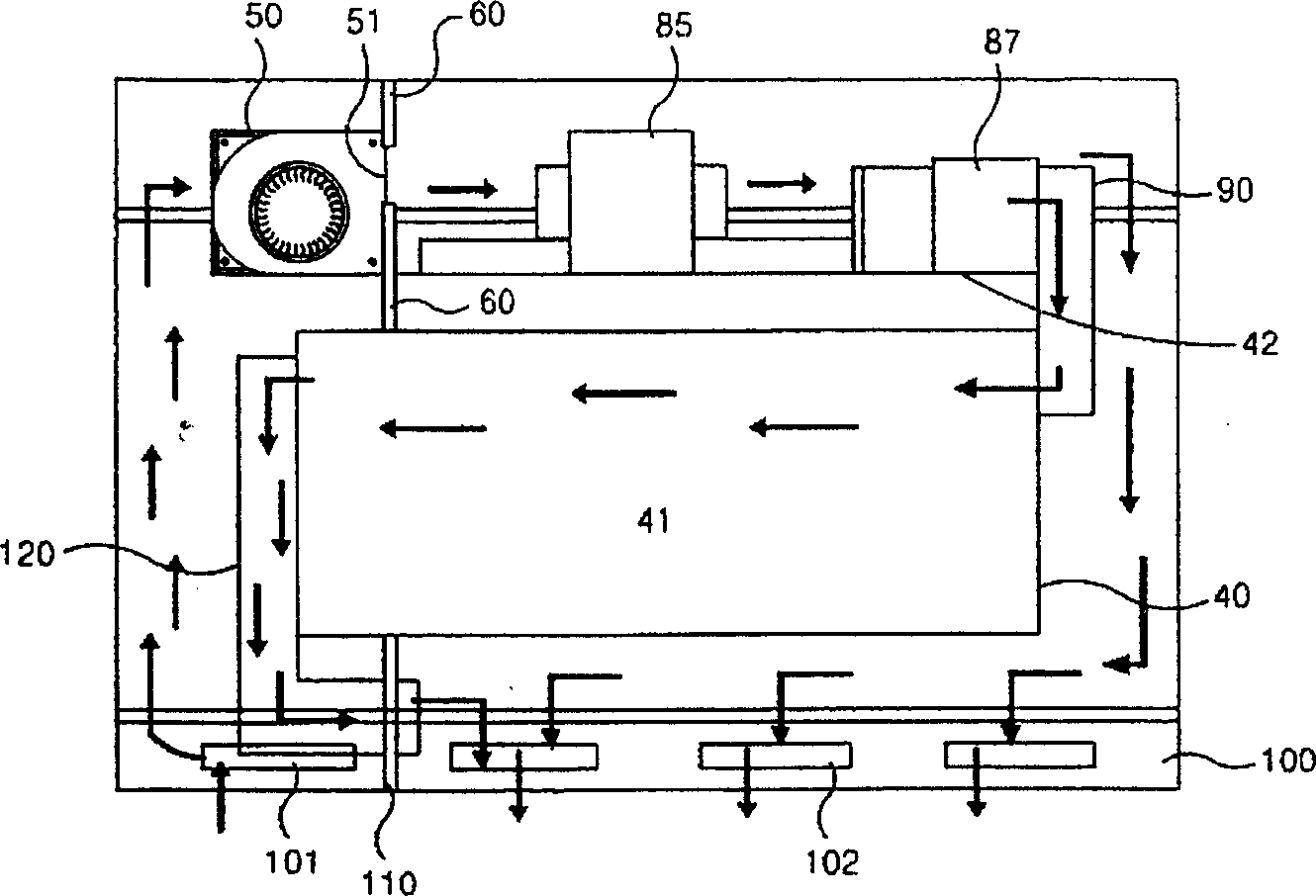

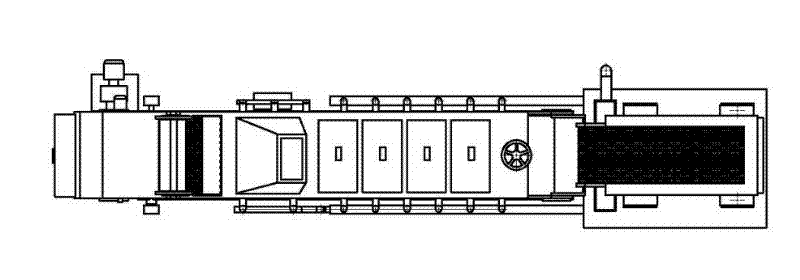

Gas, tar and activated carton co-production system

ActiveCN105018121ASimple structureNovel and reasonable designCarbon compoundsSpecial form destructive distillationWater vaporMetallurgy

The invention discloses a gas, tar and activated carton co-production system. The system comprises a pyrolysis furnace, an activation furnace and a cooling furnace which are sequentially communicated. The pyrolysis furnace comprises a preheat furnace body and a pyrolysis furnace body, a coal inlet and a pyrolyzing gas outlet are formed in one end of the preheat furnace body, a heat-isolation jacket is disposed on the outer side of the activation furnace, and a heating chamber is formed between the activation furnace and the heat-isolation jacket; one end of the cooling furnace is connected with a discharge box, an activated carbon outlet and a cooling gas inlet are formed in the discharge box, a cooling jacket is arranged on the outer side of the cooling furnace, and a cooling chamber is formed between the cooling furnace and the cooling jacket; a cooling water inlet and a steam outlet are formed in the cooling jacket, and the steam outlet is communicated with the cooling gas inlet. Semicoke activated associated gas is used in the system to supply heat for pyrolysis, pyrolysis efficiency is improved, and meanwhile the content of nitrogen in pyrolysis gas is reduced. Mixed gas of carbon dioxide and water vapor can preheat the cooling furnace when passing through the cooling furnace and can prepare for being introduced in the activation furnace and serving as a gas activation agent, and activated carbon can be effectively cooled.

