Process for producing compound fertilizer by tower granulation

A compound fertilizer and high-tower granulation technology, applied in fertilizer forms, fertilizer mixtures, sustainable manufacturing/processing, etc., can solve the problems of increasing operating costs, increasing investment, increasing the height of granulating towers, etc., to reduce investment and reduce investment. The effect of running cost, energy saving and investment reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

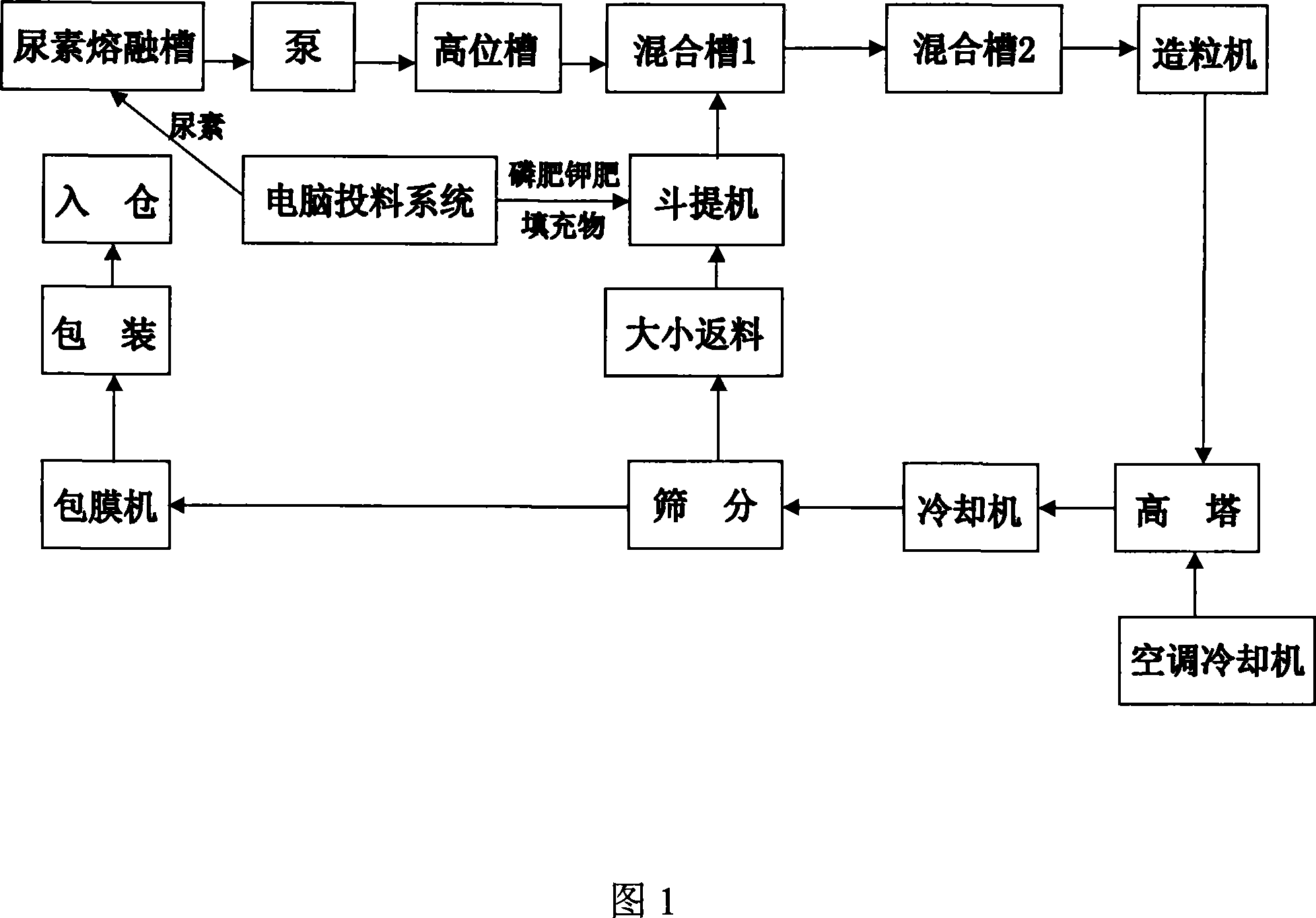

Image

Examples

Embodiment 1

[0039] The concentration is 100%, the temperature is 43% of the urea solution of 120 ℃ pumped into the top mixing reaction tank with 12% monoammonium phosphate, 32% potassium chloride (potassium sulfate), 13% filler, medium and trace elements , The pigment is mixed and stirred to react, and enters the granulator to granulate. Spray freely to the bottom of the tower, after cooling and sieving, a compound fertilizer of φ2-4.75mm can be obtained. The product analysis result is N20.98%, P 2 o 5 6%, K 2 O19.2%, total nutrient is 46.18%. The fertilizer moisture is 0.8%. The strength is 20N, and the yield rate is over 90%.

Embodiment 2

[0041] Pump 39% urea solution with a concentration of 100% and a temperature of 125°C into the tower top mixing reaction tank, mix and stir with 10% monoammonium phosphate, 19% potassium chloride, 32% filler, medium and trace elements, and pigments React, enter the granulator for granulation. Spray freely to the bottom of the tower, after cooling and sieving, a compound fertilizer of φ2-4.75mm can be obtained. The product analysis results are N18.94%, P2O5%, K2O11.4%, and the total nutrient content is 35.34%. The fertilizer moisture is 0.9%. The strength is 19N, and the yield is over 90%.

Embodiment 3

[0043] Pump 46% of the ammonium nitrate solution with a concentration of 100% and a temperature of 170°C into the tower top mixing reaction tank and react with 8% monoammonium phosphate, 40% potassium sulfate, 6% filler, medium and trace elements, and mix and stir , into the granulator for granulation. Spray freely to the bottom of the tower, after cooling and sieving, a compound fertilizer of φ2-4.75mm can be obtained. The product analysis result is N15.5%, P 2 o 5 5.8%, K 2 O20%, the total nutrient is 41.3%. The fertilizer moisture is 0.85%. The strength is 18N, and the yield rate is over 90%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com