Preparation method of Bi2O2SiO3-Si2Bi24O40-BiOX double-heterojunction composite photocatalyst

A double-heterojunction and recombination light technology, applied in the field of materials, can solve the problems of insufficient response wavelength range and limit the large-scale application of bismuth-based photocatalysts, and achieve the effects of improving photocatalytic performance, easy control, and high purity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

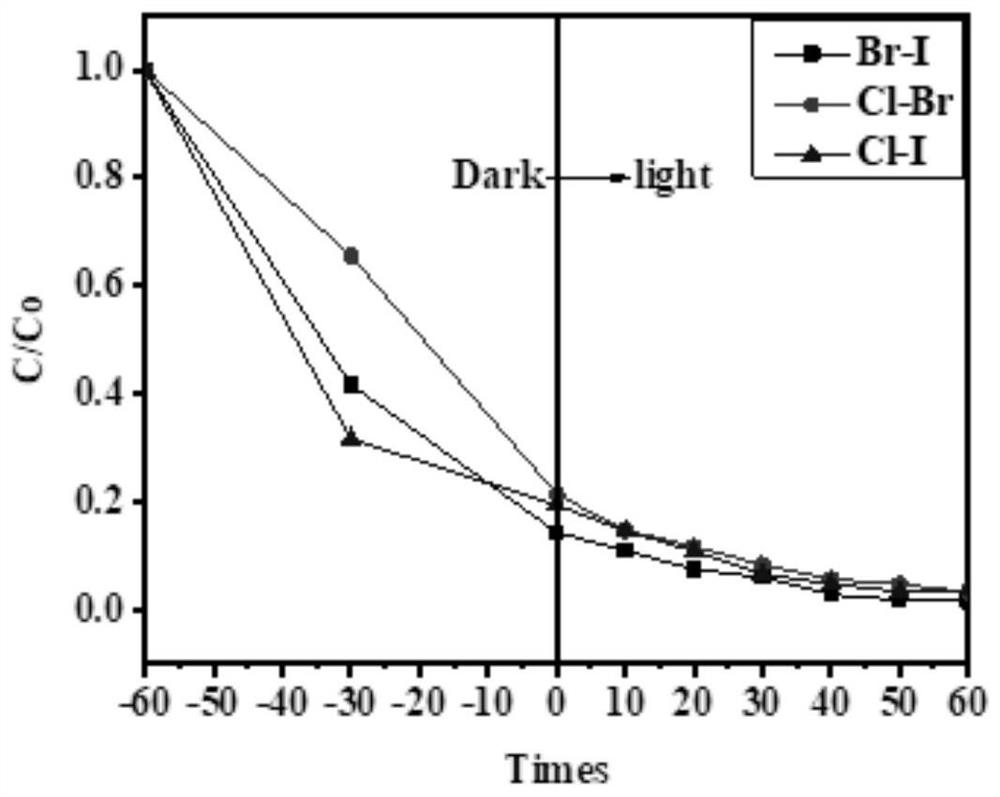

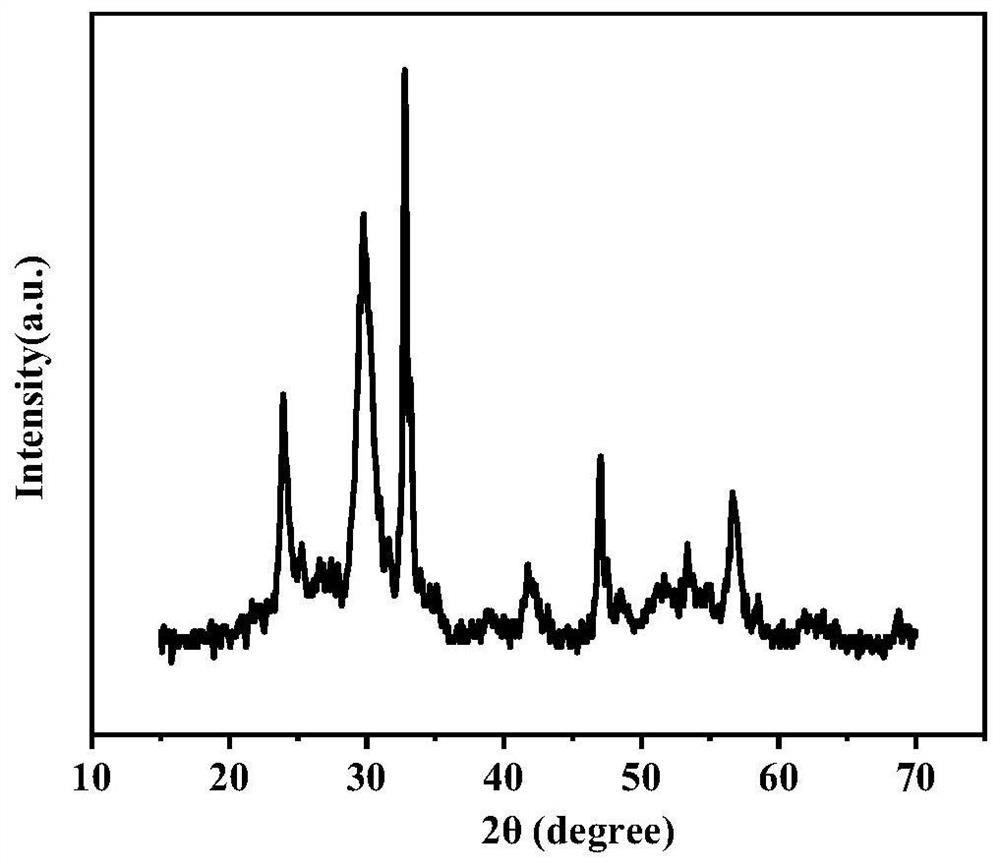

Image

Examples

Embodiment 1

[0025] (1) Dissolve a certain amount of bismuth nitrate in deionized water (concentration control is 0.6mmol / L) by stirring for 15min, and add a certain amount of polyethylene glycol 400 (volume ratio of it to bismuth nitrate solution) in the stirring process 1:1), the resulting solution is recorded as liquid A; at the same time, a certain amount of sodium metasilicate nonahydrate (n Bi / Si =(1:1) was dissolved in deionized water by stirring for 15 min, and the resulting solution was designated as liquid B. Slowly add liquid B into liquid A dropwise, and continue to stir for about 30 minutes until the solution presents a uniform white emulsion, that is, the precursor solution is obtained.

[0026] (2) The precursor solution was reacted at 180°C for 12h, then naturally cooled to room temperature, the obtained samples were collected and washed alternately with deionized water and absolute ethanol three times each, and then dried at 80°C for 12h to obtain BSO powder body.

[002...

Embodiment 2

