A Welding Repair Process for Cracks in Water Tank of Electric Reciprocating Pump Body for Wheel Phosphorus Removal

A welding repair and reciprocating pump technology, which is applied to welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of long procurement cycle, unusable use, and affecting lubrication effect, so as to reduce the loss of wheel rolling downtime and reduce maintenance The effect of stable cost and welding quality

Active Publication Date: 2022-06-03

ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

View PDF8 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

After some horizontal plunger electric reciprocating pumps are used for a long time, the water tank of the pump body will have irregular through-cracks of different lengths (such as 1M long), which will cause the cooling water for lubricating oil to flow away along the cracks, which cannot To cool the lubricating oil, because the lubricating oil cannot be cooled in time, the heat generated between the friction pairs of the moving parts cannot be taken away by the lubricating oil at all during the operation of the pump. At the same time, the high oil temperature causes the lubricating oil to deteriorate, which affects the lubrication effect. Increased wear between kinematic pairs

If it continues to run without replacement or repair, the movement of the entire horizontal plunger electric reciprocating pump will be quickly damaged, and even the mating surfaces of the pump body will not be able to continue to be used due to thermal deformation.

However, if a new pump is replaced, not only the procurement cycle will be long, but also the procurement cost of the 32MPa horizontal plunger electric reciprocating pump will be high, which will inevitably affect production