Owner:XIAN UNIV OF SCI & TECH

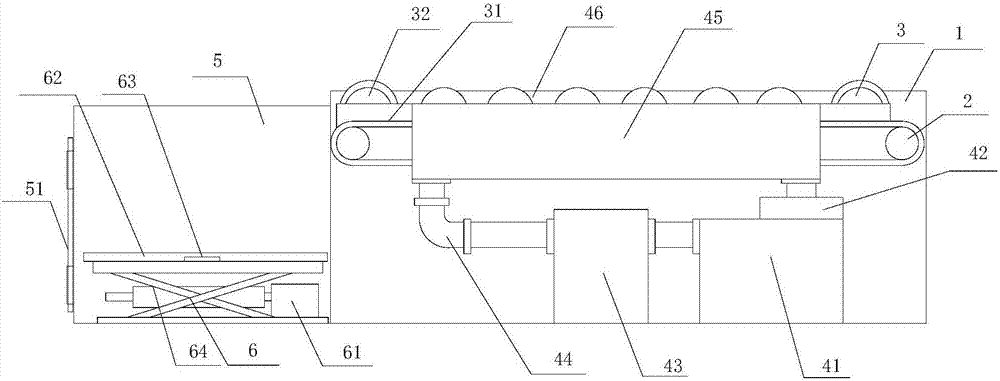

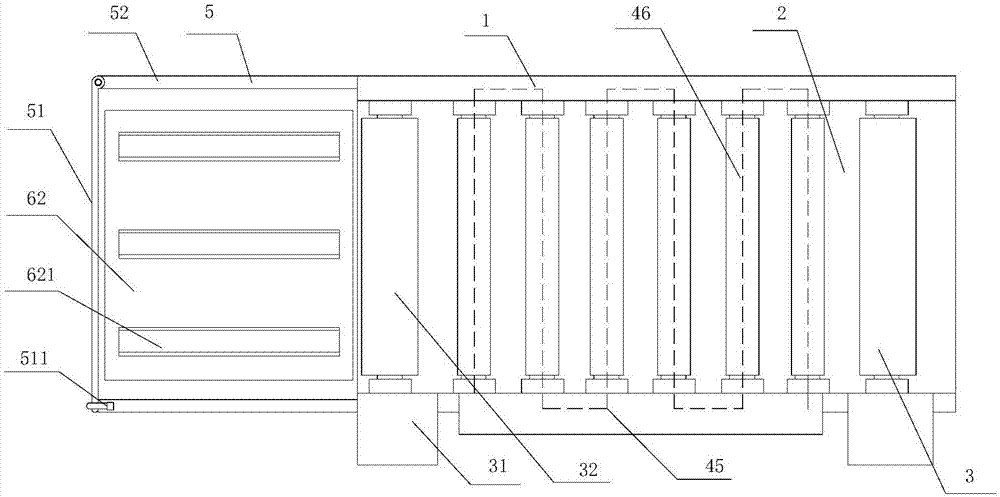

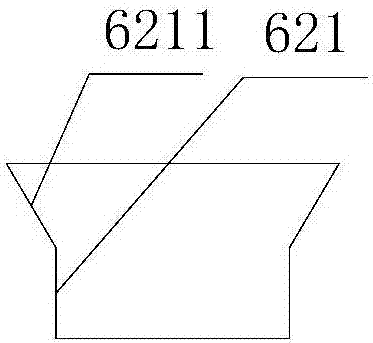

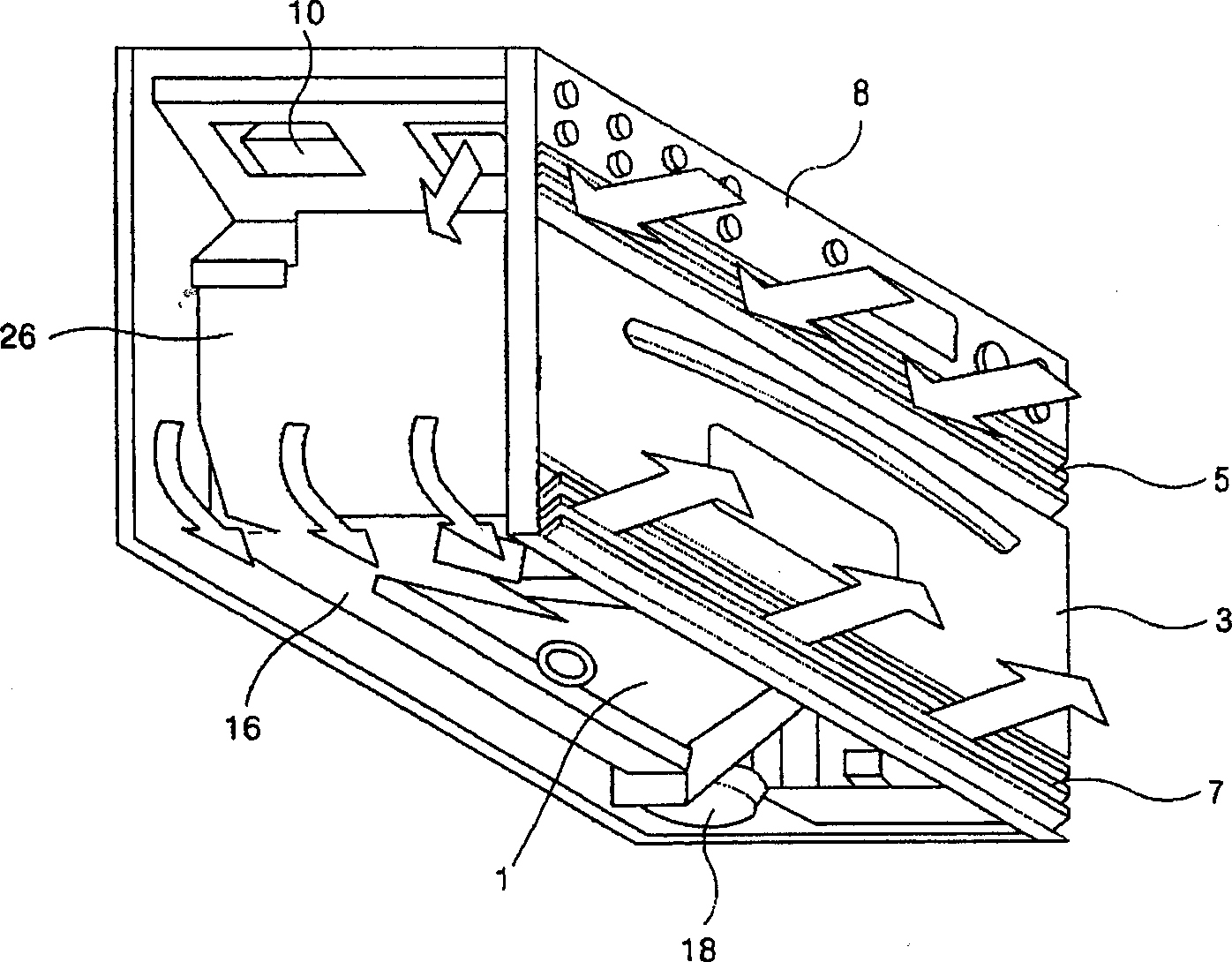

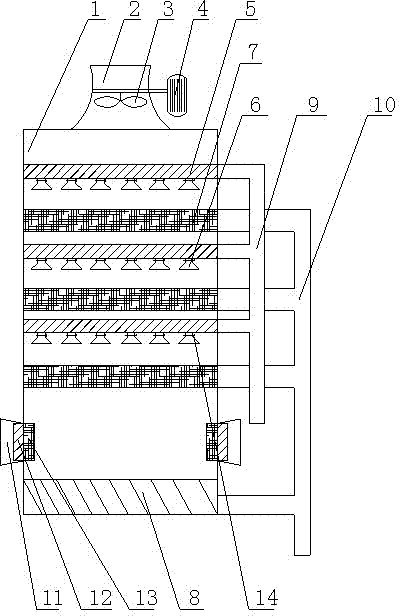

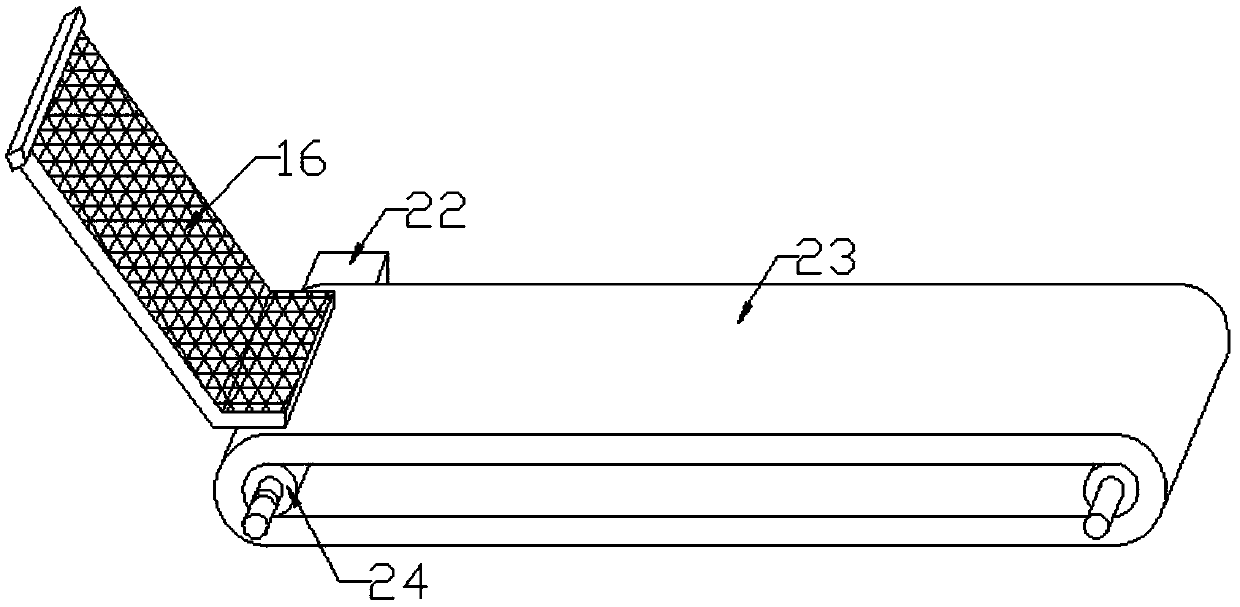

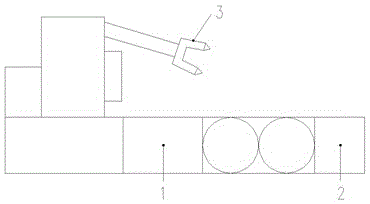

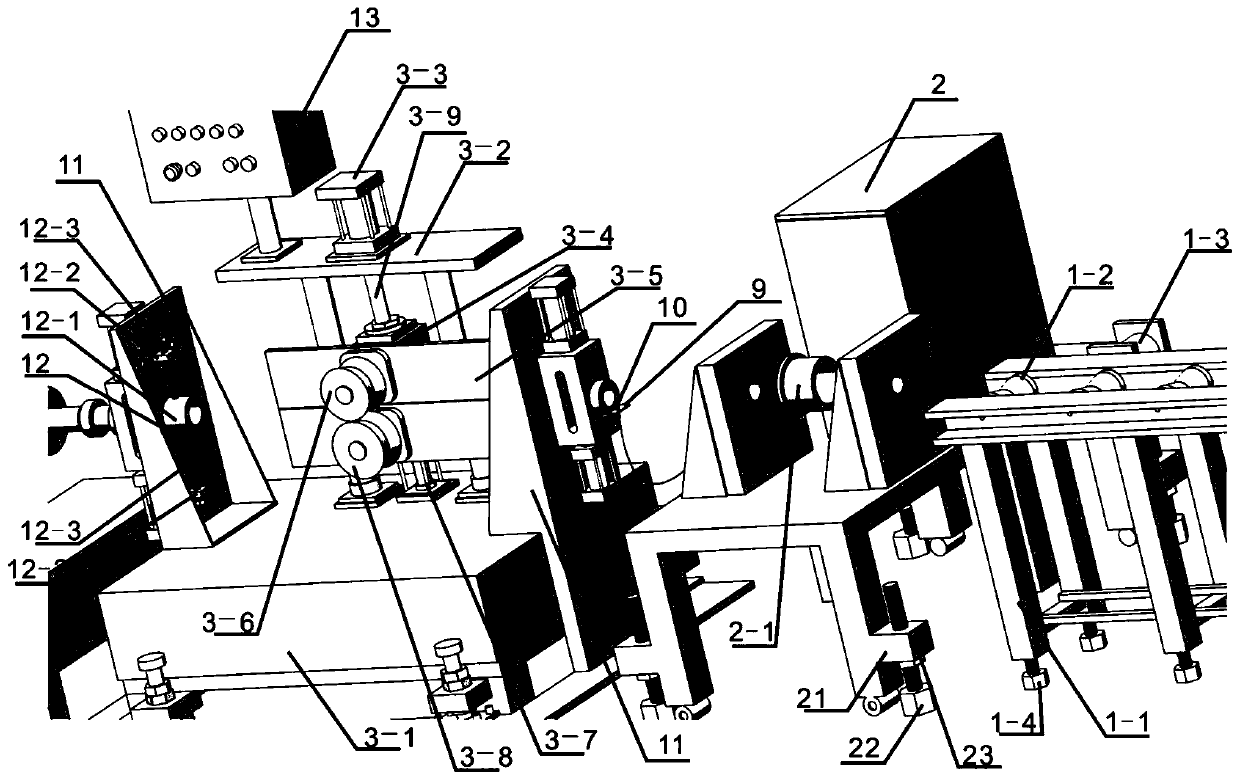

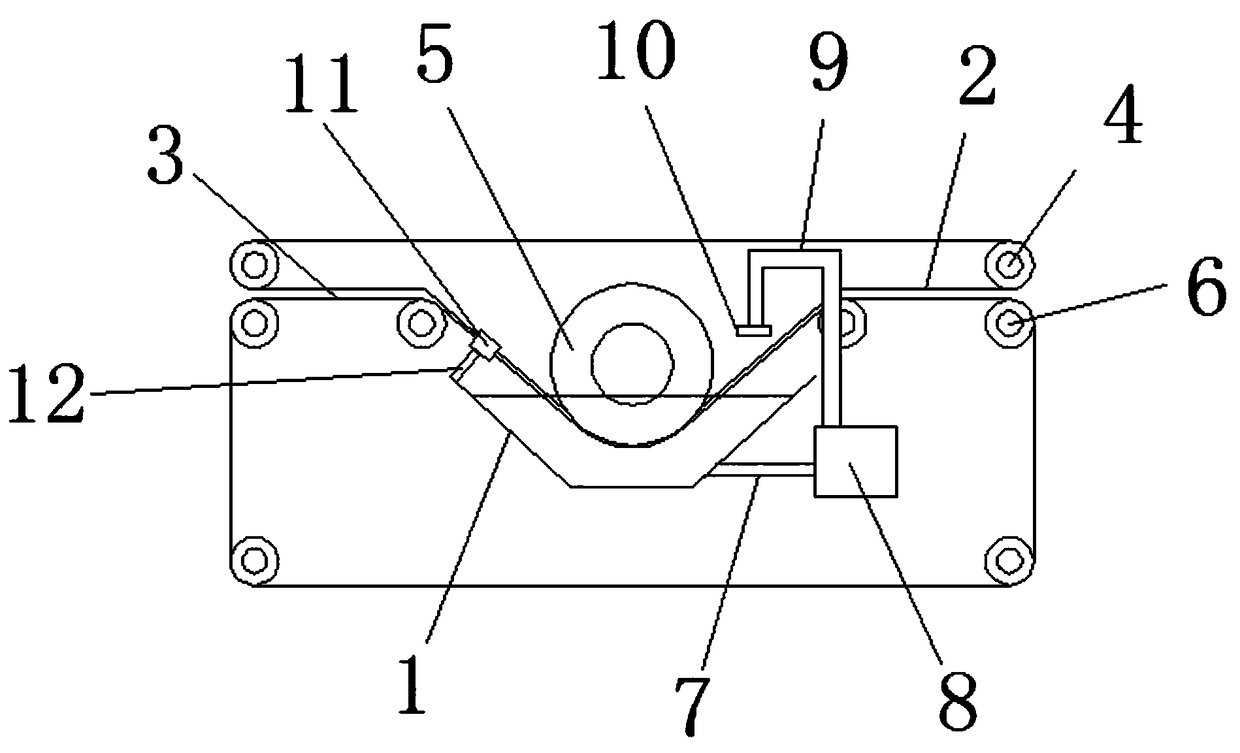

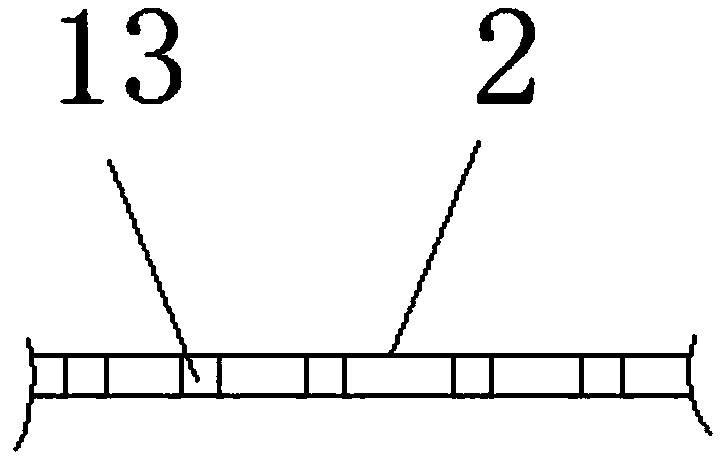

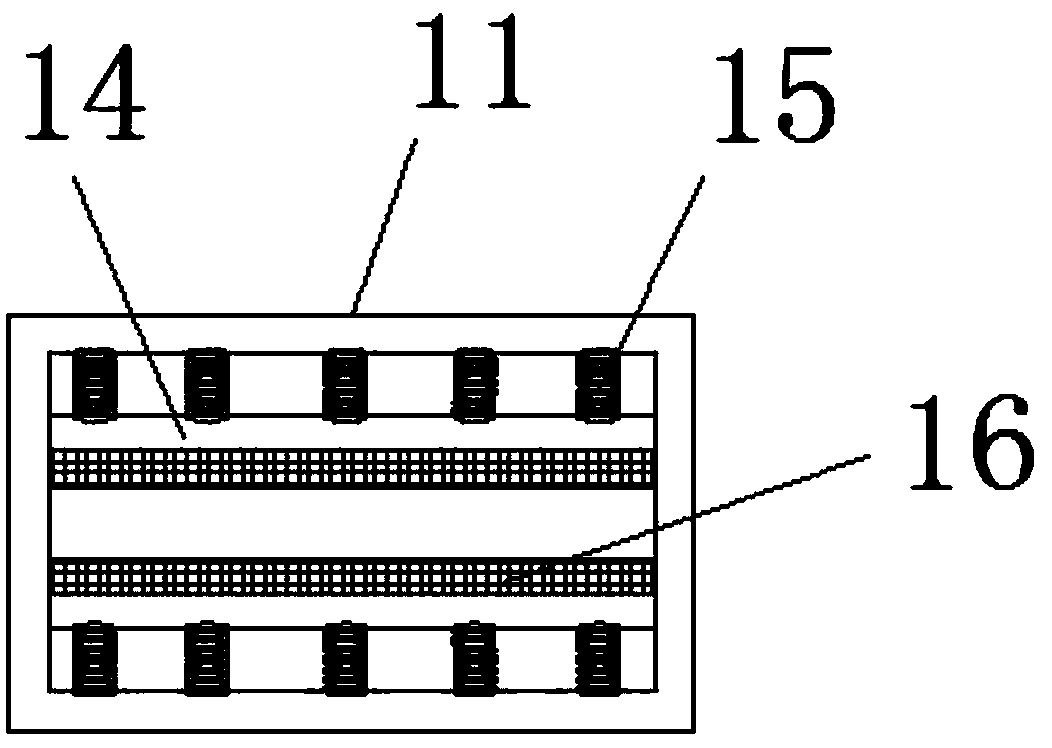

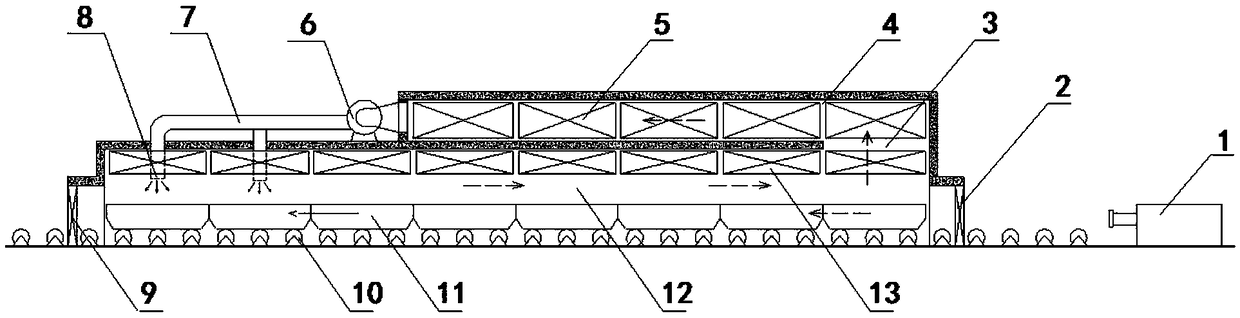

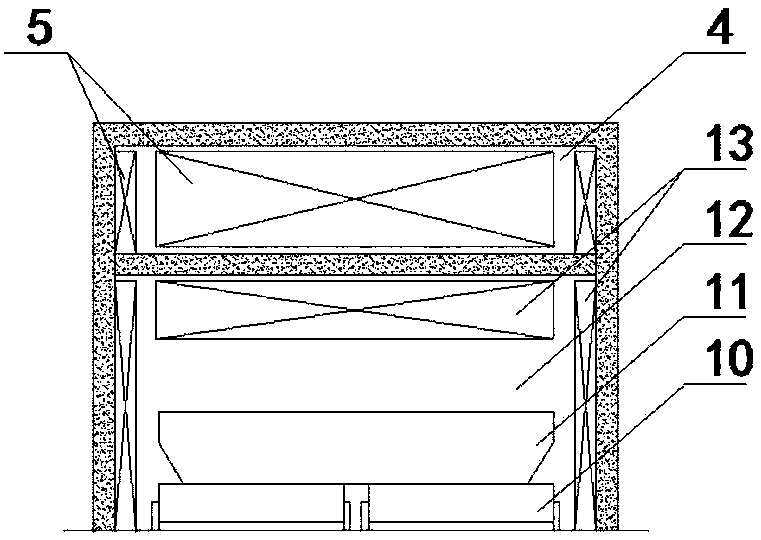

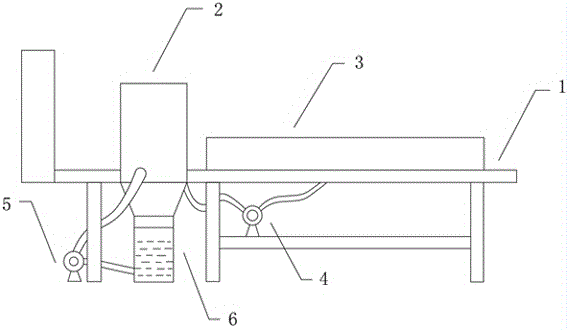

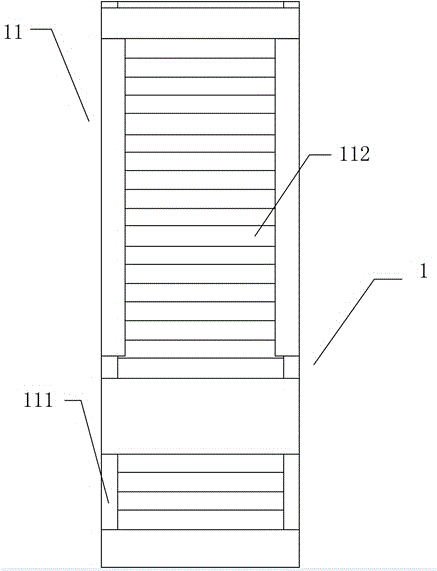

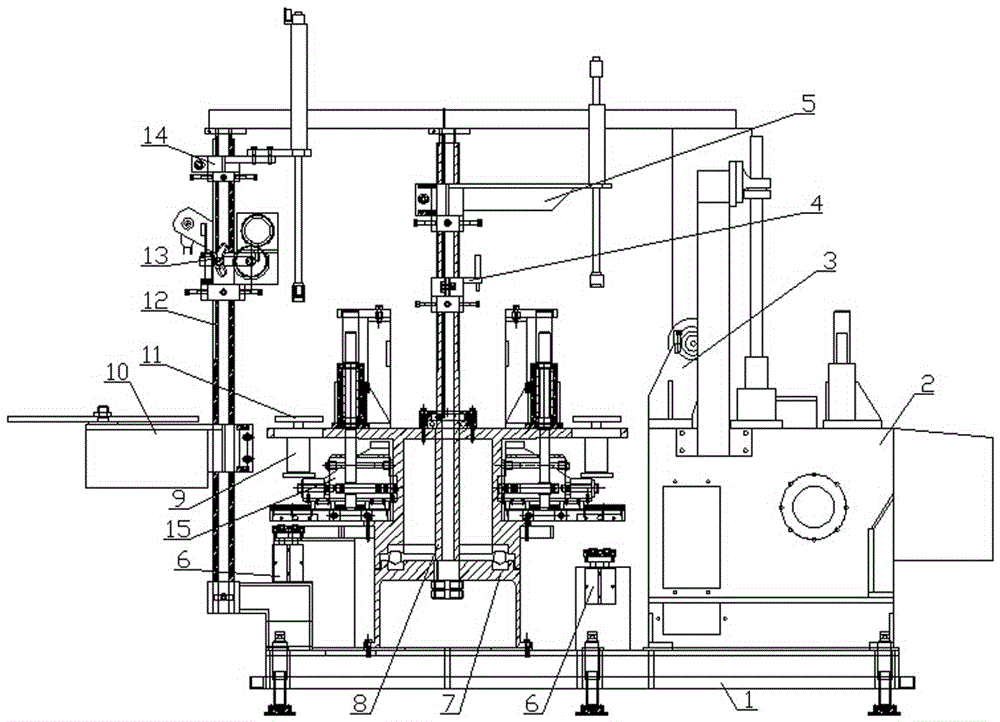

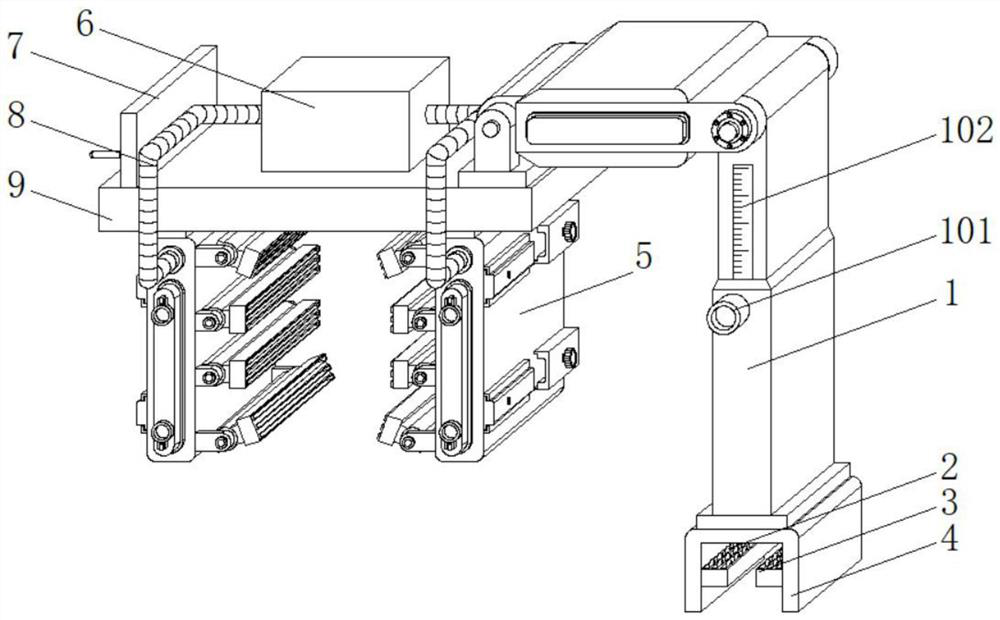

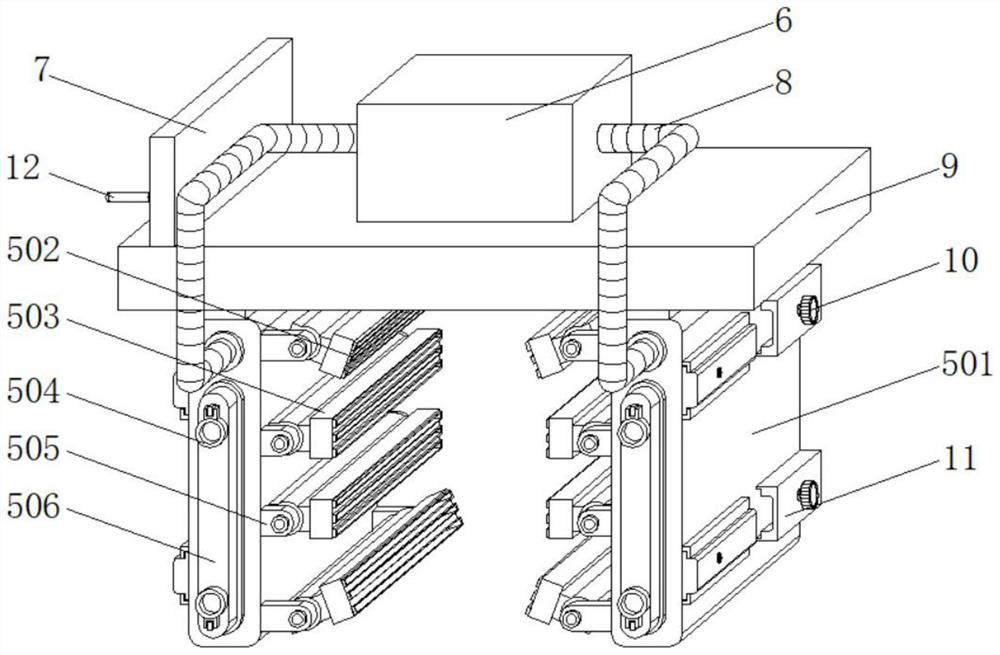

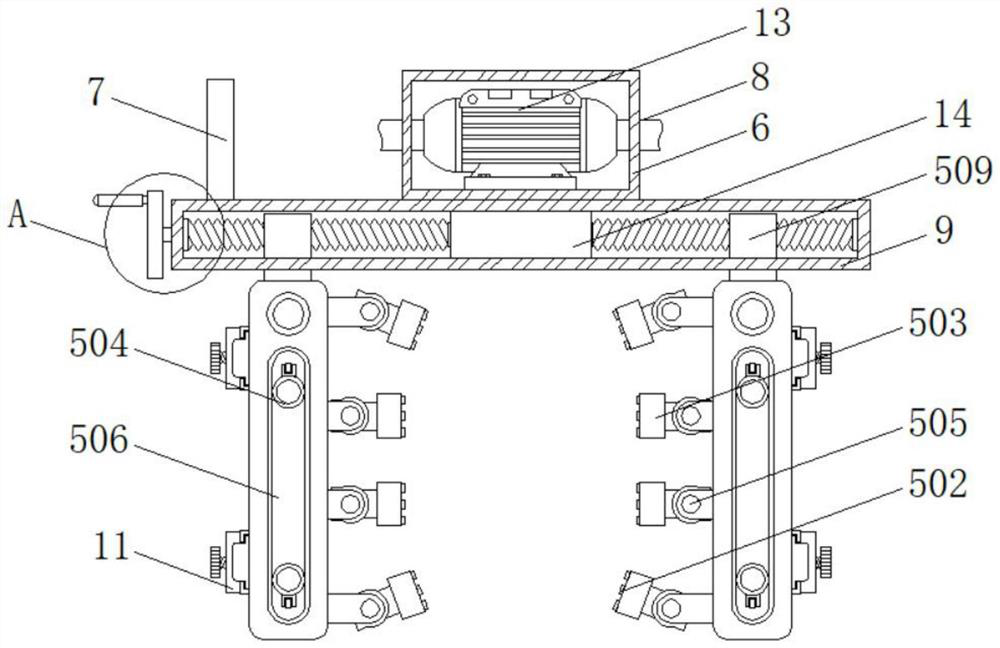

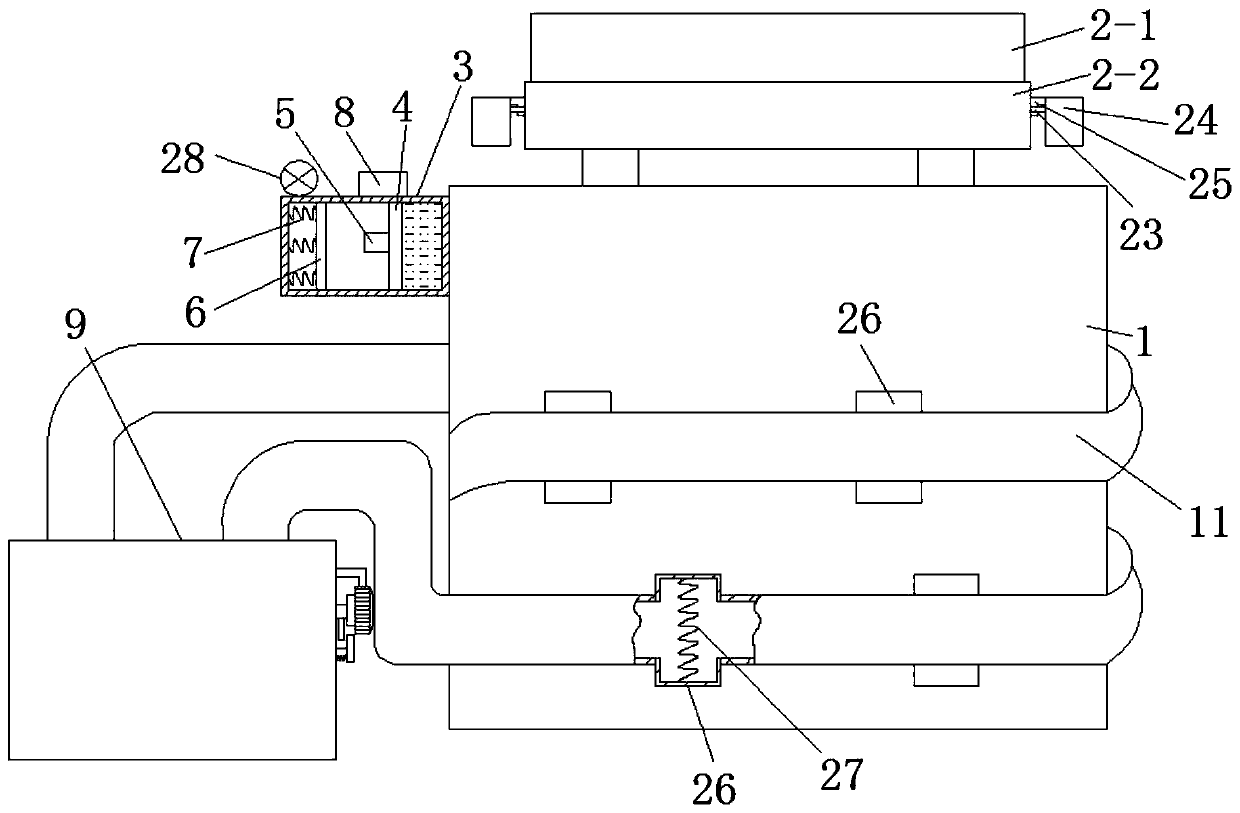

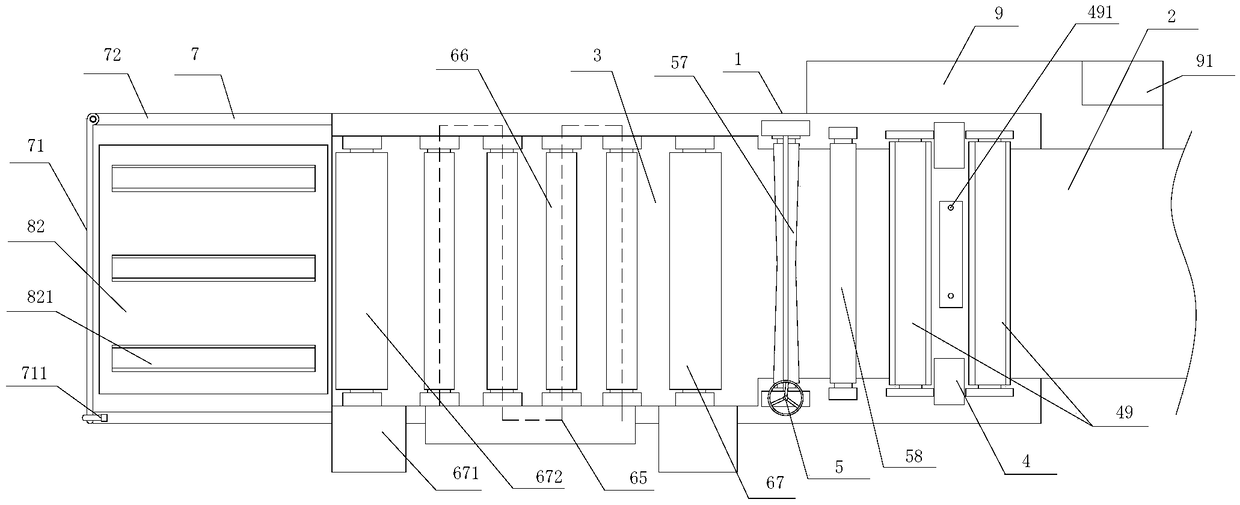

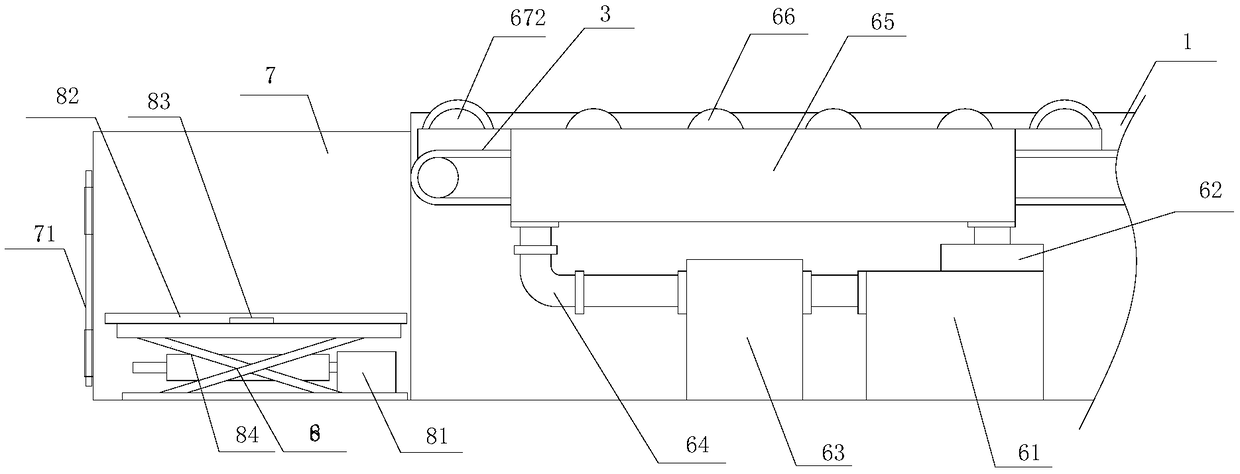

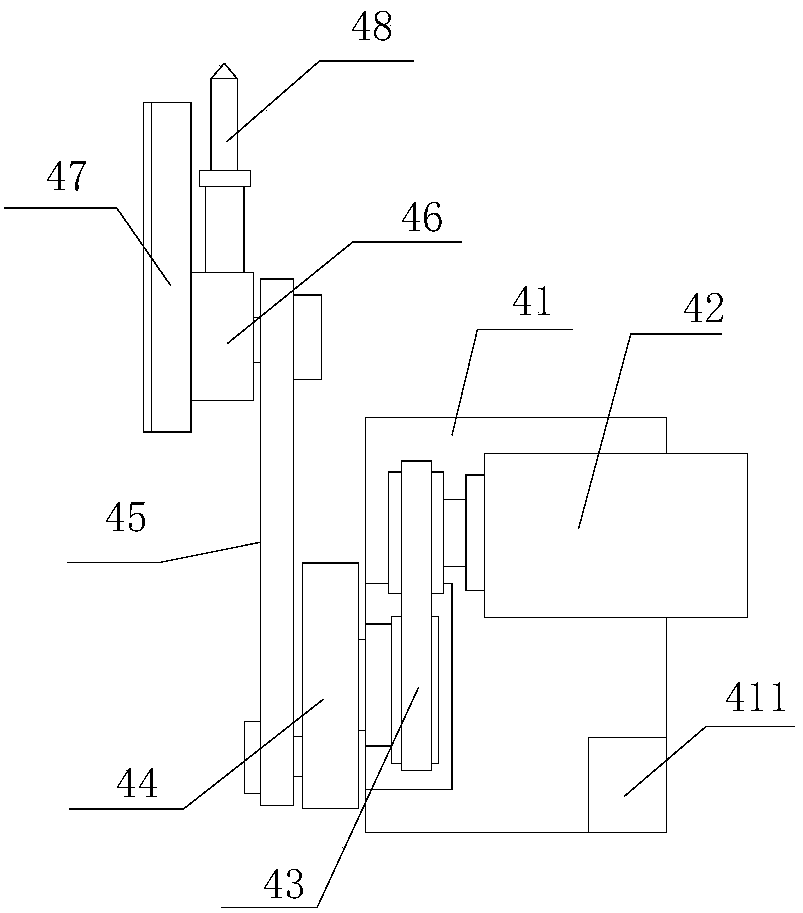

Conveying and discharging device for film laminating machine

PendingCN107415419ASmoothly fall intoCool down thoroughlyLamination ancillary operationsLaminationEngineeringMachine

The invention discloses a conveying and discharging device for a film laminating machine. The conveying and discharging device comprises a machine frame, a conveyer belt mechanism, conveying roller assemblies, a cooling and circulating device, a discharging box and a lifting bench device, wherein the conveyer belt mechanism is arranged on the machine frame, a plurality of cooling roller assemblies are arranged on the cooling and circulating device, the cooling roller assemblies are evenly distributed between the two conveying roller assemblies, the two conveying roller assemblies are respectively arranged at the two ends of the conveyer belt mechanism, the discharging box is arranged on one side of the conveying belt mechanism, the lifting bench device is arranged in the discharging box, a supporting plate is arranged on the lifting bench device, a plurality of tray locating grooves are formed in the supporting plate, a weight sensing unit is arranged under the support plate, and the lifting bench device is matched with the conveyer belt mechanism. The plurality of cooling roller assemblies are utilized to cool, so that cooling completeness is guaranteed. A lifting bench can be used for adjusting heights of material storage trays according to need, the material storage trays can be transferred by a hand fork lifter, and simple operation is achieved.

Owner:ZHEJIANG MINGJIA ENVIRONMENTAL PROTECTION TECH CO LTD

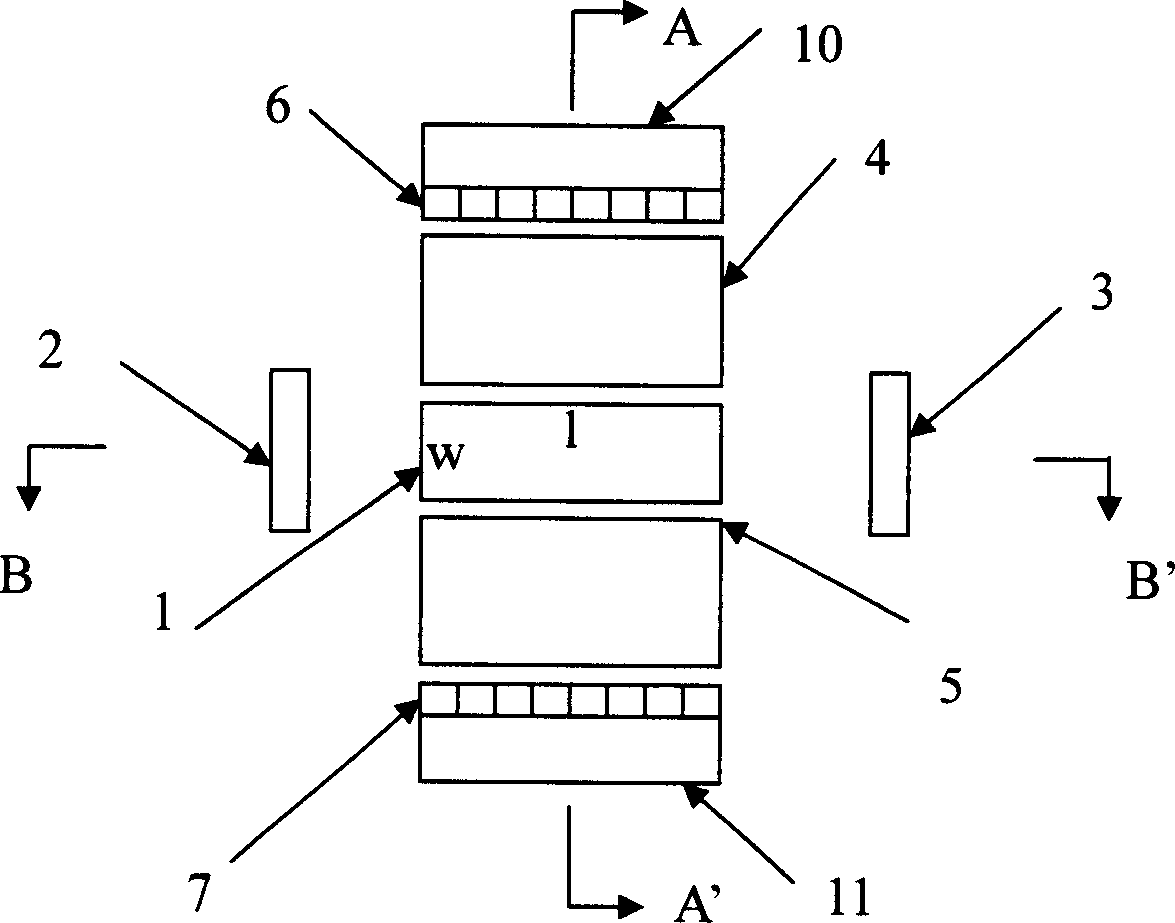

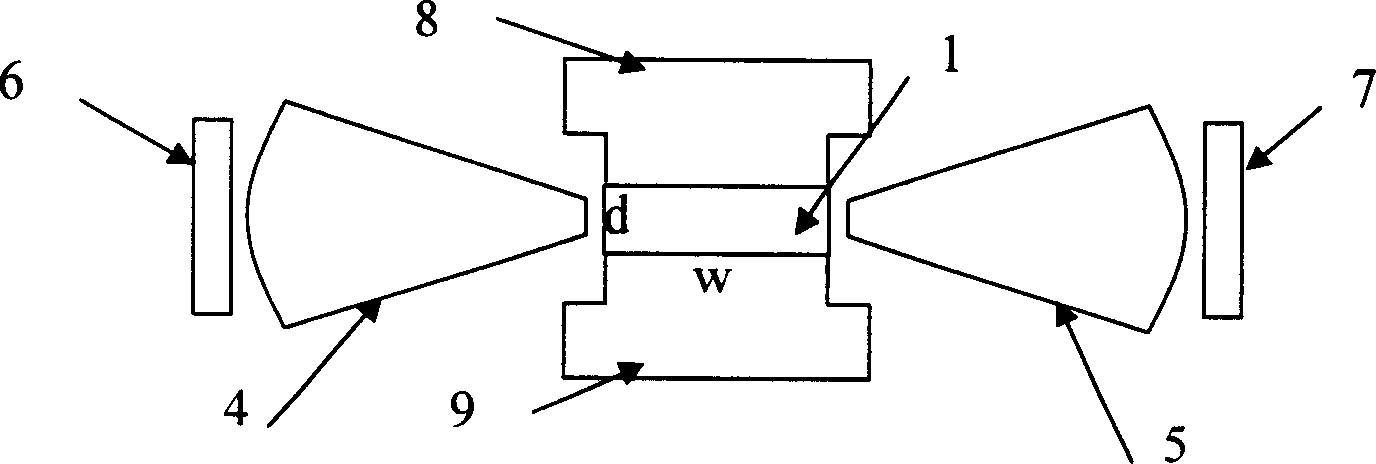

