Filtering element capable of resisting high temperature and high pressure and manufacturing method of filtering element

A manufacturing method and filter element technology, which is applied in the field of purification filter elements, can solve the problems of low filtration efficiency and unreachable, and achieve the effects of low consumption of consumables, low cost, and simple and reasonable production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

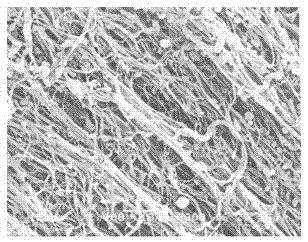

[0024] Example 1: 10 parts by weight of polyethylene terephthalate (PET) material was dried at 150°C for 6 hours, 100 parts by weight of polypropylene (PP) material and 3 parts by weight of compatibilizer The maleic anhydride grafted polypropylene (PP-g-MAH) material was dried at 100°C for 3 hours. After drying, mix and heat PP, PET, PP-g-MAH to 270°C-285°C, screw mixer speed 150 r / min, mix for about 15 minutes, keep warm at 220°C-240°C, and use the existing spray Melting production equipment spray melting figure 1 , 2 In the tubular shape shown, during the spinning process, due to extrusion and stretching, the dispersed phase PET forms microfibers in the matrix PP. Since the PET microfibers are formed in situ, the dispersion uniformity is good and the interface effect is large. , generally several hundred nanometers in diameter, and even nanofibers can be obtained.

Embodiment 2

[0025] Embodiment 2: the manufacturing method of the present embodiment is the same as that of embodiment 1, and the only difference is the content of raw materials, and the content of each component in the present embodiment is, polypropylene 100 parts by weight, polyethylene terephthalate 6 parts by weight of the ester, and 2 parts by weight of the compatibilizer maleic anhydride grafted polypropylene.

Embodiment 3

[0026] Embodiment 3: the manufacturing method of the present embodiment is the same as that of embodiment 1, and the only difference is the content of raw materials, and the content of each component in the present embodiment is, polypropylene 100 parts by weight, polyethylene terephthalate 15 parts by weight of the ester, and 3 parts by weight of the compatibilizer maleic anhydride grafted polypropylene.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com