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

Embodiment 2

[0044]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

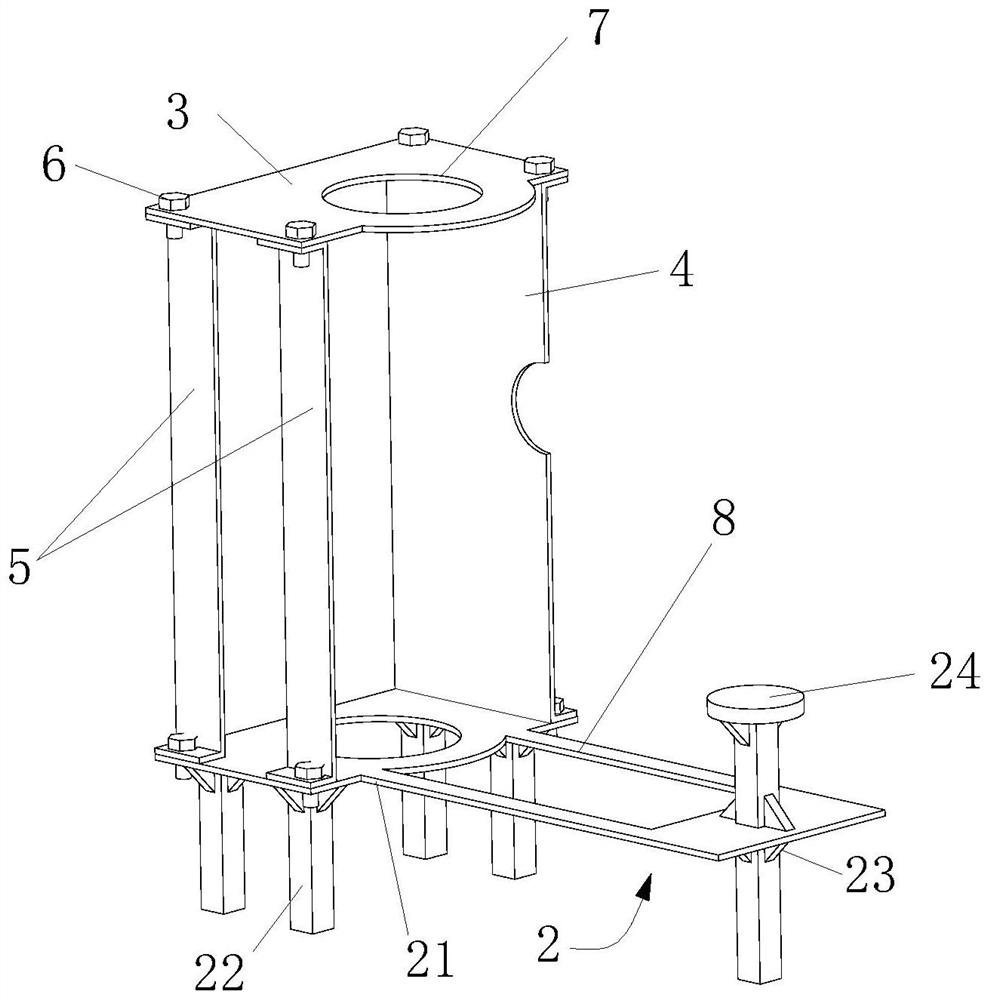

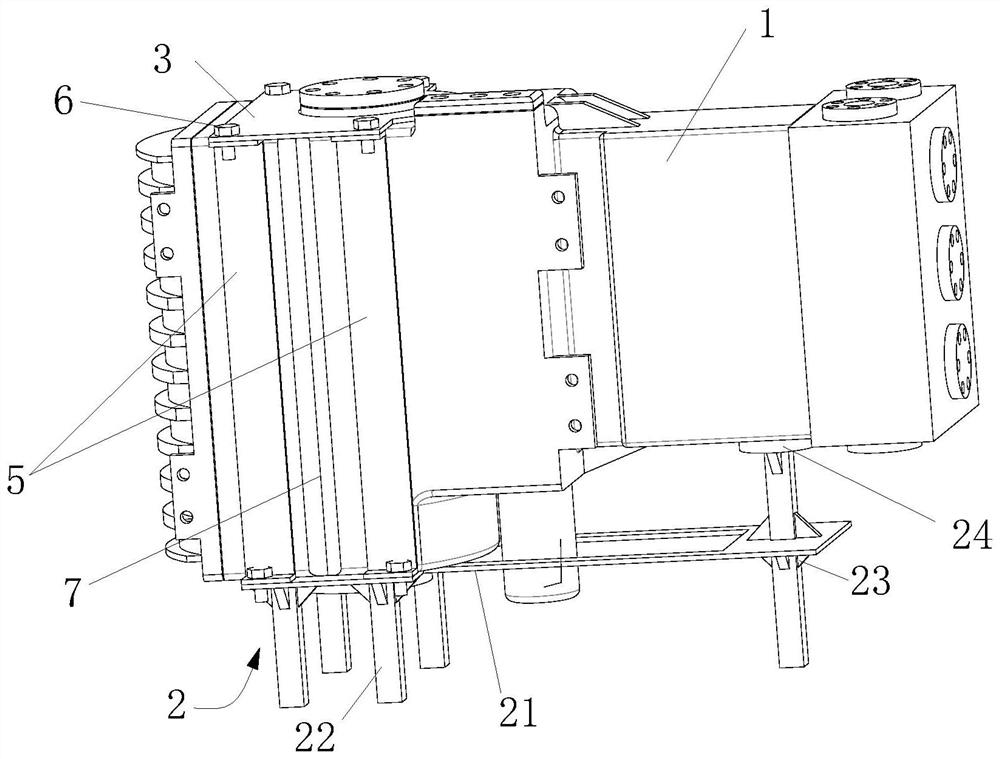

The invention discloses a water tank crack welding device for an electric reciprocating pump body for dephosphorization by wheels. The fixed draw plate on the groove surface and the fixed steel plate connected to the back side and the two fixed pull plates on the groove surface are respectively detachably connected and fixed upper pressing plate. The present invention also provides a repair process for the water tank crack welding device of the wheel dephosphorization electric reciprocating pump body. Aiming at the problems existing in the background technology, the present invention provides a repair process for the wheel phosphorus removal electric reciprocating pump body water tank crack welding device craft. The application of the present invention can quickly implement and complete the electric reciprocating cast iron pump body water tank crack welding repair, reduce procurement and maintenance costs, reduce long-term shutdown losses, and provide a guarantee for the reasonable assembly and rolling of steel to produce various domestic and foreign wheels.

Description

Welding repair process for cracks in water tank of electric reciprocating pump body for wheel dephosphorization technical field The invention belongs to welding technical field, relate to a kind of wheel dephosphorization electric reciprocating pump body water tank crack welding device and Repair process. Background technique [0002] The dephosphorization of the wheel blank after the rolling and heating of the wheel production line of Maanshan Iron and Steel Rail Transit Materials Technology Co., Ltd. is generally Using a 32MPa horizontal plunger electric reciprocating pump, the effect of phosphorus removal directly affects the rolling quality of wheel products, and its work The principle is that the motor is connected to the input shaft of the reducer through a coupling, and the output shaft of the reducer drives the crankshaft to rotate. The connecting rod, crosshead and plunger reciprocate, the plunger is sealed with packing, and the suction and discharge high Pu...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): B23K9/04B23K9/235

CPCB23K9/042B23K9/235

Inventor 范兴海章锐杨西涂俊魁张婷婷雷杰陈雪兵张玉

Owner ANHUI MA STEEL EQUIP MAINTENANCE CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com