Welding auxiliary device and welding process for fractures of mandrel baffle plate of flat uncoiling machine

A technology for auxiliary devices and welding processes, which is applied in the direction of auxiliary devices, welding/cutting auxiliary equipment, welding equipment, etc., and can solve problems such as the difficulty of repairing local dropped blocks, and achieve the effects of small space occupation, good stability, and convenient production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

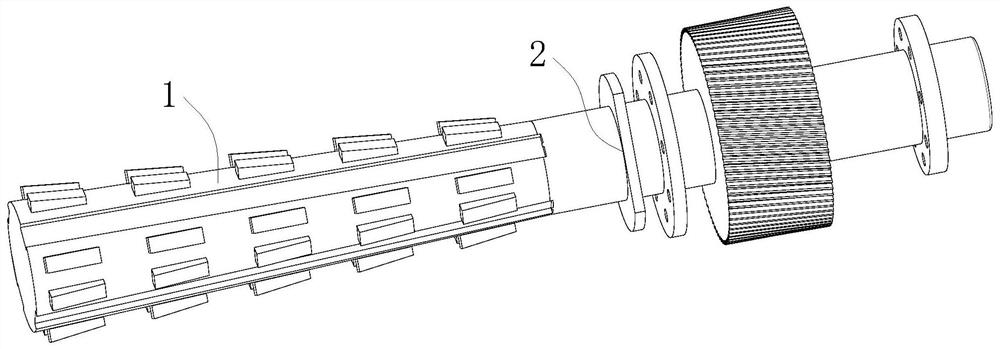

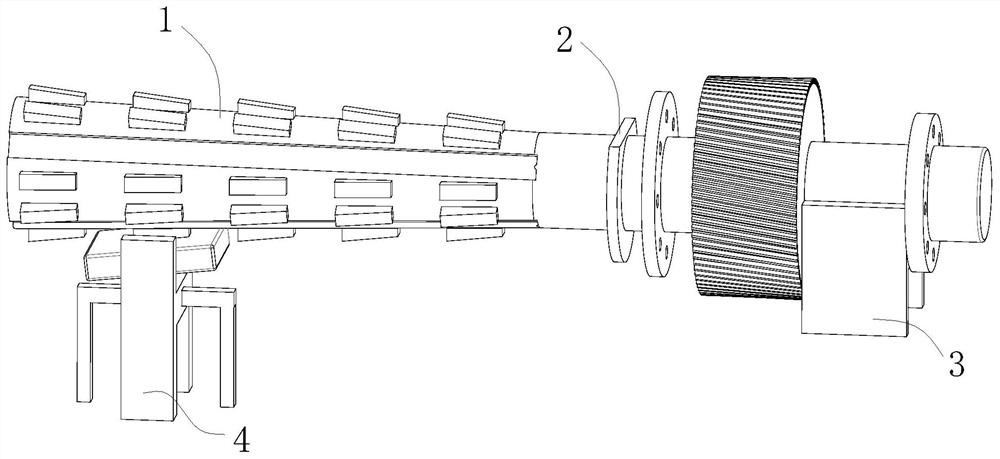

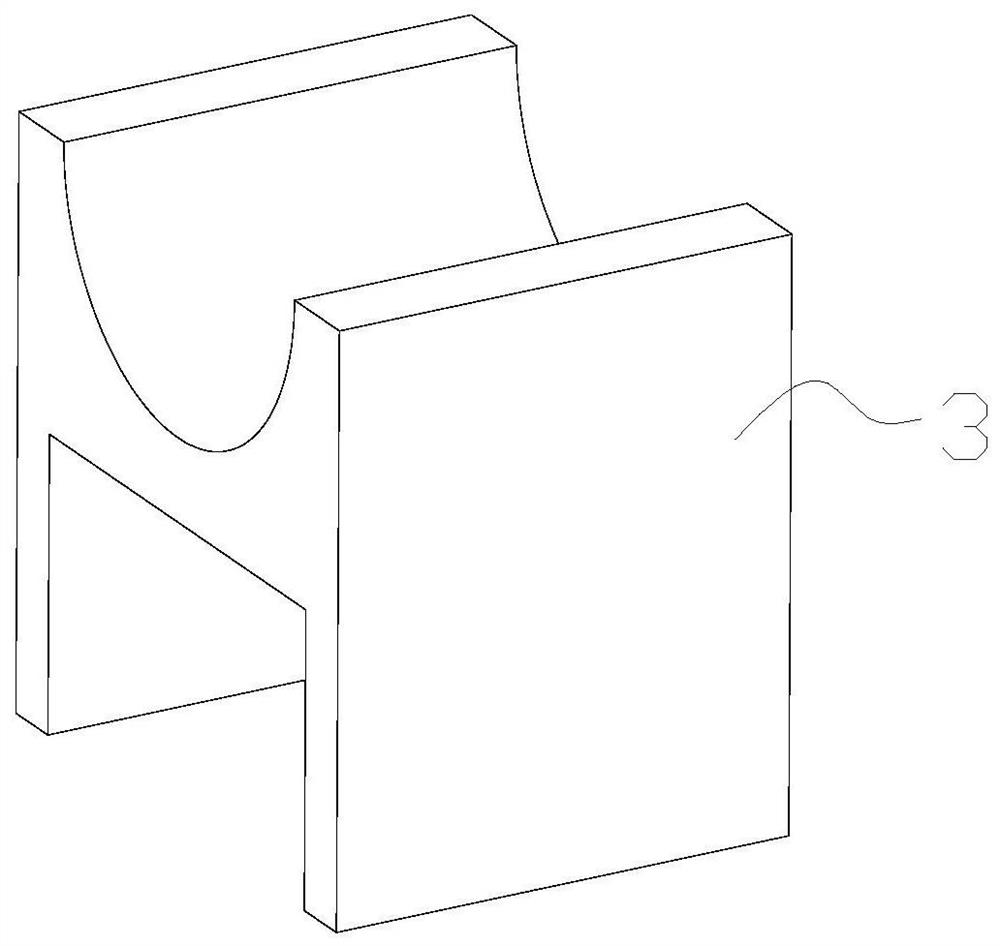

[0046] Such as Figure 1 to Figure 5 As shown, the present invention is an auxiliary device for fracture welding of a flat uncoiler mandrel shaft stop plate, which includes a front end fixing bracket 3 and a rear oblique end fixing bracket 4; The arc shape is suitable for the shaft head of the mandrel to be repaired by welding; the rear inclined end fixing bracket 4 includes a main body supporting steel frame 41 in the shape of "H", and the "H" shape of the main body supporting steel frame 41 The upper part is welded with a shaft rod 43, and the shaft rod 43 is rotated with a supporting steel plate 44. The middle part of the supporting steel plate 44 is provided with a shaft hole, which is set on the shaft rod 3 and can be rotated left and right; the shape of "H" The two sides of the main body support steel frame 41 are respectively welded with "L" shaped side support steel frames 42, and the bottom of the side wing support steel frames 42 is flush with the "H" shaped bottom o...

Embodiment 2

[0051] The invention discloses a fracture welding process for a flat uncoiler mandrel retaining plate. The shaft head (front end) of the mandrel 1 is cylindrical, the shaft body (rear oblique end) is circular, and the joint between the shaft body and the shaft head is The baffle 2 has a fracture to be repaired, and the mandrel 1 is placed horizontally on the auxiliary device for welding the baffle of the flat uncoiler mandrel described in Example 1, and the specific steps are as follows:

[0052] Step 1. Preparation before welding;

[0053] 1.1), welding equipment: multifunctional micro-arc additive manufacturing machine and WS-400T manual argon arc welding machine;

[0054] 1.2), heating device: oxygen acetylene bottle and electric heating belt;

[0055] 1.3), Auxiliary facilities: angle grinder, file, hand hammer, flat shovel, mask, insulation barrel, sample, thermometer, magnifying glass, insulation cotton;

[0056] Step 2. Welding process formulation;

[0057] 2.1), wel...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com