Converter backing ring body lug fixing assembly welding structure and welding process

A converter support ring and welding structure technology, applied in welding equipment, manufacturing tools, manufacturing converters, etc., can solve the problems of time-consuming and easily damaged body structure, and achieve the effects of stable welding quality, low investment cost and high work efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

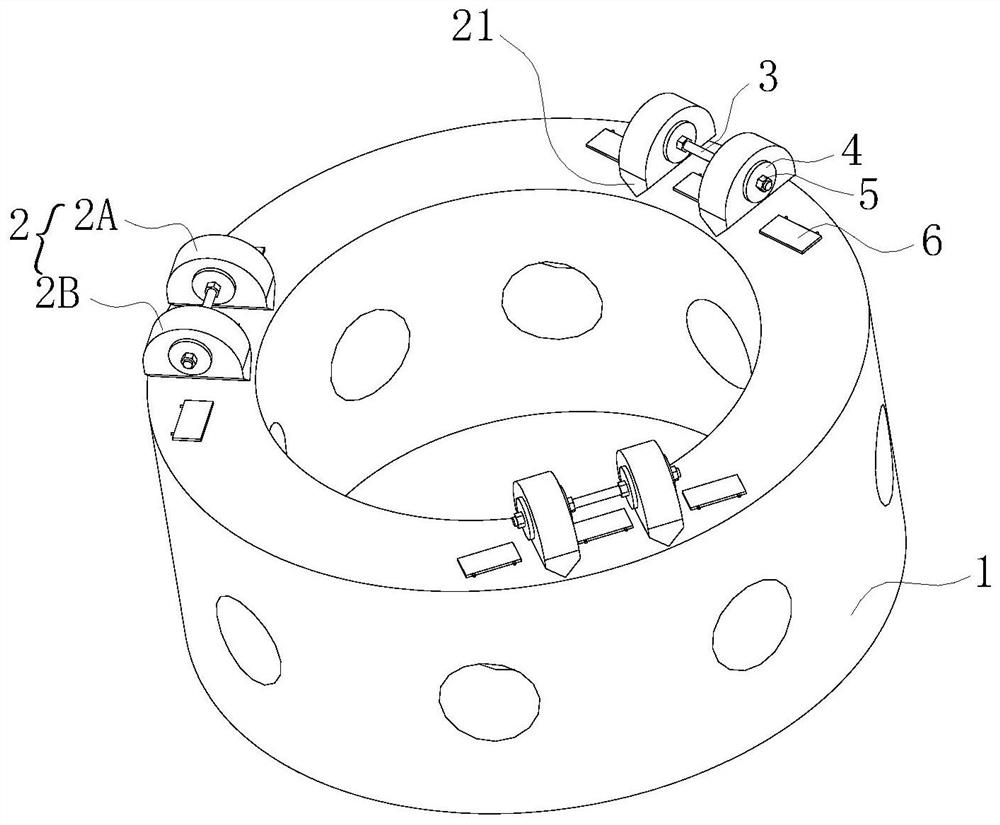

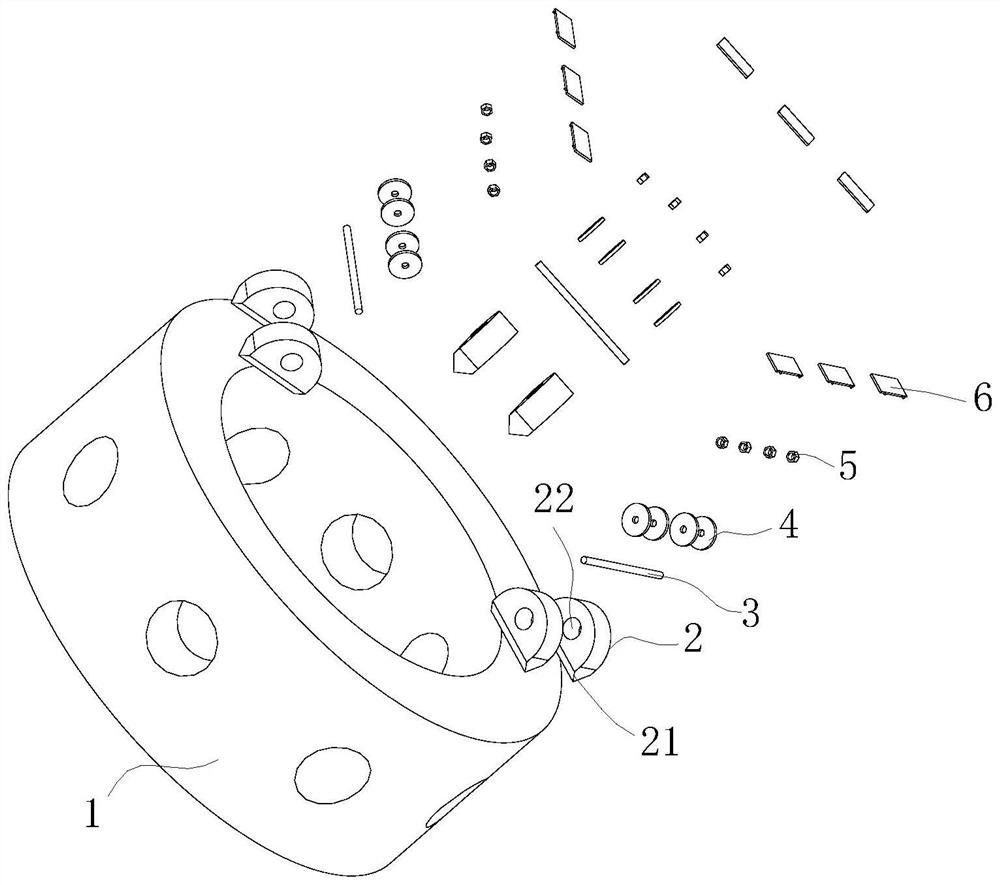

[0038] Such as Figure 1 to Figure 3 As shown, the present invention is a fixed butt welding structure of the ear seat of the converter support ring body, which includes the converter support ring body 1 and three pairs of ear seats 2 uniformly arranged along the upper surface circumference of the converter support ring body 1, each pair of ear seats 2 It includes a first ear seat 2A and a second ear seat 2B arranged in parallel at intervals, and a shaft hole 22 is opened at the center of the first ear seat 2A and the second ear seat 2B; each pair of ear seats 2 corresponds to The shaft hole 22 is connected and fixed by a fully threaded fixed connecting rod 3 .

[0039] In this embodiment, a K-shaped groove 21 is formed between the bottoms of the first ear seat 2A and the second ear seat 2B and the upper surface of the converter support ring 1 .

