A method for repairing and remanufacturing the surface of a locomotive buffer bar

A surface repair and buffer rod technology, which is applied in the direction of manufacturing tools, metal processing equipment, welding equipment, etc., can solve the problems of bumper rod working surface occurrence, low market acceptance, insufficient basic research, etc., and achieve fine grain size and repair quality Good, good metallurgical bonding effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

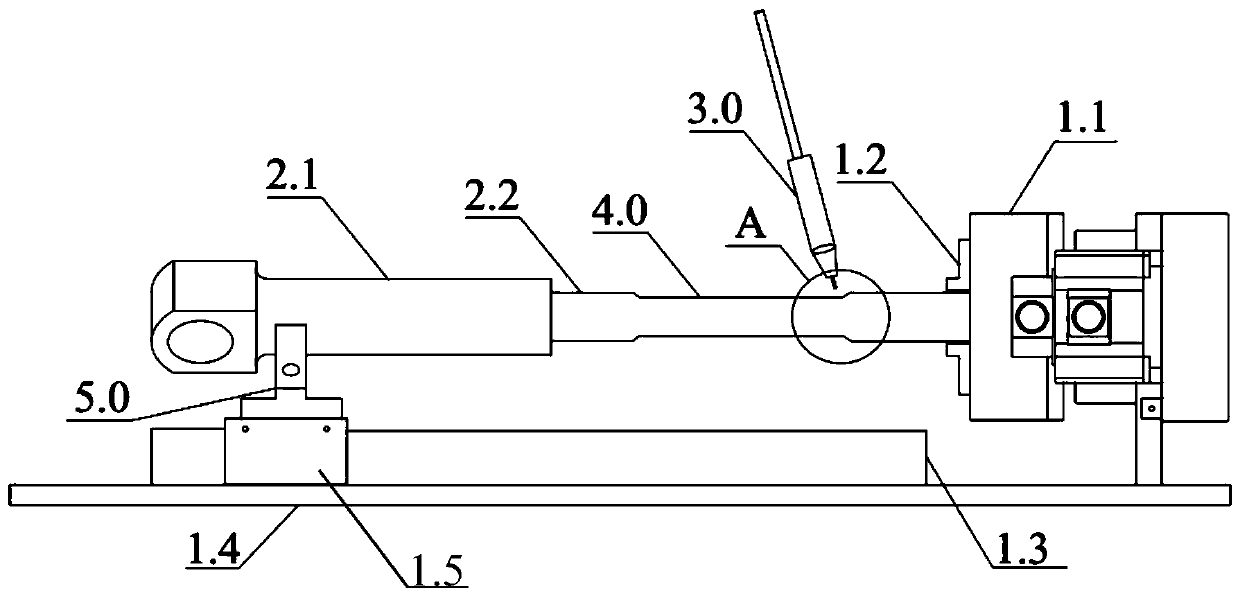

[0042] A method for repairing and remanufacturing the surface of a locomotive bumper bar, the steps are as follows:

[0043] S1. Detect and screen the damaged buffer rods after disassembly, remove the buffer rods with cracks and unqualified coaxiality through X-ray inspection and coaxiality detection, and screen out the repairable buffer rods to be repaired;

