A fracture welding repair process for large-scale inclined roll shaft of a ring rolling mill

A welding repair and skew roll technology, applied in welding equipment, welding equipment, welding accessories, etc., can solve problems such as fractures, and achieve the effect of saving investment, good stability and meeting actual needs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

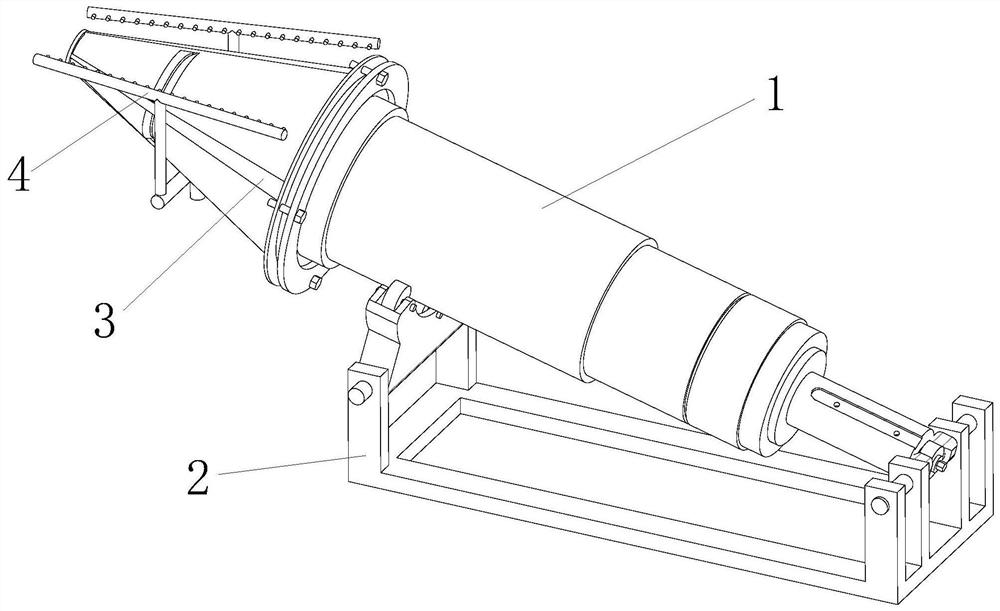

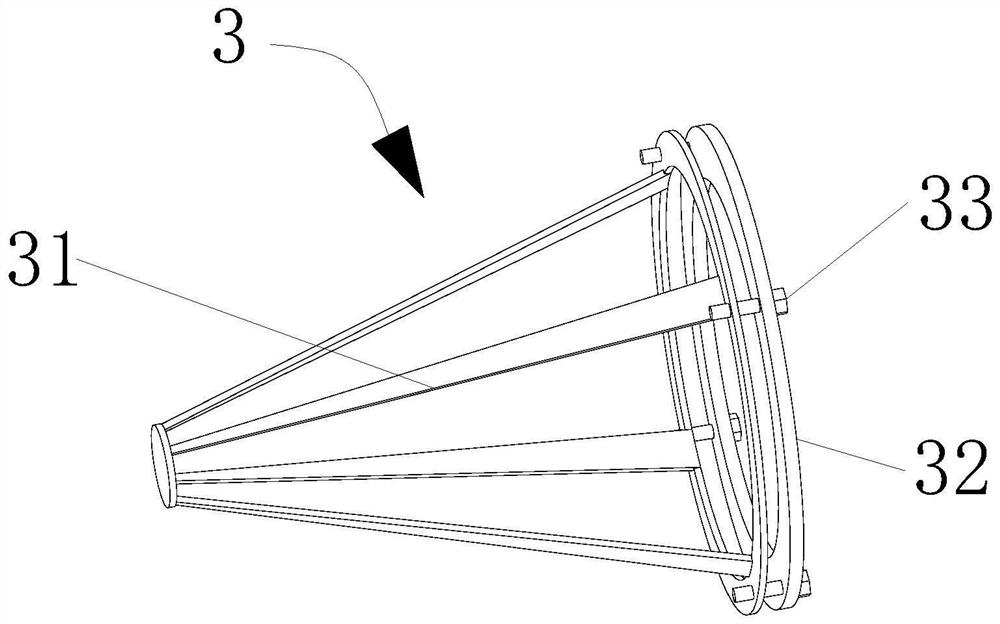

[0041] like Figure 1 to Figure 5 As shown in the figure, the present invention is a large-scale inclined roll shaft fracture welding device for a ring rolling mill, which includes a structural member fixing bracket 2, a pair of fixed structural member tooling 3 and a heating tooling 4; The roller shaft 1 can also rotate the inclined roller shaft 1 arbitrarily on the fixing bracket 2 of the structural member. The inclined roller shaft 1 is generally placed on the fixing bracket of the structural member at an angle of 45 degrees. It is used to pair and fix the broken part of the inclined roller shaft 1 and control the deformation amount during the welding process, which is suitable for the shape of the front end of the inclined roller shaft 1; Pre-heating and post-welding heat treatment.

