Preparation and formula of high-strength, high-toughness and low-density wood fiber calcium silicate board

A high-strength, high-toughness, calcium silicate board technology, which is applied in the field of building materials, can solve the problems of board strength decline, low density, high strength, high toughness, and high cost, and achieve improved impact strength, improved bonding ability, and reduced water absorption. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

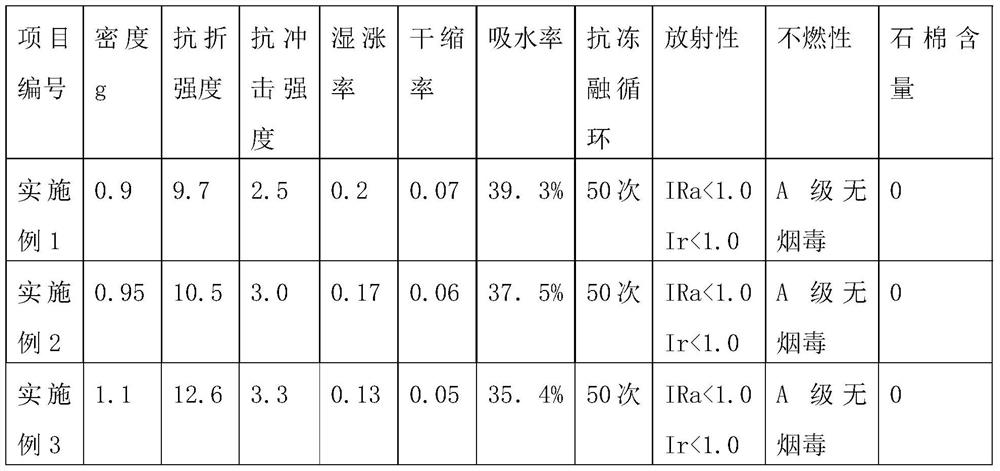

Examples

preparation example Construction

[0027] Preparation method of high-strength, high-toughness and low-density wood fiber calcium silicate board:

[0028] Step 1): Add 5000-9000L of lime water with a concentration of 0.1-0.3% in the dissolution tank, feed the steam discharged during the depressurization of the autoclave, and add wood fiber into the dissolution tank with a solid content of 8%-15%. Stir for 1-2 hours and let it stand, release the upper layer of oil and part of the dissolved water, continue to feed the recovered steam, and pass through 3-4 cycles of stirring and feeding the recovered steam to obtain wood fibers that are initially decolorized and organic matter removed, and the concentration is 5- 10% wood fiber;

[0029] Step 2): The wood fiber after step 1) is passed through the first delivery pump to the storage tank to keep stirring and standby;

[0030] Step 3): Pass the part of the wood fiber treated in step 2) through a carding machine for carding treatment, and pass through the pulp of 23-3...

Embodiment 1

[0049]The calcium silicate board is made of the following raw materials by weight ratio, 0.77% wood fiber, 0.009% wood fiber activator calculated according to the quality of wood fiber, 0.8% pulp, 2.9% cement, 5.8% quartz powder, 1% lime, 0.08% wollastonite, 1% silica fume, 0.16% mineral fiber and 87.4% water.

Embodiment 2

[0051] The calcium silicate board is made of the following raw materials in weight ratio, 0.9% wood fiber, 0.01% wood fiber activator calculated according to the quality of wood fiber, 0.8% pulp, 2.6% cement, 5.3% quartz powder, 1% lime, 0.08% wollastonite, 1% silica fume, 0.1% mineral fiber and 88.2% water.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com