Device for processing metal sheet

A technology for thin metal plates and processing equipment, applied in metal processing equipment, metal processing, metal processing machine parts, etc., can solve the problems of high cost and time, rust, lack of a device integrating drilling and grinding, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

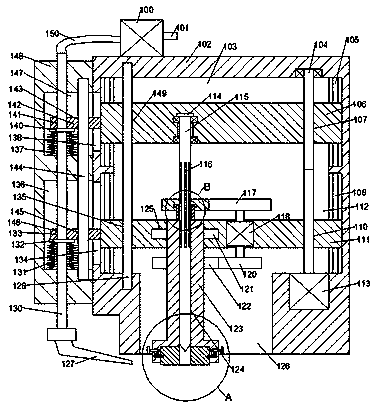

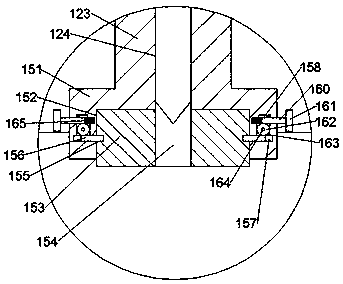

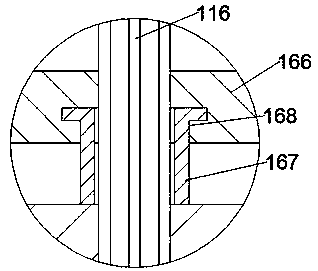

[0014] Combine below Figure 1-3 The present invention will be described in detail.

[0015] refer to Figure 1-3, according to the metal sheet processing equipment of the embodiment of the present invention, the described working box body 102 is provided, and the drilling rod lifting cavity 103 is arranged inside the working box body 102, and the drilling rod lifting cavity 103 communicates downward with a grinding wheel The lifting cavity 112, the grinding wheel lifting cavity 112 is connected downwards with a working port 126, and the left and right inner walls of the drilling rod lifting cavity 103 are symmetrically provided with a first lifting chute 105, the first lifting chute 105 The drill pipe lifting block 106 is installed by sliding and fitting between them. The drill pipe lifting block 106 on the right side is provided with a first threaded hole 107 that runs through the upper and lower end surfaces of the drill pipe lifting block 106. The drill pipe lifting block...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com