Bottom shell and welding seam assembly tool structure for electromagnetic chuck for hoisting and transporting wheel steel ingots and repair process for bottom shell and welding seam assembly tool structure

An electromagnetic chuck and steel ingot technology, which is applied in the field of machinery, can solve the problems of shifting the lifting position of the steel ingot, hitting the wheel ingot, affecting the electromagnetic chuck, etc., and achieves the effects of stable welding quality, low investment cost and high work efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

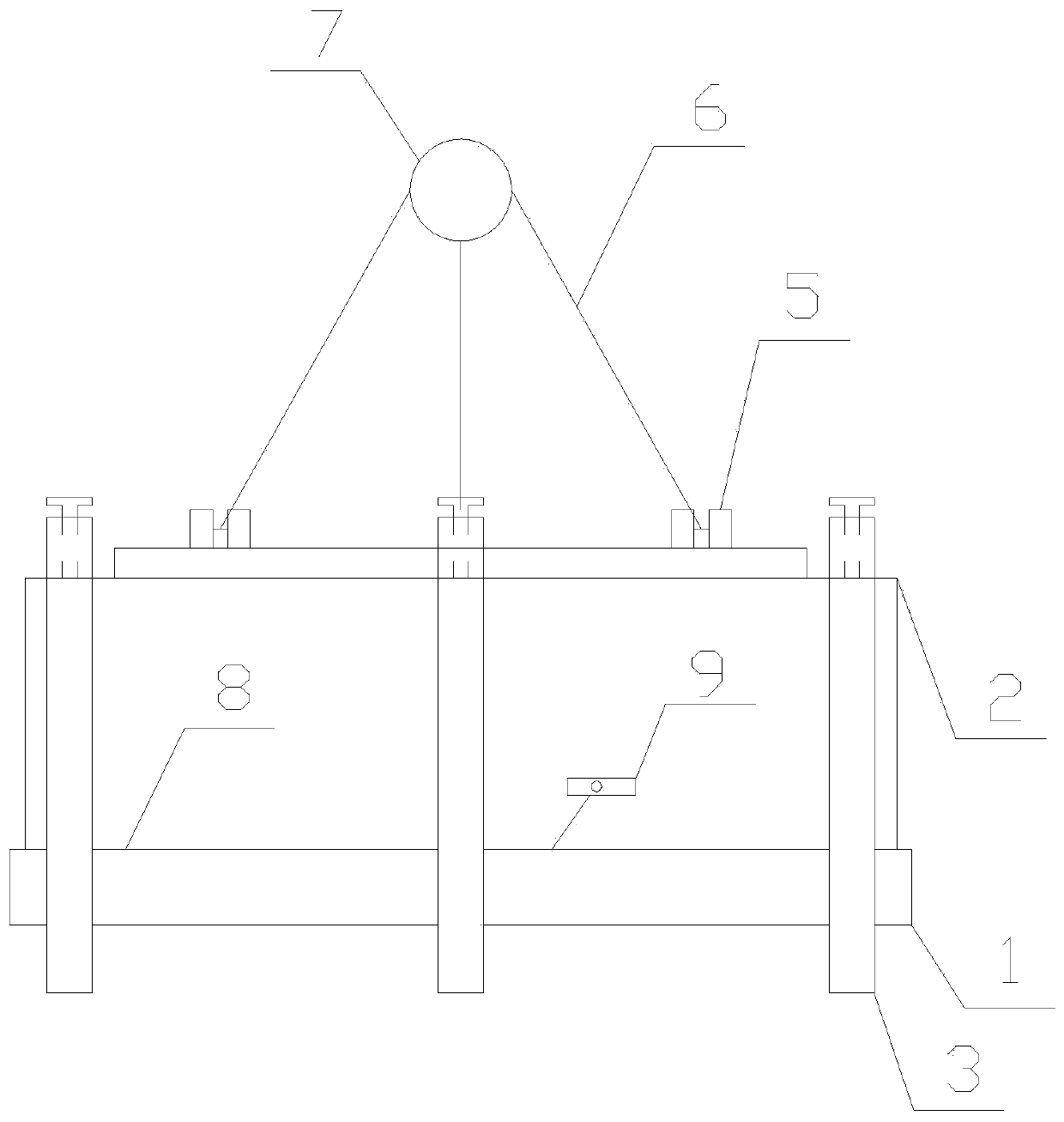

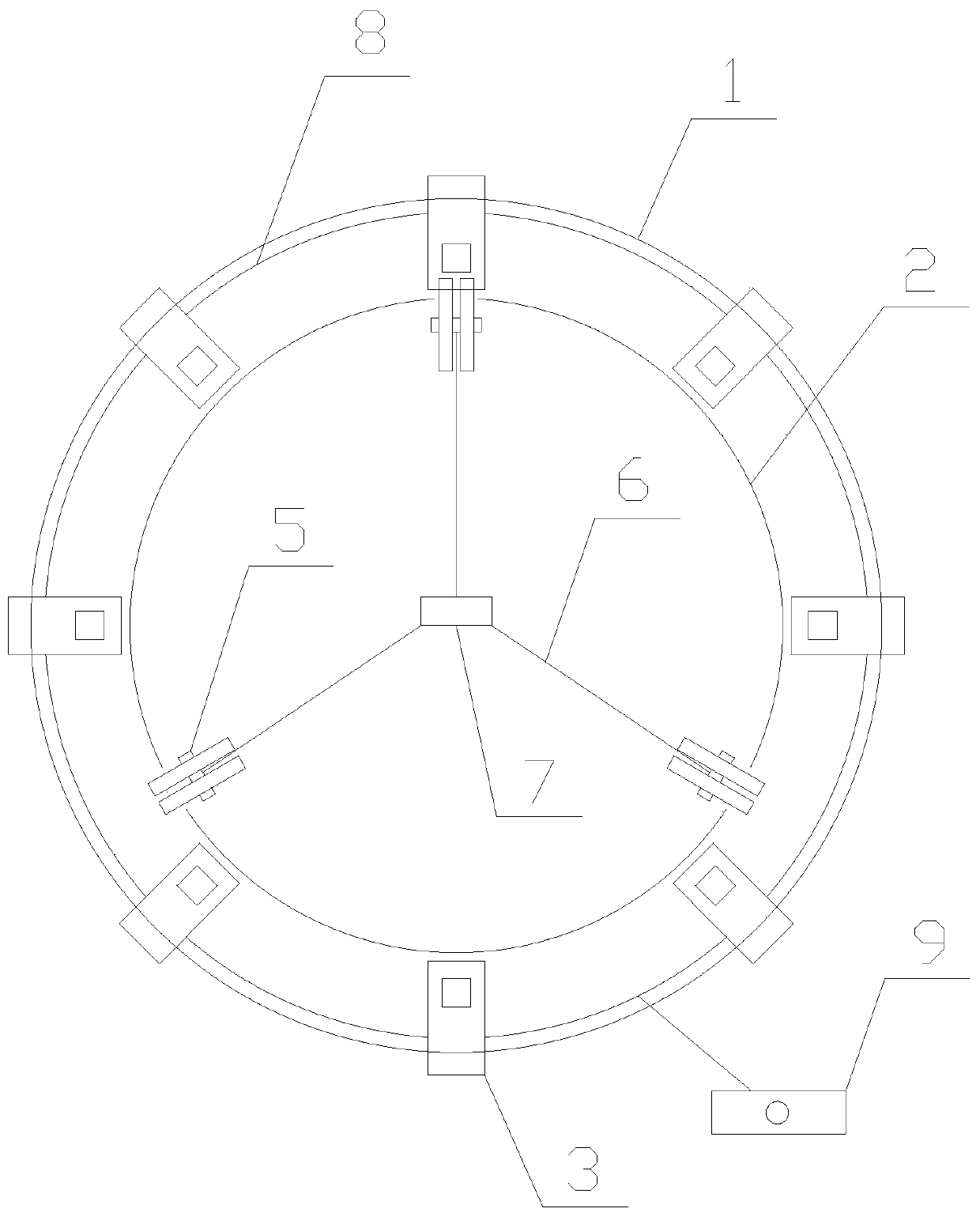

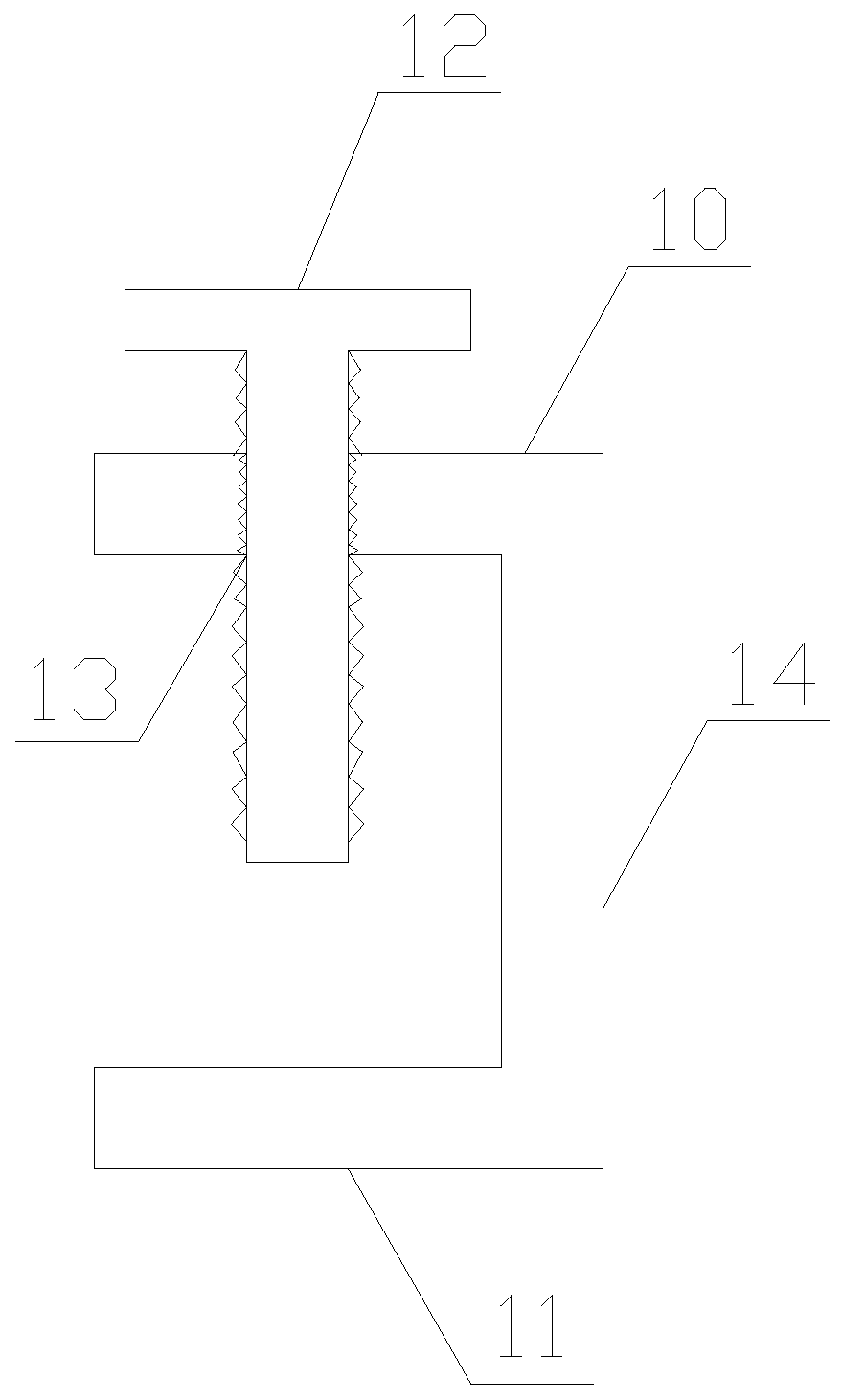

[0031] Such as Figure 1 to Figure 3 As shown, the welding seam assembly structure of the electromagnetic chuck bottom shell of the present invention for lifting and transporting wheel steel ingots includes