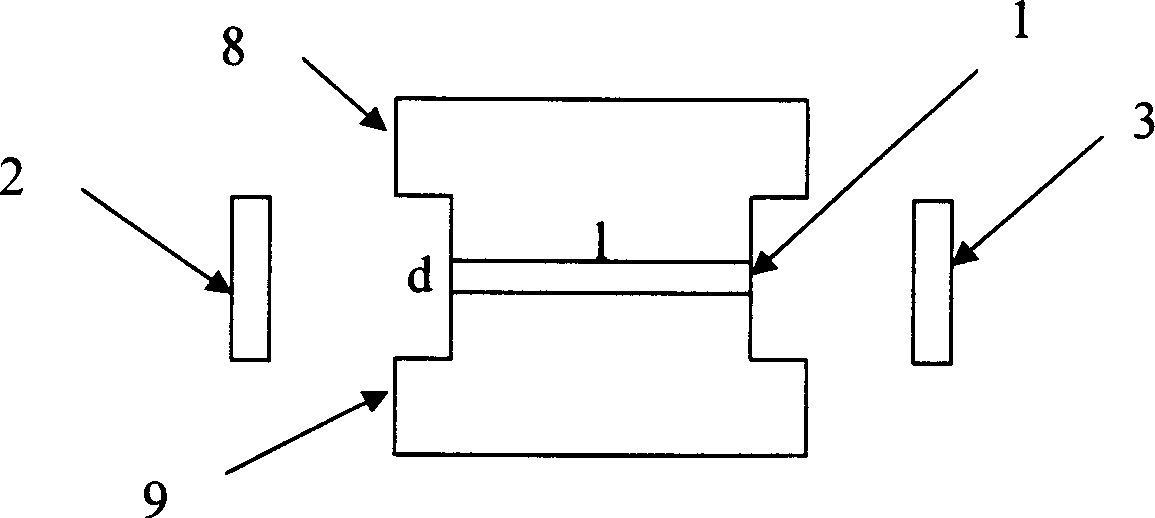

Solid plate strip laser using lens conduct coupling

InactiveCN1822452AImprove coupling efficiencyIncrease pump powerActive medium materialLaser constructional detailsWater flowLight beam

A lens conduit coupled solid slab laser adopts cuboid flake laser solid slab as laser medium. Said invention adopts solid core lens conduit coupling laser diode array outputted pump light to laser medium, said pump light lens conduit from laser solid slab side entering solid slab, total reflecting through slab two large face and absorbing by slab, laser solid slab having upper and lower large face and using water flowing heat sink to radiate heat, laser resonator adopting flat cavity. Said invented laser has compact structure, high coupling efficiency, good heat radiation effect, large laser output power and high light beam quality properties.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

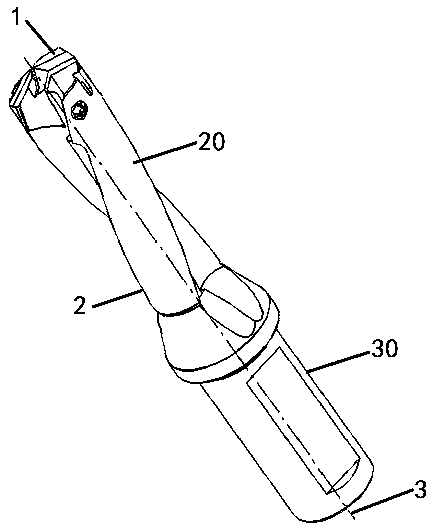

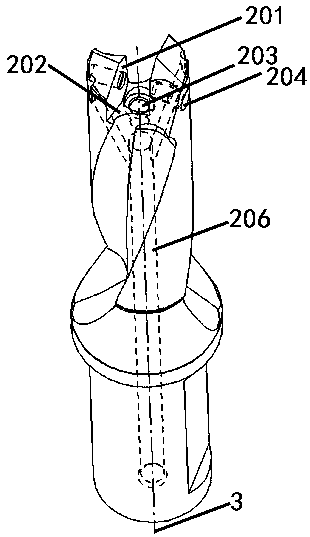

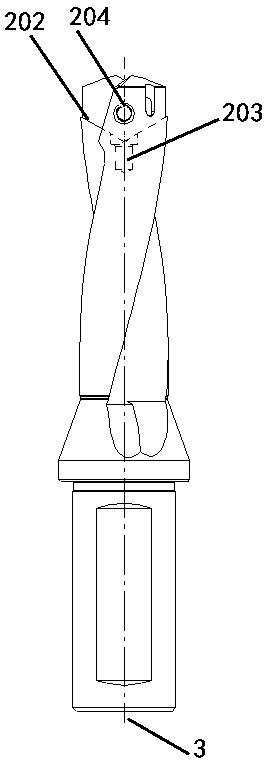

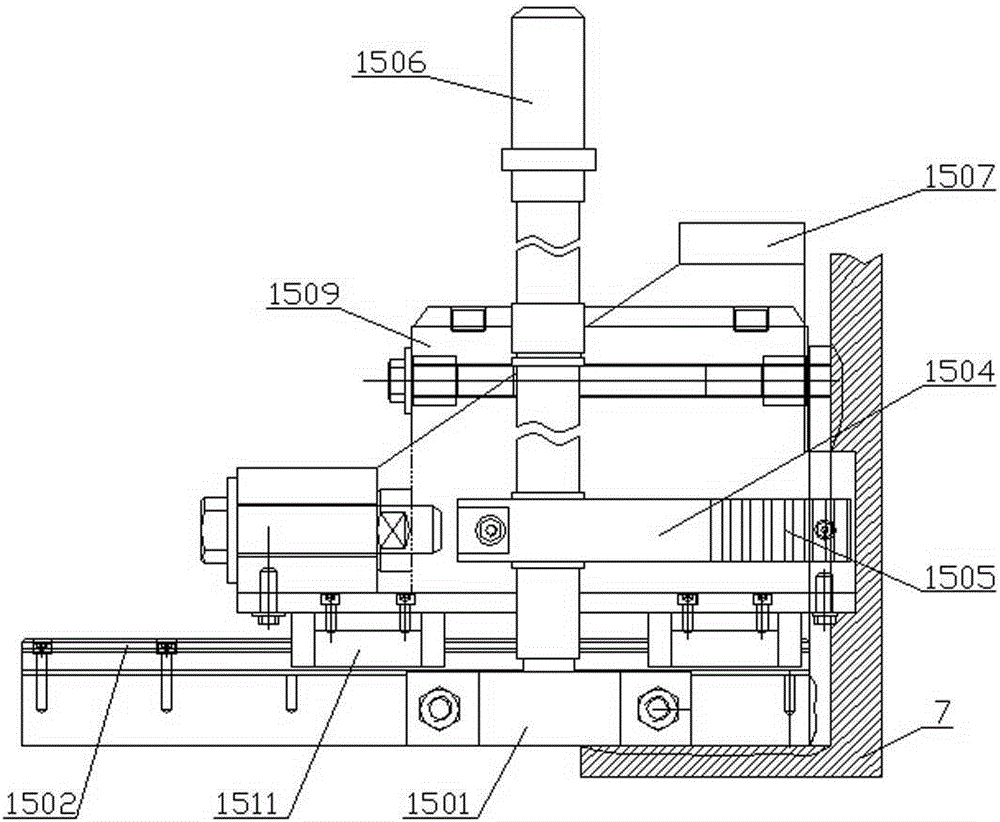

Rotary cutting tool with replaceable tool bit and rotary cutting method and tool bit mounting method thereof

ActiveCN107626960AEffective resistance to radial displacementNot easy to damageMilling cuttersTool bitCooling effect

The invention relates to a rotary cutting tool with a replaceable tool bit and a rotary cutting method and a tool bit mounting method thereof and belongs to the field of hole processing in machining industry. At present, a twist drill used for drilling is of an integrated structure, and the tool bit reaching the service life needs to be replaced integrally, so that the cost is relatively high. Ina drilling tool with the replaceable tool, as the tool bit is subjected to relatively great radial and axial actions in the drilling hole, the condition of no fine drilling as the tool bit shifts radially at the connection is avoided. According to the replaceable structure of the tool bit, the drilling tool at the connection of the tool bit is relatively weak, and the drilling tool matrix is weaker due to a design of a chip removal chute. According to the rotary cutting tool with the replaceable tool bit provided by the invention, the tool bit is detachably connected to a cutter bar and the connection of the tool bit and the cutter bar is a V-shaped locating surface, so that the rotary cutting tool is good in tool bit positioning and fixing effect, and is unlikely to shift. The strength ofthe cutter bar is improved due to different spiral angles of the chip removal chute; the cooling effect is enhanced by a design of a cooling guide slot, and the tool bit is simple to mount and detach.

