Biofertilizer cooling device

A cooling device and bio-fertilizer technology, applied in heat exchange equipment, direct contact heat exchangers, heat exchanger types, etc., can solve problems such as low work efficiency, external cold and internal heat, limited cooling area of fertilizers, etc., and achieve improved The effect of the cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

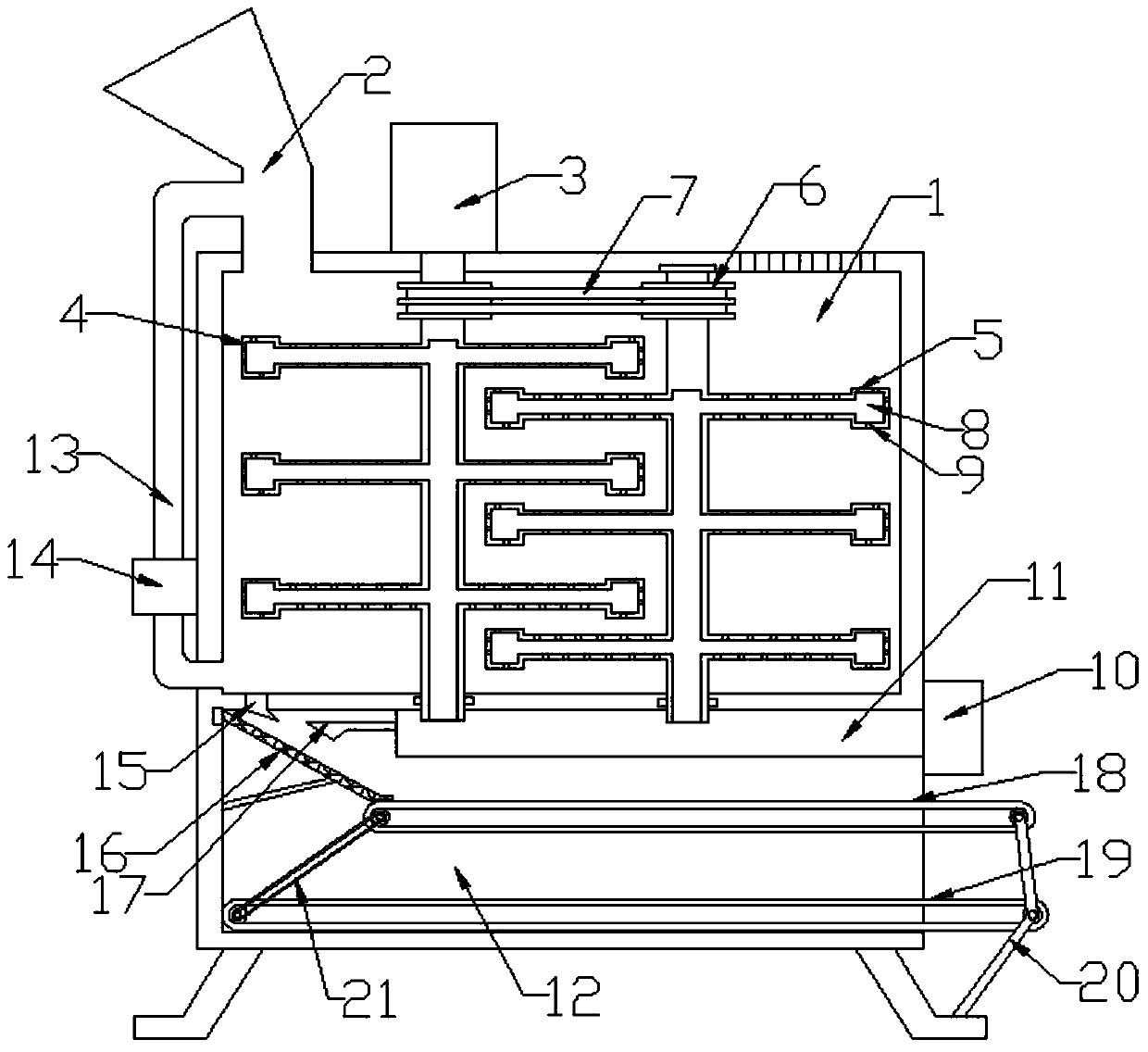

[0028] Such as Figure 1-4 As shown, a biological fertilizer cooling device includes a cooling box 1, a discharging box 12, a stirring cooling system composed of a servo motor 3, a main agitator 4, a sub-agitator 5 and a cooler 10, a feeding pipe 13 and a feeding pump 14 A feeding and mixing system composed of an inclined vibrating screen 16, a first conveyor belt 18, and a second conveyor belt 19 is a screening and discharging system. The bottom of the discharging box 12 is welded with a discharging box 12, and the discharging box 12 passes through its bottom. Supported by a support column welded at the ends, a feed hopper 2 is connected to the top side of the cooling box 1 and a discharge port is provided on one side of the discharge box 12.

