Patents

Literature

121 results about "Sodium metasilicate nonahydrate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and production method thereof

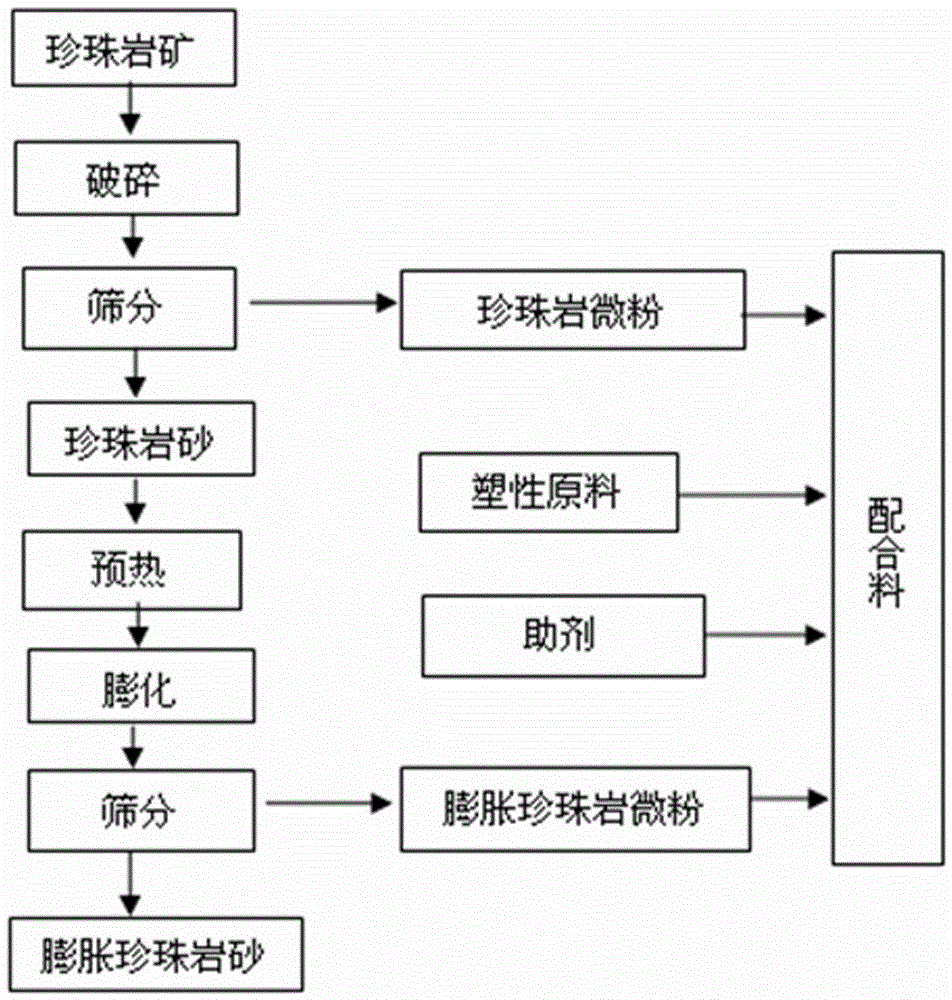

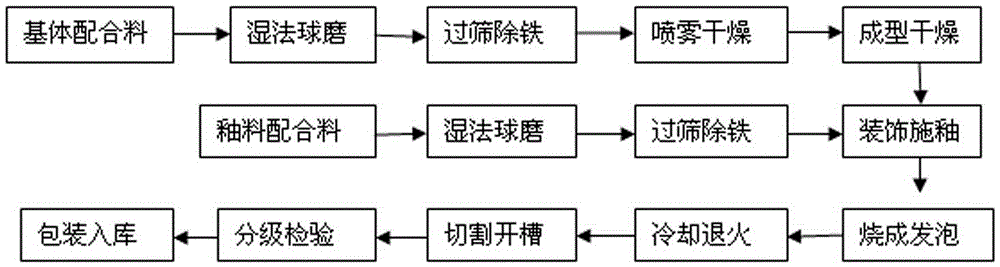

The invention discloses a thermal insulating decorative ceramic plate produced by comprehensive utilization of perlite waste and a production method thereof. A matrix formula consists of: 25%-100% of perlite micropowder, 20%-80% of expanded perlite micropowder, 2%-25% of Guangdong black mud, 0%-10% of limestone, 0.1%-5% of fluorite, 0.1%-2% of black silicon carbide, 0.5%-15% of bentonite, 0.1%-5% of sodium metasilicate nonahydrate, 0.1%-0.5% of sodium humate, and 0.1%-1.0% of sodium tripolyphosphate. A glaze formula consists of: 50-90% of expanded perlite powder, 50-90% of low temperature frit, 0.1-5% of zinc oxide, 0.1-5% of fluorite, 0-5% of apatite, 0.1-2.0% of sodium tripolyphosphate, 0.5-5% of kaolin, and 0.1-0.5% of sodium methyl cellulose. The production method is characterized by naked firing in a roller kiln at a low temperature of 900DEG C-1050DEG C. After firing, the thermal insulating decorative ceramic plate with a water absorption rate of less than 0.5%, a volume density of less than 500kg / m<3>, a rupture modulus of greater than 3.5Mpa, a thermal conductivity coefficient of less than 0.08 / W / (m.k), and a combustion level of A can be obtained.

Owner:XINYANG KEMEI NEW MATERIALS

Method for treating ammonia nitrogen wastewater

InactiveCN102001721AScientific and reasonable processEasy to operateWater/sewage treatment by irradiationWater/sewage treatment by sorptionActivated carbonPotassium hydroxide

The invention relates to a method for treating ammonia nitrogen wastewater, which comprises the steps of: removing ammonia nitrogen under the irradiation of a microwave field; before removing the ammonia nitrogen, sequentially measuring the ammonia nitrogen concentration of the ammonia nitrogen wastewater and adding the operation of modifying active carbon, wherein the ammonia nitrogen mass ratioof the modified active carbon to the ammonia nitrogen wastewater is 2-212:1; adding the modified active carbon to the ammonia nitrogen wastewater to form a liquid and solid mixture solution; and removing the ammonia nitrogen of the liquid and solid mixture solution under the irradiation of the microwave field. The modified active carbon is used for modifying active carbon by using one or more of sodium hydroxide, potassium hydroxide, sodium chloride, potassium chloride, sodium metasilicate nonahydrate, hydrochloric acid and sulfuric acid. The time for removing the ammonia nitrogen under the irradiation of the microwave field is 4-15min, and the temperature is 50-117 DEG C. The method can also be used for continuously treating the wastewater by using a solid-carrying active carbon modifying method, has the advantages of scientific and reasonable process, low investment and operation cost and high removing efficiency, and is simple and easy to operate.

