Solid plate strip laser using lens conduct coupling

A technology of slab lasers and catheters, which is applied in the direction of lasers, laser parts, laser parts, etc., can solve the problems that the luminous intensity cannot meet the requirements of high-power solid-state lasers, uneven pumping, and low efficiency, and achieve compact structure, pumping Uniform light and thorough cooling effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

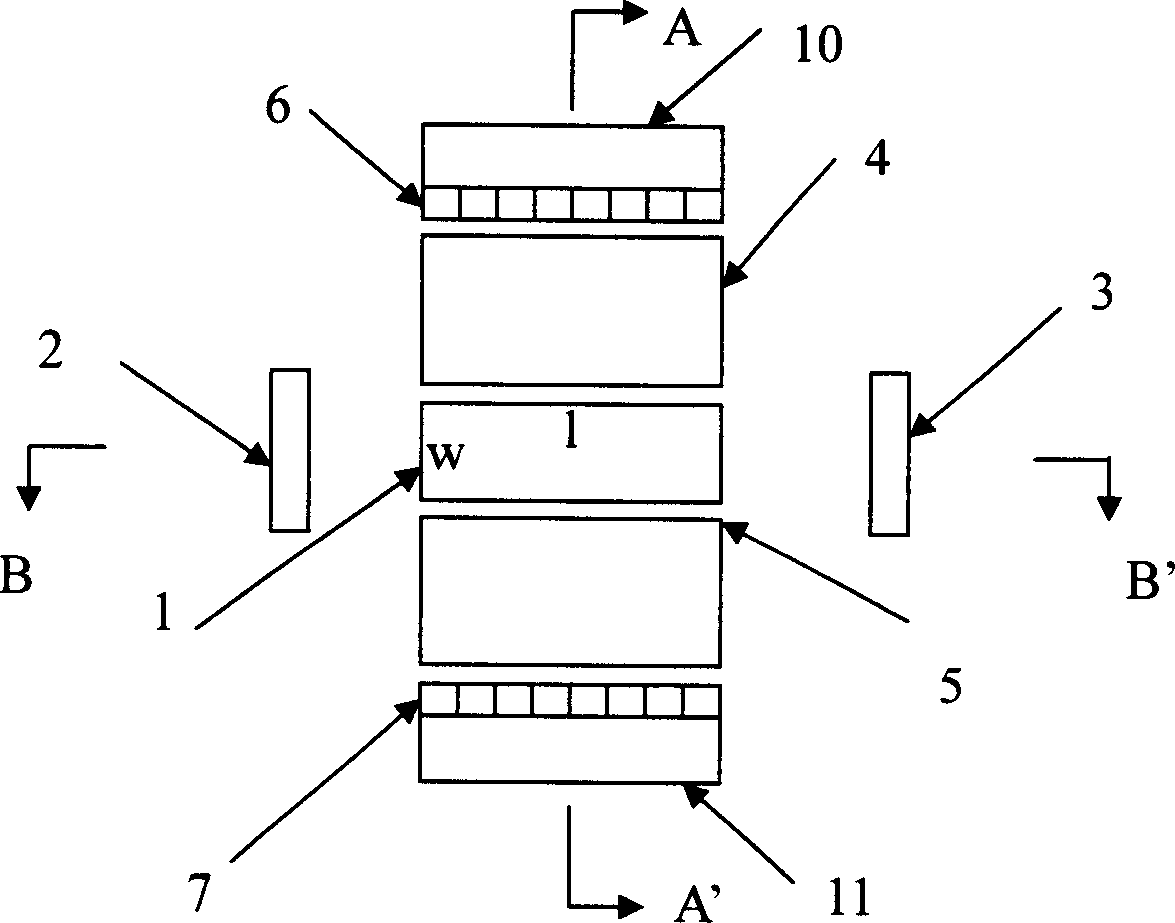

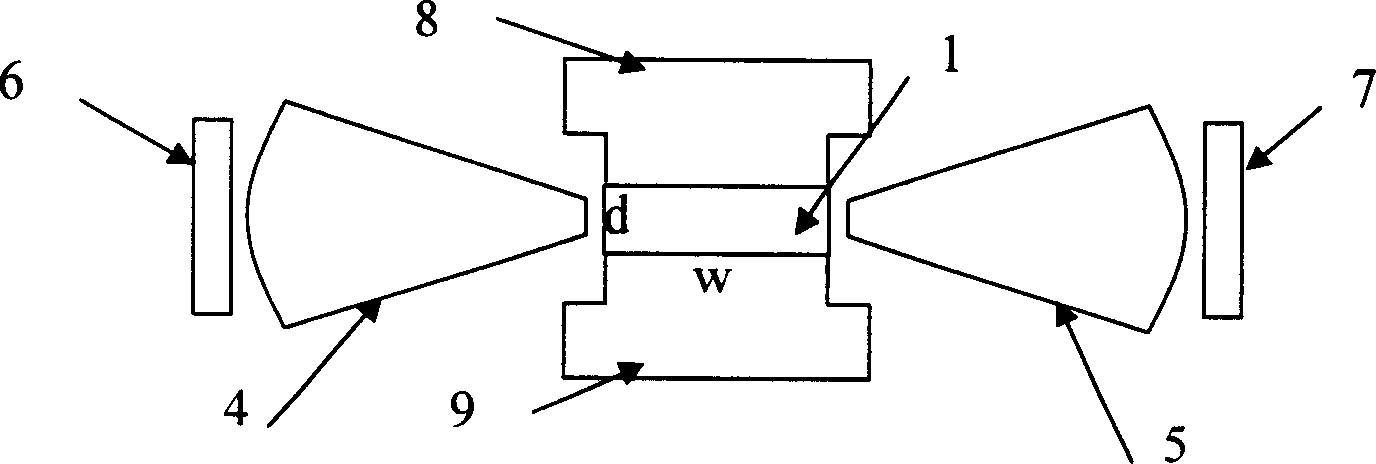

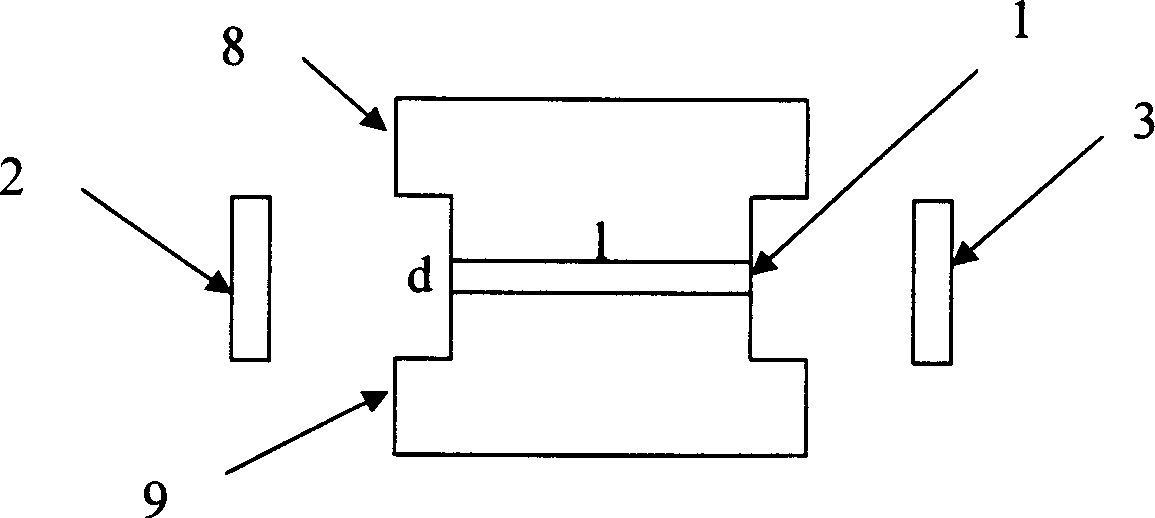

[0021] Please see first by figure 1 , figure 2 and image 3 , as can be seen from the figure, the present invention adopts the solid-state slab laser coupled by the lens duct, including a slab-shaped laser medium 1 and a front cavity mirror 3 and a rear cavity mirror 2 arranged before and after, and the rear cavity mirror 2 and the front cavity mirror 3 Placed in parallel, and parallel to the lath end face of the lath-shaped laser medium 1, the first laser medium cooling heat sink 8 and the second laser medium are provided on the upper and lower two large surfaces of the lath-shaped laser medium 1 The medium cooling heat sink 9 is provided with a first laser diode array 6 and a second laser diode array 7 on both sides of the slab-shaped laser medium 1, and the slab-shaped laser medium 1 and the first laser diode array Between the array 6 and the second laser diode array 7 are respectively the first lens conduit 4 and the second lens conduit 5, and the first laser diodes are...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com