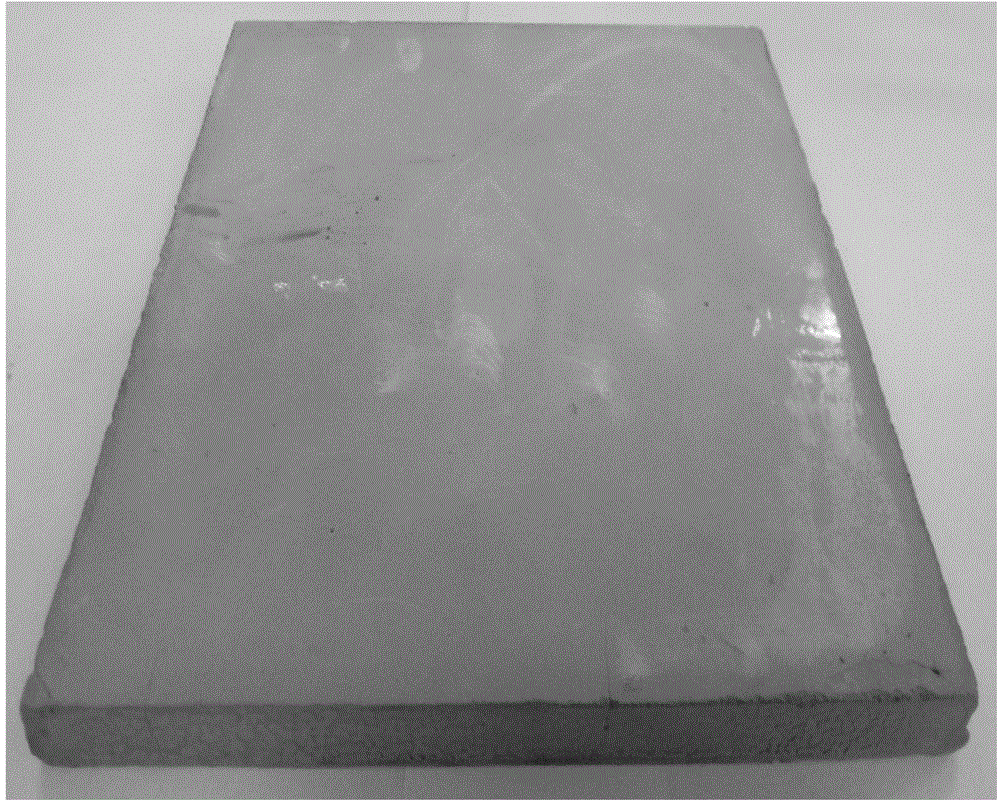

A kind of geopolymer-polymer composite board and its preparation method

A composite plate and polymer technology, applied in cement production, etc., can solve problems such as shortage of natural resources, and achieve the effects of no need for high-temperature sintering, good water resistance, and high compressive strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