Owner:XIANGTAN UNIV

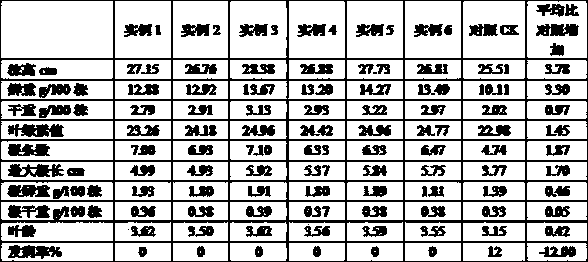

Full-nutrient paddy rice seedling breeding matrix and preparation method thereof

The invention discloses a paddy rice seedling breeding matrix, and belongs to the technical field of soilless culture. The full-nutrient paddy rice seedling breeding matrix is prepared from the following raw materials: decomposed organic manure, turf, clay, zeolite powder or bentonite, vermiculite, fine river sand, rice hull powder or corn straw powder or mushroom residue powder, soybean meal, ammonium sulfate, calcium superphosphate, potassium chloride, magnesium sulfate heptahydrate, zinc sulfate heptahydrate, ferrous sulfate heptahydrate, boric acid, copper sulfate pentahydrate, manganese sulfate monohydrate and sodium metasilicate nonahydrate. The full-nutrient paddy rice seedling breeding matrix disclosed by the invention has the advantages of high fertilizer-retaining property and water-retaining property, good air permeability, high buffering, full nutrient and more persistence in fertility, achieves the pH of 5.0-5.5, and is lower in cost by utilizing agricultural wastes, namely rice hulls, corn straws, mushroom residues and the like, suitable for batch production, good in seedling breeding effect and convenient for a farmer to use.

Owner:NORTHEAST AGRICULTURAL UNIVERSITY

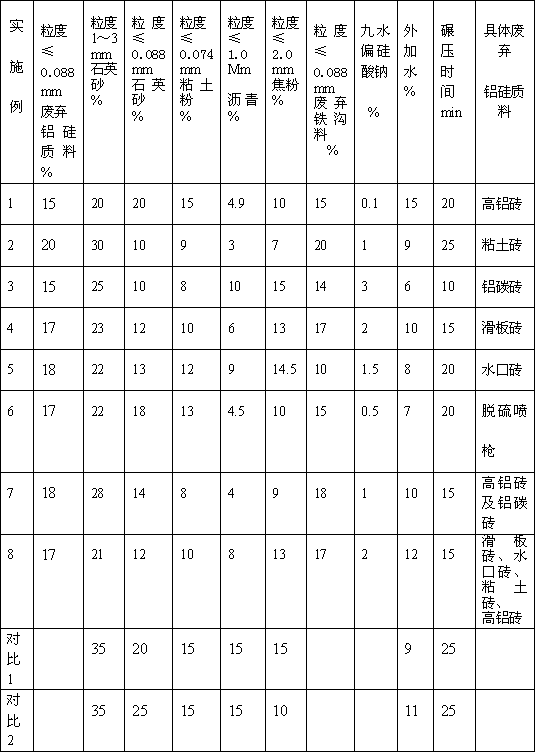

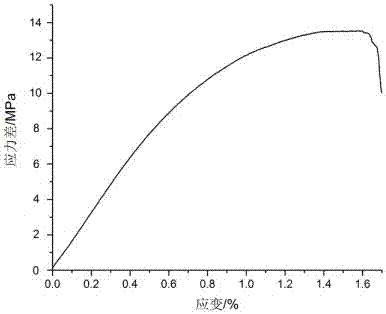

Sand mouth material for blast furnace and preparation method for sand mouth material

The invention relates to a sand mouth material for a blast furnace and a preparation method for the sand mouth material. The sand mouth material comprises the flowing components in percentage by weight: 15 to 20 percent of waste alumina-silica material of which the particle size is less than or equal to 0.088mm, 20 to 30 percent of quartz sand of which the particle size is 1 to 3mm, 10 to 20 percent of quartz sand of which the particle size is less than or equal to 0.088mm, 8 to 15 percent of clay powder of which the particle size is less than or equal to 0.074mm, 3 to 10 percent of asphalt of which the particle size is less than or equal to 1.0mm, 7 to 15 percent of coke powder of which the particle size is less than or equal to 2.0mm, 10 to 20 percent of waste iron runner material fine powder of which the particle size is less than or equal to 0.088mm, and 0.1 to 3 percent of sodium metasilicate nonahydrate. According to the sand mouth material, the production cost can be reduced by at least 20 percent, the compression strength is at least 10 Mpa, the breaking strength is at least 3Mpa, the service life can be prolonged from 8 to 48 hours, the used high-alumina bricks containing the alumina-silica material and the used iron runner materials can be utilized comprehensively, and the occupied areas of the used high-alumina bricks containing the alumina-silica material and the used iron runner material, and the recyclable resources are reduced.

Owner:武汉钢铁有限公司

High-performance moderate-temperature phase-change energy-storage material and preparation method thereof