Owner:ZHEJIANG XINXING TOOLS CO LTD

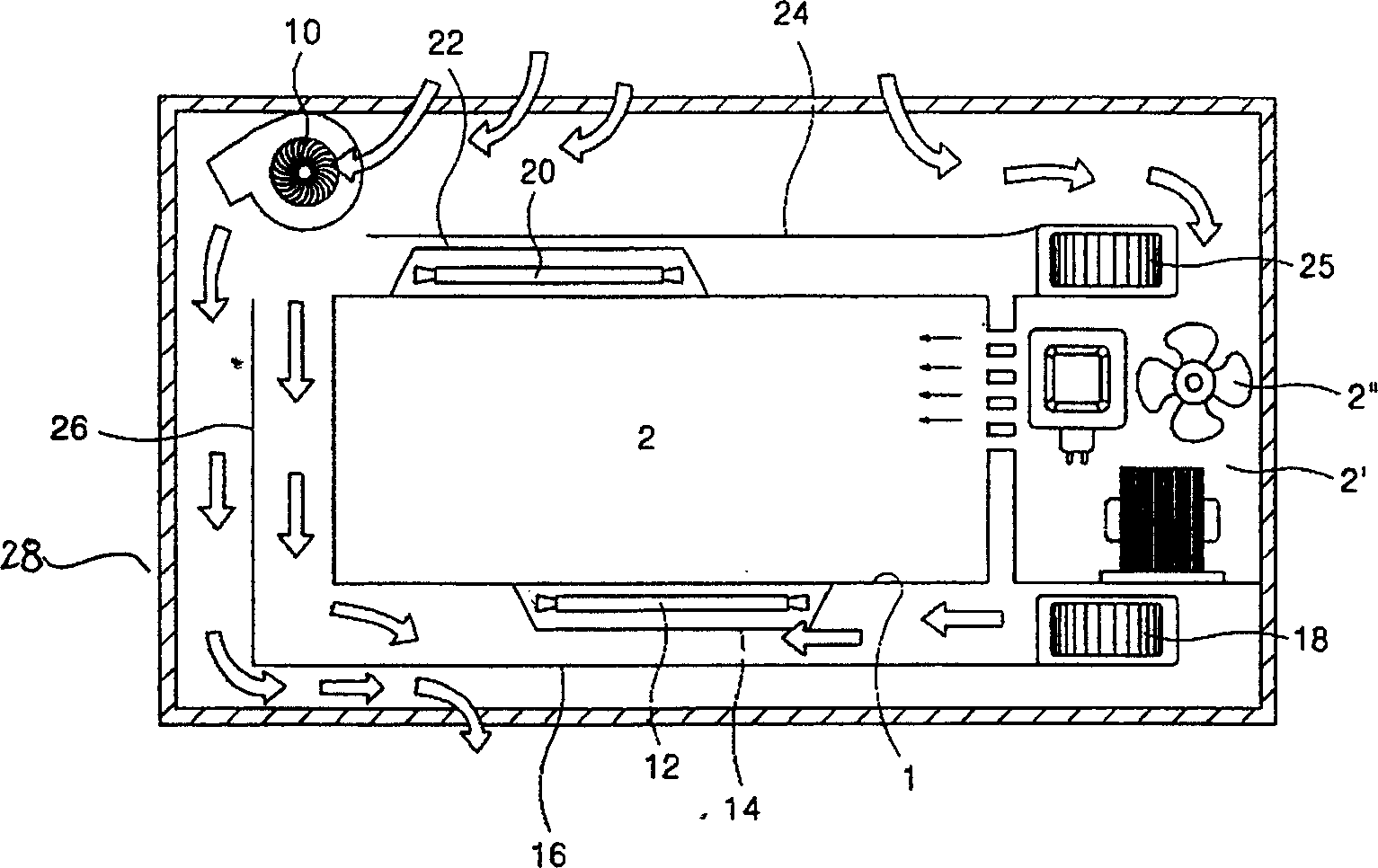

Air flow system for microwave oven

InactiveCN1455179AReduce noiseLow manufacturing costDomestic stoves or rangesLighting and heating apparatusMicrowave ovenAirflow

The system comprises the inspiration part, the exhaustion part and the airflow generation part. The inspiration part sucks external air into the microwave oven. The exhaustion part including the grid in front of oven outputs the circulated air in oven to outside. The airflow generation part is located on one side of the cavity. With the parts outside the cavity being cooled by the airflow generated from the airflow generation part moved along the cavity, one part of the airflow through the exhaustion part is output forming the airflow to cool parts and the other part of the airflow is fed into the cavity. With being circulated, the airflow in the cavity through the exhaustion part is output. The invention reduces the part number of fan assembly, simplifies the installing technique, lowers the production cost and raises the noise level.

Owner:LG ELECTRONICS (TIANJIN) APPLIANCES CO LTD

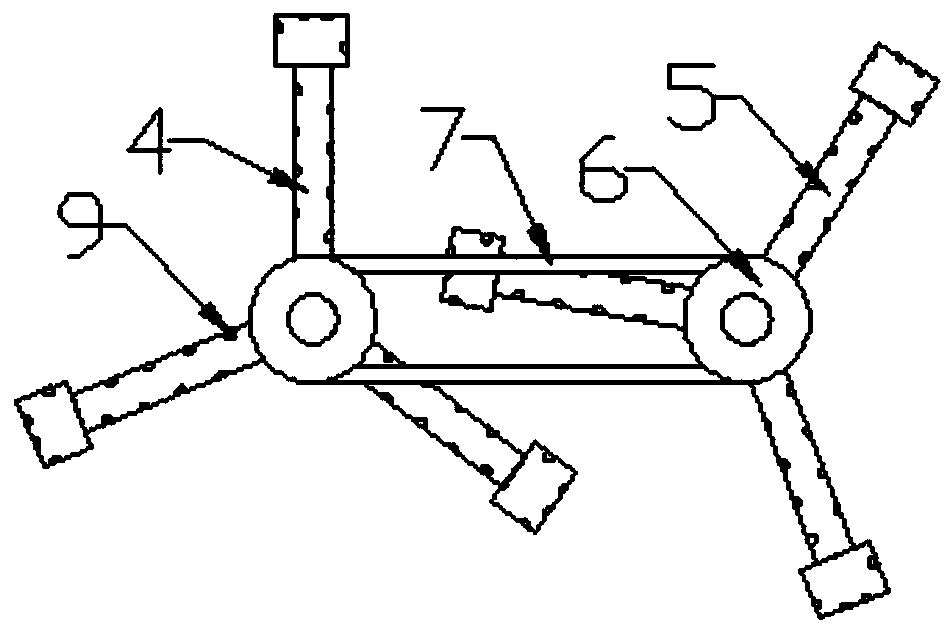

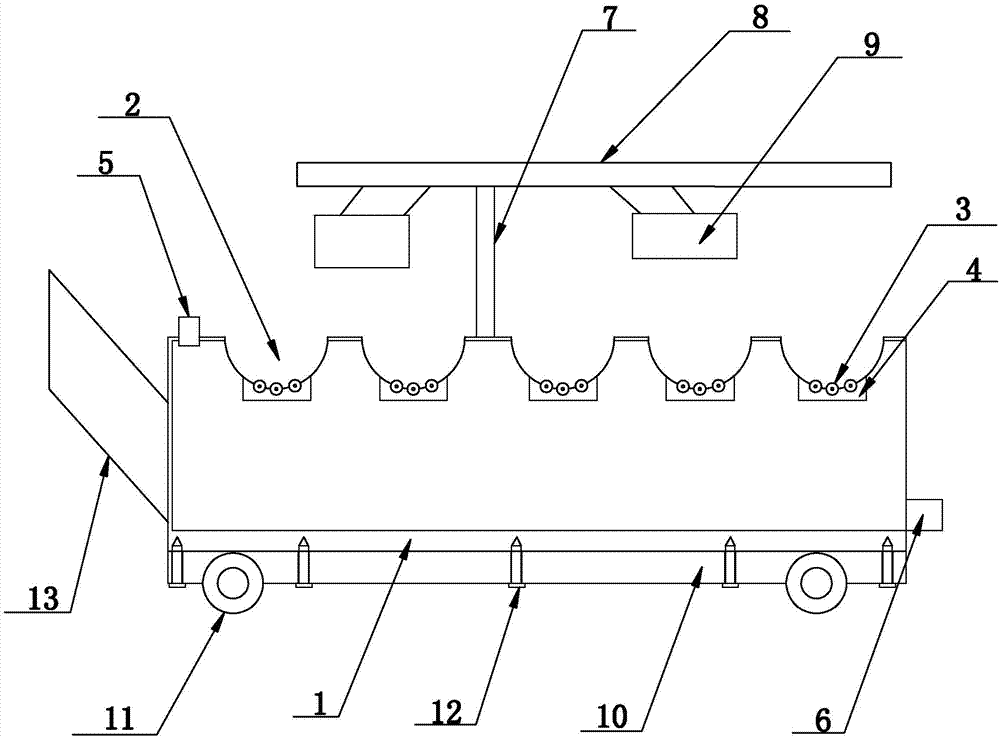

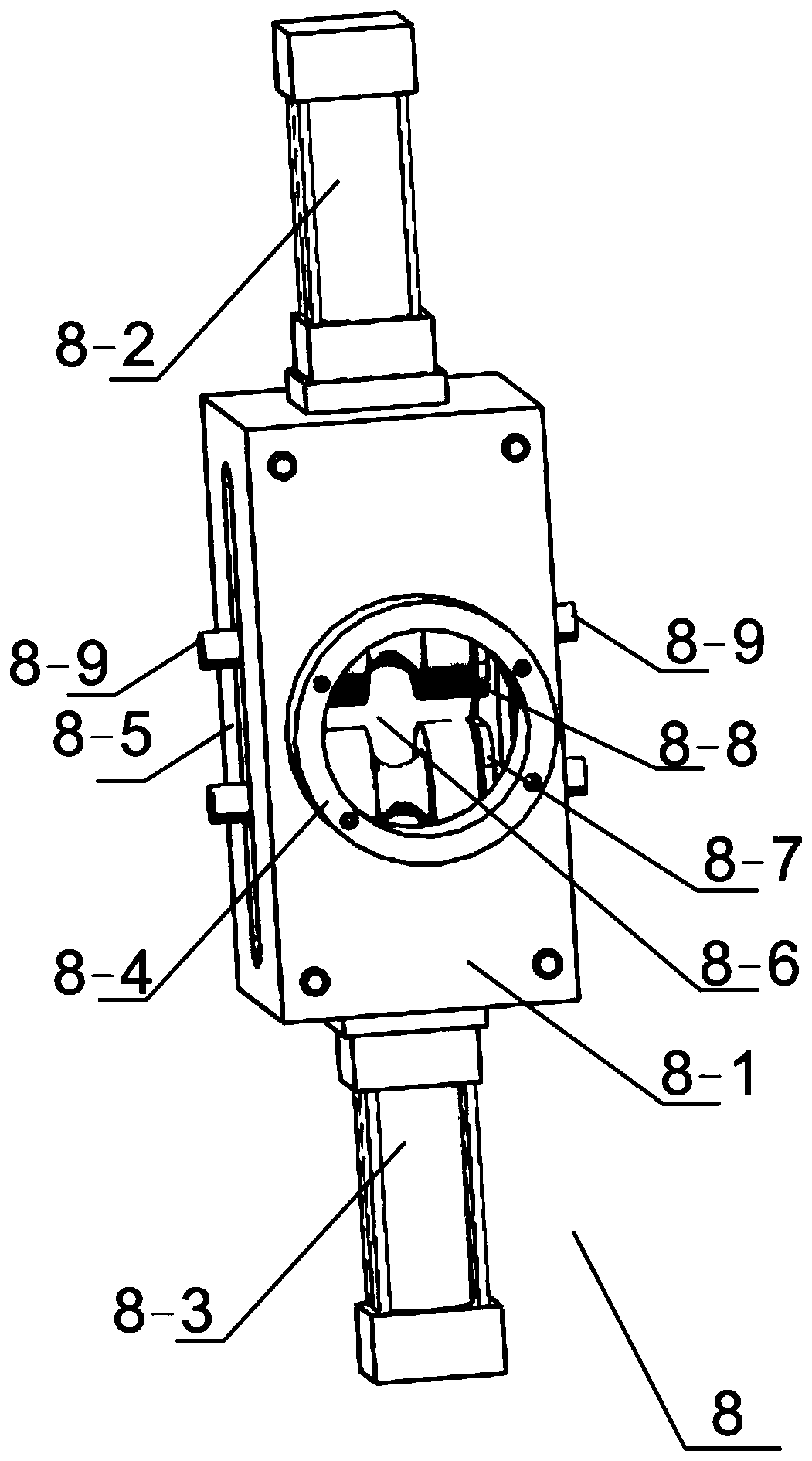

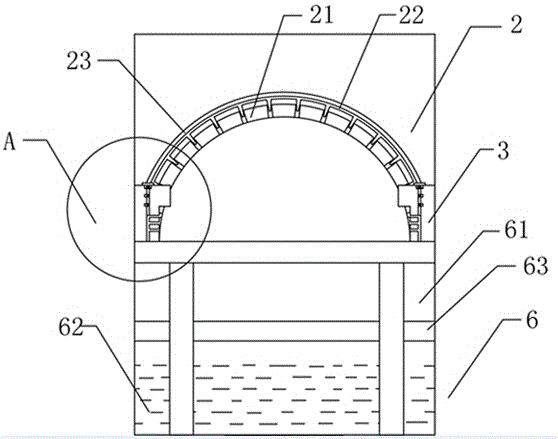

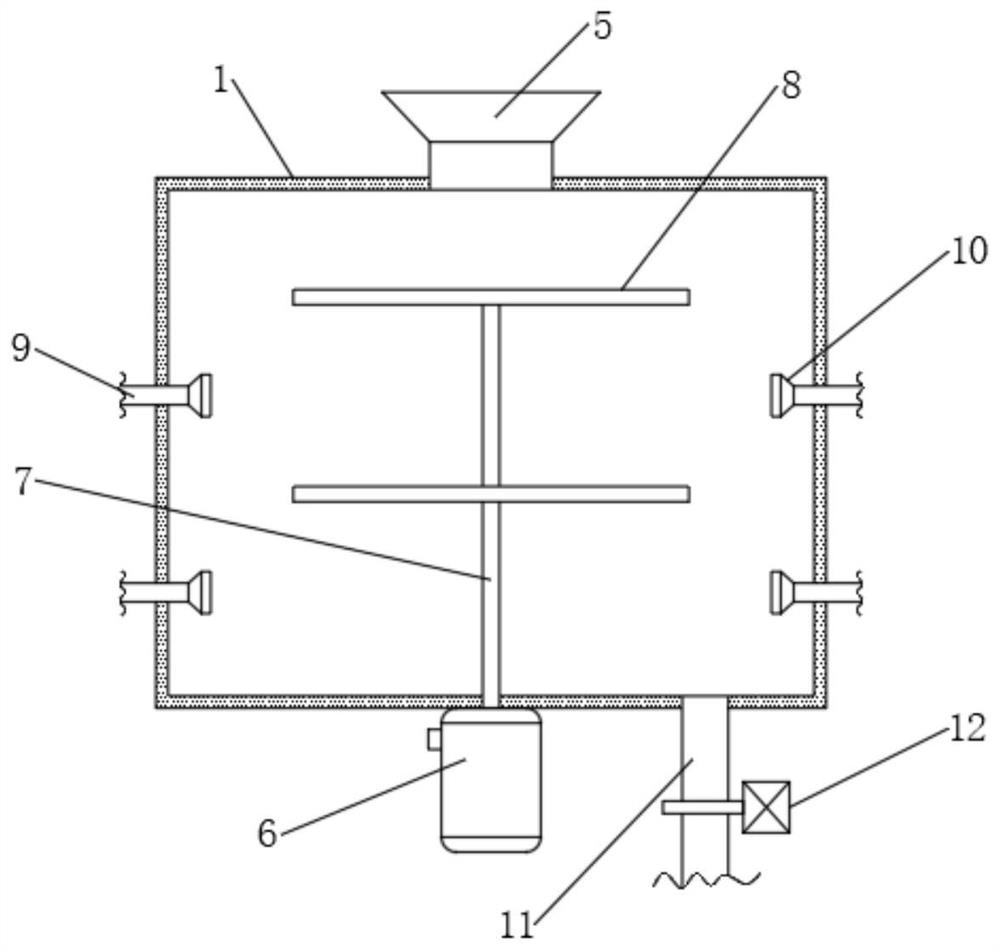

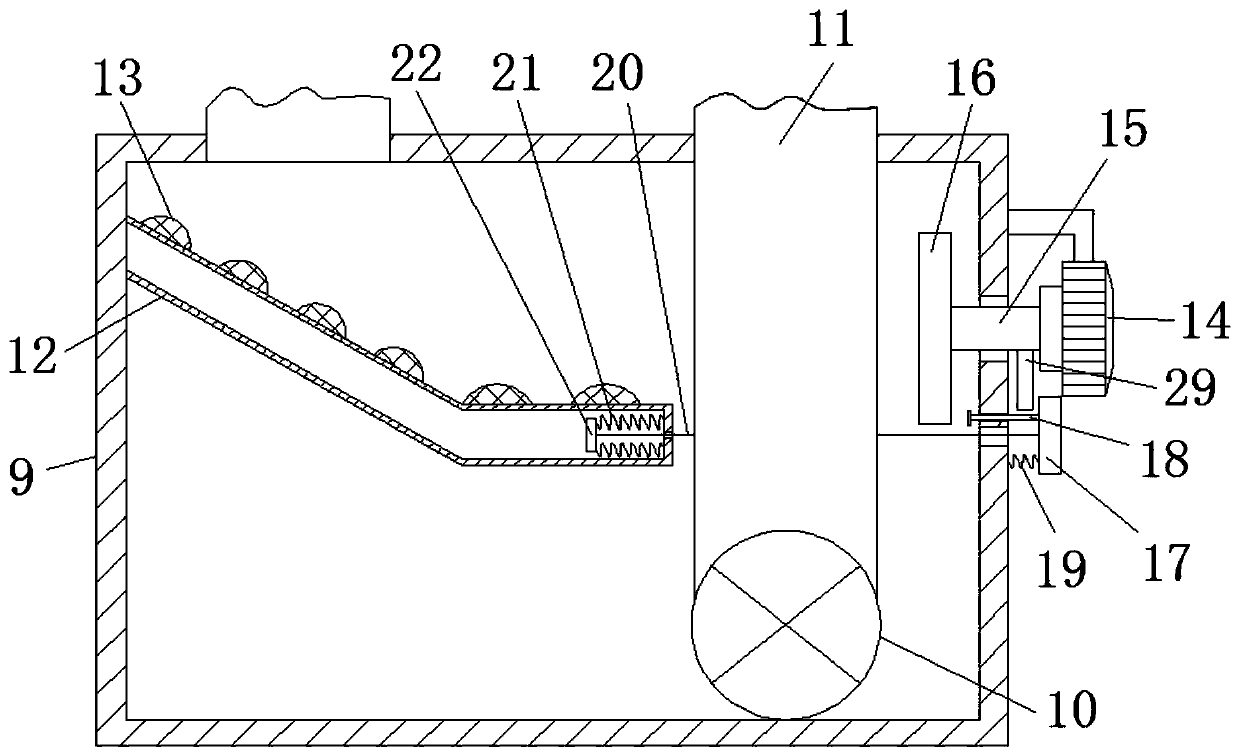

Wine brewing device

InactiveCN102417873AAdd and stir wellCool down thoroughlyAlcoholic beverage preparationEngineeringControl valves

The invention relates to a wine brewing device, which comprises discharging equipment (1), a conveyor belt (2) and a motor (10). The wine brewing device is characterized in that: a control valve (3) is arranged above the conveyor belt (2) and close to the discharging equipment (1); the control valve (3) is connected with a rice cooking unit (4); the rice cooking unit (4) is provided with cooling equipment (5); the cooling equipment (5) is sequentially provided with an auxiliary material holding device (6), a stirring device (7) and a receiving end (8) in the direction of the conveyor belt; and a waste tank (9) is arranged below the conveyor belt (2). Through the wine brewing device, rice of different categories and rice of different quantity can be cooked, the cooked degree can be controlled in a proper range, meanwhile, the cooked rice is cooled thoroughly, auxiliary materials are added and stirred relatively uniformly, the later brewed wine is mellow, and the whole quality of the brewed wine is improved.

