High flexural strength composite Portland cement and preparation method thereof

A technology of composite Portland and Portland cement, which is applied in the field of building materials, can solve the problems of limited improvement range, decrease in compressive strength, excessive addition, etc. The effect of improving the structural strength in all directions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0041] A preparation method of high flexural composite Portland cement, the preparation method of high flexural composite Portland cement is used to prepare the high flexural composite Portland cement described in any one of the above, the high flexural composite The preparation method of Portland cement comprises the following steps:

[0042] Step 1: Taking materials according to the following proportions by weight of raw materials: 35-65 parts of Portland cement clinker, 17.5-40 parts of calcined clay, 10-22.5 parts of limestone, and 2.5-5 parts of gypsum;

[0043] Step 2: Mix the raw materials obtained in Step 1 except calcined clay, and grind them together until the specific surface area is 380-500m 2 / kg;

[0044] Step 3: Separately grind the calcined clay raw material obtained in Step 1 to a specific surface area of 550-900m 2 / kg;

[0045] The present invention adopts separate grinding, calcined clay is a soft material, and clinker and limestone are hard materials....

Embodiment 1-3 and comparative Embodiment 1-3

[0051] The components of Portland cement clinker, calcined clay and low-grade limestone are shown in Table 1:

[0052] Table 1: Raw material composition

[0053] raw material loss SiO 2

Al 2 o 3

Fe 2 o 3

CaO MgO SO 3

K 2 o

Na 2 o

TiO 2

Total Clinker 1 0.33 23.16 5.21 3.31 63.31 2.92 0.62 0.64 0.13 0.00 99.65 Calcined Clay 1 0.67 66.77 25.82 1.36 3.11 0.96 0.13 0.04 0.11 0.71 99.69 Limestone 1 36.38 13.06 0.58 0.24 46.02 1.01 0.52 0.13 0.02 1.80 99.76 plaster 1 21.39 6.66 2.22 0.83 29.32 1.82 38.04 0.44 0.11 0.10 100.98

