Compound plugging agent

A plugging agent and composite gel technology, applied in the field of building materials, can solve the problems of limited plugging capacity, difficult to control the size, poor plugging effect, etc., and achieve a wide range of applicable temperatures, hourly strength and compression resistance High strength, high plugging strength effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

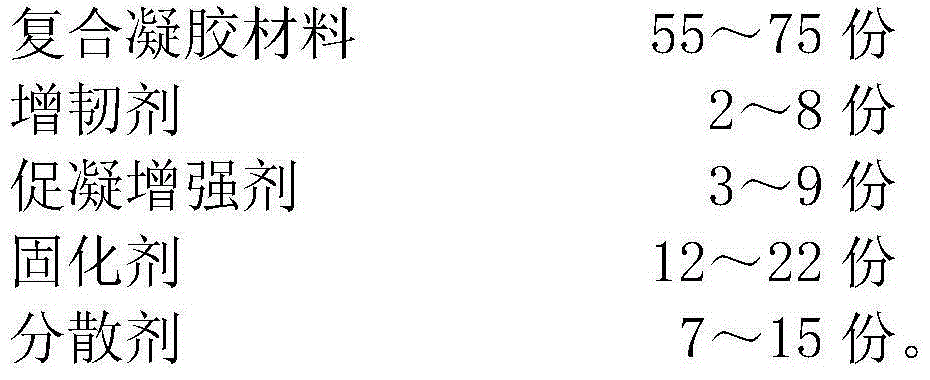

[0023] 1) Take the raw material by the following parts by weight:

[0024]

[0025] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0026] The composite gel material is a mixture of 5 parts of silicone rubber, 10 parts of sulfoaluminate cement and 20 parts of polytetrafluoroethylene; the toughening agent is fiber cotton; the coagulation accelerator is 10 parts of salt gypsum, 10 parts of silicon dioxide and 8 parts of sodium sulfate; the curing agent is a mixture of 10 parts of melamine, 10 parts of talcum powder and 10 parts of bentonite; the dispersant is a mixture of 8 parts of sodium tripolyphosphate and 10 parts of sodium hexametaphosphate; the parts are parts by weight.

[0027] The particle size of talc powder is 0.022mm; the particle size of polytetrafluoroethylene is 0.01mm.

Embodiment 2

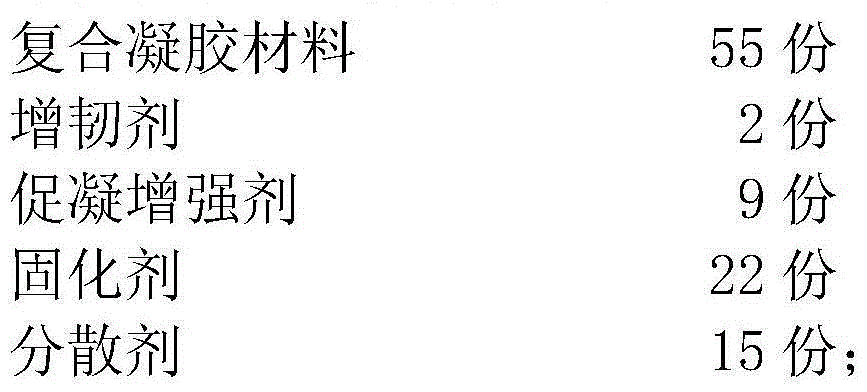

[0029] 1) Take the raw material by the following parts by weight:

[0030]

[0031] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0032] The composite gel material is a mixture of 7 parts of silicone rubber, 13 parts of sulfoaluminate cement and 12 parts of polytetrafluoroethylene; the toughening agent is fiber cotton; the coagulation accelerator is 13 parts of salt gypsum, 9 parts of silicon dioxide and 7 parts of sodium sulfate; the curing agent is a mixture of 13 parts of melamine, 9 parts of talc and 9 parts of bentonite; the dispersant is a mixture of 9 parts of sodium tripolyphosphate and 9 parts of sodium hexametaphosphate; the parts are parts by weight.

[0033] The particle size of talc powder is 0.020mm; the particle size of polytetrafluoroethylene is 0.02mm.

Embodiment 3

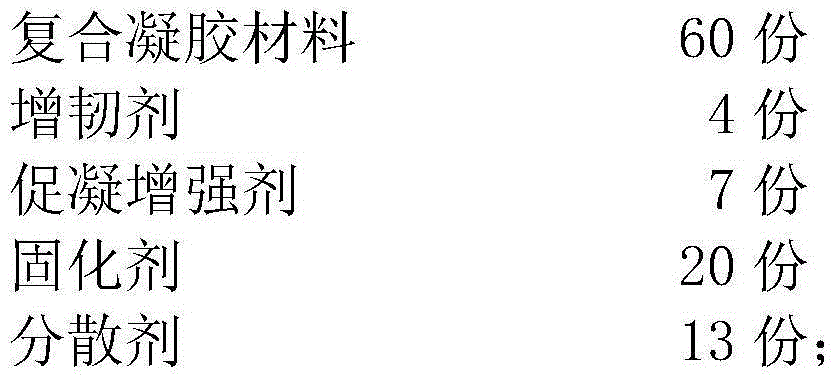

[0035] 1) Take the raw material by the following parts by weight:

[0036]

[0037] 2) All the raw materials are added into the mixing equipment and stirred evenly to obtain the product.

[0038] The composite gel material is a mixture of 8 parts of silicone rubber, 15 parts of sulfoaluminate cement and 15 parts of polytetrafluoroethylene; the toughening agent is fiber cotton; the coagulation accelerator is 15 parts of salt gypsum, 8 parts of silicon dioxide and 6 parts of sodium sulfate; the curing agent is a mixture of 15 parts of melamine, 8 parts of talcum powder and 7 parts of bentonite; the dispersant is a mixture of 11 parts of sodium tripolyphosphate and 8 parts of sodium hexametaphosphate; the parts are parts by weight.

[0039] The particle size of talc powder is 0.017mm; the particle size of polytetrafluoroethylene is 0.03mm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com