Automatic production method of polytetrafluoroethylene (PTFE) dispersion resin

A polytetrafluoroethylene and dispersing resin technology, which is applied in the field of fluoroplastics manufacturing and production, can solve the problems of inability to carry out continuous production and a large amount of manual operation, and achieve the effects of good temperature and pressure resistance, good uniformity and long length.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

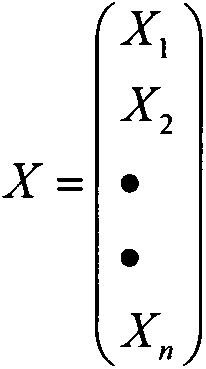

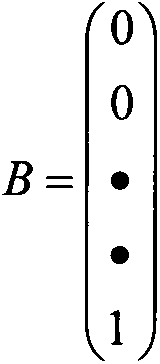

[0023] In view of the polytetrafluoroethylene (PTFE) that can be used has multiple grades, and the polytetrafluoroethylene (PTFE) of different grades has different molecular weight distributions and characteristics, the present invention selects and uses molecular weight in 1 million-5 million, particle Dispersion resin with a diameter of 0.1-0.5 microns, together with suitable auxiliary components, constitutes a two-member mixed component, and different process formulations and corresponding process conditions are determined for different purposes. The main process includes: 1. Raw material mixing, 2. Aging and infiltration, 3. Pre-pressing molding, 4. Pushing molding, 5. Extrusion position measurement and feedback adjustment, 6. High temperature sintering, 7. Quenching treatment, 8. Speed measurement and winding adjustment after sintering, 9. Finished winding. The manufacture polytetrafluoroethylene dispersion resin (PTFE) product is carried out by process below.

[0024]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com