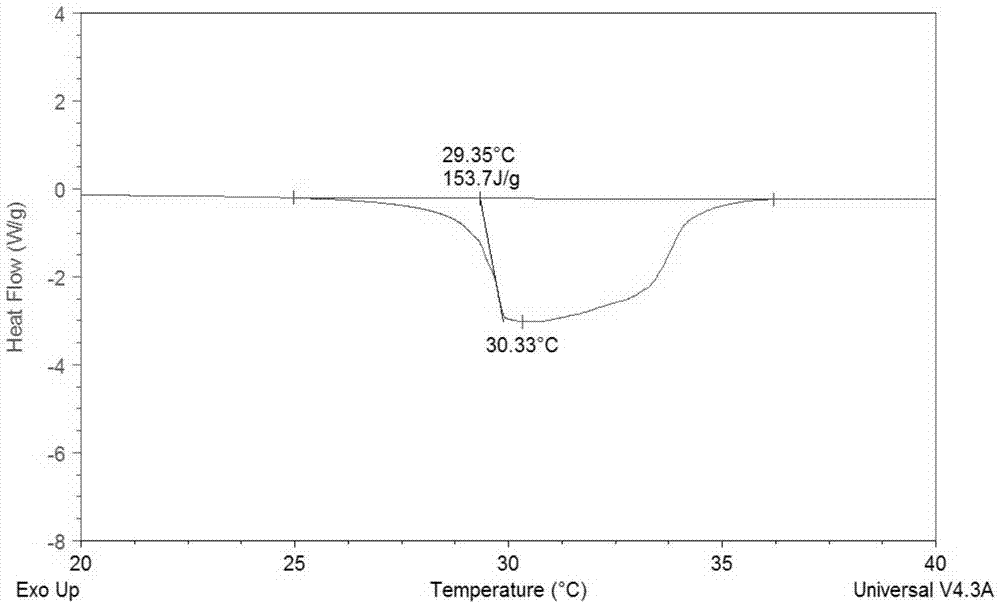

InactiveCN103045175AHigh densityImprove solubilityHeat-exchange elementsSodium phosphatesPhase change

The invention relates to a high-performance moderate-temperature inorganic phase-change energy-storage material and a preparation method thereof. The material comprises the following components by weight percent: 95-99% of sodium phosphate dibasic dodecahydrate and 1-5% of sodium salt additive, wherein the sodium salt additive comprises sodium metasilicate nonahydrate, sodium salt of carboxy methyl-cellulose and sodium polyacrylate. According to the invention, as an improvement of a traditional inorganic phase-change energy-storage material, the material provided by the invention has larger phase change latent heat larger than 210 J / g and appropriate phase change temperature 30-40 DEG C, is an energy storage material with good performance within the temperature range, and has a wide application prospect.

Owner:TIANJIN UNIV OF SCI & TECH

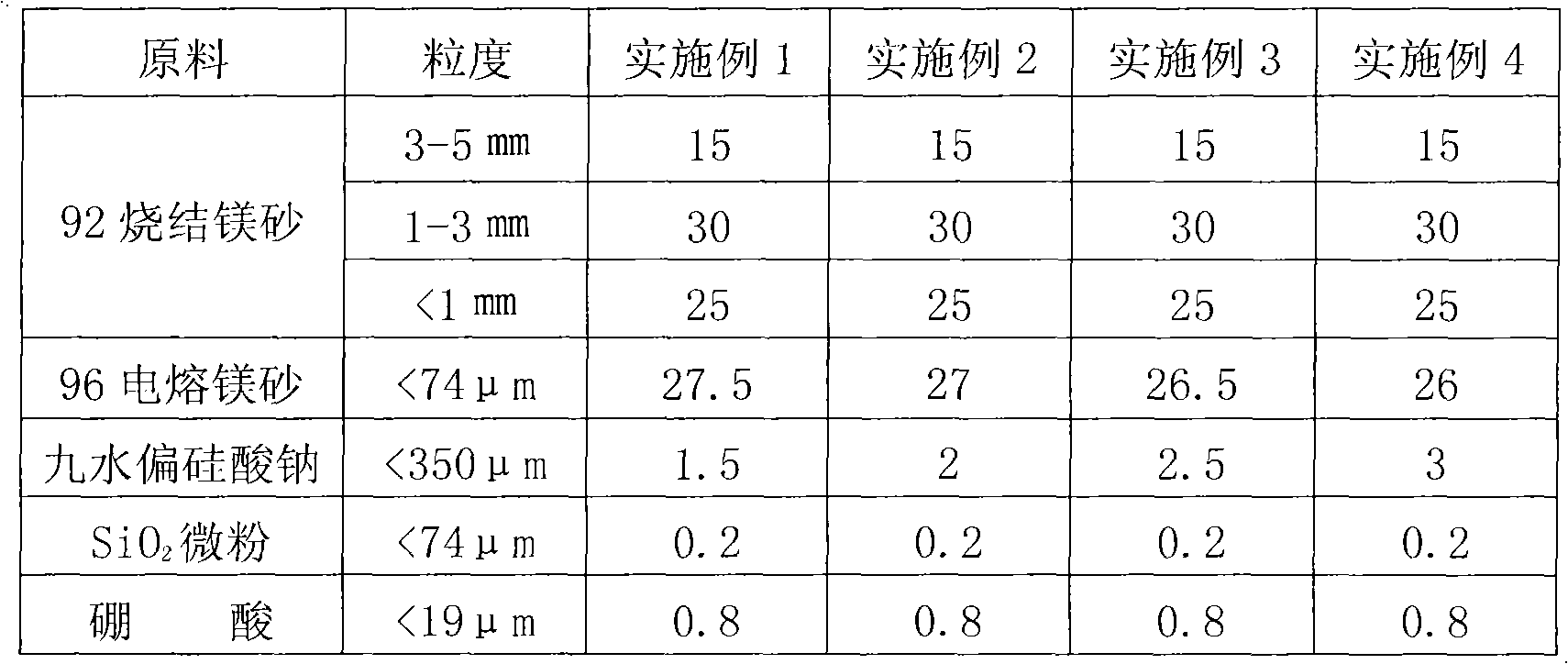

Working lining for continuous cast steel tundish with environmental-friendly binder

The invention discloses a working lining for a continuous cast steel tundish and with environmental-friendly binder; and the raw material components and the content thereof in percentage by weight are as follows: 70 weight percent of 92 sintered magnesia, 26 to 27.5 weight percent of 96 fused magnesia, 0.2 weight percent of SiO2 micro powder, 0.8 weight percent of boric acid, and 1.5 to 3 weight percent of sodium metasilicate nonahydrate. The invention provides the working lining which is first prepared from the dry material binder which comprises sodium metasilicate nonahydrate, micro silica powder and boric acid, eliminates the acieration problem of molten steel, reduces the cost and the environmental pollution, and simultaneously solves the problems of low-temperature strength and high-temperature slag resistance of the dry material.