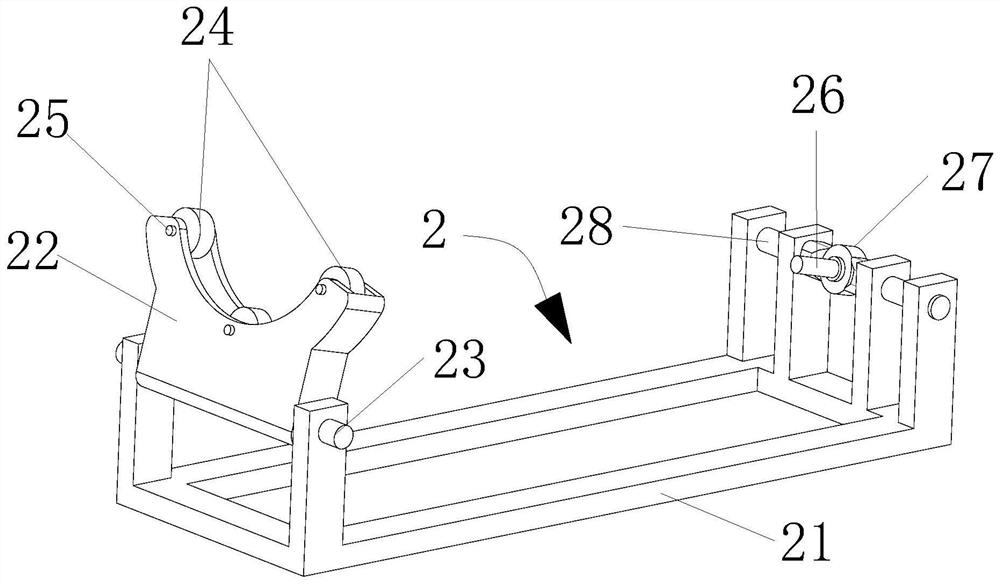

[0042] In this embodiment, the structural member fixing bracket 2 includes a supporting frame 21 that is in the shape of a "Zhong" as a whole. The supporting frame 21 is made of 50mm steel p...

Embodiment 2

[0046] like Figure 1 to Figure 5 As shown, based on the repair process of a large-scale inclined roll shaft fracture welding device for a ring rolling mill described in Example 1, it is used for the welding repair of the fractured inclined roll shaft 1. The inclined roll shaft 1 is broken after long-term operation. The front end 12 of the fractured shaft and the shaft connection part 11 are formed, and the connection between the front end 12 of the fractured shaft and the shaft connection part 11 is the part to be repaired. The welding repair process steps are as follows:

[0047] Step 1. Pre-treatment of the weldment; first, the front end 12 of the fractured shaft and the shaft connecting part 11 are respectively provided with bevel surfaces at the fractured parts to be repaired, and then the front side of the inclined roller shaft 1 is placed at 45° on the structural member fixing bracket 2 On the roller 24 of the U-shaped pallet, the rear end of the inclined roller shaft 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com