Welding device and repair process for fracture of large crankshaft of high-pressure pump body

A welding device and high-pressure pump technology, applied in auxiliary devices, welding equipment, welding equipment, etc., can solve problems such as difficult control of all-position welding, and achieve the effects of reducing process shutdown losses, reducing maintenance costs, and facilitating production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

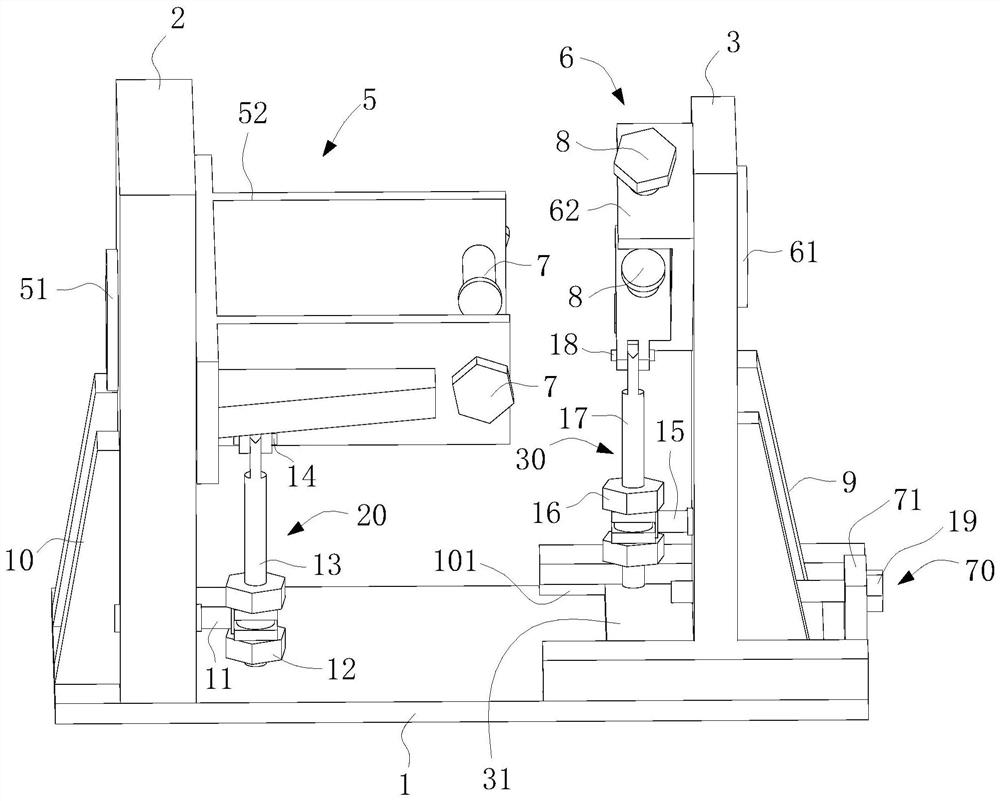

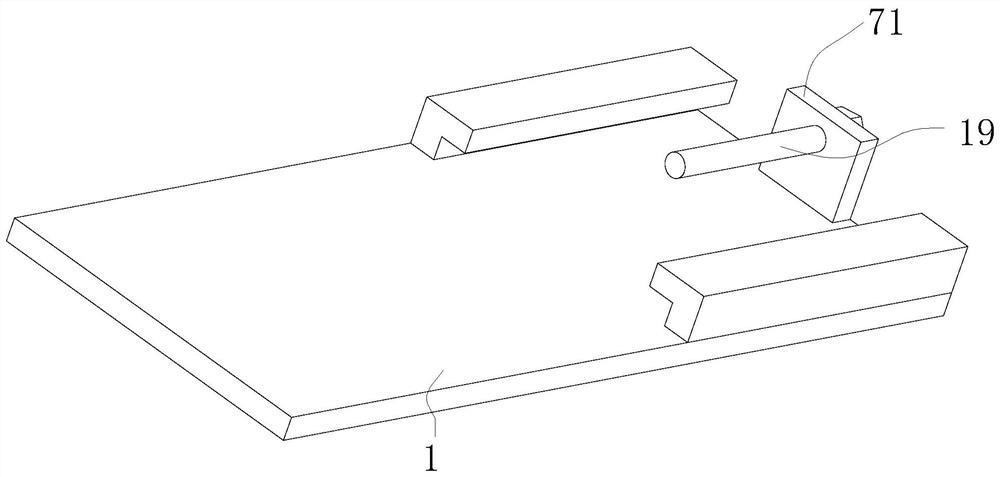

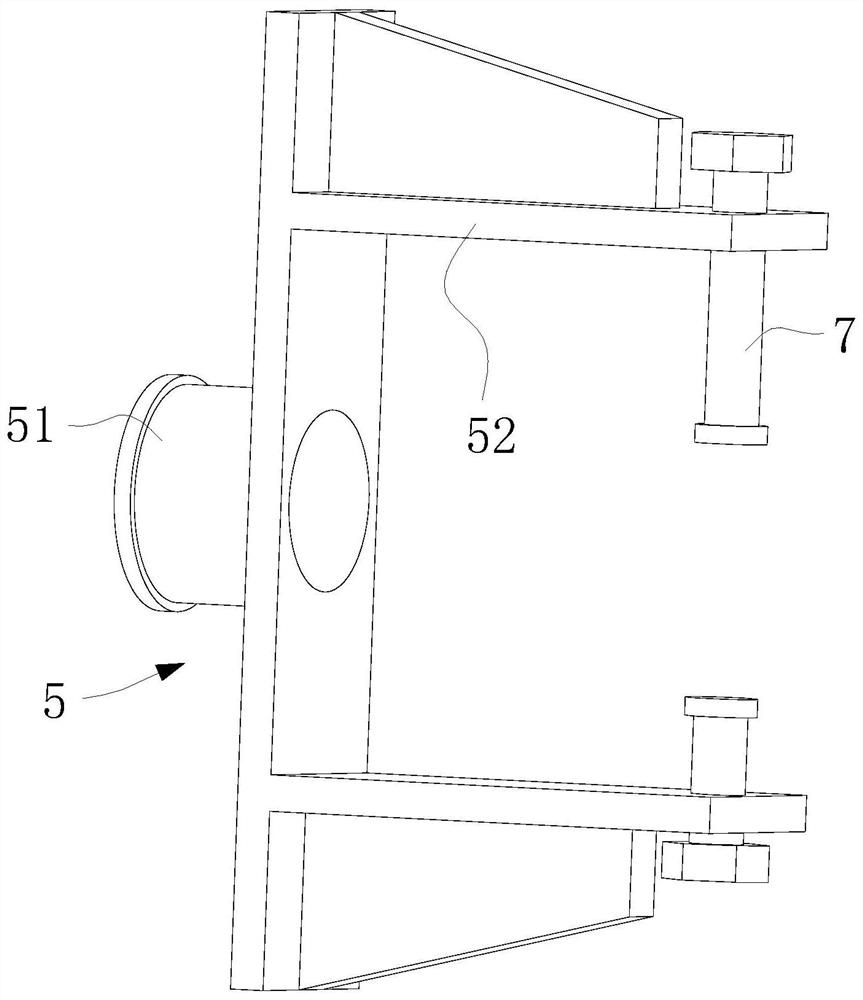

[0042] As shown in the figure, after the crankshaft 4 breaks, it can be divided into the left part 41 of the crankshaft and the right part 42 of the crankshaft. Because the shape of the crankshaft body is irregular, it is difficult to control the assembly and all-position welding of the fractured parts. In order to solve the problem of assembling and all-position welding of the fractured crankshaft 4 to be repaired, the present invention provides a welding device for a large crankshaft fracture of a high-pressure pump body. One side of the tooling base plate 1 is fixedly provided with a left bracket 2, and the other side is slidably provided with a right bracket 3, and a right bracket adjustment device 70 is arranged between the right bracket 3 and the structural part tooling base plate 1; The right support 3 is respectively rotatably provided with a left clamping fixture 5 and a right clamping fixture 6; a left fixture adjusting device 20 is movably provided between the left c...

Embodiment 2

[0049] As shown in the accompanying drawings, the present invention is a repair process for a large crankshaft fracture of a high-pressure pump body. After the crankshaft 4 is broken, it is divided into a left crankshaft 41 and a right crankshaft 42, and the left crankshaft 41 and right crankshaft 42 are broken respectively. The left groove surface 4A and the right groove surface 4B for docking repair are provided at the place to be repaired, and the left groove surface 4A and the right groove surface 4B are machined into a single side 35°, and then through the method described in embodiment 1 The welding device for the fracture of the large crankshaft of the high-pressure pump body is repaired, and the left part 41 of the crankshaft and the right part 42 of the crankshaft are respectively fixed on the left clamping and fixing frame 5 and the right clamping and fixing frame 6, and the left part of the crankshaft is adjusted by the right bracket adjustment device 70 41 and the r...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com