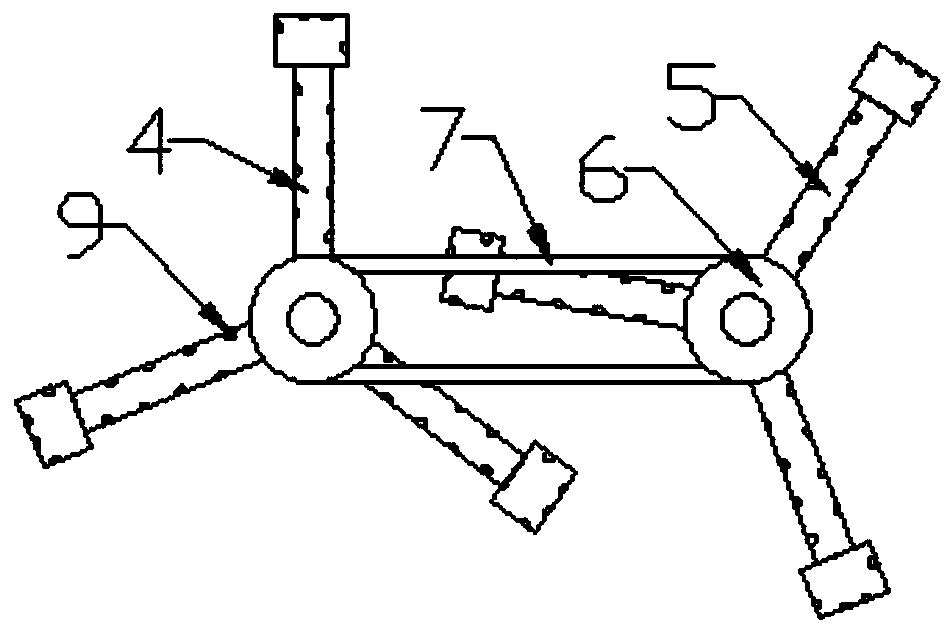

[0029] The servo motor 3 in the mixing cooling system is fixed on the top of the cooling box 1 by bolts, and the output end of the servo motor 3 is also connected to the main agitator 4, the auxiliary agitator 5 and the main agitator 4 in...

Embodiment 2

[0033] Such as Figure 1-4 As shown, the feeding pipe 13 in the feeding mixing system is connected below one side of the cooling box 1, the feeding pump 14 is installed on the feeding pipe 13, and the tail end of the feeding pipe 13 is connected to the feeding hopper 2 for connecting the cooling box The fertilizer cooled in 1 is mixed with the original fertilizer in the feeding hopper 2, and then sent to the cooling box 1 for mixing and cooling.

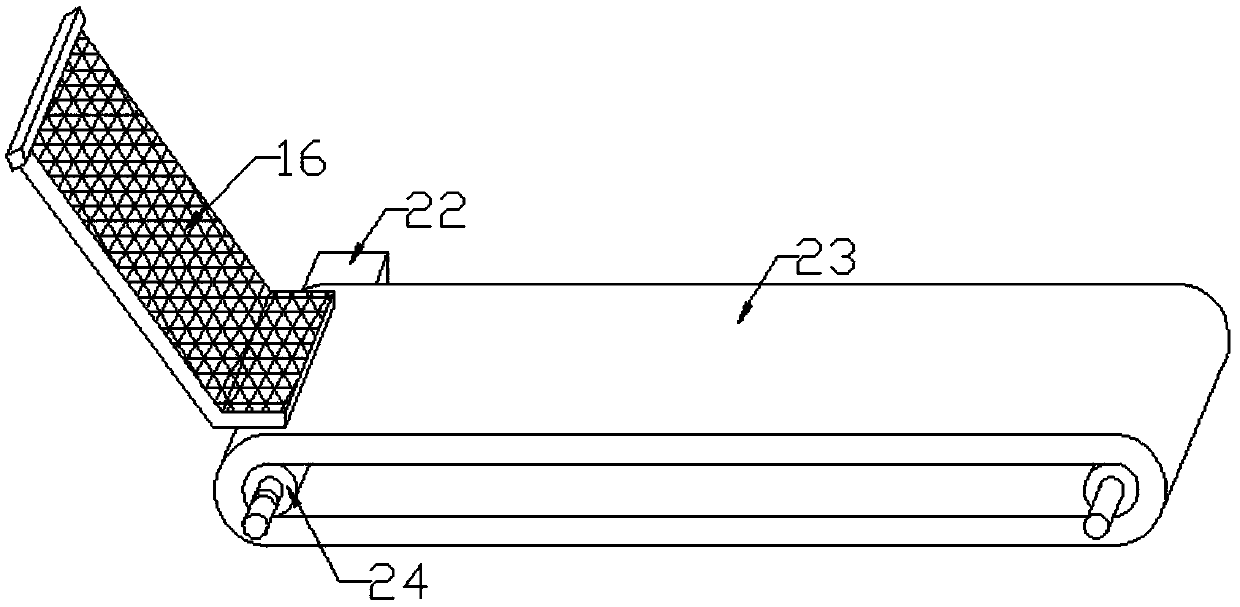

[0034] In the screening and discharging system, the material guide port 15 provided at the bottom end of the cooling box 1 is connected to the discharge box 12, and an inclined vibrating screen 16 is installed below the material guide port 15, and the air outlet hopper 17 connected to the top of the air pipe 11 is directly inclined. The vibrating screen 16 is used to cool the fertilizer on the inclined vibrating screen 16. The end of the inclined vibrating screen 16 is connected to the first conveyor belt 18, and a second conveyor belt ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com