Gas, tar and activated carton co-production system

A technology of activated carbon and tar, applied in coke ovens, gas dust removal, petroleum industry and other directions, can solve the problems of unreachable chemical utilization, high water content in products, polluting the atmosphere, etc., to improve yield and recovery rate, novel and reasonable design , the effect of increasing production capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

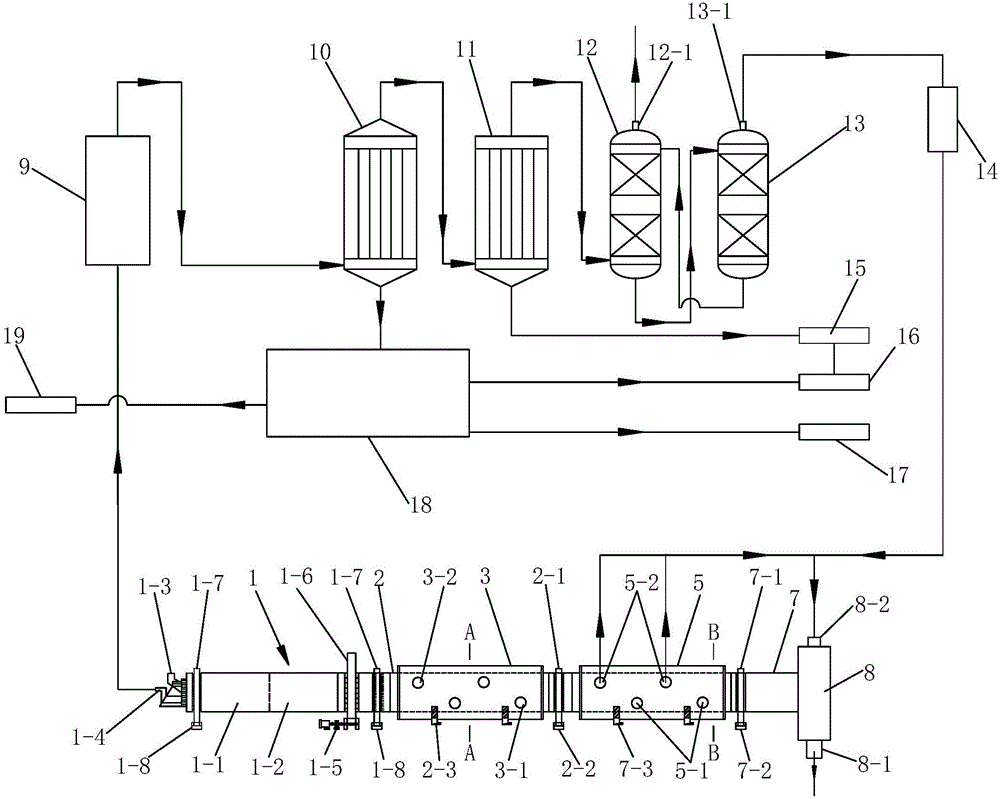

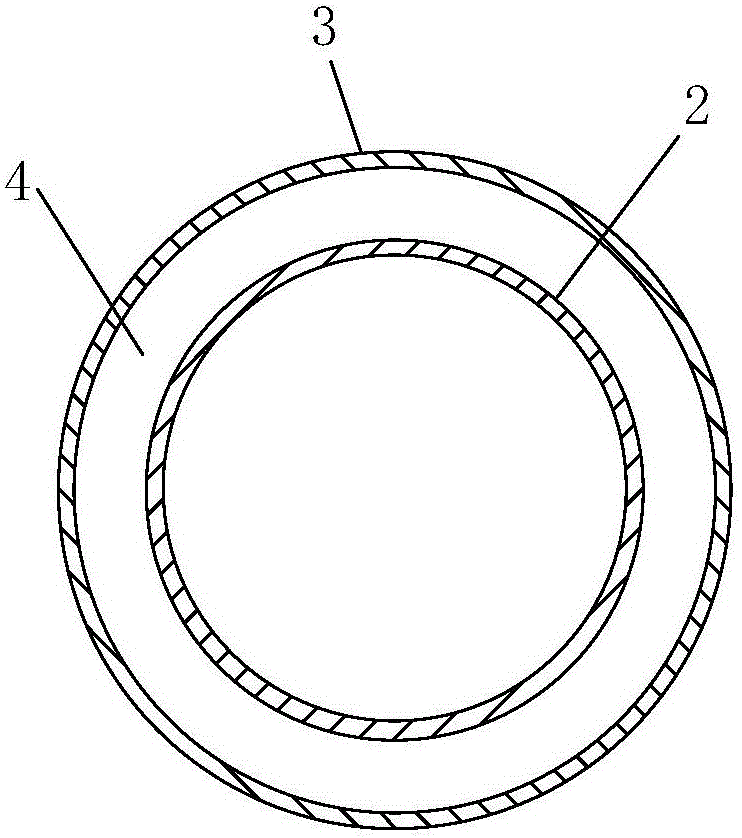

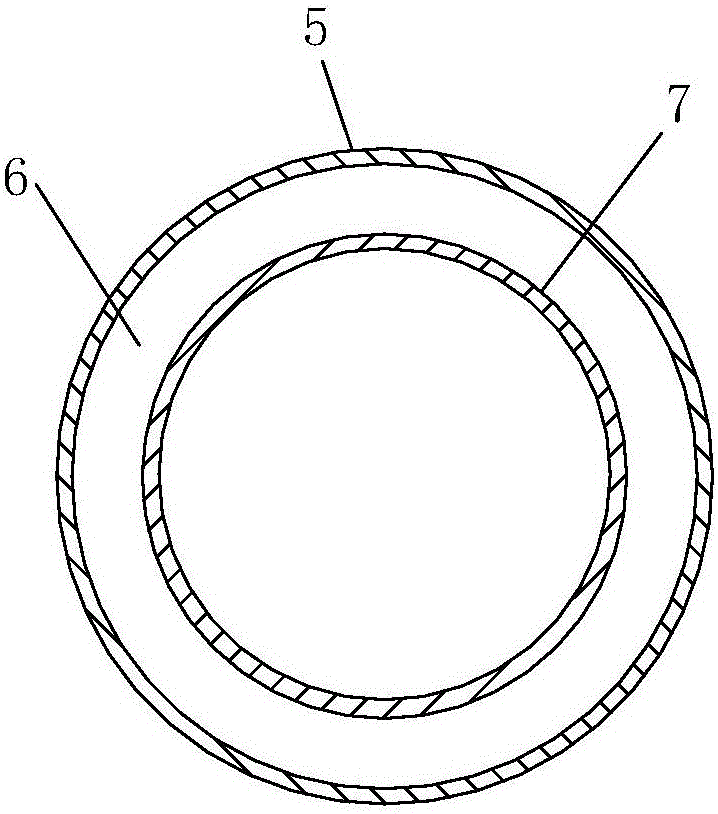

[0043] Such as figure 1 , figure 2 with image 3A co-production system of gas, tar and activated carbon is shown, including a pyrolysis furnace 1 for preheating and pyrolysis of coal, an activation furnace 2 for activating the semi-coke produced by pyrolysis, and a furnace for A cooling furnace 7 for cooling the activated carbon produced by activation, the pyrolysis furnace 1, activation furnace 2 and cooling furnace 7 are connected successively, and the pyrolysis furnace 1, activation furnace 2 and cooling furnace 7 are all rotary furnaces, so Described pyrolysis furnace 1 comprises preheating furnace body 1-1 and the pyrolysis furnace body 1-2 that is communicated with preheating furnace body 1-1, and described preheating furnace body 1-1 is away from pyrolysis furnace body 1-2 One end is provided with a coal inlet 1-3 and a pyrolysis gas outlet 1-4, and the outer side of the activation furnace 2 is provided with a thermal insulation jacket 3, and the activation furnace 2...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com