Wine brewing device

A technology of wine making device and stirring device, which is applied in the field of wine making, can solve the problems of large waste of steam, high energy consumption, and influence on the quality of wine making, and achieve the effect of improving the overall quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

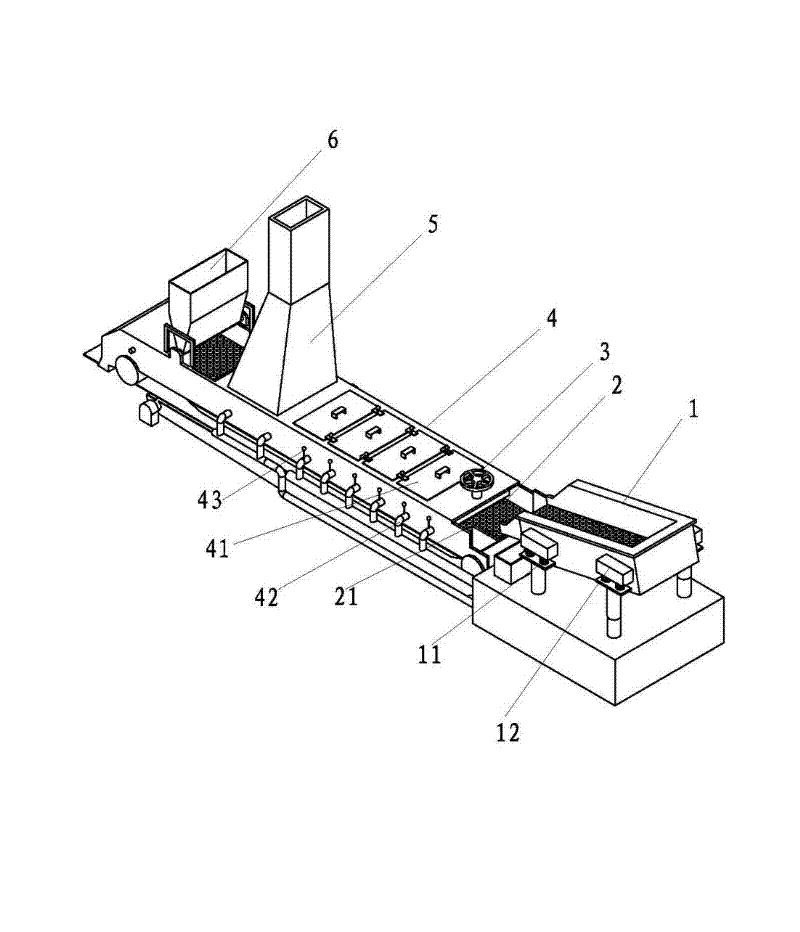

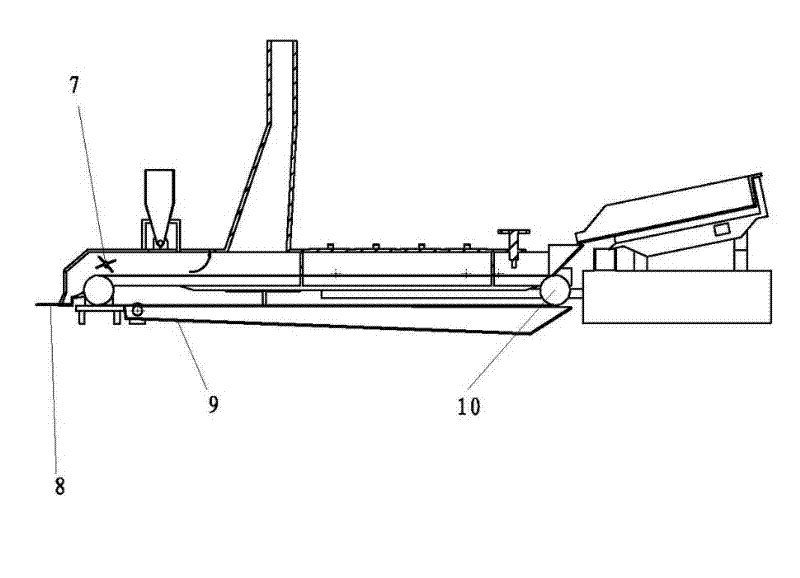

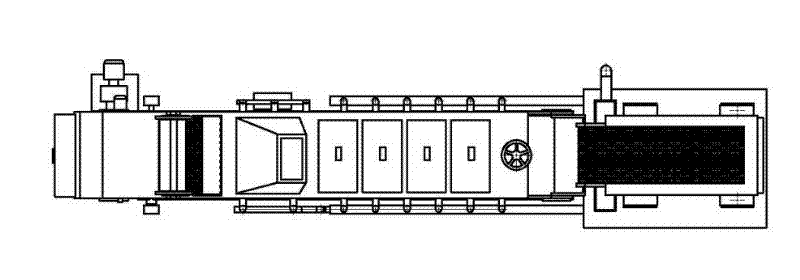

[0017] Embodiment one, such as figure 1 , 2 , Shown in 3, the brewing device includes a feeding device 1, a conveyor belt 2 and a motor 10, and the motor 10 drives the transmission belt 2 to run. The transmission belt 2 is provided with a filter hole, the discharge device 1 is provided with springs 11 on both sides, and a vibrating unit 12 is provided below. A control valve 3 is arranged on the top of the transmission belt 2 close to the feeding device 1. The control valve 3 adopts a gate valve. The control valve 3 is connected to a rice steaming unit 4. A steam pipe 42 is communicated, and a steam controller 43 is also provided. The rice steaming unit 4 is provided with a cooling device 5, the cooling device 5 adopts air cooling and water cooling equipment, and the cooling device 5 is also successively provided with an auxiliary material putting device 6, a stirring device 7 and a receiving end 8 along the conveying direction of the conveyor belt, and the stirring device 7 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com