Portable high-temperature and high-pressure mechanical test device

A high-temperature, high-pressure, mechanical test technology, applied in the direction of applying stable tension/pressure to test the strength of materials, etc., can solve the problems of limiting the use range of stretching machines, limiting the ultimate pressure of containers, increasing equipment investment costs, etc., and achieving temperature resistance Good pressing effect, less material consumption and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

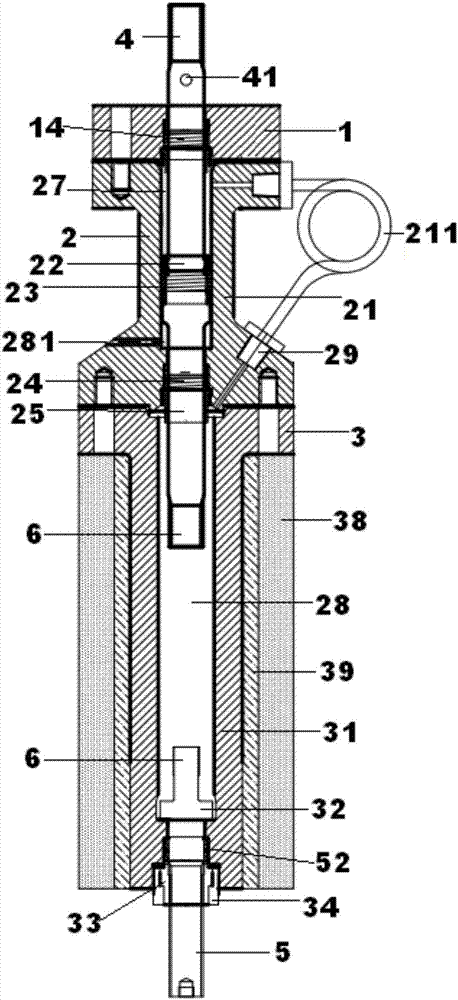

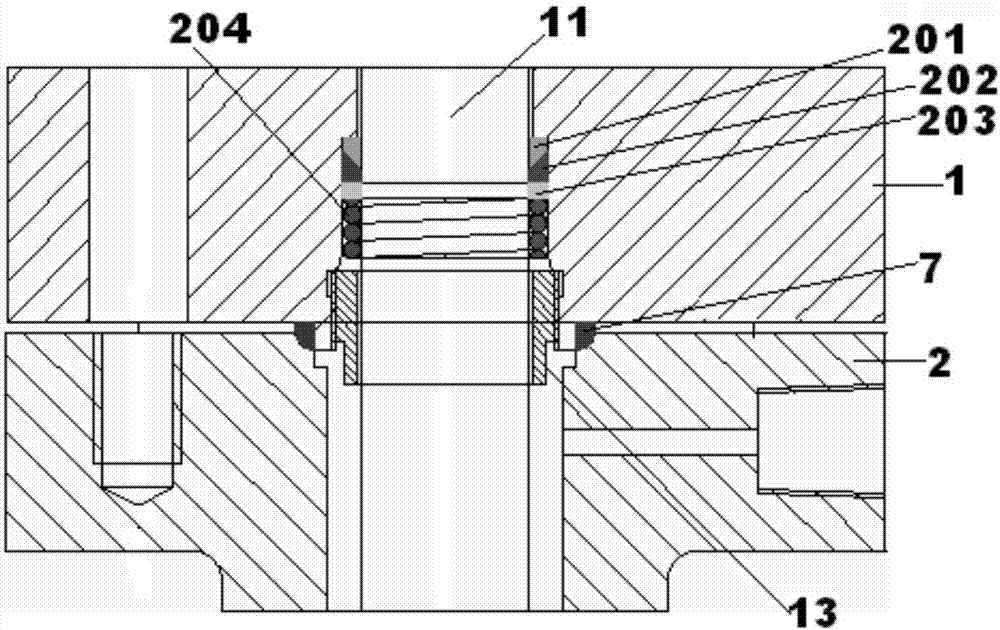

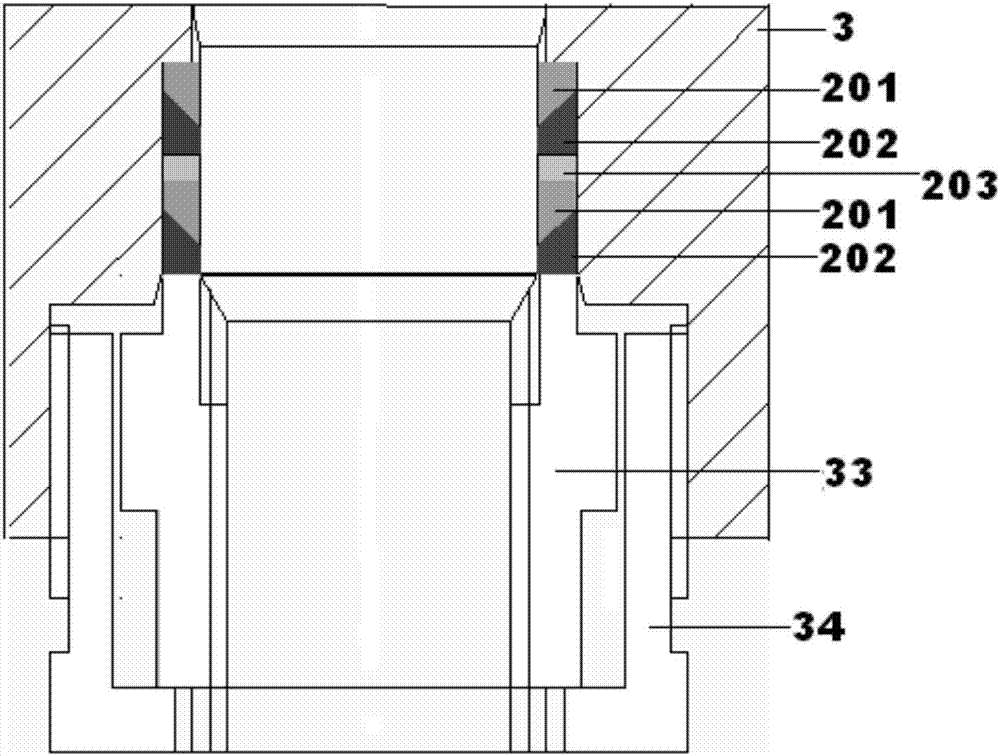

[0037] Such as figure 1 A portable high-temperature and high-pressure mechanical test device shown includes a cover 1, an upper kettle body 2 connected to the cover, a lower kettle body 3 connected to the upper kettle body, an upper stretch rod 4 and a lower stretch rod 5; The upper end of the upper stretching rod is connected with the stretching machine, the upper stretching rod extends into the cover, the upper kettle body and the lower kettle body, the upper part of the lower stretching rod extends into the lower kettle body, and the relative distance between the upper stretching rod and the lower stretching rod Each end is provided with chucks 6; the upper kettle body includes an upper cavity 21 with a first vertical through hole, which is sequentially arranged between the middle part of the upper stretch rod and the first vertical through ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com