Owner:TIANJIN UNIV

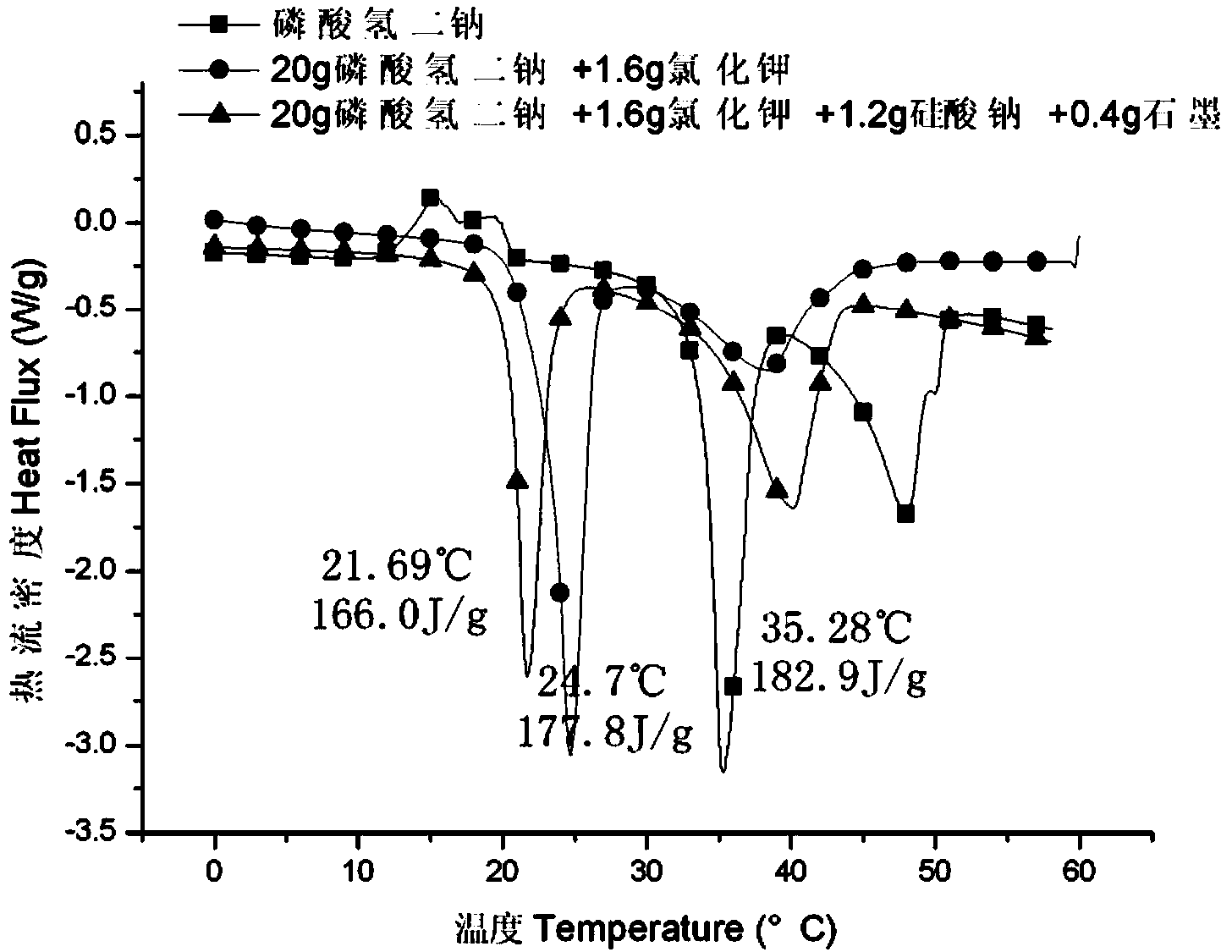

Low-temperature inorganic phase-change heat storage material and preparation method thereof

InactiveCN104004500AEasy to prepareRaw materials are easy to getHeat-exchange elementsPotassiumMaterials science

The invention discloses a low-temperature inorganic phase-change heat storage material and a preparation method thereof. The low-temperature inorganic phase-change heat storage material is prepared from the following raw materials in percentage by mass: 85-90% of disodium hydrogen phosphate dodecahydrate, 5-10% of potassium chloride, 5-8% of sodium metasilicate nonahydrate and 1-5% of graphite, totaling 100%. The phase-change temperature of the inorganic phase-change heat storage material is 25 DEG C or so, the phase-change latent heat value is 170J / g or so, and the degree of supercooling is 0-0.5 DEG C; and the inorganic phase-change heat storage material does not have the phenomenon of phase separation after long-term usage, is suitable for agricultural production greenhouses and agricultural buildings, and can be used for other heat storage and cold storage systems.

Owner:NORTHWEST A & F UNIV

Low-temperature calcium chloride hexahydrate heat-storage material and preparation method

InactiveCN103923613AHigh phase change enthalpyPhase transition temperature is suitableHeat-exchange elementsCelluloseCalcium Chloride Hexahydrate

The invention discloses a low-temperature calcium chloride hexahydrate heat-storage material and a preparation method. The prepared low-temperature calcium chloride hexahydrate phase-change heat-storage material comprises a nucleating agent and a thickener according to mass percent, wherein the nucleating agent is borax, alumina or sodium metasilicate nonahydrate, the thickener is sodium carboxymethl cellulose (CMC), wherein calcium chloride hexahydrate is a phase-change base material, and the usage amount of the calcium chloride hexahydrate is 95%-98%; the preparation method comprises the step of: respectively adding 1wt% of borax and 1% of CMC or 1% alumina and 4% of CMC or 1% of sodium metasilicate nonahydrate and 2% CMC for modifying the calcium chloride hexahydrate, to obtain the low-temperature calcium chloride hexahydrate heat-storage material. The phase-change latent heat of the low-temperature calcium chloride hexahydrate heat-storage material is about 150J / g, the phase-change temperature of the low-temperature calcium chloride hexahydrate heat-storage material is at 25-30DEG C, the cooling degree is less than 2DEG C, and the heat suction and release performances of the low-temperature calcium chloride hexahydrate heat-storage material after being circulated for 3000 times are stable. The low-temperature calcium chloride hexahydrate heat-storage material has excellent application prospects in agricultural facilities and residential housing.

