Stud embedding device on roller of mine high-pressure roller mill and repair welding process thereof

A high-pressure roller mill and stud technology, applied in the field of machinery, can solve the problems of wear and tear, affecting the effect of ore abrasives, etc., and achieve the effects of high work efficiency, reduced labor intensity, and reduced maintenance costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

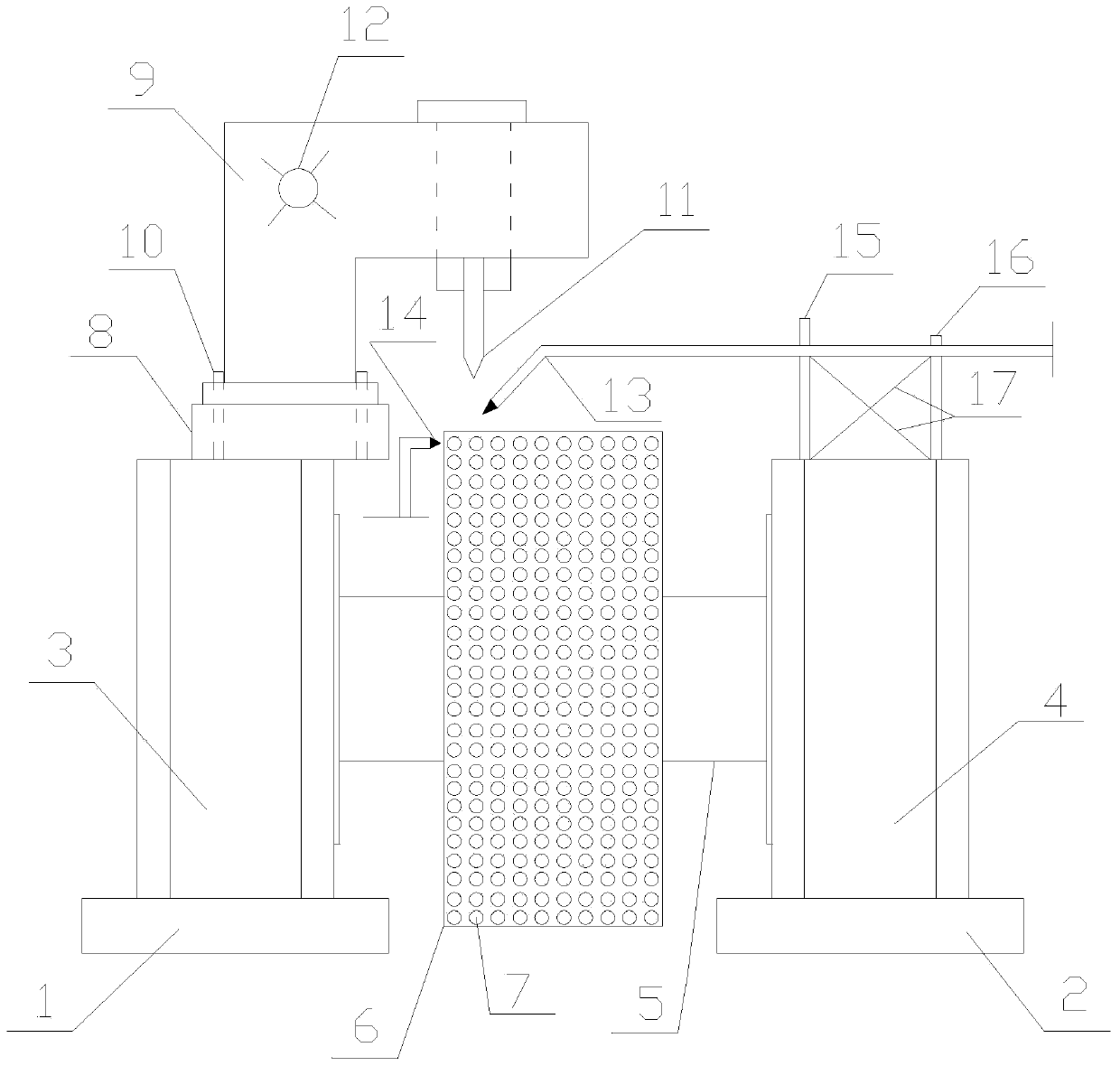

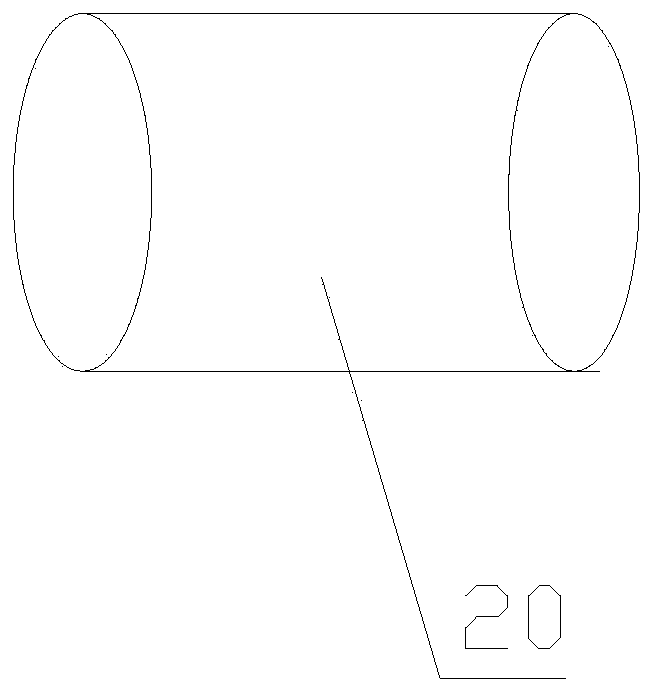

[0036] Such as figure 1 with figure 2 As shown, the present invention is a stud inlay device on the roller of a mine high-pressure roller mill. The high-pressure roller mill includes a left frame 3 and a right frame 4, and the left frame 3 and the right frame 4 is provided with a squeeze roller 6 through a universal coupling 5, and a number of studs 20 are uniformly arranged on the outside of the squeeze roller 6. It is characterized in that the bottom of the left frame 3 and the right frame 4 The left side sleeper 1 and the right side sleeper 2 are respectively provided with; the top of the left side frame 3 is provided with a stud inlay drilling device, and the right side frame 4 is provided with a heating device; the stud inlay device A welding torch 14 is also included. In