Spinning cup with one free end capable of being mounted with supporting spindle cap

A spinning cup and free end technology, which is applied in the field of supporting caps, can solve the problems of supporting caps falling off, splitting of supporting caps, thick wall of supporting caps, etc., so as to avoid axial vibration, keep the distance stable, easy-to-manufacture effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

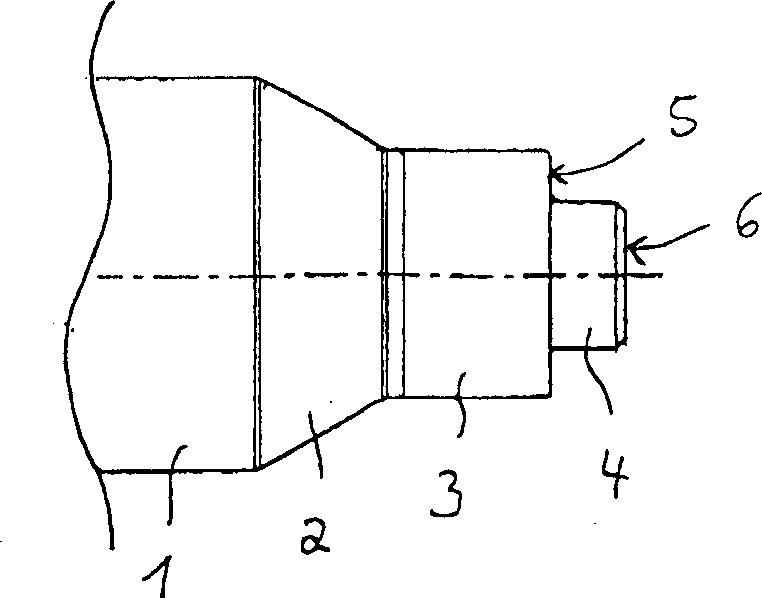

[0029] figure 1 The free end of the shaft 1 of the rotor of an open-end spinning machine is shown. The free end of the spinning cup shaft 1 is located on the side opposite to the spinning cup, and has a conical portion 2 with a gradually decreasing shaft diameter, a cylindrical portion 3 and a shaft-diameter portion 4 . The cylindrical part 3 has a front bead 5 which serves as a stop or facing surface for a wearing cap 7a, b, c, d. Furthermore, the shaft-shaped part 4 has a planar front side 6 which also serves as an alignment or stop surface for the wear cap.

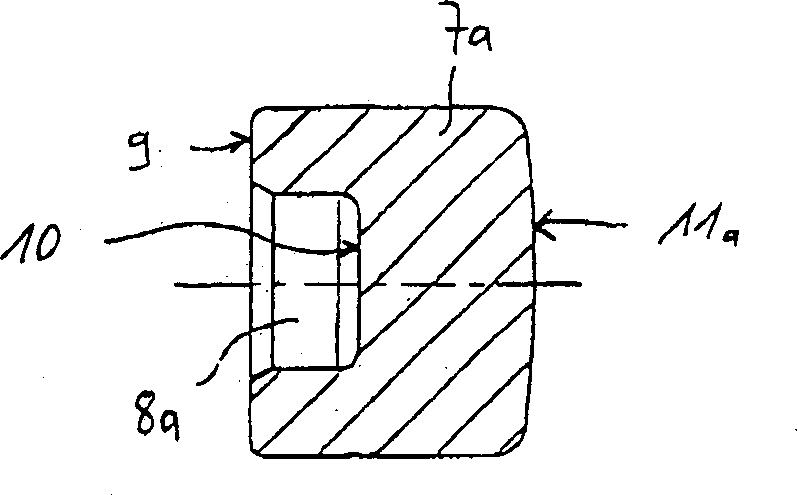

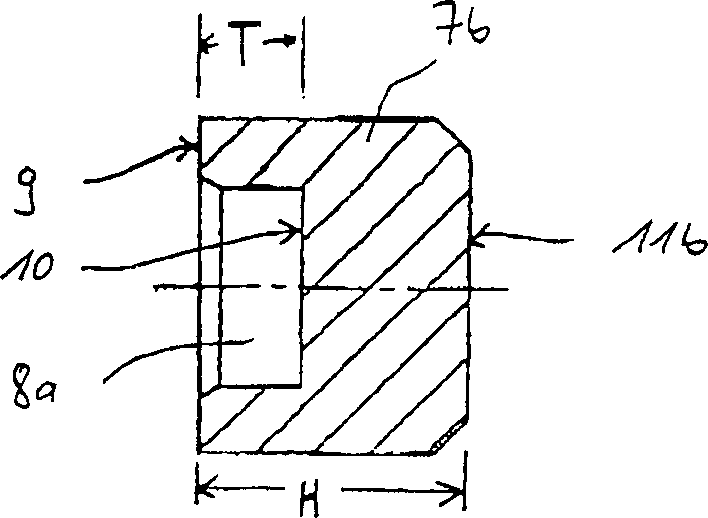

[0030] A first embodiment of the worn cap 7a is in figure 2 shown in . The outer diameter of the wear cap 7a corresponds to the outer diameter of the cylindrical portion 3, and the shaft-shaped portion 4 of the shaft 1 can be completely inserted into the substantially cylindrical recess 8 of the wear cap 7a. Its back side, ie the annular front side 9 of the wear cap 7 a, serves as a stop or opposite face to the be...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com