Owner:NORTHWEST A & F UNIV

Primary crystallization hydrothermal preparation method of A-type and X-type molecular sieves containing pure Na ions

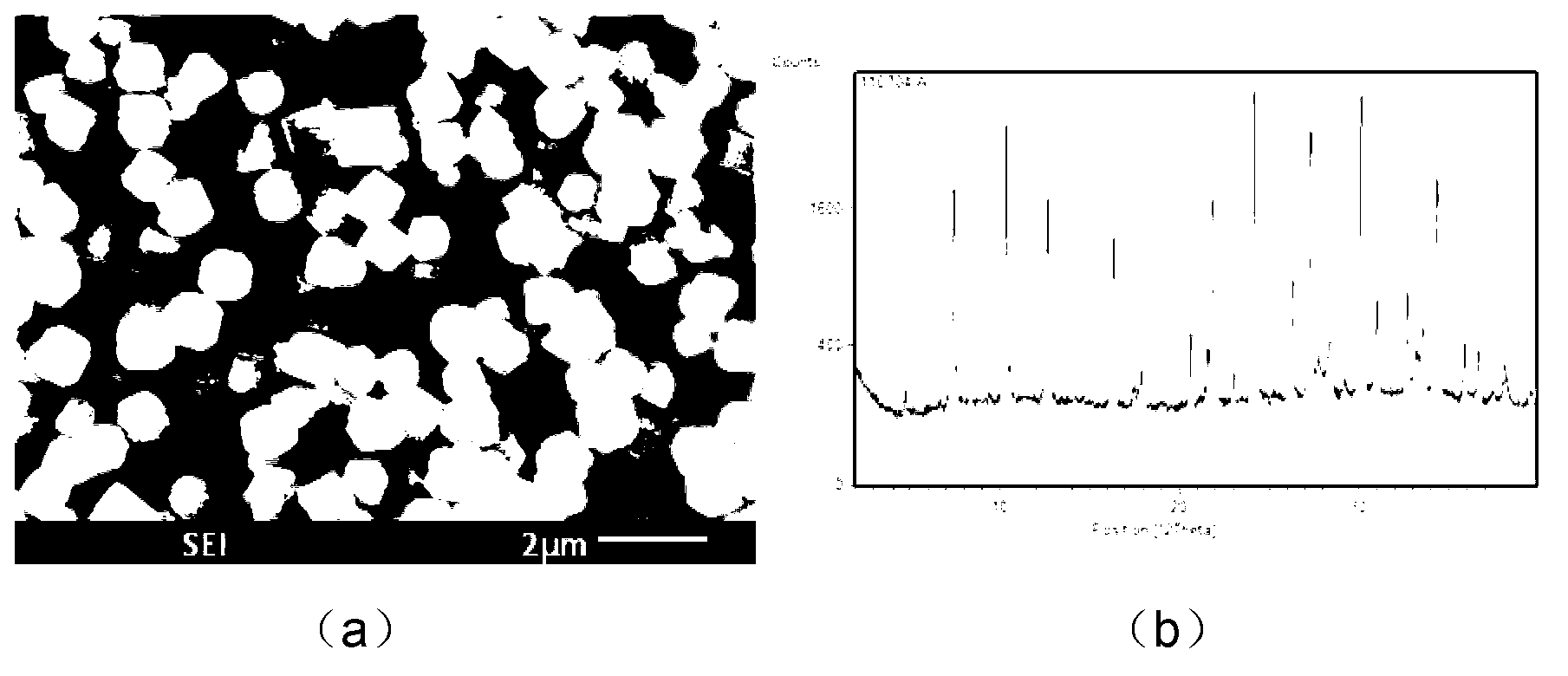

InactiveCN102838127AEasy to getEasy to synthesizeFaujasite aluminosilicate zeoliteAluminosilicate zeolite type-AMolecular sieveMicrometer

The invention belongs to the technical field of microporous molecular sieve preparation, in particular to a primary crystallization hydrothermal preparation method of NaA and NaX microporous molecular sieves with adsorption cations which are all Na ions without a template agent, a guide agent and aging time. According to the preparation method, sodium aluminate (NaAlO2), sodium hydroxide (NaOH), sodium metasilicate nonahydrate (NA2SiO3.9H2O) and deionized water are used for synthesis, and two solutions based on a silicon source and an aluminum source are respectively prepared by synthetic steps; and the two solutions are uniformly stirred and then mixed, and after the mixed solution is persistently stirred for a period of time, the mixed solution is crystallized for several days in a high-temperature oven to obtain the NaA and NaX microporous molecular sieves with the adsorption cations which are all Na ions. The preparation method has the advantages of simple synthetic process, easiness of operation, convenience in industrialized production, commonality and easiness of obtaining reaction raw materials and low production cost, and the sizes of sample particles are 0.7-11 micrometers, so that the NaA and NaX microporous molecular sieves are moderate in sizes and convenient to use.

Owner:KEY LAB OF INORGANIC SYNTHESIS & PEPARATIVE CHEM AT JILIN UNIV IN ZHUHAI

Wood treatment solution and process

InactiveUS20090130475A1Less-expensive to manufactureBiocideWood treatment detailsSolubilitySodium metasilicate

The present invention features a single aqueous solution that imparts acceptable levels of water resistance, fire resistance, mold resistance and pest resistance to wood, and which may be used in standard wood treatment techniques commonly utilized in the wood treatment industry. In one preferred embodiment, the aqueous solution comprises a fire retardant, preferably sodium metasilicate nonahydrate (about 5% to 30% by mass), an insect and termite repellant, preferably sodium tetraborate decahydrate, also known as borax, (about 1.5% to 9% by mass), a mold inhibitor, preferably thymol (about 0.01% to 0.1% by mass) or ethanolamine (about 0.5% to 20% by mass), and a pH buffer, preferably sodium carbonate (about 1% to 10% by mass). It is believed that the borate / silicate components polymerize upon drying, and become water insoluble, which in turn prevents leaching and provides water repellent characteristics to the wood after treatment. It has been observed that the sodium carbonate may also act as a mold inhibitor, so that the ethanolamine and thymol may be optional ingredients in the solution. The calcium carbonate, in addition to serving as a buffer and imparting some mold and mildew inhibiting properties, is thought to also serve as a catalyst that maintains the water solubility before and during the immersion (impregnation) step, and helps to polymerize the silicate / borate compounds during the drying step. The aqueous solution should have a pH in the range of 9.5 and 13. Additionally, a powder mixture of the above-recited components may be prepared, and may be added to an appropriate amount of water to form the aqueous solution.