Owner:WUZHANMAO WINE

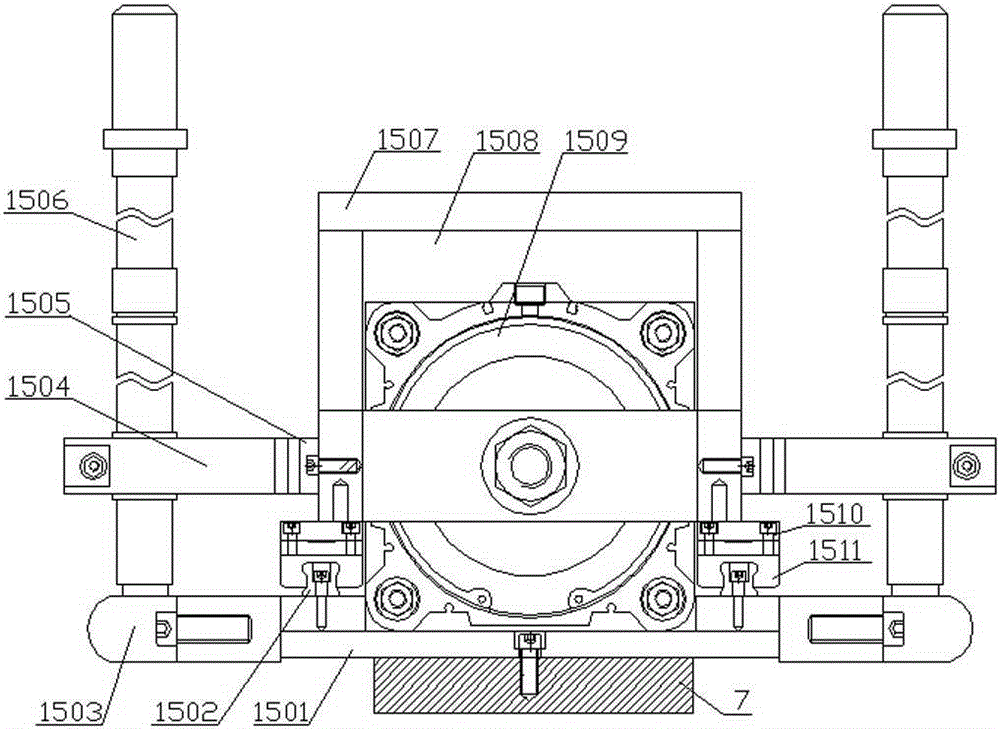

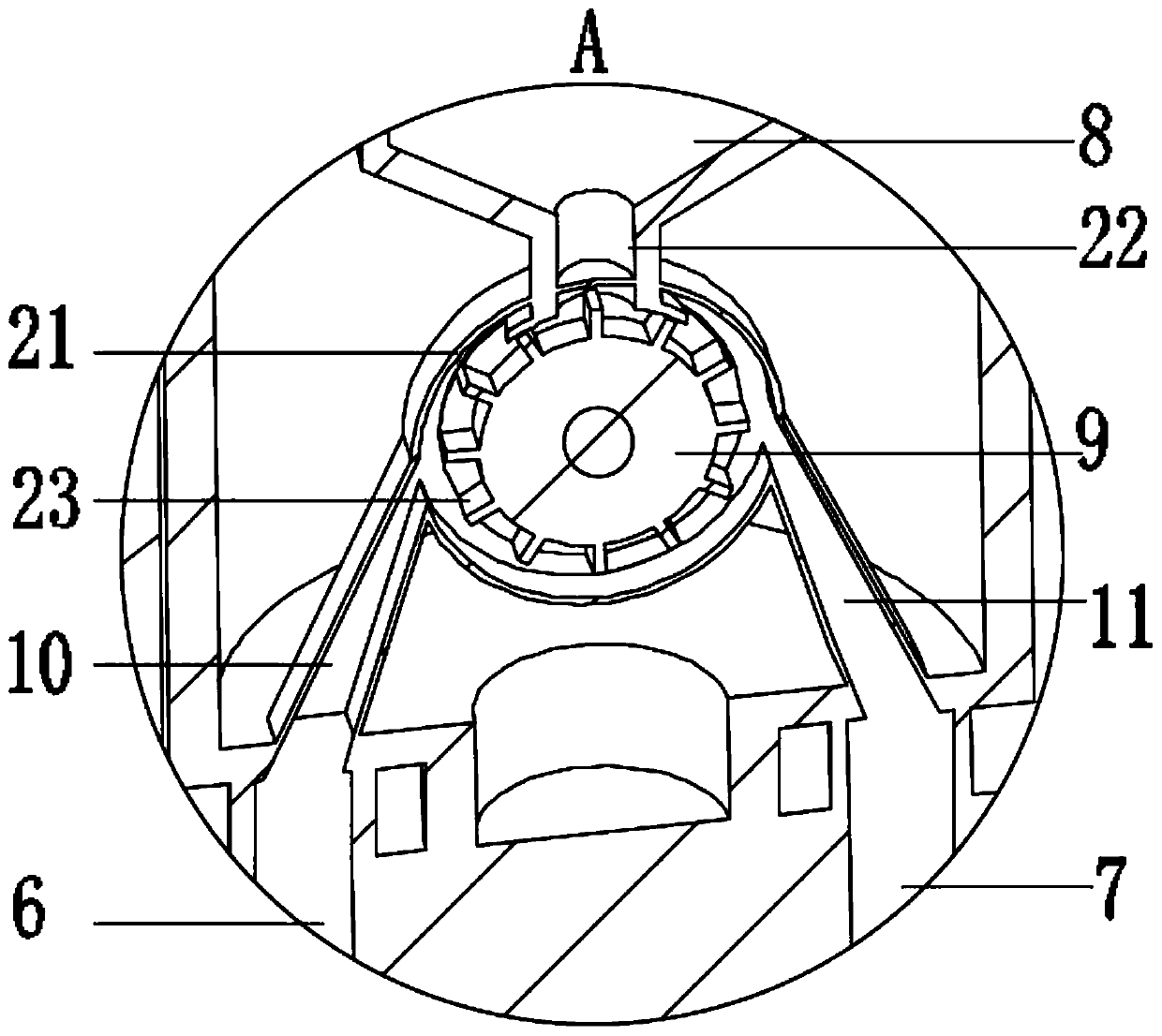

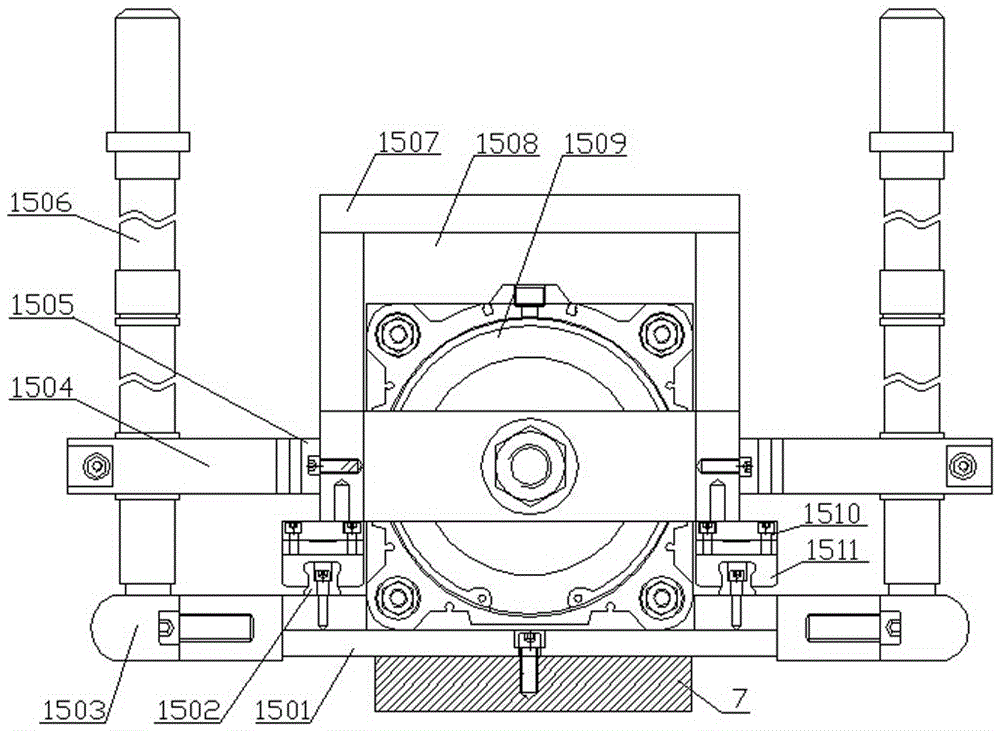

Rotating disc type glass bottle-making machine

The invention belongs to the technical field of bottle-making machines, and discloses a rotating disc type glass bottle-making machine. According to the rotating disc type glass bottle-making machine, the problems that an existing bottle-making machine is complex in structure and is inconvenient to mount and maintain are solved. The rotating disc type glass bottle-making machine comprises a base, a forward blowing mechanism and an air supplementing mechanism; a blank mold mechanism and a turnover mechanism are arranged on the base; a rotating disc machine body is also arranged on the base and is driven by a rotating disc motor to rotate; a vertical shaft is arranged on the rotating disc machine body in a sleeving way; the forward blowing mechanism and the air supplementing mechanism are arranged on the vertical shaft in a sleeving way; a mold opening / closing mechanism is arranged on the rotating disc machine body and comprises air cylinder seat base plates arranged on the rotating disc machine body; sliding rails are arranged on the air cylinder seat base plates; an air cylinder which can slide on the sliding rails is arranged on the sliding rails; the air cylinder is communicated with an external air source; the air cylinder is provided with a rack support; racks are arranged on the rack support; mold opening / closing shafts for driving holding clamps to move are arranged on the corresponding air cylinder seat base plates through bearings in a sleeving way; a sector gear which is meshed with the corresponding rack is arranged on each mold opening / closing shaft.

Owner:LONGCHANG LIANGGONG SCI & TECH CO LTD

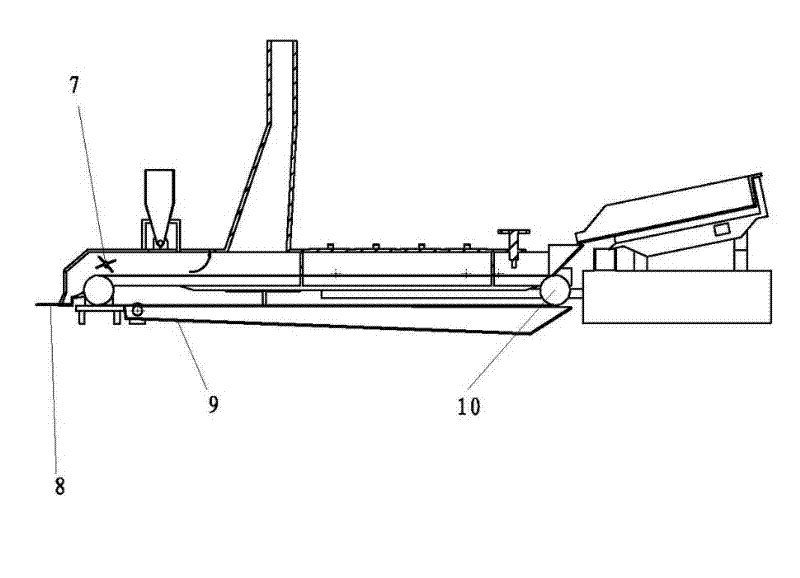

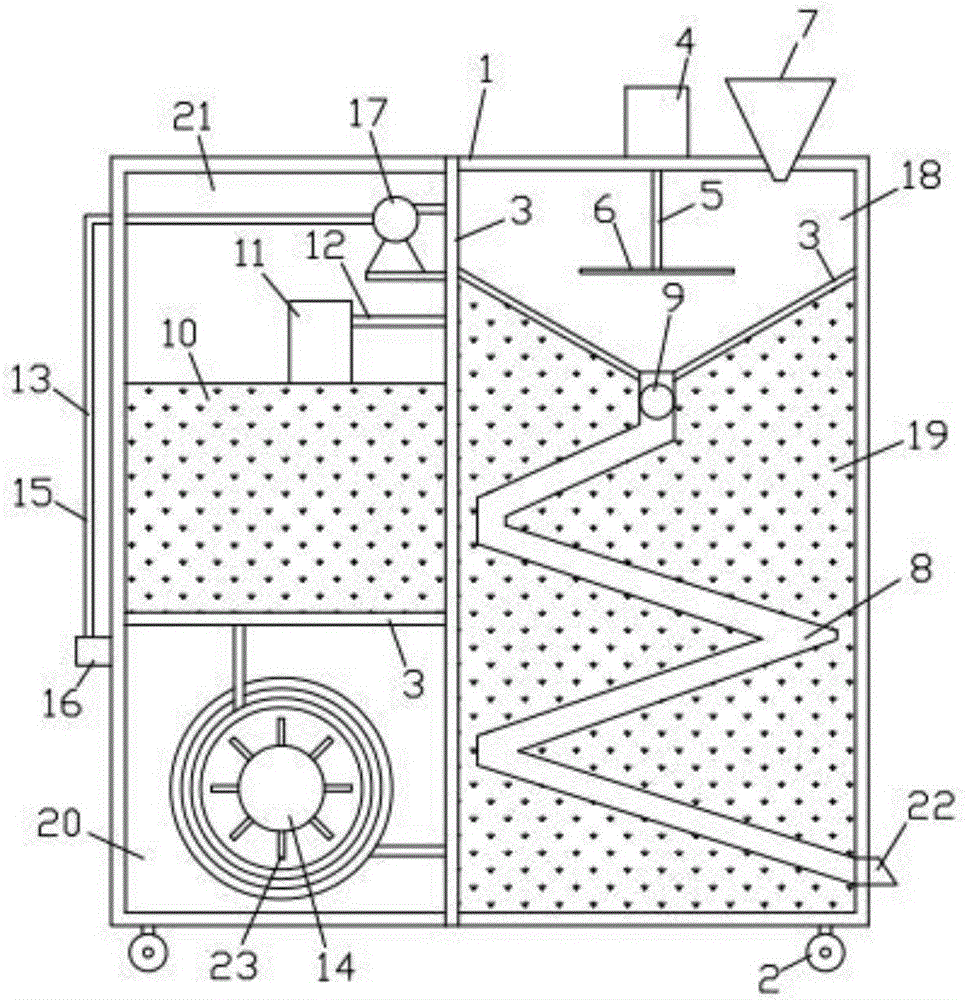

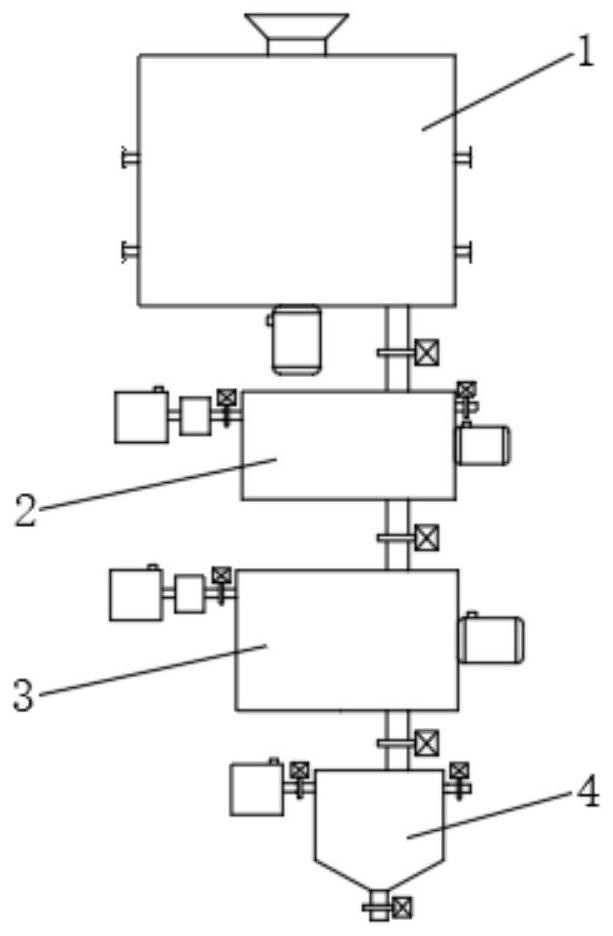

Device for cooling before packaging of feed

The invention discloses a device for cooling before packaging of feed. The device comprises a box body, casters, separating plates, a motor, a spindle, a stirring paddle, a feeding hole, a cooling pipe, a flow control valve, a water tank, a water pump, a water inlet pipe, a water return pipe, a cold exchanger, an air supply pipeline, a drying oven and an induced draft fan, wherein the casters are arranged at four corners of the bottom of the box body, three separating plates are arranged inside the box body, and the three separating plates divide the interior of the box body into a primary cooling chamber, a secondary cooling chamber, a cold exchange chamber and a mounting chamber; and a feeding hole is formed in the top of the primary cooling chamber, the bottom of the primary cooling chamber is in an inverted cone shape, the motor is arranged at the center of the top of the primary cooling chamber, and the spindle is arranged at the output end of the motor. The device disclosed by the invention is novel in structure, scientific and reasonable in design and convenient in maintenance, the cost is saved, and the device can move flexibly; the device adopts two-stage cooling, so that cooling is more thorough, and the feed can be still easily stored; and after cooling, excessive moisture can not be brought to the feed, and the quality safety of a finished product is guaranteed.

Owner:CHONGQING FURUICHENG AGRI CO LTD

Transmission device with safety pressurization in terminal transmission application

ActiveCN109585133AEasy to cycle heatGuaranteed cooling efficiencyTransformers/inductances coolingTransformerFuel tank

The invention discloses a transmission device with safety pressurization in terminal transmission application. The transmission device comprises a transformer body, wherein an auxiliary cooling deviceis arranged on the transformer body and comprises a cooling oil tank, an oil pump, an oil pipe, a baffle plate, convex strips, a power motor, a rotation rod, a fan blade and an induction starting device. Cooling water in an induction box is heated and evaporated and become a gas, a first conduction piece is pushed to move leftwards and contact with a second conduction piece, a series circuit is connected, and the oil pump and the power motor are started; heat absorption oil of the cooling oil box is pumped into the oil pipe by the oil pump so as to absorb heat of the transformer body, and thecooling efficiency of the transformer body is ensured; and when heat absorption oil returns to the cooling oil tank after heat exchange, and the heat absorption oil after heat exchange can slowly descend along an inclination segment of the baffle plate, at the moment, the fan blade is driven to rotate by the power motor so as to performing air cooling on the slowly-descending heat absorption oilafter heat exchange, and cycle heat absorption of the heat absorption oil at the next time is facilitated.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

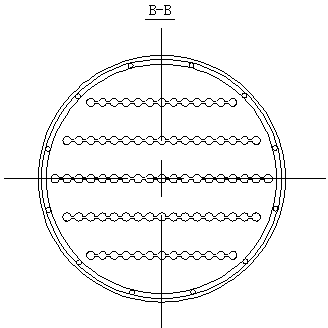

Improved cooling tower

The invention discloses an improved cooling tower, which comprises a tower body. The improved cooling tower is characterized in that an air outlet is arranged at the top of the tower body; a fan is arranged at the air outlet; a deceleration motor connected with the fan is arranged at the outer end of the top of the tower body; multiple groups of spray devices are arranged at the lower end of the fan; each spray device comprises a water distribution pipe, water distributors and a water collector; a plurality of water distributors are arranged on each water distribution pipe; a water collecting groove is arranged at the lower ends of the spray devices; the water distribution pipes are connected with water inlet pipes; the water collecting groove and the water collectors are connected with water return pipes; four walls of the tower body are connected with air inlets; and air suction devices and air cooling devices are arranged at the air inlets. The improved cooling tower has the advantages that circulating water is cooled by adopting air; resource is saved; moreover, the air can be also circularly utilized; the air cooling devices at the air inlets on the tower body can quickly cool the air, so that the circulating water is cooled thoroughly; and the use is convenient and quick.

Owner:江苏海菱碳制品有限公司

Biofertilizer cooling device

PendingCN109539822AImprove cooling effectWell mixedDirect contact heat exchangersHeat exchange apparatusFertilizerPre screening

The invention discloses a biofertilizer cooling device which comprises a stirring and cooling system composed of a cooling box, a discharging box, a servo motor, a main stirrer, an auxiliary stirrer and an air cooler, a feeding and mixing system composed of a feeding pipe and a feeding pump, and a screening and discharging system composed of an inclined vibrating screen, a first conveyor belt anda second conveyor belt. The discharging box is welded to the bottom end of the discharging box, and a feeding hopper communicates to one side of the top end of the cooling box. The cooling device stirs and mixes a fertilizer through double stirrers, cold air blown by the air cooler is exported through an air outlet hole and is fed into the fertilizer along with rotation of the stirrers to cool thefertilizer from inside to outside, the fertilizer exported from a material guide port is pre-screened by the inclined vibrating screen, and two fertilizers of different levels are fed to different positions through the first conveyor belt and the second conveyor belt to be screened again. In the pre-screening process, an air outlet hopper is aligned to the inclined vibrating screen to blow cold air to cool the fertilizer thereon again.

