Closed-loop control system early failure detection and diagnosis method and closed-loop control system early failure detection and diagnosis system

A closed-loop control and early failure technology, which is applied in general control systems, control/regulation systems, test/monitoring control systems, etc., can solve problems such as the inability to identify minor faults, and achieve the effects of fast speed, avoiding misjudgment, and high efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

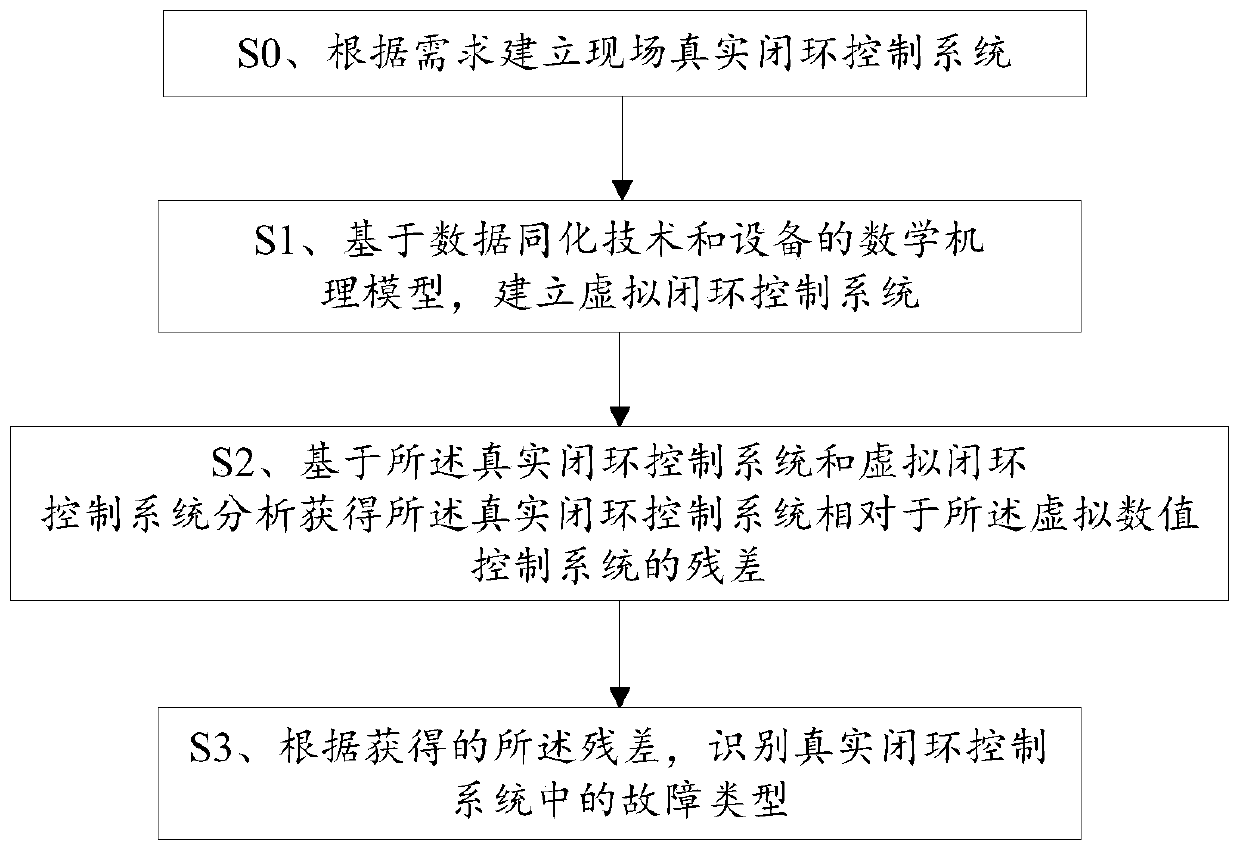

[0033] The embodiment of this application provides an early fault detection and diagnosis method for a closed-loop control system, please refer to figure 1 , the method comprises the steps of:

