Soft-package aqueous lithium iron phosphate power battery and making method thereof

A technology for lithium iron phosphate and power batteries, which is applied in the field of flexible packaging water-based lithium iron phosphate power batteries and its preparation, can solve problems such as the shortage of oil-based lithium-ion battery adhesives and reduce battery manufacturing costs, and achieve excellent performance and reduce battery costs. cost, cost reduction effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

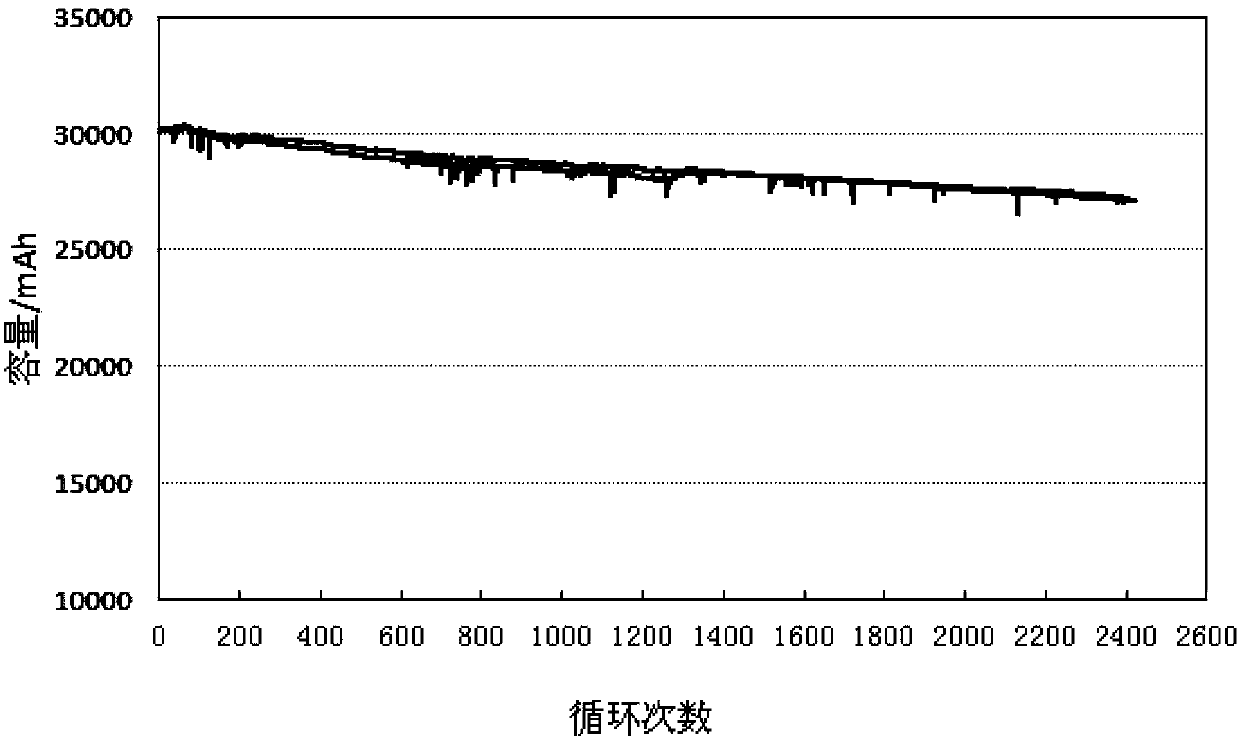

[0034] The specification and model of the battery is HPPF10173248 / 3.2V / 30Ah.

