Repairing device for surface abrasion of large wheel fixing table base and repairing process

A surface wear and fixed platform technology, applied in the direction of manufacturing tools, metal processing equipment, arc welding equipment, etc., can solve the problems of affecting the rolling size of the wheel, affecting the installation accuracy, and the long cycle of new spare parts, so as to reduce the loss of process downtime, The effect of reducing maintenance cost and stabilizing welding quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

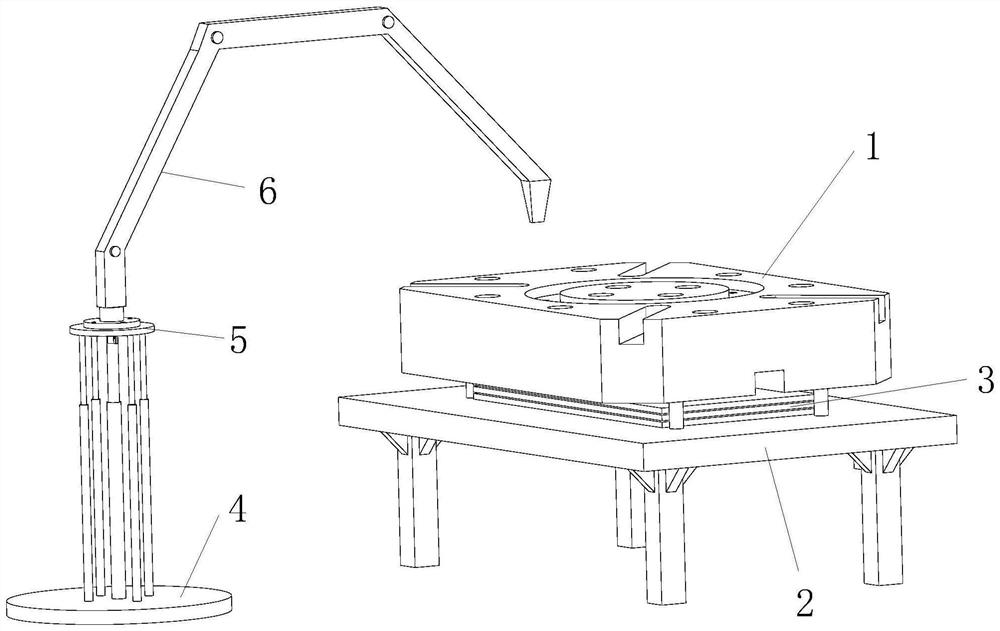

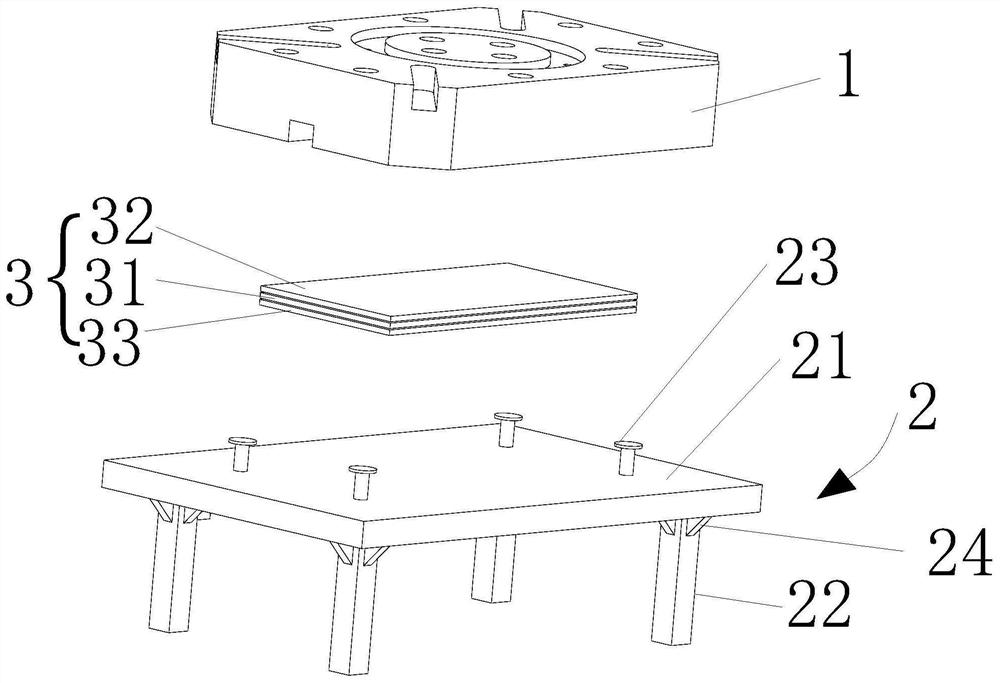

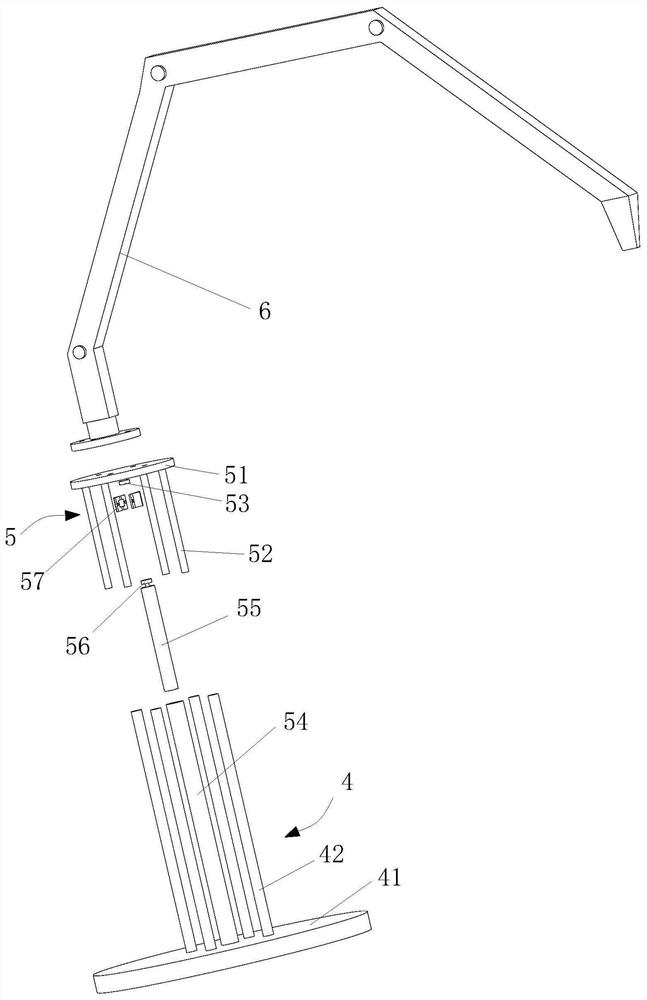

[0032] Such as Figure 1 to Figure 3 As shown, the present invention is a repairing device for surface wear of a large wheel fixing platform base, including a welding robot 6, a structural member support platform 2, a heating device 3 arranged on the structural member support platform 2, a manipulator base 4 and a manipulator lifting adjustment device 5; the manipulator lifting adjustment device 5 is movably arranged on the manipulator base 4, and can be adjusted up and down on the manipulator base 4 to meet the welding requirements of the welding robot 6 installed subsequently; the base of the welding robot 6 is arranged on the manipulator On the lifting adjustment device 5.

[0033] In this embodiment, the manipulator base 4 includes a base plate 41 and several bottom steel pipes 42 uniformly welded on the upper surface of the base plate 41. The base plate 41 is machined from a 50mm steel plate according to the designed diameter and is circular. The connection is fixed on t...

Embodiment 2

[0038] Based on the repairing process of the repairing device for surface wear of a large wheel fixing platform base described in Example 1, it is used for welding repair of the fixing platform base 1, and the rectangular parallelepiped fixing platform base 1 with a square bottom surface is placed horizontally on the fixed support bar 23, the base of the welding robot 6 is connected with the manipulator lifting adjustment device 5 and the height is adjusted according to the welding requirements of the fixed table base 1, and then the fixed table base 1 is preheated by the heating device 3, and the welding is performed. The welding process is as follows :

[0039] Step 1. Preparation before welding;

[0040] 1.1. Welding equipment: Welding robot 6 adopts Panasonic six-axis robot; Nb-500P digital pulse gas shielded welding machine, DC positive connection, welding material uses φ1.2mm 3Cr13 welding wire, carbon dioxide gas purity ≥ 99.8%; HT400D digital control inverter Manual D...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com