Low-carbon magnesia carbon brick with oxidation resistance and preparation method thereof

A technology of anti-oxidation performance and carbon-magnesium-carbon bricks, applied in the field of refractory materials, can solve the problems of product structure deterioration, reducing the service life of MgO-C bricks, corroding MgO particles, etc., and achieving high thermal shock stability and anti-oxidation performance. Good, improve antioxidant effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

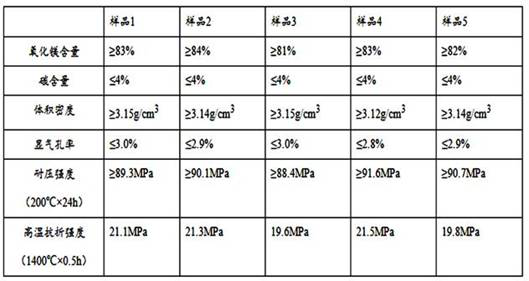

Examples

preparation example Construction

[0031] The present invention also provides a method for preparing low-carbon magnesia-carbon bricks with anti-oxidation properties as described in any one of the above, comprising the following preparation steps:

[0032] After dry mixing the fused magnesia, add resin, the speed of adding resin is 15kg / min, then add -196 graphite, mix for 5-10min, add high temperature asphalt, after stirring, finally add metal aluminum powder and ZrB 2 -Cr 7 C 3 Composite materials, after stirring evenly, obtain low-carbon magnesia-carbon brick preparation materials;

[0033] The low-carbon magnesia-carbon brick preparation material is put into the mold, pressed and formed to obtain brick embryos;

[0034] The brick embryos are pushed into a heat treatment kiln for heat treatment to obtain low-carbon magnesia carbon bricks.

[0035] Preferably, during pressing, a 1000T electric screw press is used for pressing; during heat treatment, the temperature inside the heat treatment kiln is 180°C-2...

Embodiment 1

[0039] Preparation of low-carbon magnesia-carbon bricks with excellent oxidation resistance (sample 1):

[0040] In parts by weight, it includes 95 parts of fused magnesia, 1 part of metal aluminum powder, 3 parts of liquid phenolic resin, ZrB 2 -Cr 7 C 3 1 part of composite material, 1 part of high-temperature pitch and 2 parts of -196 graphite.

[0041] 101) According to the parts by weight, after dry mixing the fused magnesia, add liquid phenolic resin, the liquid phenolic resin is added at a rate of 10~15kg / min, then add -196 graphite, mix for 5-10min, add high temperature asphalt, After stirring, finally add metal aluminum powder and ZrB 2 -Cr7 C 3 Composite materials, after stirring evenly, obtain low-carbon magnesia-carbon brick preparation materials;

[0042] 102) The low-carbon magnesia-carbon brick preparation material is put into the mould, pressed and formed, and the brick embryo is obtained;

[0043] 103) Push the brick embryo into a heat treatment kiln for ...

Embodiment 2

[0048] Preparation of low-carbon magnesia-carbon bricks with excellent oxidation resistance (sample 2):

[0049] In parts by weight, it includes 94 parts of fused magnesia, 1 part of metal aluminum powder, 3 parts of liquid phenolic resin, ZrB 2 -Cr 7 C 3 2 parts of composite material, 1 part of high-temperature pitch and 2 parts of -196 graphite.

[0050] 201) According to the number of parts by weight, after dry mixing the fused magnesia, add liquid phenolic resin, the liquid phenolic resin is added at a rate of 10~15kg / min, then add -196 graphite, mix for 5-10min, add high temperature asphalt, After stirring, finally add metal aluminum powder and ZrB 2 -Cr 7 C 3 Composite materials, after stirring evenly, obtain low-carbon magnesia-carbon brick preparation materials;

[0051] 202) The low-carbon magnesia-carbon brick preparation material is put into the mould, pressed and formed to obtain the brick embryo;

[0052] 203) Push the brick embryo into a heat treatment kil...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com