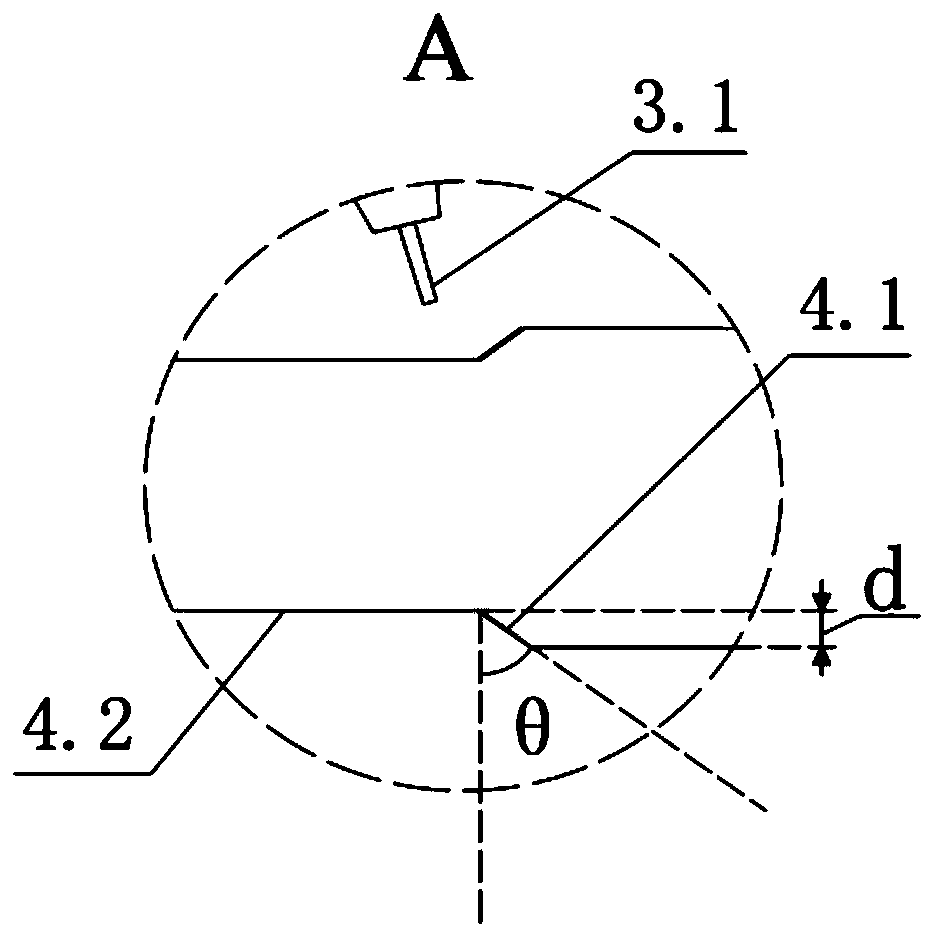

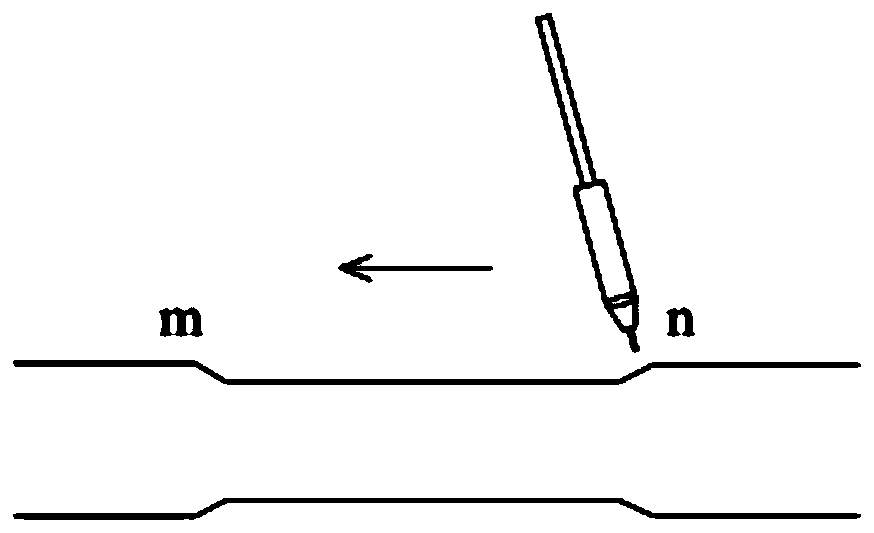

[0044] S2. Check the wear amount of the buffer rod to be repaired, respectively on the shaft sections of different radii of the buffer rod (the buffer rod includes a thick end and a thin end, the thick end is a large-radius shaft segment, and the thin end is a small-radius shaft segment. The thick end and thin end of the buffer respectively determine the area to be repaired and process the groove to be repaired, figure 1 Among them, the thick end of the buffer rod to be repaired does not need to be repaired, only the thin end wear needs to be repaired, and only the groove to be repaired is made on the thin end), the area...

Embodiment 1

[0060] S1. Detect and screen the damaged buffer rods after disassembly, remove the buffer rods with cracks and unqualified coaxiality through X-ray inspection and coaxiality detection, and screen out the repairable buffer rods to be repaired;

[0061] S2. Check the wear amount of the buffer rod to be repaired, and determine the area to be repaired according to the size of the wear amount in the shaft sections of different radii of the buffer rod, and process the groove to be repaired in the area to be repaired; in this example, the thickness of the buffer rod to be repaired is The end diameter is Φ75mm, the maximum wear depth is 3mm, and the wear length is about 20cm; the thin end diameter is Φ48mm, the maximum wear depth is 3mm, and the wear length is about 12cm;

[0062] On the butt end of the buffer rod to be repaired, the area to be repaired is determined according to the maximum wear depth and wear length of the butt end, and the groove to be repaired is processed in the a...

Embodiment 2

[0072] S1. Detect and screen the damaged buffer rods after disassembly, remove the buffer rods with cracks and unqualified coaxiality through X-ray inspection and coaxiality detection, and screen out the repairable buffer rods to be repaired;

[0073] S2. Check the wear amount of the buffer rod to be repaired, and determine the area to be repaired according to the size of the wear amount in the shaft sections of different radii of the buffer rod, and process the groove to be repaired in the area to be repaired; in this example, the thickness of the buffer rod to be repaired is The end diameter is Φ75mm, the maximum wear depth is 4mm, and the wear length is about 18cm; the thin end diameter is Φ48mm, the maximum wear depth is 4mm, and the wear length is about 14cm;

[0074] On the butt end of the buffer rod to be repaired, the area to be repaired is determined according to the maximum wear depth and wear length of the butt end, and the groove to be repaired is processed in the a...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com