a circular bottom shell 1 and an upper cover panel 2 welded on the bottom shell 1, and the two are at the junction A weld 8 is formed, and the upper surface of the upper cover panel 2 is uniformly provided with several upper fixing devices 5, and each upper fixing device 5 is connected with a lifting ring 7 through a connecting chain 6, and it is characterized in that the tooling structure also includes a welding torch 9. On the bottom shell 1 and the upper cover panel 2, several hook clips 3 are evenly arranged along the circumference; the hook clip 3 includes a "U"-shaped hook clip body 14, and the upper part of the hook clip body 14 and the bottom are respectively the upper splint 10 of the hook head and the lower splint 11 of the hook head, and the distance between the ...

Embodiment 2

[0035] The present invention is a repair process for the welding seam of the electromagnetic sucker bottom shell of the lifting wheel steel ingot, which is characterized in that the tooling structure is repaired by using the welding seam group of the electromagnetic sucker bottom shell of the lifting wheel steel ingot described in Embodiment 1, including the following step:

[0036] Step 1. Production and pairing of the hook clips; eight hook clip bodies 14 are manufactured by using a steel plate with a thickness of 100mm, and a thread hole 13 is opened on the upper splint 10 of the hook head and a fully threaded bolt 12 is set to form the hook clip 3 ;

[0037] Step 2, preparation before welding;

[0038] 2.1. The welding equipment is CMT cold welding system, and the crack cleaning equipment is carbon arc gouging ZX5-630 welding machine with plasma gouging LGK-100MA;

[0039]2.2. Welding wire: ERNI-1 welding wire with φ1.6mm, no defects on the surface;

[0040] 2.3 Gas req...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com