[0034] S0. Establish a real closed-loop control system on site according to requirements; for example, establish a real closed-loop control system according to the actual controlled object, measuring equipment and different controllers;

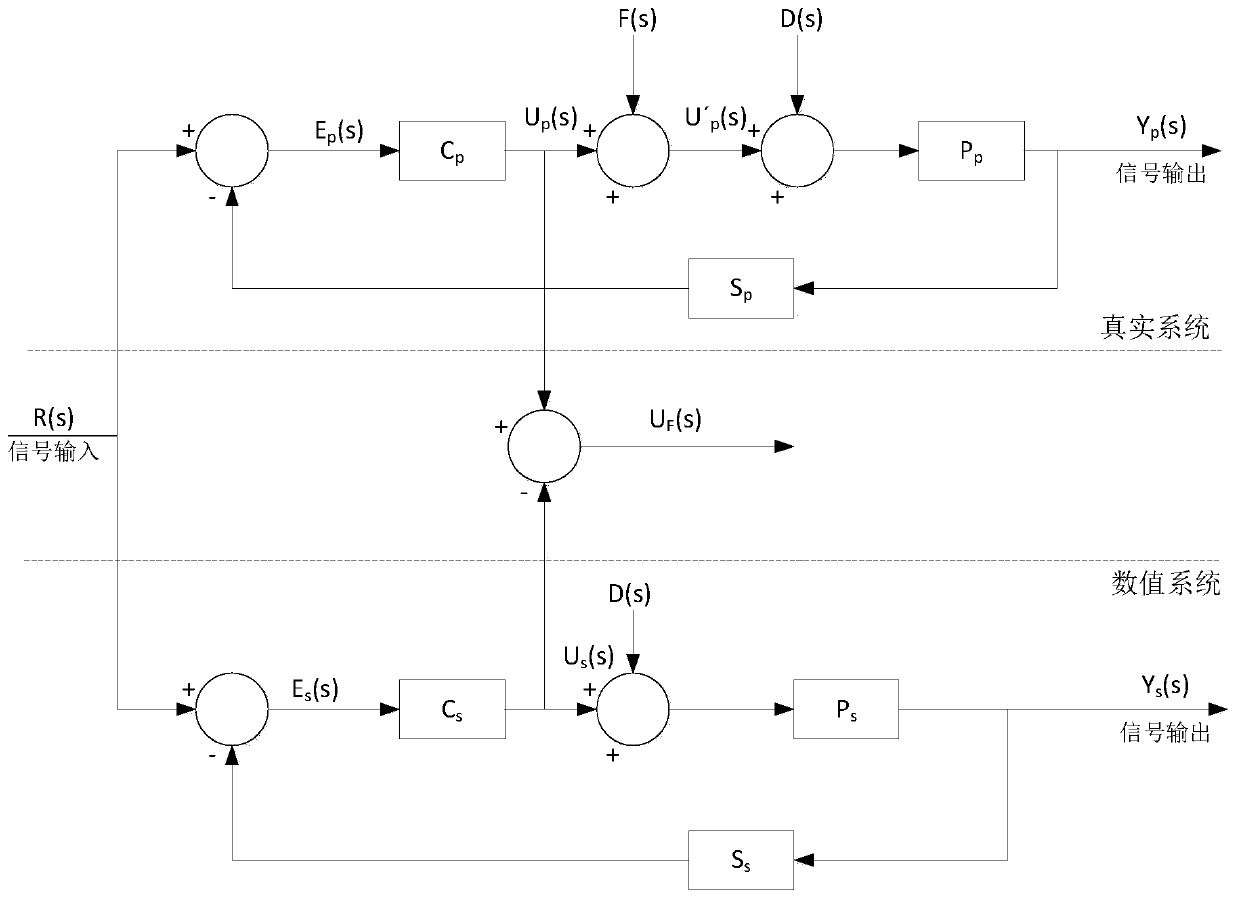

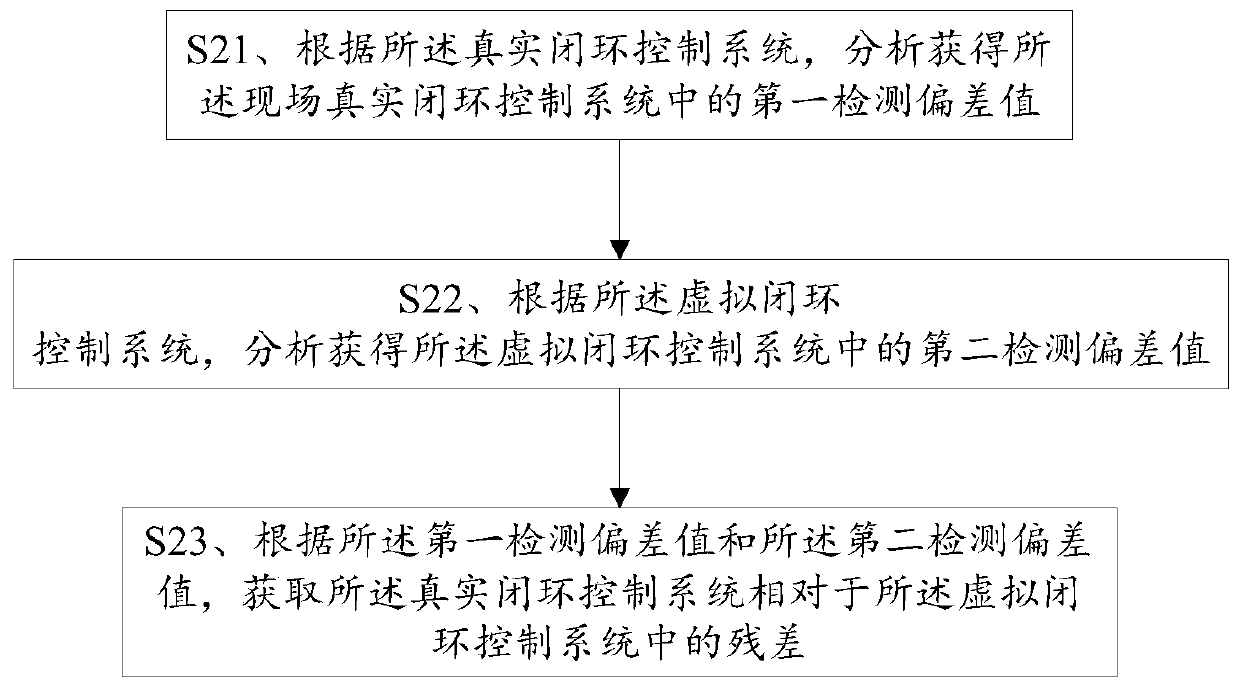

[0035] S1. Establish a virtual closed-loop control system based on the data assimilation technology and the mathematical mechanism model of the equipment; establish a virtual closed-loop control system based on the data assimilation technology, which is one-to-one mapped with the real closed-loop control system; the established virtual closed-loop control system can follow the real The closed-loop system changes and does not need to be re-established repeatedly; it avoids the interference caused by artificially establishing a virtual closed-loop contr...

Embodiment 2

[0063] An embodiment of the present invention provides an early fault detection and diagnosis system for a closed-loop control system, which is applicable to the early fault detection and diagnosis method for a closed-loop control system shown in Embodiment 1. In order to realize the above-mentioned closed-loop control system based on data assimilation fault detection and diagnostic methods, Figure 6 It is a schematic diagram of an early fault detection and diagnosis system of a closed-loop control system provided in Embodiment 2 of the present invention, and the system includes:

[0064] A real closed-loop control system establishment module 100 is used to establish a real closed-loop control system on site according to actual needs; such as establishing a real closed-loop control system according to actual controlled objects, measuring equipment and different controllers;

[0065] The virtual closed-loop control system establishment module 200 is connected to the real close...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com