[0040]In this embodiment, when each pair of ear sockets 2 is set, the fully threaded fixed connecting rods 3 on both sides of the ...

Embodiment 2

[0044] The present invention is a welding process based on the fixed butt welding structure of the ear seat of the converter support ring body described in Embodiment 1, comprising the following steps:

[0045] Step 1. Preparation before welding;

[0046] 1.1), the welding equipment is: WS-400T manual argon arc welding and manual electrode arc welding combined use welding machine, manual argon arc welding uses carbon steel welding wire ER50-6, gas purity ≥ 99.99%, manual electrode arc welding uses electrode model E5015 ;Nb-500P digital pulse gas shielded welding machine, DC positive connection, welding material selection solid wire ER50-6, carbon dioxide gas purity ≥ 99.8%;

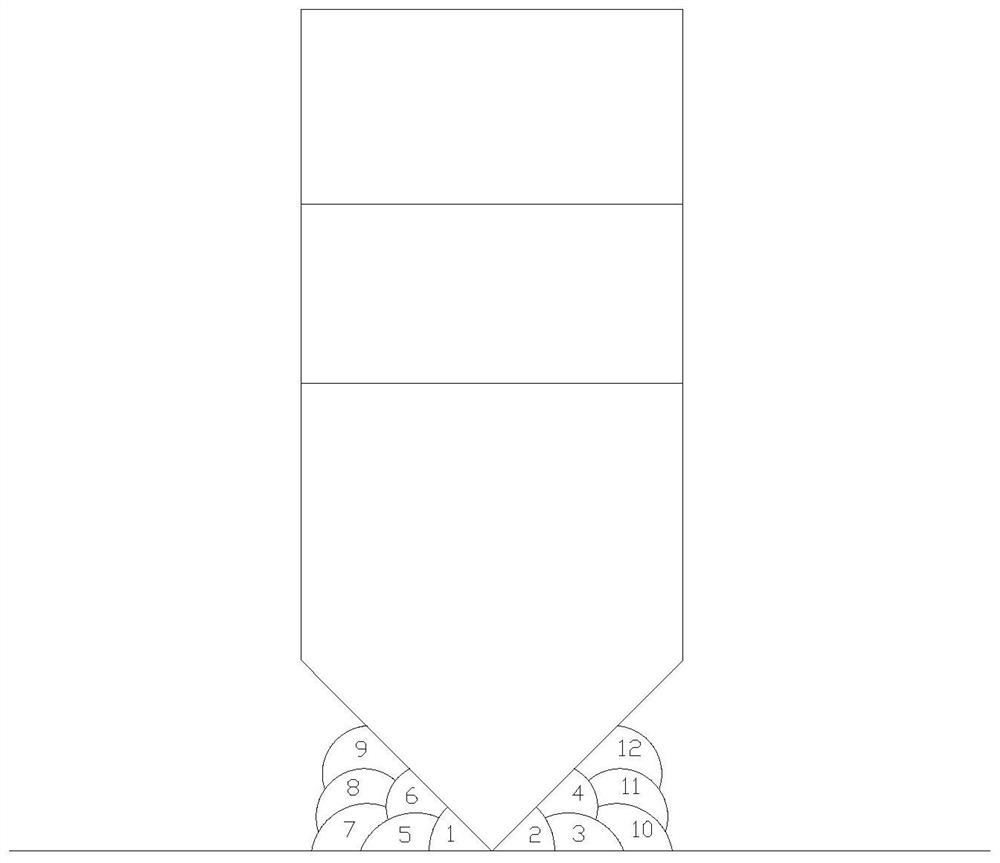

[0047] 1.2), Welding position: horizontal K-groove symmetrical welding;

[0048] 1.3) Cleaning before welding: There should be no oil, oxide layer, moisture, etc. in the welding position area and the welding wire, and the metallic luster should be exposed. Use oxyacetylene flame to remove moisture and oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com