the present embodiment, two left and right side sleepers 1, 2 are set under the left and right side frames 3, 4, which can ensure enough height to make the squeeze roller 6 operate and play the role o...

Embodiment 2

[0042] The welding repair process of the stud inlay device on the roller of a mine high pressure roller mill described in Example 1 is characterized in that it comprises the following steps:

[0043] Step 1. Preparation before welding;

[0044] 1.1), gas welding equipment: H01-12 welding torch, 3# welding nozzle, hose hoop, oxygen acetylene bottle, oxygen acetylene wind belt;

[0045] 1.2) Heating device: H01-20 roasting gun, 3# welding nozzle, throat hoop, oxygen-acetylene bottle, oxygen-acetylene wind belt;

[0046] 1.3), Auxiliary facilities: angle grinder, file, hand hammer, flat shovel, colored glasses, copper needle, sheepskin gloves, sample, thermometer and magnifying glass, etc.;

[0047] 1.4), Welding position: Rotary welding at the horizontal ring peak welding position;

[0048] 1.5) Welding requirements: All welding deposits must have no welding defects and be metallurgically fused to the base metal;

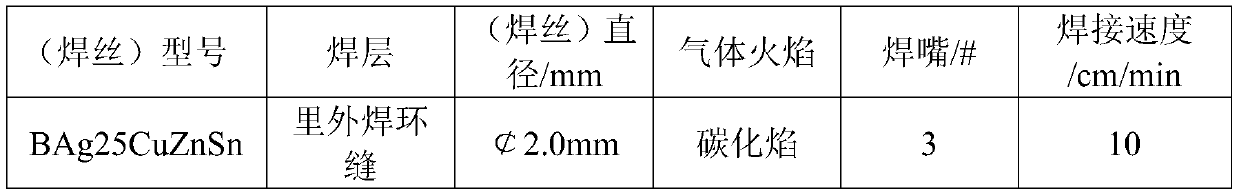

[0049] 1.6), welding material: BAg25CuZnSn, with good fluidity ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com