Owner:安徽金秋肥业有限公司

Novel casting cooling device

The invention discloses a novel casting cooling device, which comprises a water tank, wherein the upper end surface of the water tank is provided with a plurality of arc-shaped grooves, the bottom part of each arc-shaped groove is provided with at least one casting roller, the part, corresponding to the bottom part of each arc-shaped groove, of an inner cavity of the water tank is fixedly provided with a sealing cavity for the corresponding casting roller, the left end of the upper end surface of the water tank is fixedly provided with a water inlet, the lower end of the right end surface of the water tank is fixedly provided with a water drainage pipe, the upper end surface of the water tank is vertically and fixedly provided with a support rod, the upper end of the upper rod is provided with a transverse rod, blowers are fixedly arranged on the transverse rod, and an air outlet of each blower faces an opening of each arc-shaped groove. By adopting the technical scheme, the novel casting cooling device has the advantages that cooling water is added into the water tank, so when a casting is put into the corresponding arc-shaped groove, the casting can be quickly cooled by the surface of the corresponding arc-shaped groove; the bottom part of each arc-shaped groove is provided with the corresponding casting roller, so the turnover of the casting is convenient, and the casting can be completely and thoroughly cooled; in addition, the blowers are arranged above the upper end surface of the water tank, so the cooling time of the casting is greatly shortened.

Owner:长兴县李家巷铸造厂(普通合伙)

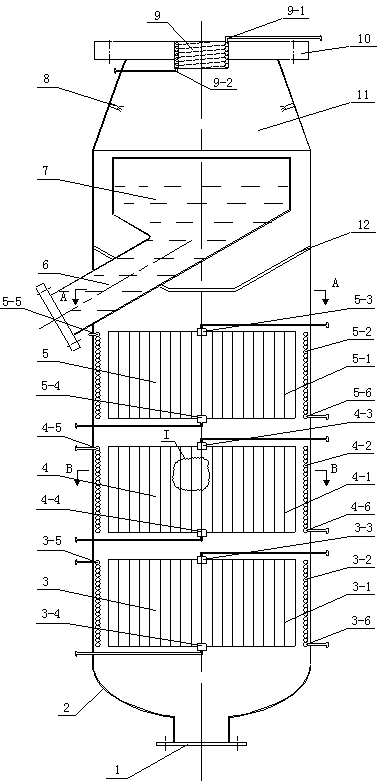

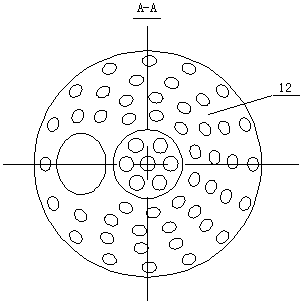

Integrated coal gasification waste heat recovery device

InactiveCN104263414AIncrease wasteAvoid wastingEnergy inputGranular/pulverulent flues gasificationSlagWastewater

The invention relates to an integrated coal gasification waste heat recovery device. The device comprises a tank, wherein a feeding hole, a quenching chamber, a slag pool, a convective waste heat boiler and a gas outlet are formed from top to bottom of the tank in sequence; the coal gas flows downwards from the feeding hole of the tank and is quenched in the quenching chamber; the temperature of the quenched coal gas is 800-900 DEG C; the wastewater enters the slag pool while the coal gas continuously flows downwards into the convective waste heat boiler to be cooled; the temperature of the cooled coal gas is 200-300 DEG C; the cooled coal gas is exhausted from the gas outlet. Combining the quenching chamber with the convective waste heat boiler into a whole, the device has the advantages that the device fully recovers high-temperature raw coal gases and slag sensible heat, removes fly ash, reduces the investment and improves the heat efficiency.

Owner:中国东方电气集团有限公司

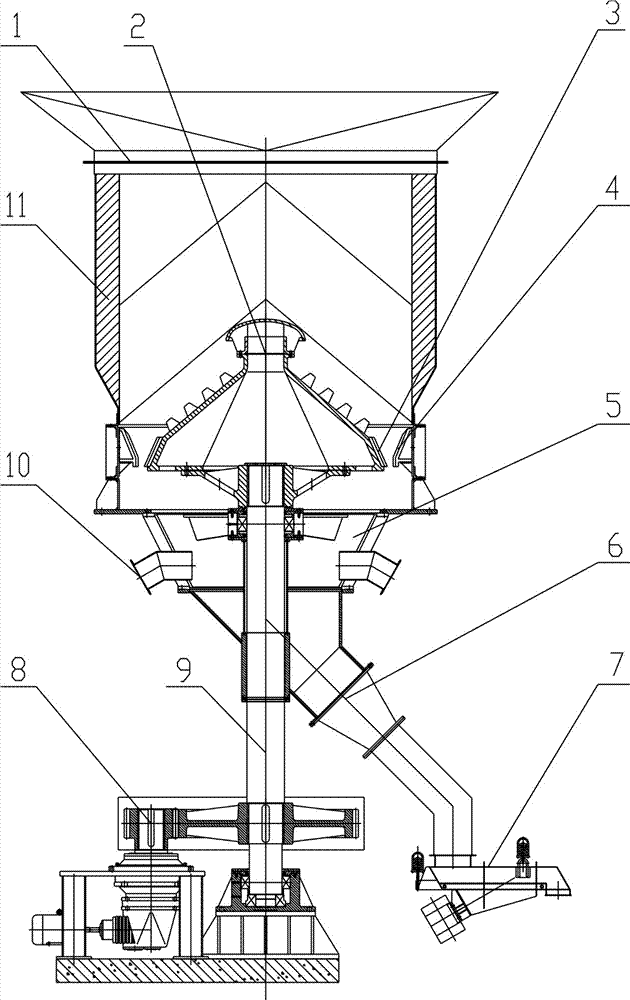

Waste incineration ash slag cooling machine

InactiveCN103075734AAvoid cloggingFully brokenIndirect carbon-dioxide mitigationIncinerator apparatusSlagEngineering

The invention discloses a waste incineration ash slag cooling machine, which comprises a casing, a disc tower, a baiting cabin, a discharging pipe, a vibration conveyor, a vertical shaft and a driving device, wherein a bottom end opening of the casing is fixedly connected with an upper end opening of the baiting cabin, a cooling air inlet is arranged in the side wall of the baiting cabin, a lower end opening of the baiting cabin is fixedly connected with one end of the discharge pipe, the other end of the discharging pipe is connected with the vibration conveyor, the disc tower is arranged in the casing, the outer surface of the disc tower is in a conical surface, an annular tooth plate A is arranged in a position on the outer surface of the disc tower near the bottom end, an annular tooth plate B is arranged in a position of the annular tooth plate A corresponding to the inner wall of the casing, a wedge-shaped space gradually reduced from top to bottom is formed between the annular tooth plate A and the annular tooth plate B, the disc tower is fixedly connected onto one end of the vertical shaft, and the other end of the vertical shaft is connected with the driving device. The waste incineration ash slag cooling machine has the advantages that high-temperature ash slag can be fast cooled, massive ahs slag can also be crushed into small blocks, the energy is saved, and the environment is protected.

Owner:CITIC HEAVY INDUSTRIES CO LTD

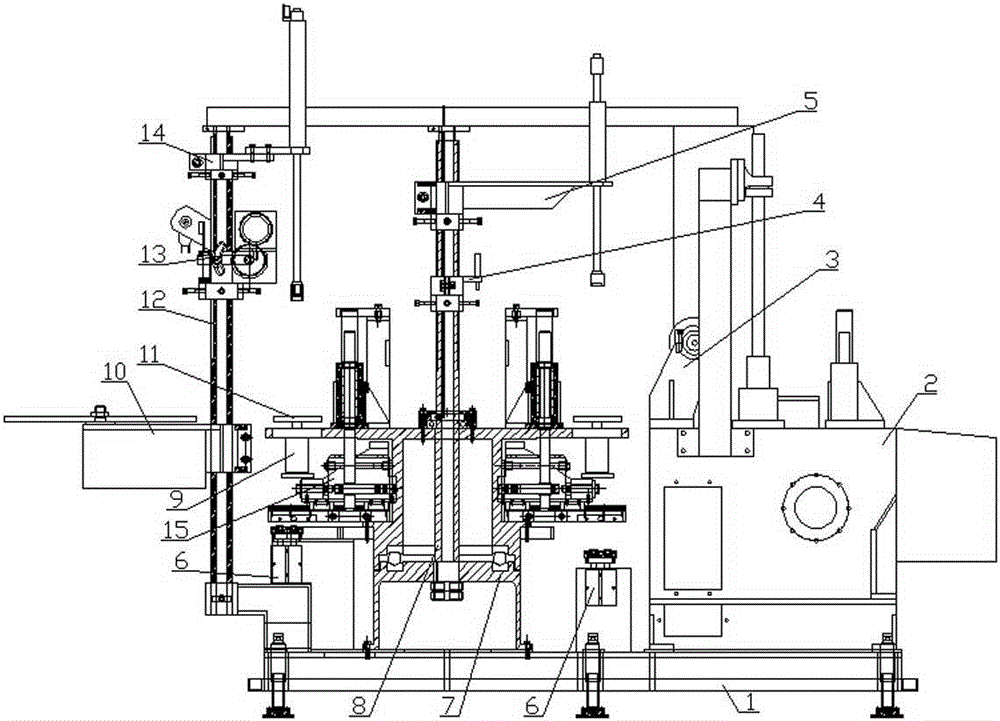

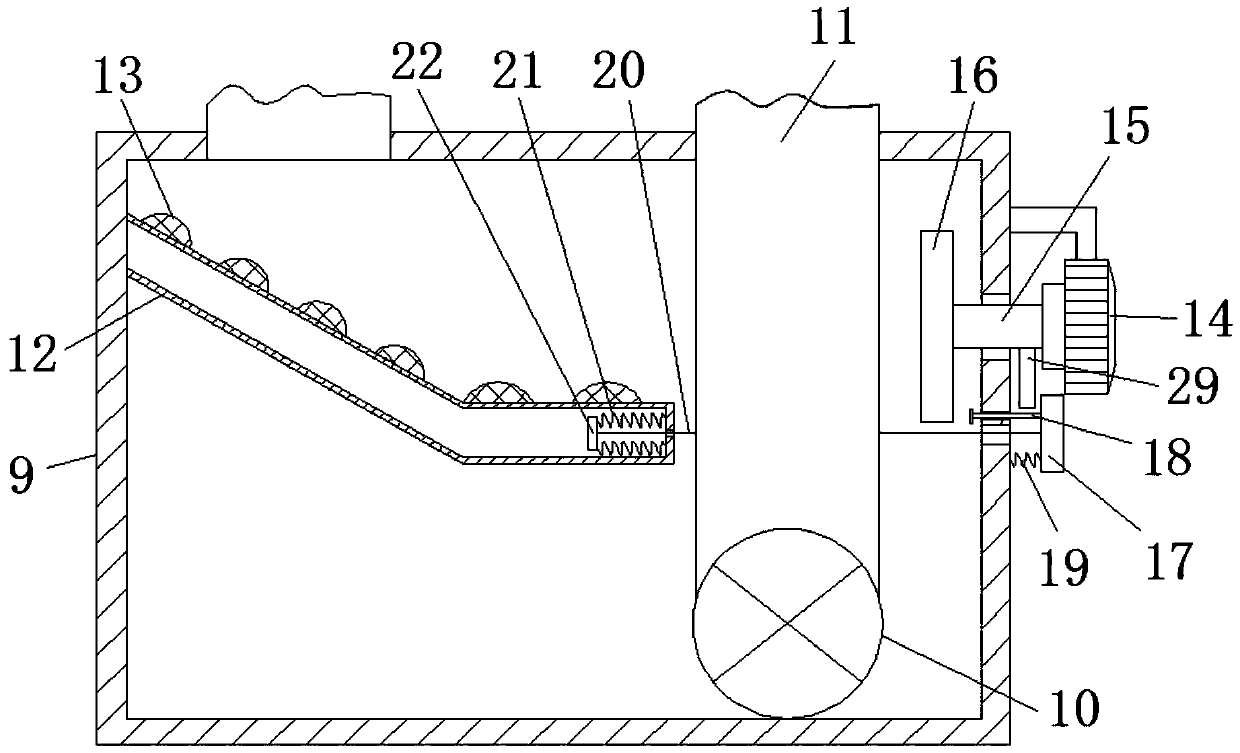

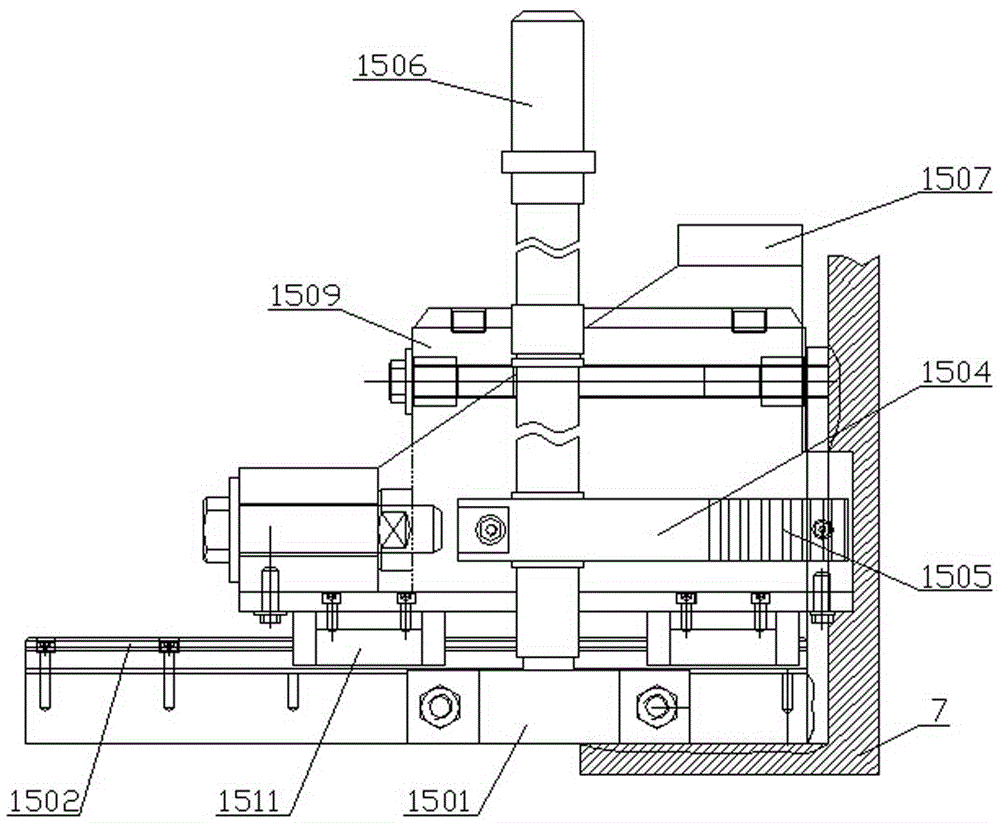

Water quenching automation equipment

The invention relates to water quenching automation equipment. The water quenching automation equipment comprises a quenching device, cooling devices and a clamping device, wherein the quenching device carries out a quenching procedure on a workpiece, and the workpiece is clamped into the cooling devices by the clamping device; the quenching device comprises a quenching machine tool and a control power supply, and the control power supply is used for controlling the quenching machine tool to carry out quenching treatment on the workpiece; the clamping device comprises a mechanical arm and a controller, and the quenched workpiece is conveyed into the cooling devices by the mechanical arm under the control of the controller; the quenched workpiece is conveyed between the first cooling device and the second cooling device through a conveying device; the first cooling device comprises a first cooling trough, and the quenched workpiece is conveyed into the first cooling trough through the mechanical arm; and the second cooling device comprises a second cooling trough, a water inlet pipe and a water outlet pipe, the water inlet pipe is arranged on one side of the second cooling trough, and the water outlet pipe is arranged on the other side of the second cooling trough. The water quenching automation equipment can evenly cool the quenched workpiece at a high speed and improves the technical requirement of the workpiece.

