Cement wall component and manufacturing process thereof

A production process, cement technology, applied in the direction of building components, ceramic products, building structures, etc., can solve the problems of unfavorable environmental protection, poor thermal insulation effect, no sound insulation, etc., to improve corrosion resistance, increase thermal inertia, and prevent heat transfer Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

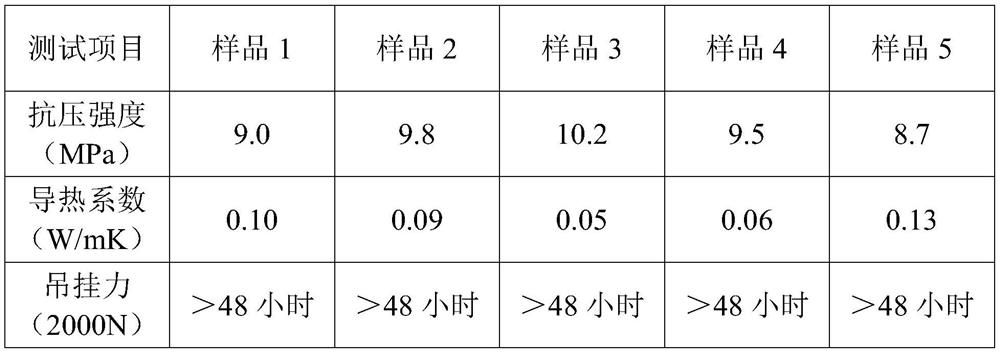

Examples

Embodiment 1

[0033] An embodiment of the present invention provides a cement wall component, comprising the following raw materials:

[0034] 15kg of cement, 10kg of micro-nano silicon powder, 15kg of calcium chloride hexahydrate / expanded graphite phase change material, 7kg of foaming agent, 1kg of foam stabilizer, 5kg of water-soluble resin powder and 10kg of toughening agent.

[0035] The embodiment of the present invention also provides a manufacturing process of the above-mentioned cement wall component, comprising the following steps: grinding and sieving the ceramsite to obtain fine particles, the mesh number of the sieving is 3 mesh; adding water to the foaming agent and foam stabilizer Foam to obtain a foam slurry, the solid content of the foam slurry is 10%; add the remaining raw materials except water-soluble resin powder to the foam slurry and stir at 50°C for 10 minutes to obtain a mixed solution, add the water-soluble resin to the mixed solution and stir Dry at a temperature o...

Embodiment 2

[0037] An embodiment of the present invention provides a cement wall component, comprising the following raw materials:

[0038] 30kg of cement, 20kg of micro-nano silicon powder, 25kg of phase change material, 15kg of foaming agent, 2kg of foam stabilizer, 10kg of water-soluble resin powder, 70kg of ceramsite and 15kg of metal fiber.

[0039] The embodiment of the present invention also provides a manufacturing process of the above-mentioned cement wall component, which includes the following steps: grinding and sieving the ceramsite to obtain fine particles, the mesh number of which is 10 mesh; adding water to the foaming agent and foam stabilizer Foam to obtain a foam slurry, the solid content of the foam slurry is 5%; add the remaining raw materials except water-soluble resin powder to the foam slurry and stir at 70°C for 15 minutes to obtain a mixed solution, add the water-soluble resin to the mixed solution and stir Dry at a temperature of 50° C. to obtain a cement wall ...

Embodiment 3

[0042] An embodiment of the present invention provides a cement wall component, comprising the following raw materials:

[0043] 23kg of cement, 14kg of micro-nano silicon powder, 20kg of phase change material, 10kg of foaming agent, 1.3kg of foam stabilizer, 8kg of water-soluble resin powder, 45kg of ceramsite and 12kg of copper fiber.

[0044] The embodiment of the present invention also provides a manufacturing process of the above-mentioned cement wall component, which includes the following steps: grinding and sieving ceramsite to obtain fine particles, the mesh number of sieving is 5 mesh; adding water to the foaming agent and foam stabilizer Foam to obtain a foam slurry, the solid content of the foam slurry is 8%; add the remaining raw materials except water-soluble resin powder to the foam slurry and stir at 60°C for 13 minutes to obtain a mixed solution, add the water-soluble resin to the mixed solution and stir The cement wall component can be obtained.

[0045] It ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com