Welding device for crack of water tank of wheel dephosphorization electric reciprocating pump body and repairing process

A welding device and welding repair technology, applied in welding equipment, arc welding equipment, manufacturing tools, etc., can solve the problems of long procurement cycle, can not continue to use, affect the lubrication effect, etc., to reduce the loss of wheel rolling downtime, welding quality Stable and reduced maintenance costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

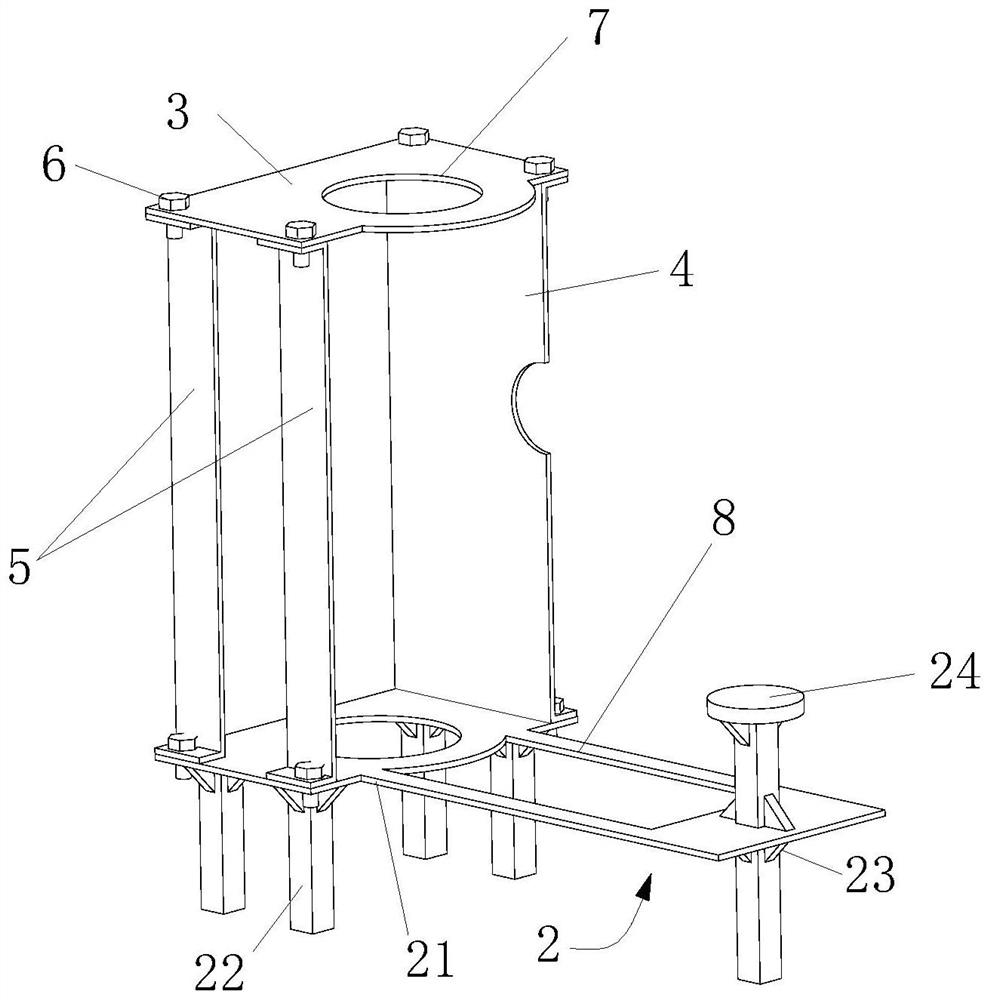

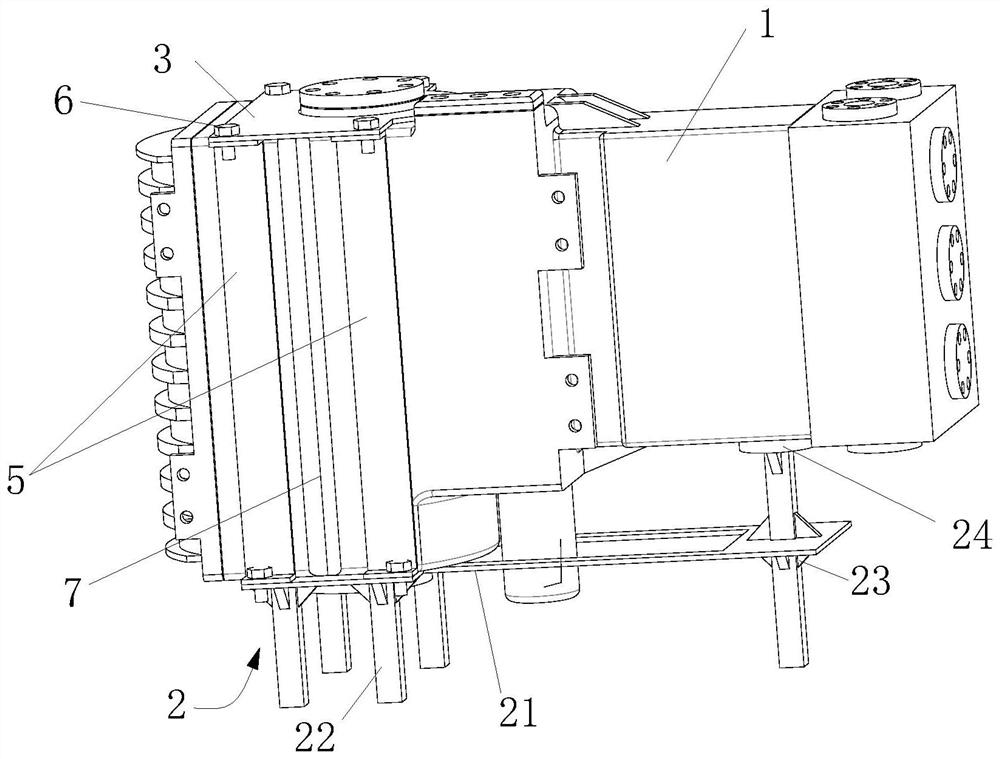

[0032] Such as figure 1 and figure 2 As shown, the present invention is a wheel dephosphorization electric reciprocating pump body water tank crack welding device, which includes a base 2, a vertically detachable back side connected to the fixed steel plate 4 arranged on the rear side of the upper surface of the base 2, respectively vertically detachable and spaced on the base 2 The two groove surface fixed pull plates 5 on the front side of the upper surface and the fixed steel plate 4 connected to the back and the two groove surface fixed pull plates 5 are respectively vertically detachable and fixedly connected to the upper pressure plate 3; the base 2 includes a bottom plate 21 and several support feet 22 arranged at the bottom of the