High-voltage permanent-magnet intelligent driving system for water-conservancy vertical shaft

A drive system and shaft technology, applied in the direction of magnetic circuit rotating parts, magnetic circuits, electric components, etc., can solve the problems of fragile reducer, short maintenance cycle, difficult assembly, etc., to meet the needs of intensive management, reduce Maintenance cost, easy to intelligent effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

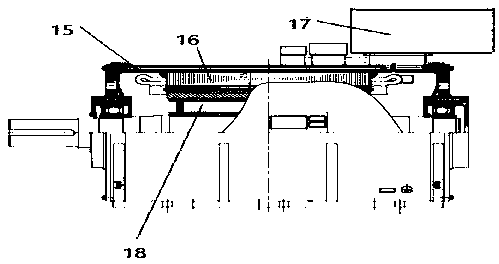

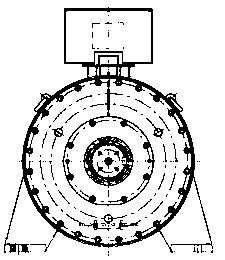

[0039] A high-voltage permanent magnet intelligent drive system for water conservancy shafts, comprising a casing 15, a stator assembly 16, a rotor assembly 18 and a high-power permanent magnet motor driver 17, the aspect ratio of the rotor is 15, and the rotor assembly 18 includes mutually coaxial and sleeved For the two rotor units on the same rotor shaft 1, a magnetic isolation spacer 2 is arranged between the two rotor units, and the two rotor units and the magnetic isolation spacer 2 are close together;

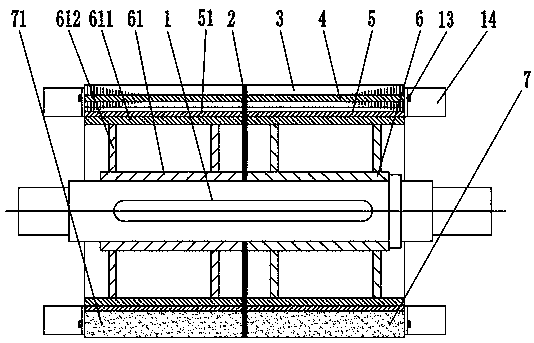

[0040] The outer cylindrical surface of the rotor rotating shaft 1 is provided with a right rotor support 6, a magnetic isolation spacer 2 and a left rotor support 61 from right to left, and the magnetic isolation spacer 2 is the middle ring in claim 1, and the right rotor support 6. The structure is the same as that of the left rotor bracket 61. Taking the left rotor bracket 61 as an example, the left rotor bracket outer cylinder 611 is fixed on the outer cylindrical sur...

specific Embodiment 2

[0045] A high-voltage permanent magnet intelligent drive system for water conservancy shafts, including a housing 15, a stator assembly 16, a rotor assembly 18, and a high-power permanent magnet motor driver 17, the aspect ratio of the rotor is 18, and the rotor assembly 18 includes mutually coaxial and sleeved For the two rotor units on the same rotor shaft 1, a magnetic isolation spacer 2 is arranged between the two rotor units, and the two rotor units and the magnetic isolation spacer 2 are close together;

[0046] The outer cylindrical surface of the rotor rotating shaft 1 is provided with a right rotor support 6, a magnetic isolation spacer 2 and a left rotor support 61 from right to left, and the magnetic isolation spacer 2 is the middle ring in claim 1, and the right rotor support 6. The structure is the same as that of the left rotor bracket 61. Taking the left rotor bracket 61 as an example, the left rotor bracket outer cylinder 611 is fixed on the outer cylindrical su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com