[0032] (1) Dissolve a certain amount of bismuth nitrate in deionized water (concentration control is 0.6mmol / L) by stirring for 15min, and add a certain amount of polyethylene glycol 400 (volume ratio of it to bismuth nitrate solution) in the stirring process 1:1), the resulting solution is recorded as liquid A; at the same time, a certain amount of sodium metasilicate nonahydrate (nBi / Si =(1:1) was dissolved in deionized water by stirring for 15 min, and the resulting solution was designated as liquid B. Slowly add liquid B into liquid A dropwise, and continue to stir for about 30 minutes until the solution presents a uniform white emulsion, that is, the precursor solution is obtained.

[0033] (2) The precursor solution was reacted at 180°C for 12h, then naturally cooled to room temperature, the obtained samples were collected and washed alternately with deionized water and absolute ethanol three times each, and then dried at 80°C for 12h to obtain BSO powder body.

[0034]...

Embodiment 3

[0039] (1) Dissolve a certain amount of bismuth nitrate in deionized water (concentration control is 0.6mmol / L) by stirring for 15min, and add a certain amount of polyethylene glycol 400 (volume ratio of it to bismuth nitrate solution) in the stirring process 1:1), the resulting solution is recorded as liquid A; at the same time, a certain amount of sodium metasilicate nonahydrate (n Bi / Si =(1:1) was dissolved in deionized water by stirring for 15 min, and the resulting solution was designated as liquid B. Slowly add liquid B into liquid A dropwise, and continue to stir for about 30 minutes until the solution presents a uniform white emulsion, that is, the precursor solution is obtained.

[0040] (2) The precursor solution was reacted at 180°C for 12h, then naturally cooled to room temperature, the obtained samples were collected and washed alternately with deionized water and absolute ethanol three times each, and then dried at 80°C for 12h to obtain BSO powder body.

[004...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com