bottom plate 21; the upper plate 3 is connected to the back side between the fixed steel plate 4 and the upper ends of the two groove surface fixed pull plates 5, and the bottom plate 21 is connected to the back side to fix the steel plate 4...

Embodiment 2

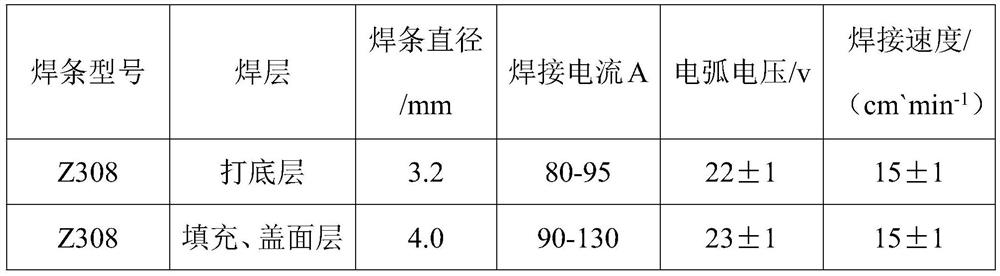

[0034]Based on the repair process of a water tank crack welding device for wheel dephosphorization electric reciprocating pump body described in Example 1, it is used for welding repair of cracks in the electric reciprocating pump body water tank. The welding device is based on the electric reciprocating pump body 1 to be repaired. The model size is used to make the lower material. First, open a V-shaped groove 7 along the water tank crack of the electric reciprocating pump body 1, then set up the base 2, place the electric reciprocating pump body 1 on the base 21, and install the back on the front and rear sides of the base 21 respectively. Connect the fixed steel plate 4 and the two fixed pull plates 5 on the groove surface to ensure that the crack of the water tank to be repaired by welding is located between the two fixed pull plates 5 on the groove surface, and finally install the upper pressure plate 3 to fix the electric reciprocating pump body 1 and perform welding. Pro...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com