Owner:PREVENTIVE TECH

Cultivation method for increasing yield of mechanically-transplanted rice with long seedling age

InactiveCN103891567AEnhanced tillering abilityImprove grouting strengthRice cultivationOryzaUniconazole

The invention discloses a cultivation method for increasing yield of mechanically-transplanted rice with long seedling age, and belongs to technical field of rice cultivation. According to the cultivation method, from plate placement of a rice seedling bed to a one-leaf one-core period of seedlings, irrigation is preformed to enable seedling plates to be soaked by water, and water is drained; when soil in the plates dries up, irrigation is performed again to enable the seedling plates to be soaked by the water, and the water is drained; the steps are performed repeatedly. In the one-leaf one-core period, nitrogen-phosphorus-potassium compound fertilizer is applied into the seedling plates, and fertilization is not needed in later period. A wetting-drying alternation method is adopted for water management. 6-7 seedlings are transplanted in each hole during mechanical rice transplantation, and uniconazole is sprayed onto leaves during tillering. In a panicle primordium differentiation stage, liquid silicon fertilizer is used for irrigating roots after being diluted by water, and a silicon solution (prepared by Na2SiO3 9H2O (sodium metasilicate nonahydrate)) is sprayed onto the leaves. By the nutrient and water management mode and the like of the cultivation method, tillering capability and grouting firmness of the mechanically-transplanted rice with the long seedling age are improved greatly, effective ear numbers and actual ear numbers are remarkably increased, and the yield of the mechanically-transplanted rice with the long seedling age is effectively increased.

Owner:SHANDONG RICE RES INST

Well-cementation working fluid system prepared from waste drilling fluid and drill cuttings

ActiveCN105925254ASolve the emission problemGood recycling valueDrilling compositionWorking fluidSlag

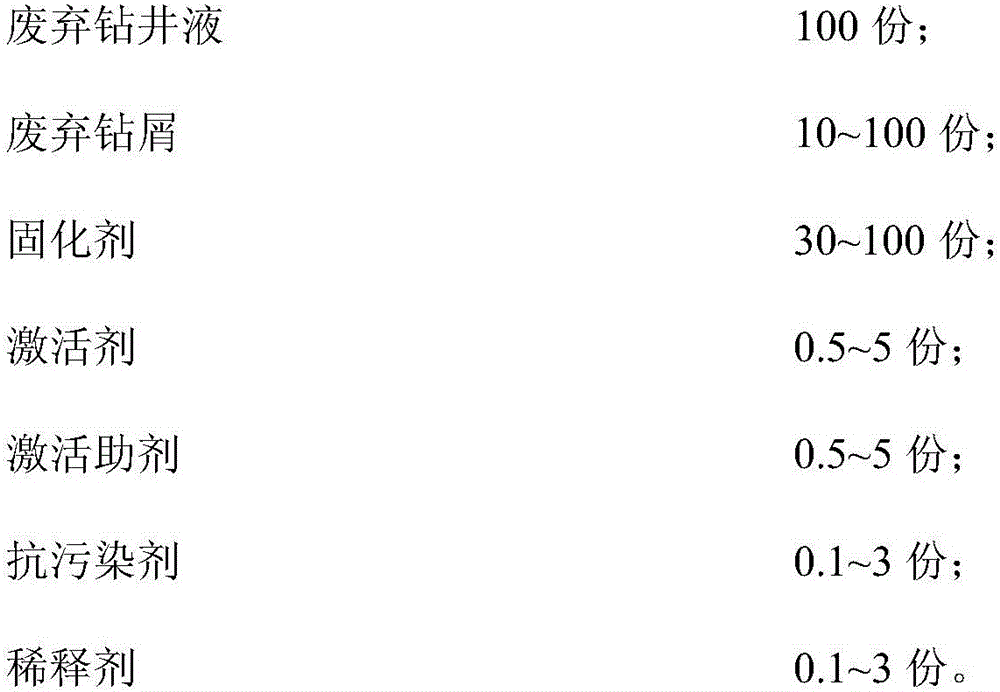

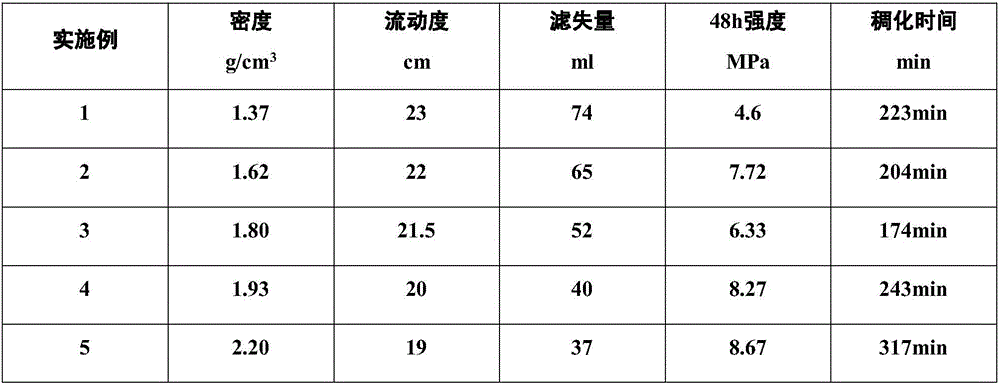

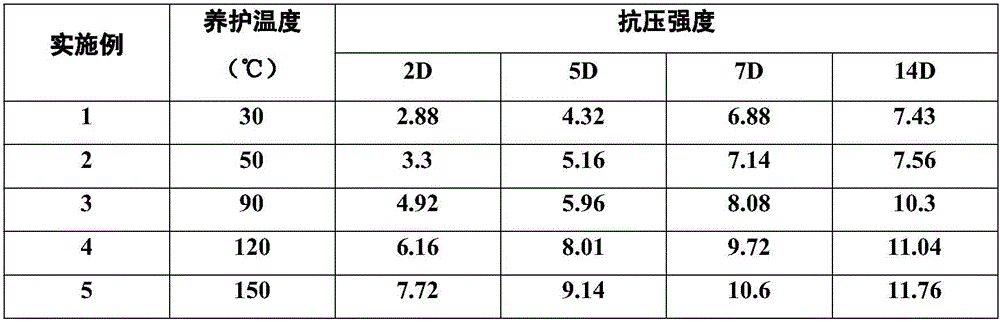

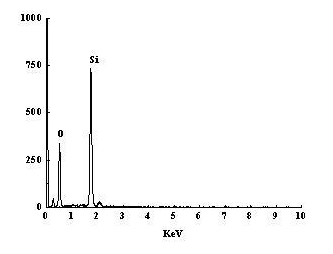

The invention discloses a well-cementation working fluid system prepared from waste drilling fluid and drill cuttings. The well-cementation working fluid system prepared from the waste drilling fluid and drill cuttings is prepared from the following components in parts by weight: 100 parts of the waste drilling fluid, 10 to 100 parts of the waste drill cuttings, 30 to 100 parts of curing agent, 0.5 to 5 parts of activating agent, 0.5 to 5 parts of activation accessory ingredient, 0.1 to 3 parts of antipollution agent and 0.1 to 3 parts of diluting agent, wherein the curing agent is formed by compounding slag and sepiolite in a mass ratio of 50 to 2; the activating agent is sodium hydroxide or potassium hydroxide; the activation accessory ingredient is one or a mixture of sodium metasilicate nonahydrate, sodium carbonate and calcium carbonate; the antipollution agent is one or a mixture of sodium salicylate, potassium citrate and sodium pentaborate; the diluting agent is one or a mixture of sodium lignin sulfonate, calcium lignosulphonate and hydroxyethyl cellulose. The well-cementation working fluid system prepared from the waste drilling fluid and drill cuttings is reliable in principle and low in cost, is environment-friendly and is convenient in field application; a resource is saved; the well-cementation working fluid system is particularly applied to cementing operation of an oil gas well with low abundance, low pressure and low permeability on a leaky block.