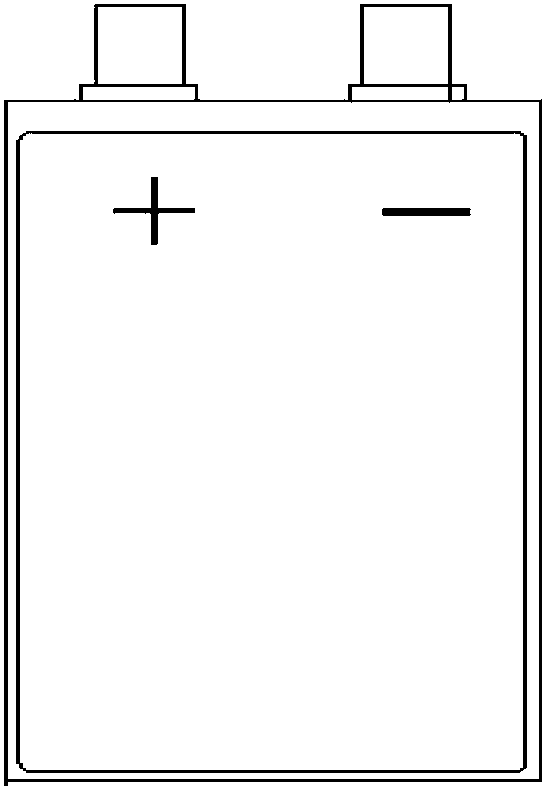

[0035] The following takes the preparation process of HPPF10173248 / 3.2V / 30Ah battery as an example to illustrate, the shape of the battery and the pole pieces are as follows: figure 1 with 2 As shown, the positive electrode material of the battery includes lithium iron phosphate, super-P (conductive carbon black), KS-6 (conductive graphite), LA133 (aqueous dispersion of acrylonitrile multi-polymer copolymer), deionized water, and its mass The ratio is 91:4:2:3:80; the negative electrode material includes mesophase carbon microspheres, super-P, styrene-butadiene rubber, sodium carboxycellulose, and the mass ratio of deionized water is 95:2:2:1:130 .

[0036] The positive electrode of the battery uses aluminum foil with a thickness of 25 μm, and the negative electrode uses copper foil with a thickness of 16 μm; the positive tab is an aluminum strip or an aluminum-nickel strip with a thickness of 0.2...

Embodiment 2

[0043] The specification and model of the battery is HPPF60100131 / 3.2V / 5Ah.

[0044] The following takes the preparation process of HPPF60100131 / 3.2V / 5Ah battery as an example to illustrate, the shape of the battery and the pole pieces are as follows: Figure 4 with Figure 5 As shown, the positive electrode material includes lithium iron phosphate, super-P, KS-6, LA133, deionized water, and its mass ratio is 86:2:2:10:90; the negative electrode material includes mesophase carbon microspheres, super-P , styrene-butadiene rubber, sodium carboxycellulose, deionized water, the mass ratio is 91:2:5:2:110.

[0045]The positive electrode of the battery uses aluminum foil with a thickness of 15 μm, and the negative electrode uses copper foil with a thickness of 9 μm; the positive tab is an aluminum strip or an aluminum-nickel strip with a thickness of 0.3 mm and a width of 20 mm; the negative tab is nickel-plated copper with a thickness of 0.3 mm. The width is 20mm; the thickness o...

Embodiment 3

[0052] In the positive electrode material of the battery, the mass ratio of lithium iron phosphate, super-P (conductive carbon black), KS-6 (conductive graphite), LA133 (aqueous dispersion of acrylonitrile multi-polymer copolymer), and deionized water is 85:5 :2:8:70;

[0053] In the negative electrode material, the active material is graphite, and the mass ratio of the graphite, super-P, styrene-butadiene rubber, sodium carboxycellulose, and deionized water is 93:1:4:2:120;

[0054] The positive electrode of the battery uses aluminum foil with a thickness of 20 μm, and the negative electrode uses copper foil with a thickness of 15 μm; the positive tab is an aluminum strip or an aluminum-nickel strip with a thickness of 0.2 mm and a width of 40 mm; the negative tab is nickel-plated copper with a thickness of 0.2 mm. The width is 40mm; the thickness of the aluminum-plastic film is 0.152mm.

[0055] Others are the same as embodiment 1.

[0056] In this example, we have changed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com