Cooling device for deslagging agent production process

A production process, cooling device technology, applied in heat exchange equipment, damage protection, direct contact heat exchangers, etc., can solve problems such as poor cooling effect and unevenness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

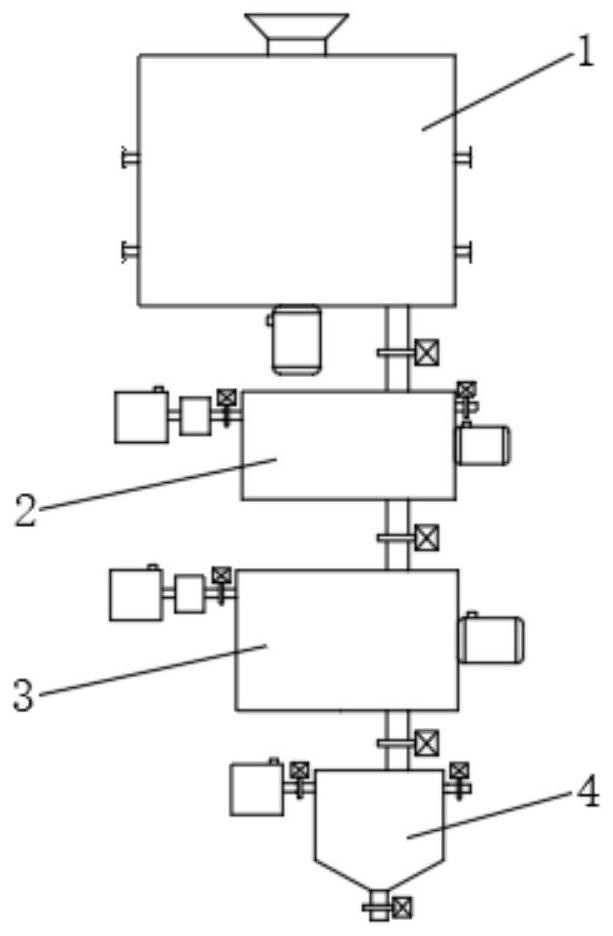

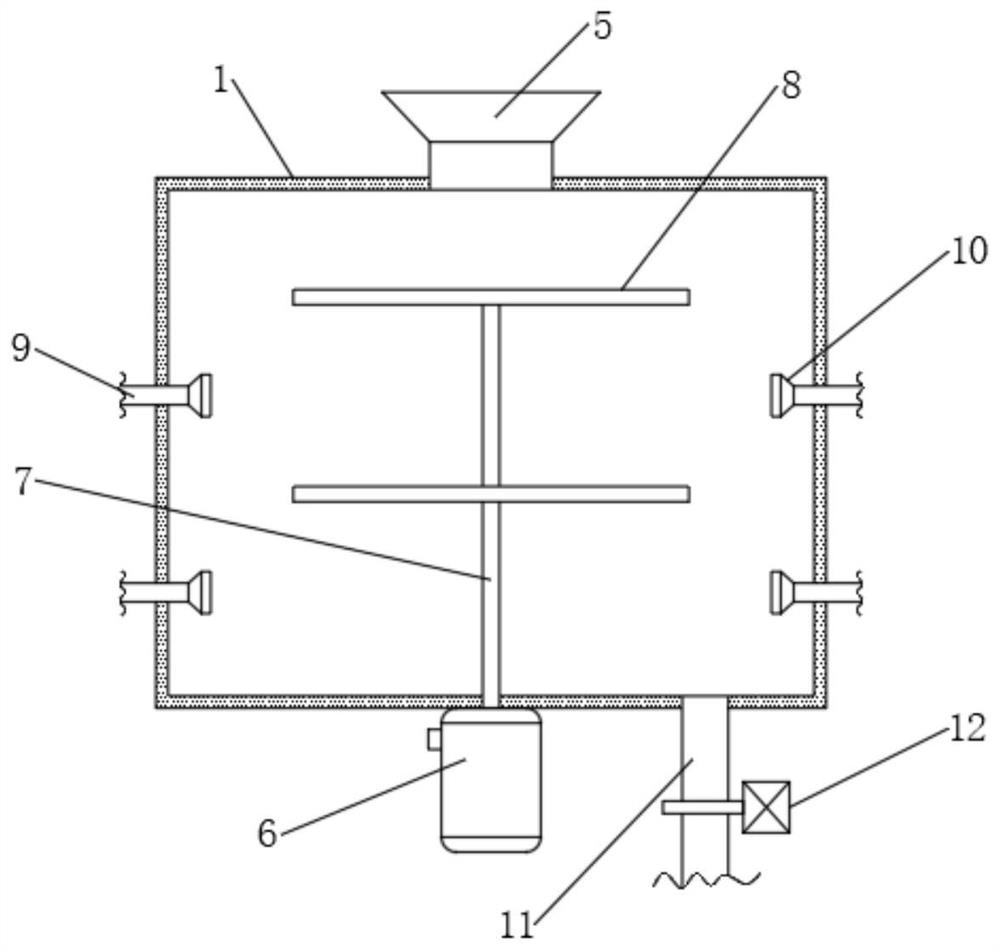

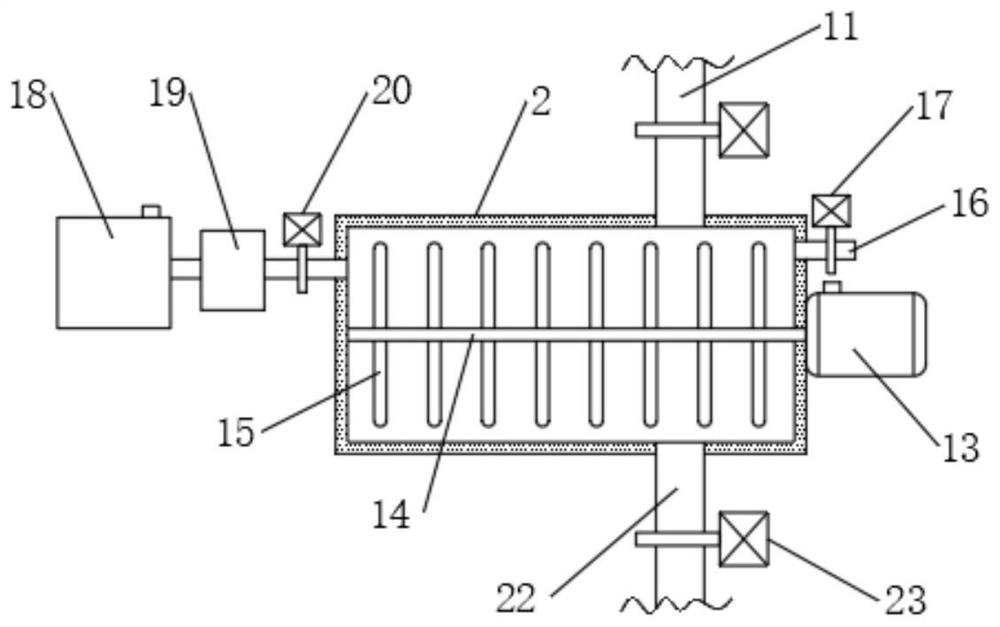

[0029] Such as Figure 1-6As shown, the embodiment of the present invention provides a cooling device for the slag removal agent production process, including a first box body 1, a first motor 6 is fixedly connected to the center of the bottom of the first box body 1, and the output end of the first motor 6 is fixed The first rotating shaft 7 is connected and extends inwardly through the bottom of the first casing 1 , the top and middle part of the first rotating shaft 7 are fixedly connected with the turntable 8 , and the middle and lower parts around the first casing 1 are fixedly connected There are evenly distributed water pipes 9 and the output ends of the water pipes 9 are fixedly connected with atomizing nozzles 10. When cooling the powder material, starting the first motor 6 can make the first rotating shaft 7 rotate and drive the two turntables 8 Rotate to break up the materials entering the first box 1, and then input cold water into the atomizing nozzle 10 through t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com