Owner:SOUTHWEST PETROLEUM UNIV

Wood treatment solution and process

InactiveUS20110151129A1Less-expensive to manufactureFireproof paintsAntifouling/underwater paintsFiberCellulose

The present invention features a single aqueous solution that imparts acceptable levels of water resistance, fire resistance, mold resistance and pest resistance to wood, and which may be used in standard wood treatment techniques commonly utilized in the wood treatment industry. In one preferred embodiment, the aqueous solution comprises a fire retardant, preferably sodium metasilicate nonahydrate (about 5% to 30% by mass), an insect and termite repellant, preferably sodium tetraborate decahydrate, also known as borax, (about 1.5% to 9% by mass), a mold inhibitor, preferably thymol (about 0.01% to 0.1% by mass) or ethanolamine (about 0.5% to 20% by mass), and a pH buffer, preferably sodium carbonate (about 1% to 10% by mass). It is also contemplated that this aqueous solution may be applied directly to cellulosic materials and products that include naturally occurring fibers such as cotton, hemp, bamboo, and paper products, among others.

Owner:CASTILLO DONALD +1

Rubber anti-adhesive agent

The invention provides a rubber anti-adhesive agent. A certain amount of sodium hydroxide, trisodium phosphate, trimeric sodium phosphate, sodium pyrophosphate, anhydrous sodium sulfate and sodium metasilicate nonahydrate are prepared into a solution, and zinc stearate powder is added into the solution to be fully stirred after the solution is diluted to acquire the rubber anti-adhesive agent. The rubber anti-adhesive agent is pasty emulsion, can be conveniently and uniformly painted and avoids the dust pollution of original anti-adhesive materials.

Owner:NANTONG OERSTED SHOES

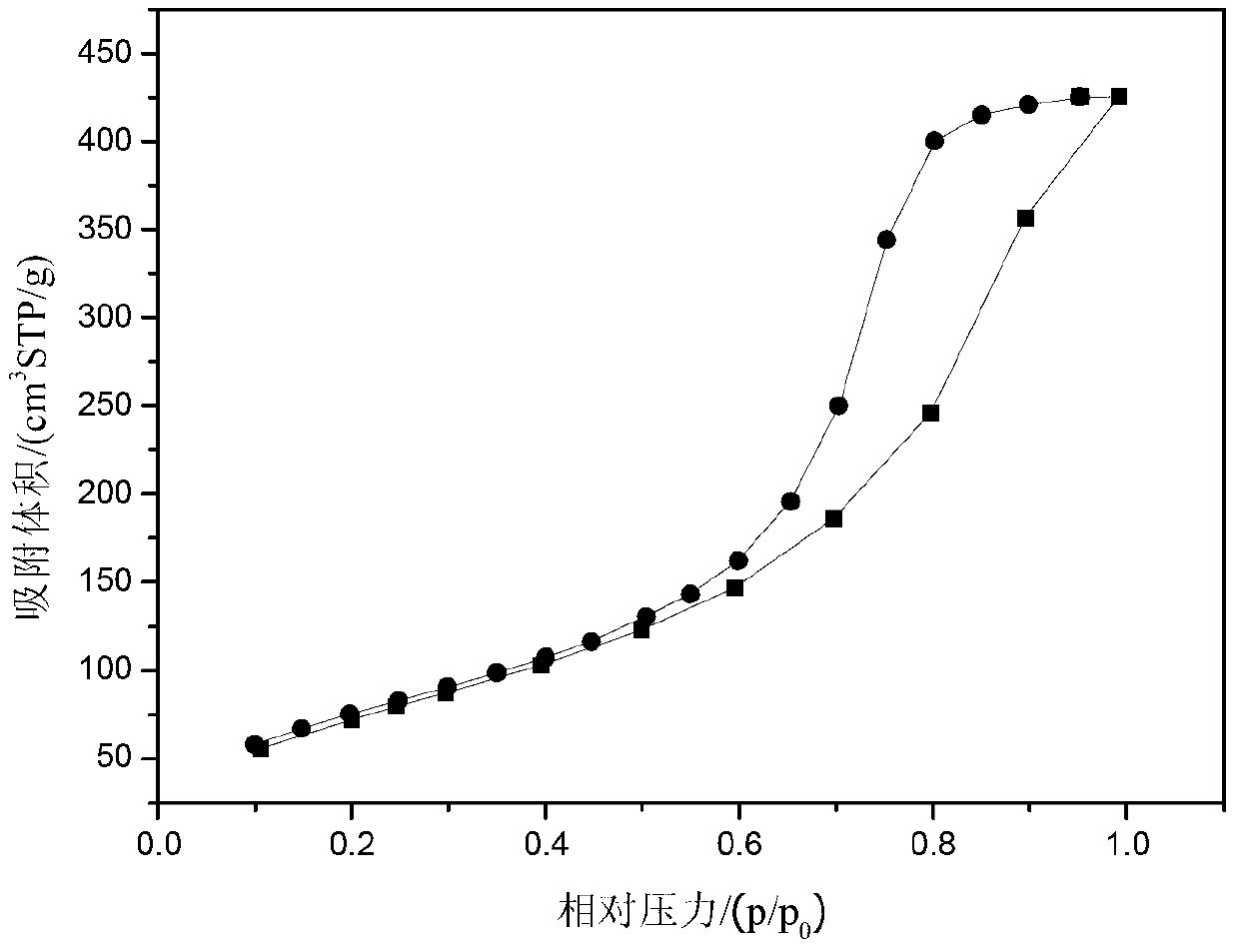

Method for preparing silicon-based aerogel with different contact angles by drying with low cost under normal pressure