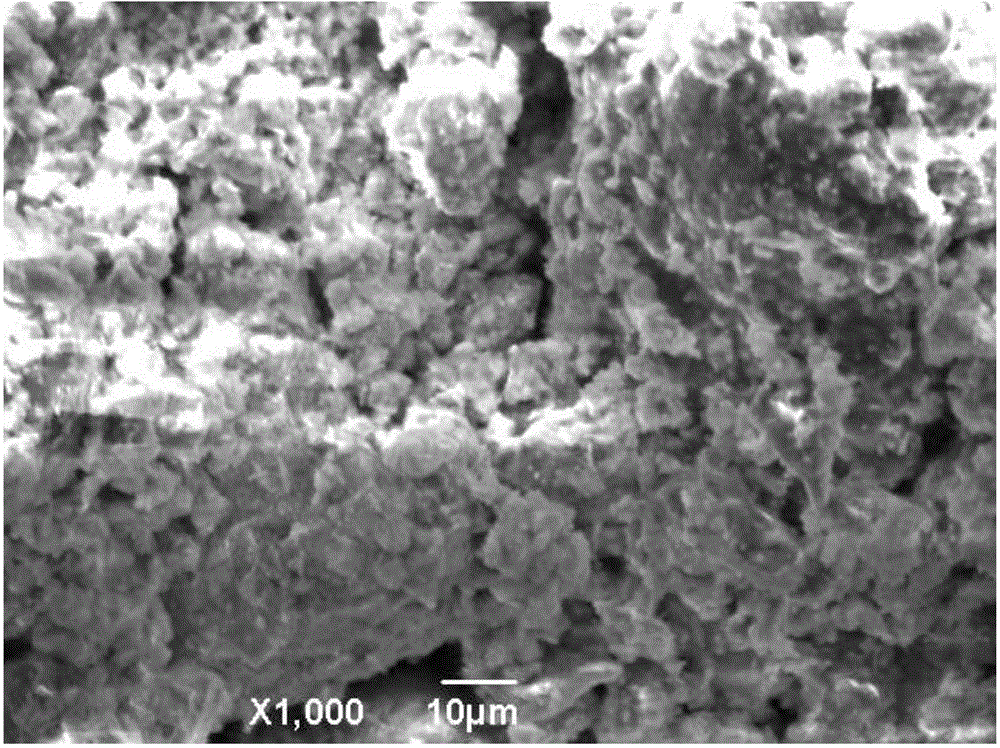

[0031] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

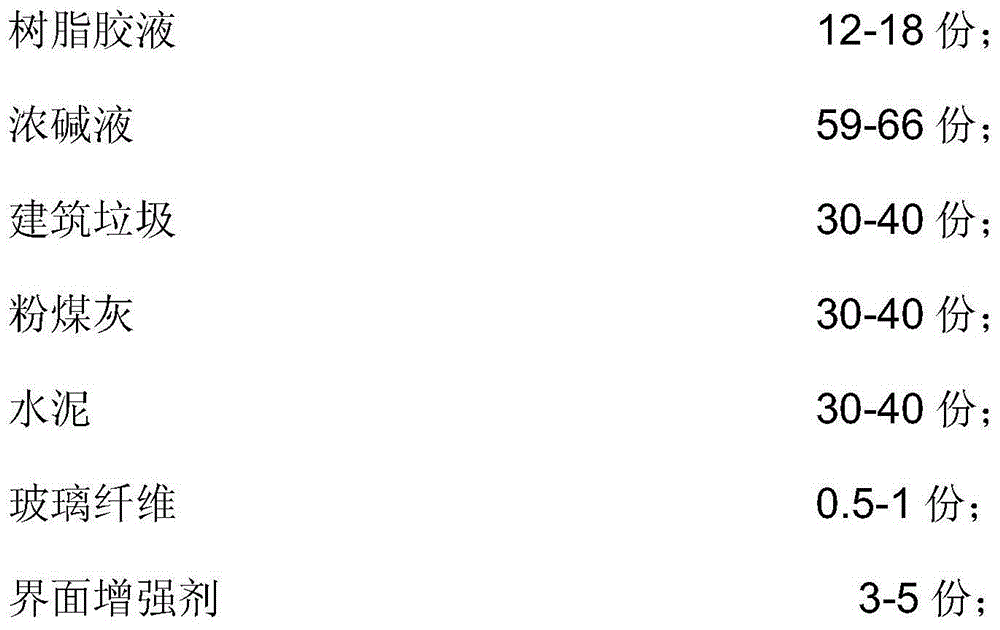

[0032] 1. Materials, reagents and equipment used in the invention patent

[0033] 1) The materials and reagents used are as follows:

[0034] Construction waste powder, 200 mesh, construction demolition site;

[0035] Fly ash, 200 mesh, Hanzhong Zinc Industry Co., Ltd.;

[0036] Heavy and Portland cement, P-C32.5, Sinoma Hanjiang Cement Co., Ltd.;

[0037] NaOH, chemically pure, Tianjin Jinbei Fine Chemical Co., Ltd.;

[0038] Benzyl alcohol, chemically pure, Xi'an Miura Fine Chemical Factory;

[0039] Epoxy resin, E-44, Xi'an Keda Adhesive Co., Ltd.;

[0040] Ethylenediamine, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0041] Hexamethylenetetramine, chemically pure, Sinopharm Chemical Reagent Co., Ltd.;

[0042] Methyl silicone oil, chemically pure, Chengdu Xiangshun Silicone Co., Ltd.;

[0043] Glass fiber, 20mm, Langfang Yudaya I...

PUM

| Property | Measurement | Unit |

|---|---|---|

| density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com