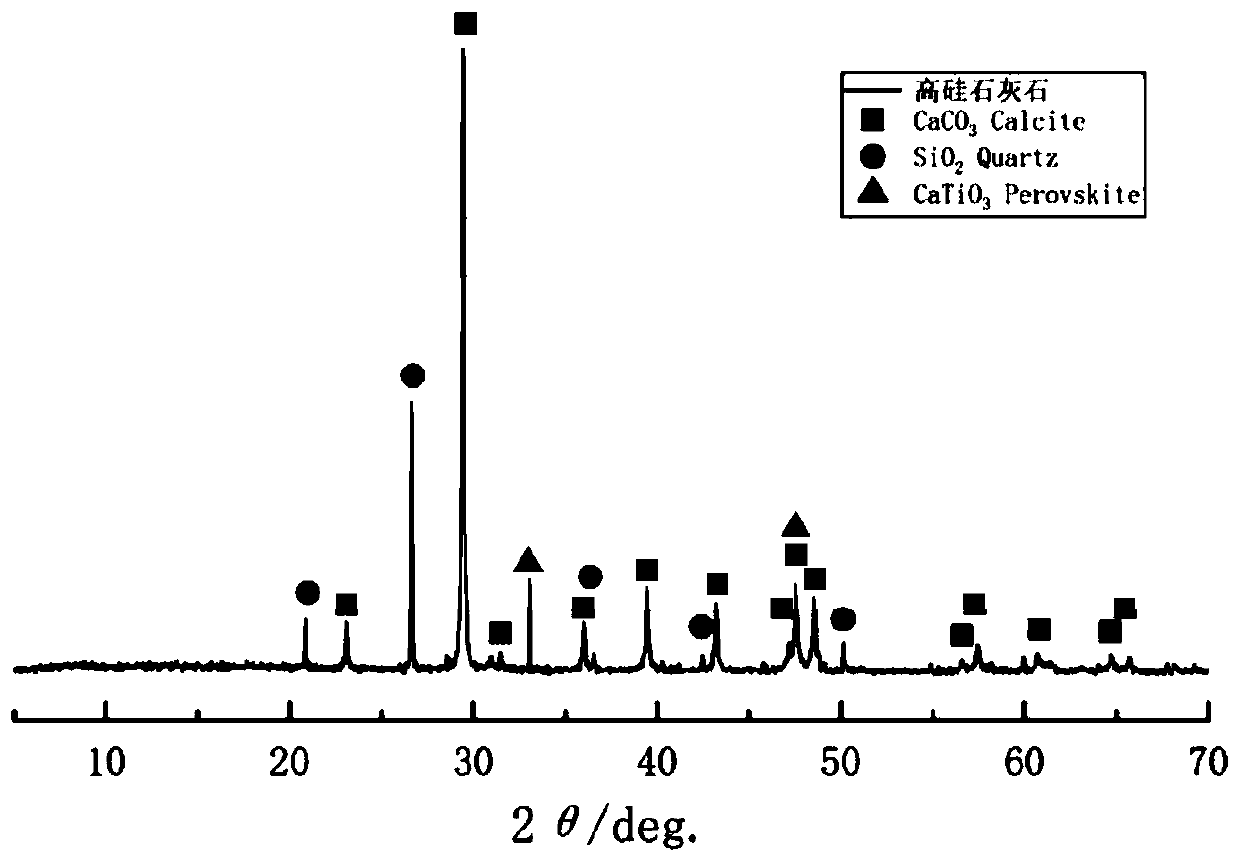

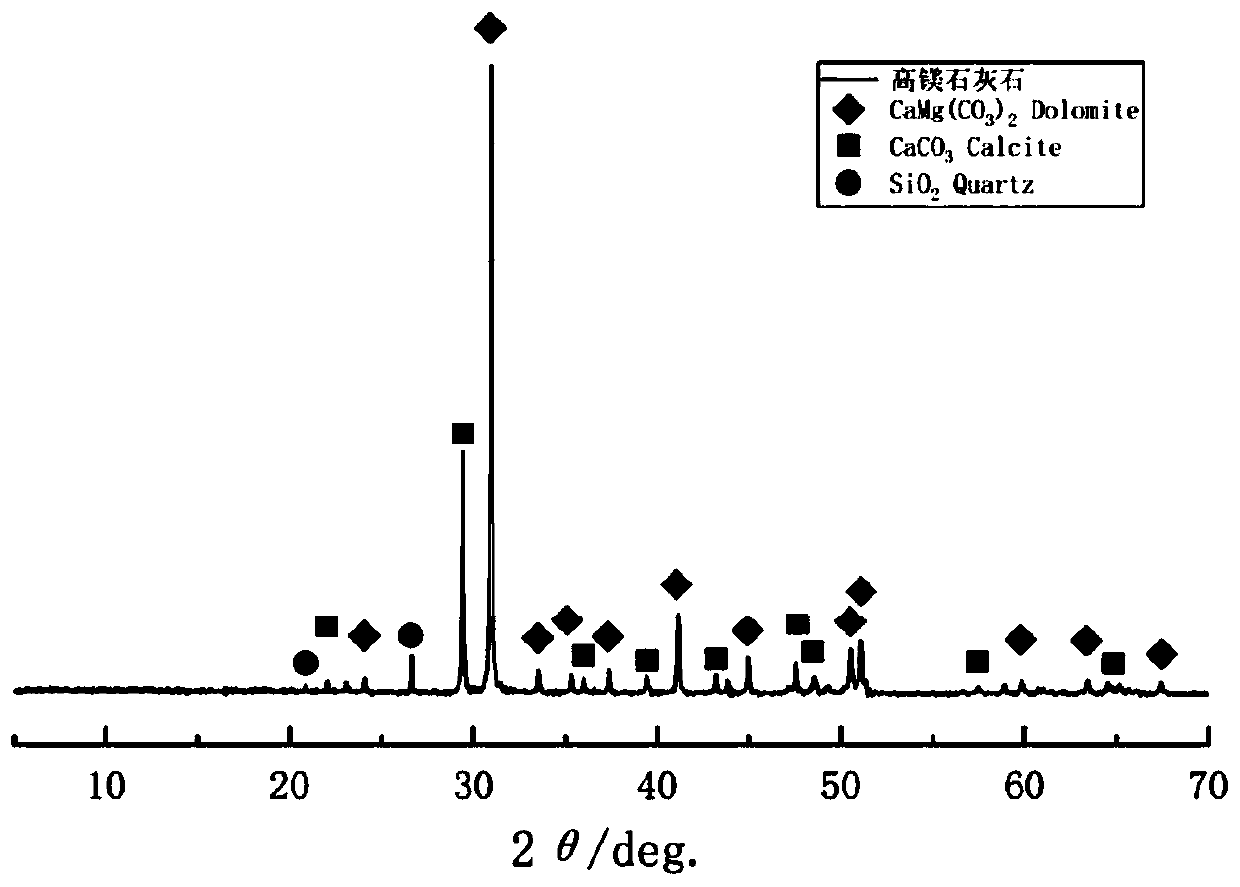

[0054] For the mineral composition analysis of limestone 1, please refer to the attached figure 1 According to X-ray diffraction analysis, the main mineral contained in limestone 1 is calcite, followed by quartz, and then perovskite.

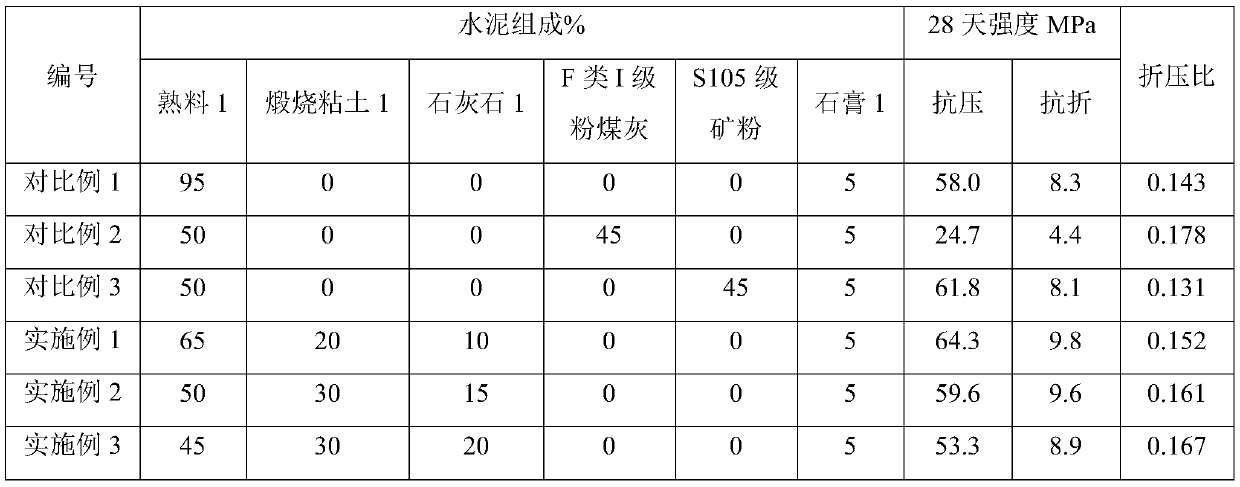

[0055] According to the proportions of the examples and comparative examples listed in Table 2,...

Embodiment 2

[0059] Embodiment 2 and comparative examples 2 and 3, that is, the high-bending composite Portland cement of the present invention is compared with the existing high-quality fly ash and ground slag powder of the same clinker coefficient of 0.50 to prepare composite Portland cement. The flexural strength that the invention focuses on is significantly improved, and the compressive strength is also very good, which reflects the improvement of the performance of the existing traditional materials by the present invention.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com