Calcination-free phosphogypsum brick and manufacturing method thereof

A production method and calcination-free technology, which is applied in the field of building materials, can solve the problems that phosphogypsum is difficult to be used, occupies a large amount of land, and air pollution, etc., and achieves the effects of high flexural strength, increased utilization rate, and reduced pollution rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

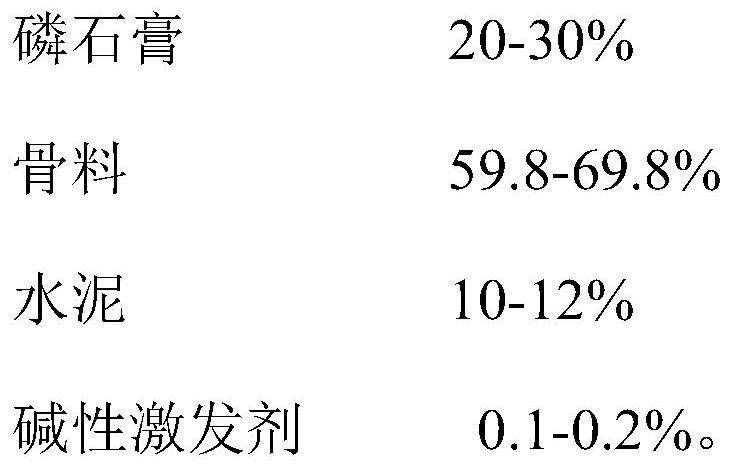

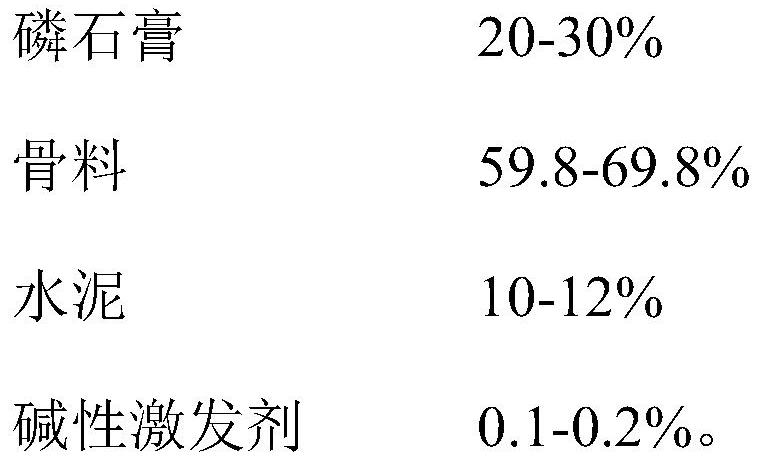

Method used

Image

Examples

Embodiment Construction

[0025] The following specific examples further illustrate the present invention, so that those skilled in the art can better understand the present invention and implement it, but the given examples are not intended to limit the present invention.

[0026] The aggregate contains active SiO2 and Al2O3, which can react with Ca(OH)2 to produce C-S-H gel and calcium sulfate hydrate, and increase the relationship between the components in the PGS (phosphogypsum-based cementitious material) solidified body and the fine aggregate. The bonding of phosphogypsum bricks improves the compactness of phosphogypsum bricks; the alkaline activator increases the alkalinity of the PGS system, neutralizes the acid of phosphogypsum, promotes the hydration of the phosphogypsum system, shortens the setting time, and improves the compactness and strength of PGS and water resistance; under the stimulation of sulfate, activator and cement, the aggregate generates a large number of flocs, covering each c...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| Power level | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com