Owner:WUXI LEHUA AUTOMATION TECH

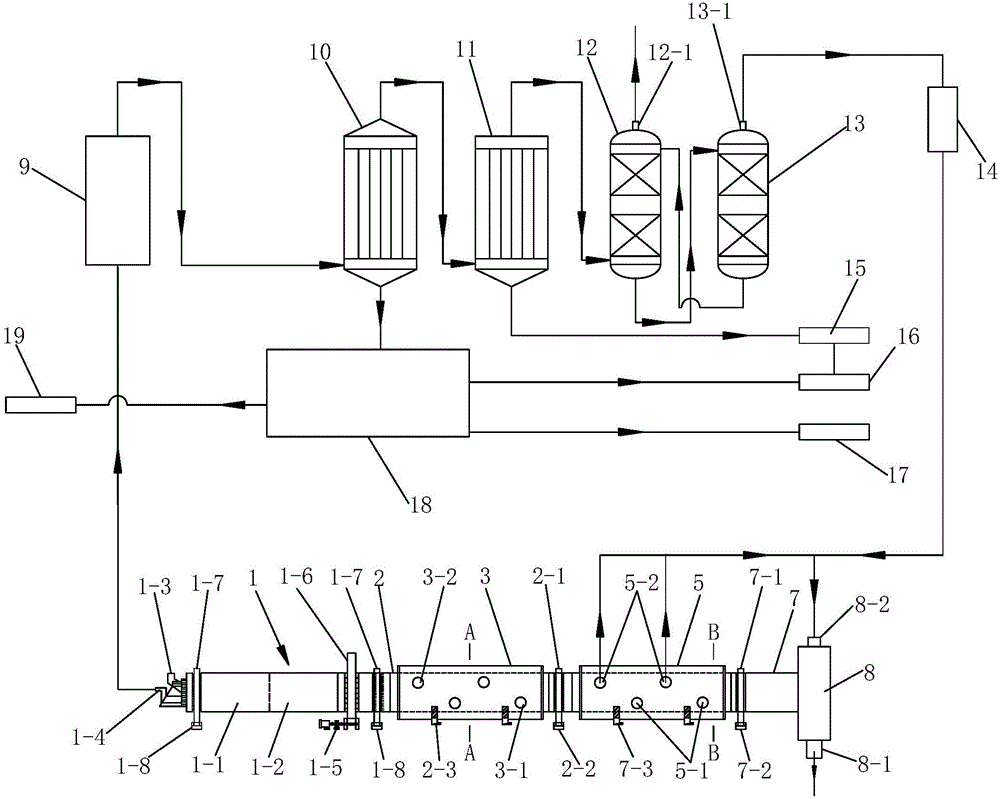

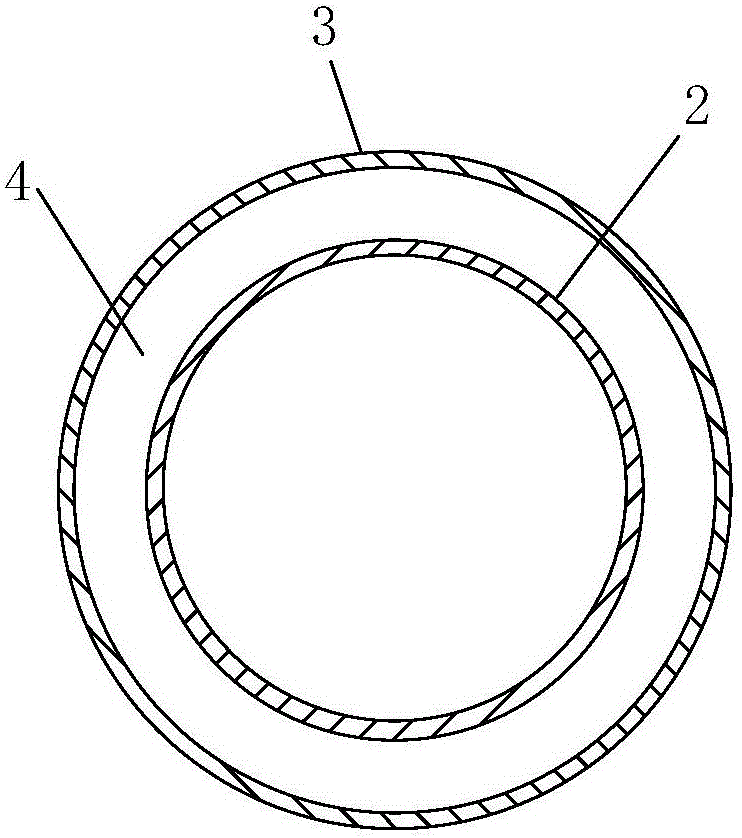

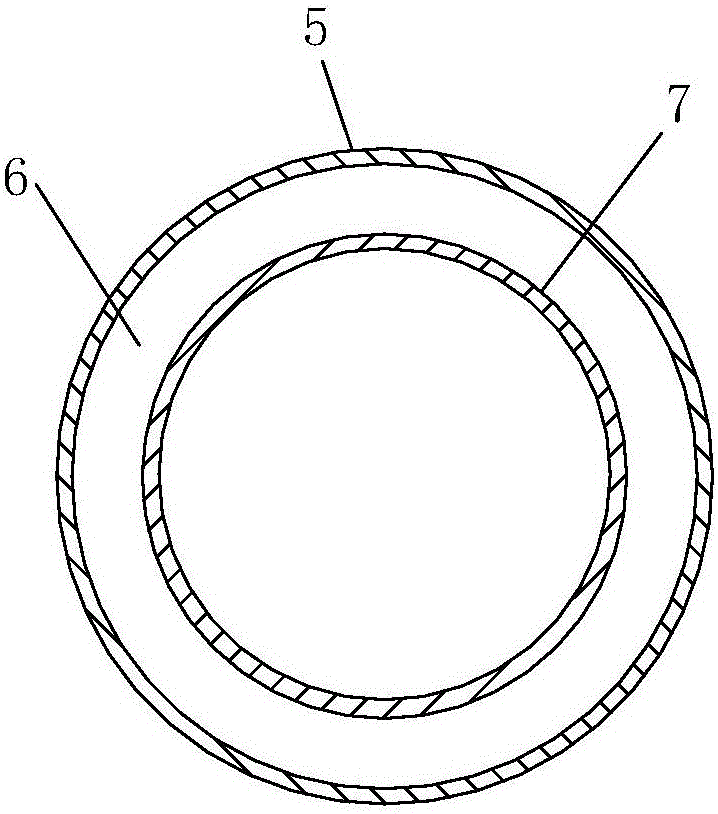

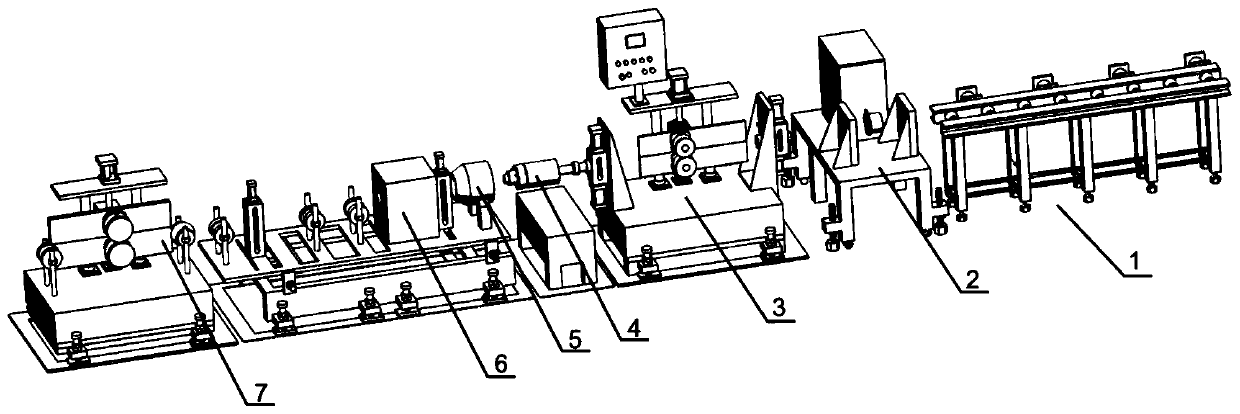

Oil-sucking rod continuous full cladding production line and cladding method thereof

The invention relates to the field of oil-sucking rods and provides an oil-sucking rod continuous full cladding production line and a cladding method thereof. The oil-sucking rod continuous full cladding production line comprises a wheel type conveying mechanism, an intermediate frequency heating device, a front traction device, a cladding module, an air cooling device, a water cooling device anda rear traction device in sequence, wherein positions between the intermediate frequency heating device and the front traction device as well as between the front traction device and the cladding module as well as between the air cooling device and the water cooling device as well as between the water cooling device and the rear traction device are all provided with positioning devices, distance sensors are arranged between the intermediate frequency heating device and the positioning devices, a terminal control device is fixed on the front traction device and controls the whole line, the cladding module comprises a cladding unit and a cladding material supplying unit, and a fixed platform II and the position between the water cooling device and the rear traction device are further provided with 4 sets of transmission devices. The oil-sucking rod continuous full cladding production line and the cladding method thereof have the beneficial effects that the oil-sucking rod continuous fullcladding production line and the cladding method thereof can adapt to cladding of the oil-sucking rods with different diameters, the cladding thickness can be adjusted, and the cladded oil-sucking rods have good corrosion resistance and abrasive resistance.

Owner:TIANJIN HAOHANG COMPOSITE PIPE

Laser cladding powder feeder

PendingCN111424275AFlexible materialsReduce wasteMetallic material coating processesEngineeringStructural engineering

The invention discloses a laser cladding powder feeder, and belongs to the technical field of laser cladding. The laser cladding powder feeder comprises a powder storage device and a powder feeding head, wherein the powder storage device comprises a fixed disc, a group of storage cylinders are fixedly mounted at the top of the fixed disc, a mixing cylinder is fixedly connected to the bottom of thefixed disc, the storage cylinders communicate with the mixing cylinder through mixing pipes, powder discharging hoppers are fixedly connected to the middle of the storage cylinders, rotating wheels are arranged below the powder discharging hoppers, a mixed material pipe and a powder feeding pipe are fixedly arranged on the side wall of each rotating wheel, the top of the mixing cylinder communicates with an output pipe, a homogenizing pipe is fixedly connected to the middle of the output pipe, homogenizing fan blades are fixedly installed in the middle of the homogenizing pipe, the output pipe communicates with a powder feeding head, the powder feeding head comprises a water cooling sleeve, a protective sleeve and a powder feeding sleeve, a powder feeding channel is arranged between the powder feeding sleeve and the protective sleeve, an air curtain channel is arranged between the protective sleeve and the water cooling sleeve, and a water cooling cavity is formed in middle of the water cooling sleeve. According to the laser cladding powder feeder, with the arrangement of the multiple groups of the powder feeding paths, the flexible material utilization is achieved, the material waste is reduced, the mixing is simple and convenient, the ratio is accurate, the cladding quality is improved, and the powder sintering blocking is avoided to a certain extent.

Owner:XINJIANG HUIXIANG LASER TECH

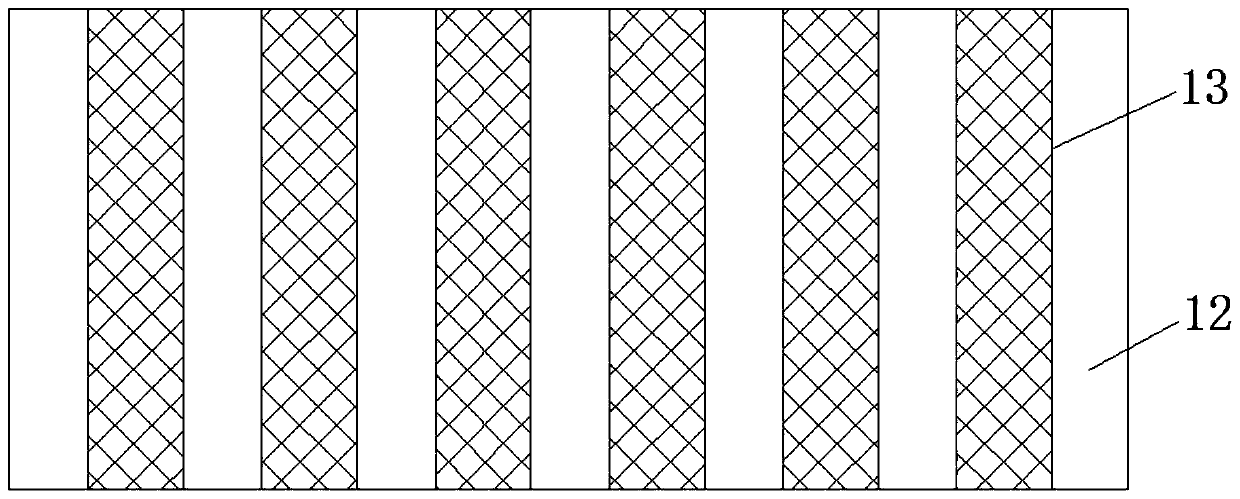

Novel rubber processing cooling tank

The bottom of the first conveying belt is mounted on the outer wall of a liquid soaking wheel in a sleeved manner, the lower conveying belt is in bypass connection with the outer walls of six second rollers, the bottom of the cooling tank is communicated with one end of a first guide pipe, the other end of the first guide pipe is communicated with the left side of one side of a liquid pump, and the top of the liquid pump is communicated with one end of a second guide pipe. Through holes are formed in the surface of each of the upper conveying belt and the lower conveying belt, cooling liquid cools the upper surface of a rubber material through the through holes, and the lower surface of the rubber material is also cooled in the same way, so that cooling is thorough; the novel rubber processing cooling tank is practical and suitable for wide popularization and use.

Owner:NANJING HUI LONG RUBBER PROD CO LTD

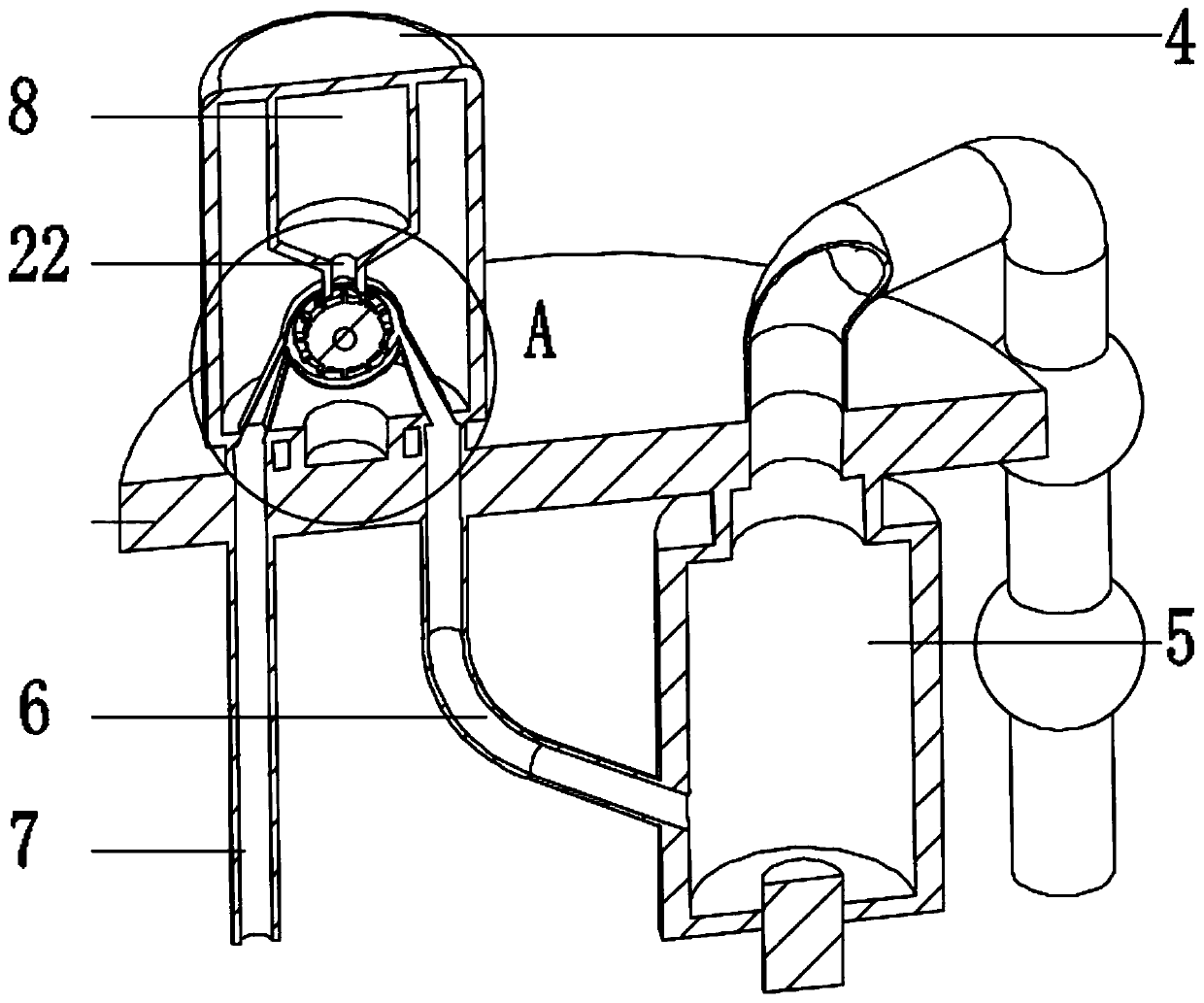

High-temperature steel slag waste heat recovery device and method

ActiveCN108220512AAchieving forced coolingCool down thoroughlyIncreasing energy efficiencyWaste heat treatmentCold airSlag

The invention discloses a high-temperature steel slag waste heat recovery device and method. The high-temperature steel slag waste heat recovery device comprises a radiant heat exchange chamber, a convection heat exchange chamber, a circulating fan and a plurality of cold air spray heads, wherein the radiant heat exchange chamber is internally provided with first heat exchanger sets, an inlet moving gate, an outlet moving gate, a hot air outlet and the multiple cold air spray heads; the top wall and the side wall of the radiant heat exchange chamber are provided with the first heat exchanger sets; the hot air outlet is formed in the position, close to the inlet moving gate, of the top of the radiant heat exchange chamber; the multiple cold air spray heads are arranged in the position, close to the outlet moving gate, of the top of the radiant heat exchange chamber; the convection heat exchange chamber is arranged above the radiant heat exchange chamber and communicates with the radiantheat exchange chamber through the hot air outlet, a second heat exchanger set is arranged in the convection heat exchange chamber, a heat exchange medium is injected into the second heat exchanger set, and the end, close to the outlet moving gate, of the convection heat exchange chamber is provided with a cold air outlet; and an inlet of the circulating fan is connected with the cold air outlet through a pipeline, and an outlet of the circulating fan is connected with the multiple cold air spray heads.

Owner:烟台羽林节能科技有限公司

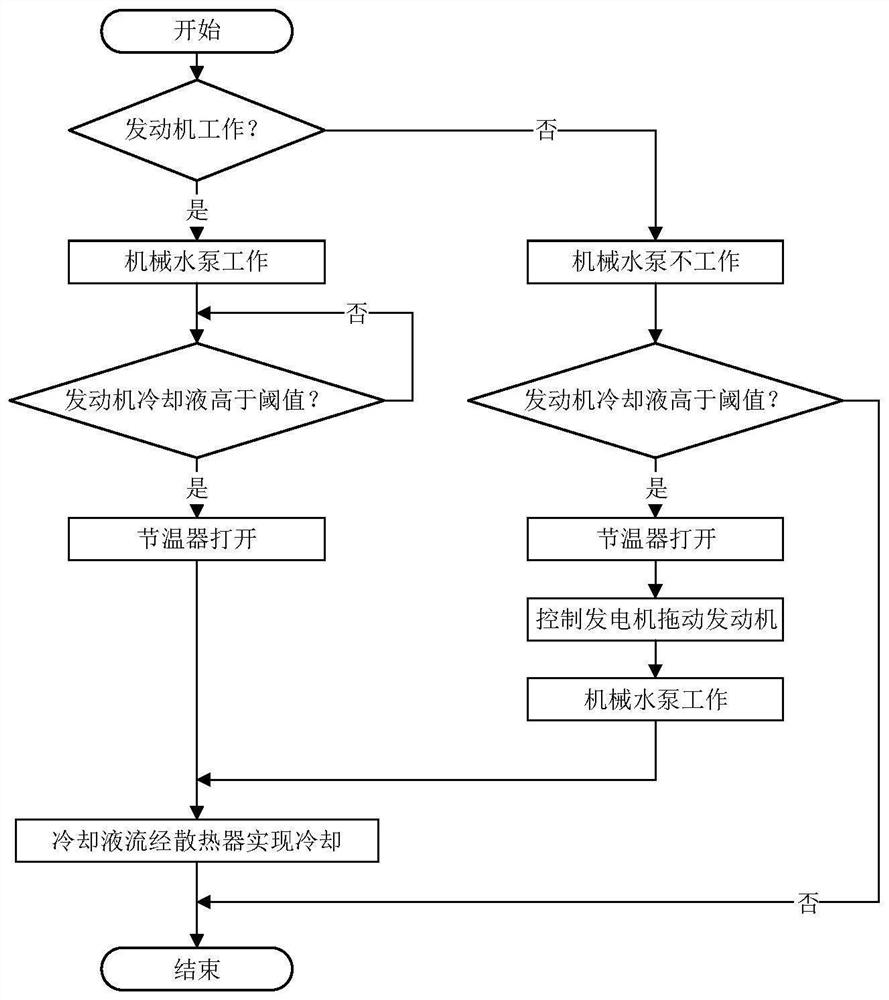

Engine thermal management method and system of extended-range automobile and automobile

InactiveCN113323748ACool down thoroughlyAvoid boilingCoolant flow controlMachines/enginesHeat managementThermal management system

The invention belongs to the technical field of thermal management of automobiles, and particularly relates to an engine thermal management method and system of an extended-range automobile and the automobile. The thermal management method comprises the following steps: obtaining working information and temperature information of an engine; identifying the state type of the engine according to the working information and the temperature information of the engine; and taking corresponding thermal management measures according to the state type. By the adoption of the technical scheme, under the condition that parts of an existing extended-range electric vehicle are not increased, thermal management can be conducted on the engine in the normal working state and the shutdown state, so that the engine is thoroughly cooled, the problems of power reduction, heat damage, cylinder pull and the like caused by the fact that the temperature of the engine is too high are solved, particularly, when the engine is in a shutdown state, a power generator is used for dragging the engine to operate, a water pump works along with the engine, and thus, the engine can be continuously cooled by cooling liquid, and a boiling phenomenon is avoided.

Owner:重庆赛力斯新能源汽车设计院有限公司

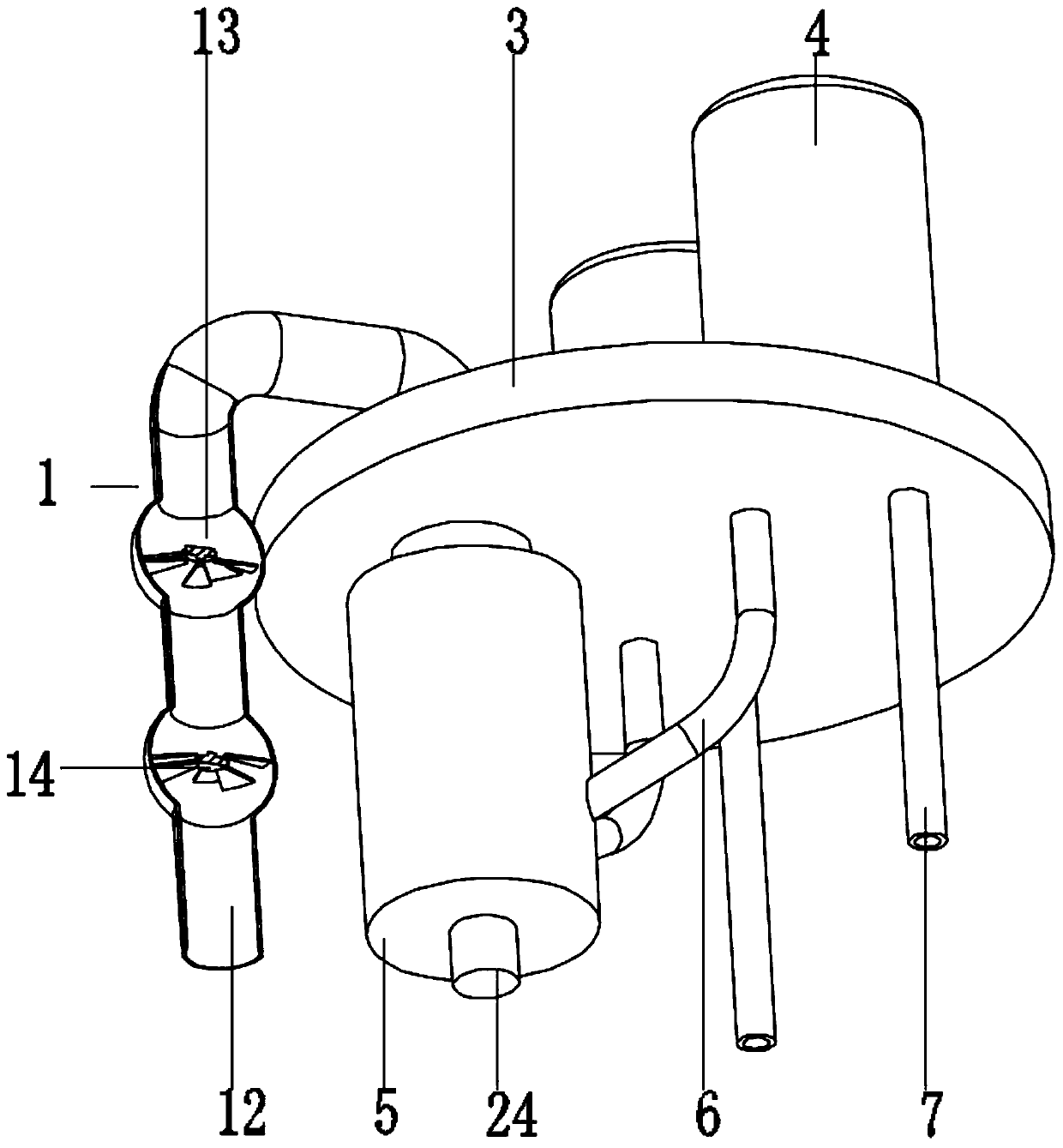

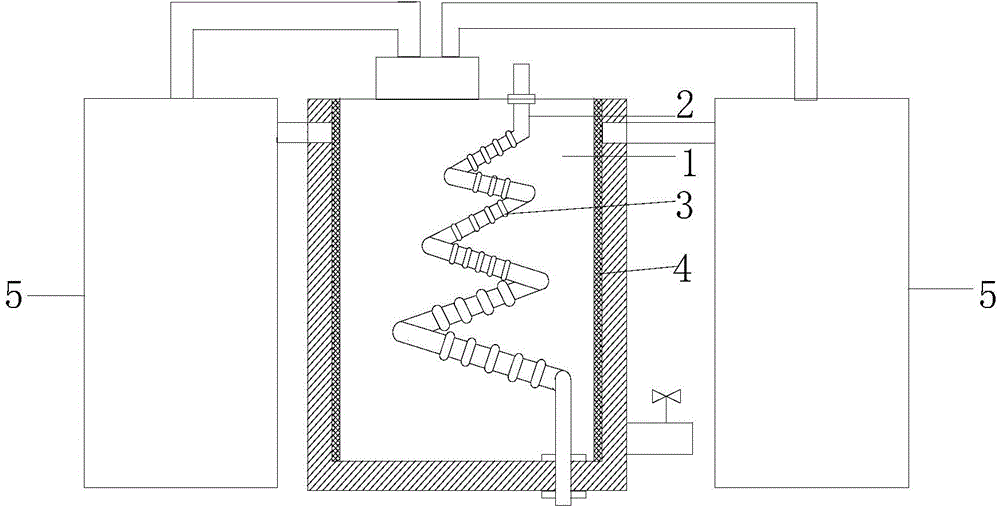

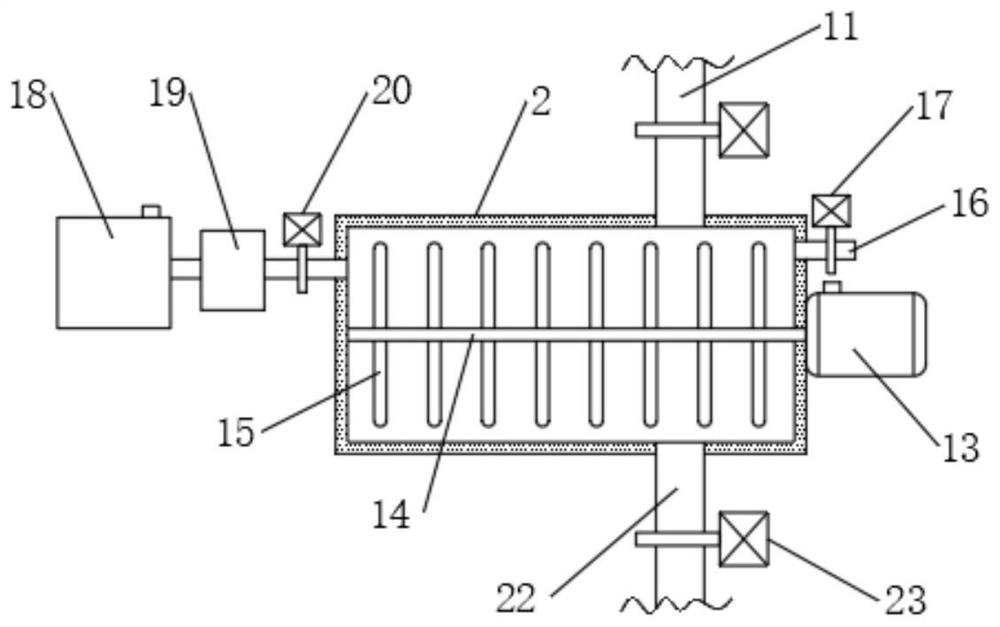

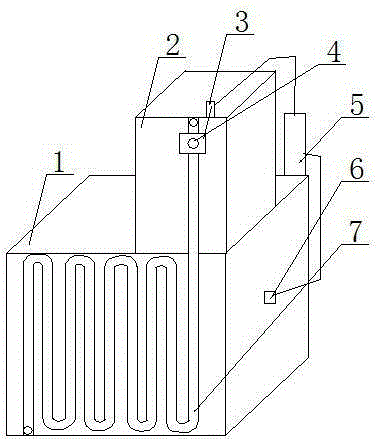

Liquor brewage cooling system

InactiveCN105754824AIncrease cooling areaImprove efficiencyAlcoholic beverage preparationEngineeringCirculating pump

The invention discloses a liquor brewage cooling system. The system comprises a cooling cylinder provided with a liquor steam inlet and circulating cylinders connected through a circulating pump and arranged at two sides of the cooling cylinder, a screw cooling tube provided with a cooling medium is arranged in the cooling cylinder, and the cooling tube is arranged in the cooling cylinder in a sealing manner, can horizontally rotate along the cooling cylinder, and traverses out from the bottom of the cooling bottom. The screw cooling tube capable of horizontally rotating is adopted, and cycle cooling of the circulating cylinders is combined, so the cooling area is increased, thereby liquor steam is thoroughly cooled, and the efficiency is improved; and the system has the advantages of simple structure, convenient manufacturing, and increase of the liquor yield by 30%.

Owner:CHONGQING JIALI LIQUOR IND

An aluminum profile cooling channel

Owner:TAIZHOU GAOGANG ZONE SHENGYUAN RUBBER CO LTD

Cooling device for deslagging agent production process

PendingCN112683082AWet evenlyLow boiling pointCorrosion preventionDirect contact heat exchangersProcess engineeringNozzle

The invention provides a cooling device for a deslagging agent production process, and relates to the technical field of deslagging agent production. The cooling device for the deslagging agent production process comprises a first box body, water conveying pipes which are evenly distributed are fixedly connected to the middle and the lower part of the periphery of the first box body, atomizing nozzles are fixedly connected to the output ends of the water conveying pipes, one side of a second box body is fixedly connected with a first filter through an exhaust pipe, the first filter is fixedly connected with a first vacuum pump through an exhaust pipe, one side of a third box body is fixedly connected with a second filter through an exhaust pipe, and the second filter is fixedly connected with a second vacuum pump through an exhaust pipe. Materials can be scattered through a rotary disc, then are evenly soaked through the atomization spray heads and then enter the second box body and the third box body, water on the materials is rapidly vaporized in the vacuum state, thus heat on the materials can be absorbed, even and thorough cooling is achieved, and the cooling device is worthy of wide popularization.

Owner:江西新熙铸造材料有限公司

A rotary glass bottle making machine

The invention belongs to the technical field of bottle-making machines, and discloses a rotating disc type glass bottle-making machine. According to the rotating disc type glass bottle-making machine, the problems that an existing bottle-making machine is complex in structure and is inconvenient to mount and maintain are solved. The rotating disc type glass bottle-making machine comprises a base, a forward blowing mechanism and an air supplementing mechanism; a blank mold mechanism and a turnover mechanism are arranged on the base; a rotating disc machine body is also arranged on the base and is driven by a rotating disc motor to rotate; a vertical shaft is arranged on the rotating disc machine body in a sleeving way; the forward blowing mechanism and the air supplementing mechanism are arranged on the vertical shaft in a sleeving way; a mold opening / closing mechanism is arranged on the rotating disc machine body and comprises air cylinder seat base plates arranged on the rotating disc machine body; sliding rails are arranged on the air cylinder seat base plates; an air cylinder which can slide on the sliding rails is arranged on the sliding rails; the air cylinder is communicated with an external air source; the air cylinder is provided with a rack support; racks are arranged on the rack support; mold opening / closing shafts for driving holding clamps to move are arranged on the corresponding air cylinder seat base plates through bearings in a sleeving way; a sector gear which is meshed with the corresponding rack is arranged on each mold opening / closing shaft.

Owner:LONGCHANG LIANGGONG SCI & TECH CO LTD

Production equipment and production method of low-halogen low-smoke radio frequency cable

PendingCN114551001AEasy to change temperatureImprove adaptabilityCable/conductor manufactureHalogenCooling effect

The invention relates to the technical field of low-halogen low-smoke cables, and discloses a low-halogen low-smoke radio frequency cable production device and method, and the device comprises a bottom plate, a barrier block is fixedly connected between the top and the bottom of the inner wall of the bottom plate, and the two sides of the bottom of the bottom plate are each provided with a shaping structure. The low-halogen low-smoke radio frequency cable production equipment comprises a shaping structure, the shaping structure comprises a communicating shell, an exhaust outlet, an exhaust cylinder, a pull ring, a rotating shaft, a sealing cover, an air inlet pipe, a threaded rod and a movable block, and the shaping structure has the advantages that the shaping structure can cool a thermoplastic outer rubber layer of a cable through the exhaust cylinder; the number of the exhaust cylinders is four, the angle of each exhaust cylinder can be rotated, wrapping type air blowing on the cable is guaranteed, the conditions of dead angles and non-uniform cooling are avoided, the cooling effect is not weaker than that of water cooling under the condition that water cooling is effectively replaced, and the temperature can be changed more conveniently than that of water cooling.

Owner:陈德进

A transmission device with safety pressurization applied in terminal transmission

ActiveCN109585133BEasy to cycle heatGuaranteed cooling efficiencyTransformers/inductances coolingTransformerFuel tank

The invention discloses a transmission device with safety pressurization in terminal transmission application. The transmission device comprises a transformer body, wherein an auxiliary cooling deviceis arranged on the transformer body and comprises a cooling oil tank, an oil pump, an oil pipe, a baffle plate, convex strips, a power motor, a rotation rod, a fan blade and an induction starting device. Cooling water in an induction box is heated and evaporated and become a gas, a first conduction piece is pushed to move leftwards and contact with a second conduction piece, a series circuit is connected, and the oil pump and the power motor are started; heat absorption oil of the cooling oil box is pumped into the oil pipe by the oil pump so as to absorb heat of the transformer body, and thecooling efficiency of the transformer body is ensured; and when heat absorption oil returns to the cooling oil tank after heat exchange, and the heat absorption oil after heat exchange can slowly descend along an inclination segment of the baffle plate, at the moment, the fan blade is driven to rotate by the power motor so as to performing air cooling on the slowly-descending heat absorption oilafter heat exchange, and cycle heat absorption of the heat absorption oil at the next time is facilitated.

Owner:ANHUI ZENITH ELECTRICITY & ELECTRONICS

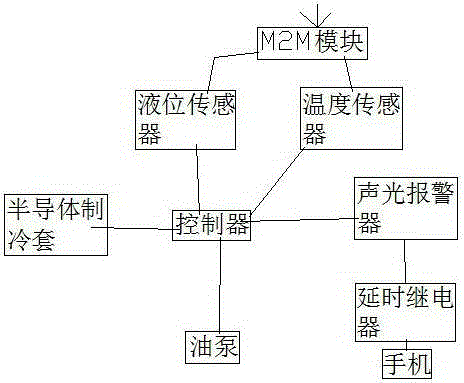

A transformer anti-burning protection device and using method

ActiveCN103474202BIncrease contact areaFull accessTransformers/inductances coolingTemperature control using electric meansTransformerFuel tank

The invention discloses a transformer burning-preventive protecting device comprising an oil tank. An auxiliary oil tank is arranged on the oil tank, an external oil cooling mechanism communicated with the oil tank is arranged on one side of the oil tank, an oil pump is arranged on a pipeline used for communicating the external oil cooling mechanism with the oil tank, and an automatic monitoring and controlling mechanism is connected to the oil pump. By the transformer burning-preventive protecting device, cooling oil in the oil tank can be cooled thoroughly, cooling efficiency of the cooling oil in the oil tank is quite low, cooling rate is quite high, and temperature is reduced to 5-10 DEG C in one minute; automatic adjustment can be performed according to temperature of the cooling oil in a transformer, real-time monitoring and controlling on temperature and liquid level of the cooling oil in the oil tank are realized, and remote alarming can be realized to notify electrical technicians of oil leakage of the transformer; current and voltage information of transformer operation can be sent to an electrical background in real time, convenience is brought to the electrical technicians to monitor operation situations of the transformer and to schedule electric energy, and the transformer burning-preventive protecting device has good promotion and application value.

Owner:STATE GRID CORP OF CHINA +1

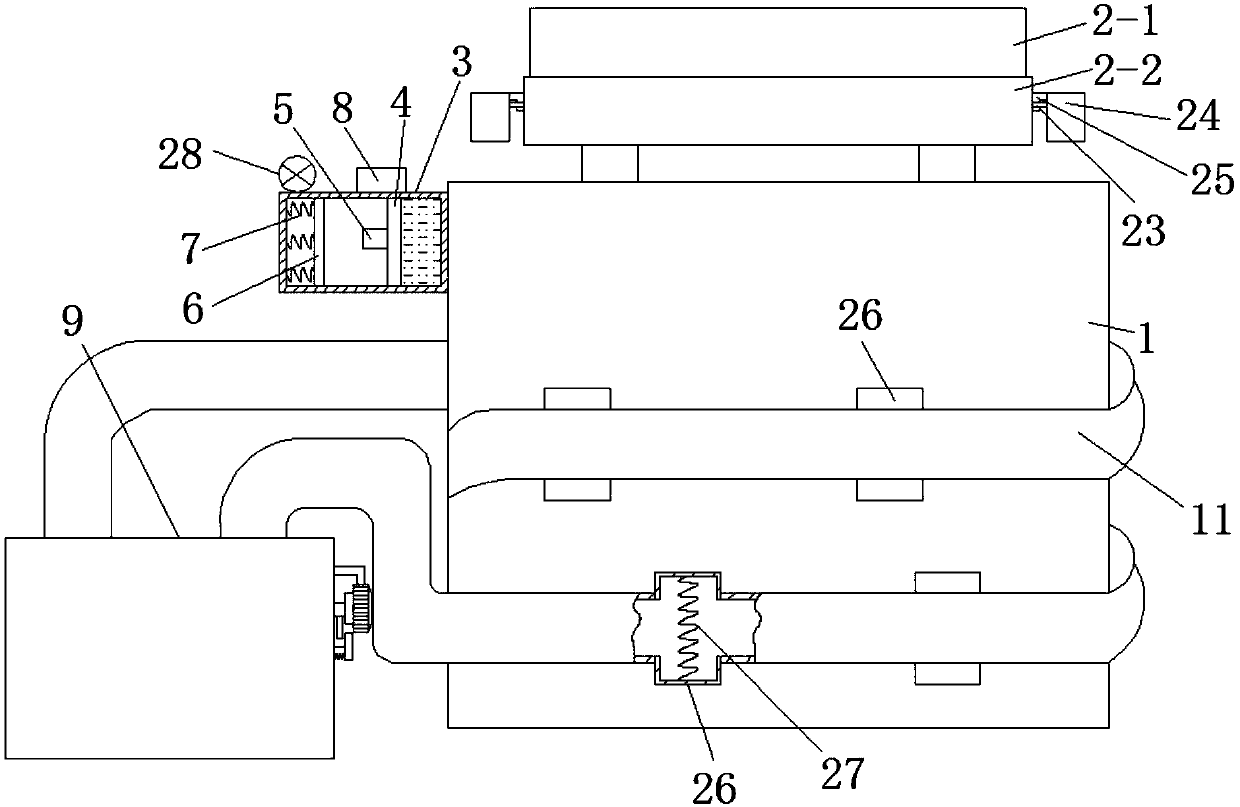

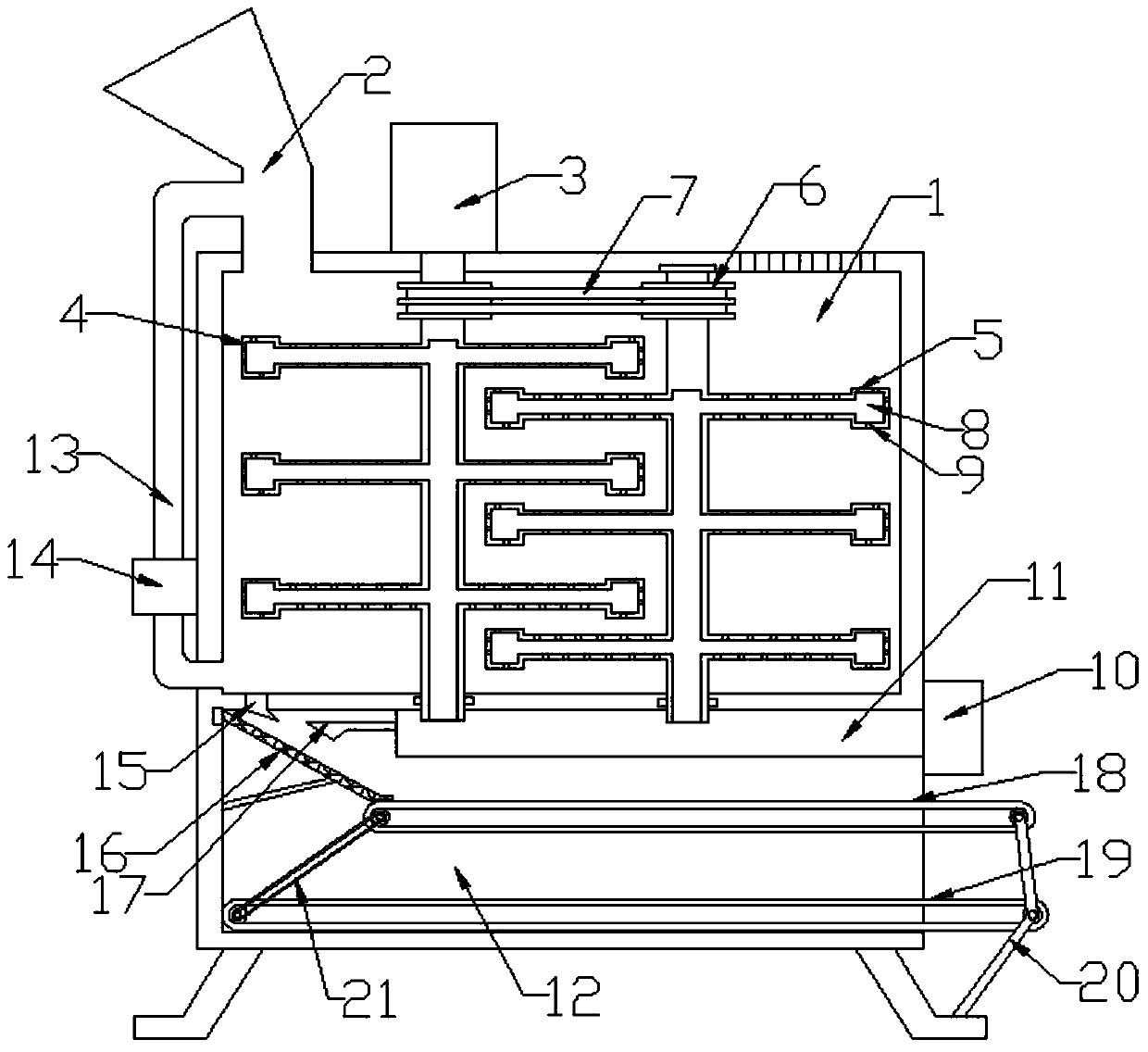

A slitting and conveying device for a laminating machine

InactiveCN106994702BSmoothly fall intoSnap offLamination ancillary operationsLaminationConveyor beltServo control

The invention provides a slitting and conveying device for a laminating machine. The slitting and conveying device comprises a rack, a first conveyor belt mechanism, a second conveyor belt mechanism, a slitting device, a slitting roller assembly, a cooling circulating device, a discharging tank, a lifting platform device and a servo control box. The first conveyor belt mechanism and the second conveyor belt mechanism are arranged on the rack. The slitting device is arranged between the first conveyor belt mechanism and the second conveyor belt mechanism. First conveying roller assemblies, an auxiliary pressing roller, a slitting pressing roller, second conveying roller assemblies and a cooling roller assembly are sequentially arranged above the second conveyor belt mechanism in the operating direction. The discharging tank is arranged on one side of the second conveyor belt mechanism. The lifting platform device is arranged in the discharging tank. Shearing is conducted from the two sides by the adoption of the slitting roller assembly, it is guaranteed that laminated notches are flush with each other, a lifting platform is arranged in the discharging tank, the vertical movement of storage trays is controlled according to the needs, it is guaranteed that laminated plates on conveyor belts smoothly fall into the storage trays, the storage trays are transferred through a hand-operated fork lift, and the operation is simple.

Owner:滁州市雪山粮油机械制造有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com