InactiveCN102198943ALarge specific surface areaImprove hydrophobicitySilicaWater bathsSurface modification

The invention relates to a method for preparing silicon-based aerogel with different contact angles by drying with low cost under normal pressure, and belongs to the technical field of novel material preparation. The method comprises the following steps of: mixing a certain amount of sodium metasilicate nonahydrate and deionized water in a breaker, arranging a rotor to seal the breaker, stirring in a water bath of 35 to 60 DEG C, cooling after 20 to 40 minutes, dropwise adding glacial acetic acid, regulating the pH to be acidic, ageing for 2 to 6 days after gel is formed, adding distilled water, soaking and cleaning for 24 hours in the water bath of 35 to 60 DEG C, immersing the wet gel into the modified n-hexane / trimethylchlorosilane solution, performing surface modification for 24 hours at the temperature of 50 DEG C, adding a certain amount of n-hexane to exchange the un-reacted modifier twice in 24 hours, sealing the breaker by using a preservative film with pin holes and an aluminum foil, performing graded drying under normal pressure, and finally cooling to room temperature to obtain the modified silicon-based aerogel. The method has the advantages of low cost, low energy consumption and easily controlled reaction.

Owner:JIANGSU UNIV

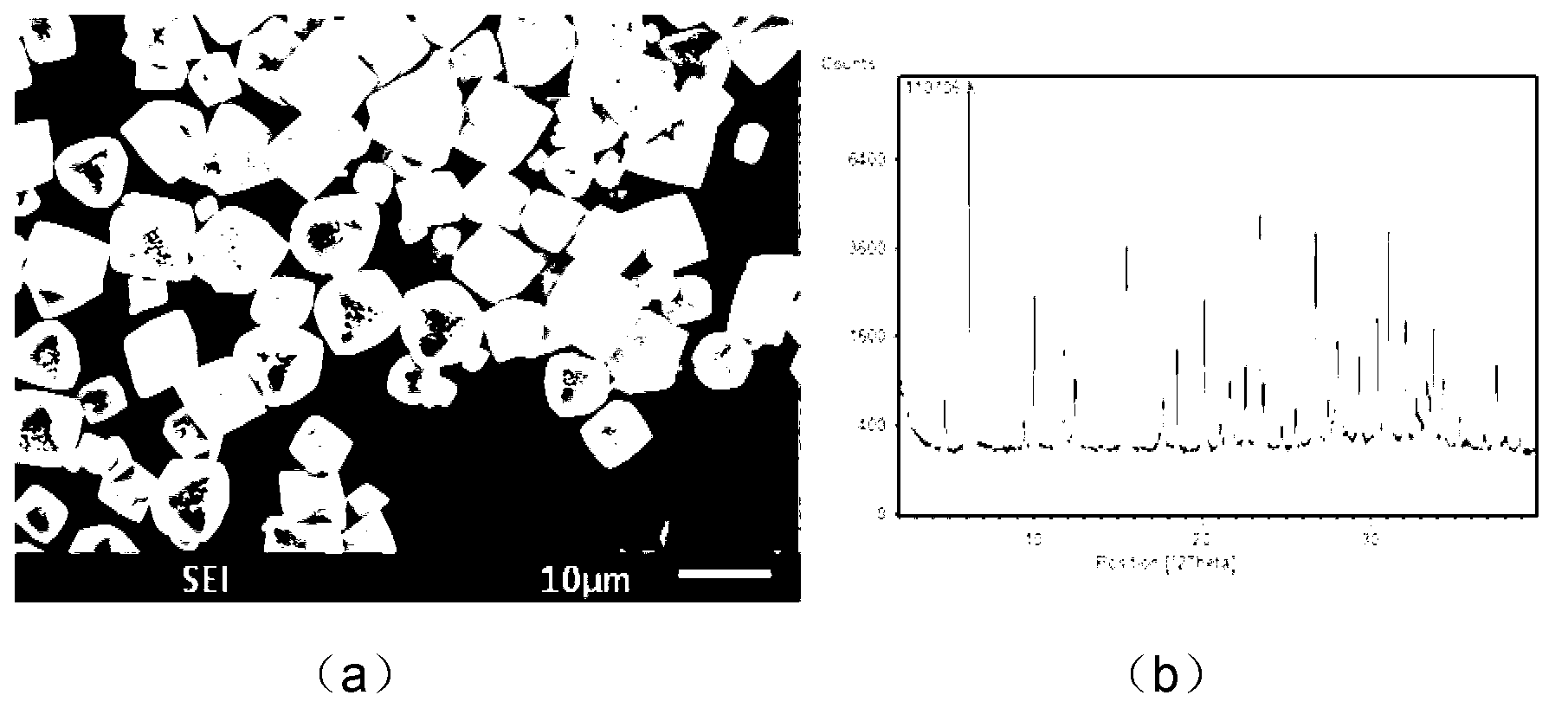

High-adsorption-capacity oxygen generation molecular sieve and preparation method thereof

InactiveCN105984882AImprove adsorption capacityWide variety of sourcesCrystalline aluminosilicate zeolitesHalloysiteOxygen

The invention discloses a high-adsorption-capacity oxygen generation molecular sieve and a preparation method thereof. The molecular sieve is prepared from, by weight, 18-29 parts of halloysite, 13-21 parts of sepiolite, 28-36 parts of diatomite, 15-25 parts of wollastonite, 14-22 parts of potassium feldspar, 10-15 parts of spodumene, 8-14 parts of albite, 48-62 parts of sodium hydroxide, 32-44 parts of sodium metaaluminate, 24-36 parts of sodium metasilicate nonahydrate and 15-20 parts of seed crystal guide agent. The molecular sieve prepared by the method is high in nitrogen balance adsorption capacity which can reach higher than 30 ml / g, and has excellent mechanical strength and nitrogen-oxygen separation performance; a production process is simple, raw materials are extensive in source, and the molecular sieve is low in cost, renewable, reusable, environment-friendly and economical and can be popularized and applied in pressure-variable adsorption oxygen generators on a large scale.

Owner:MINGGUANG FEIZHOU NEW MATERIAL

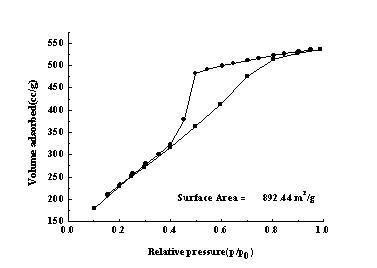

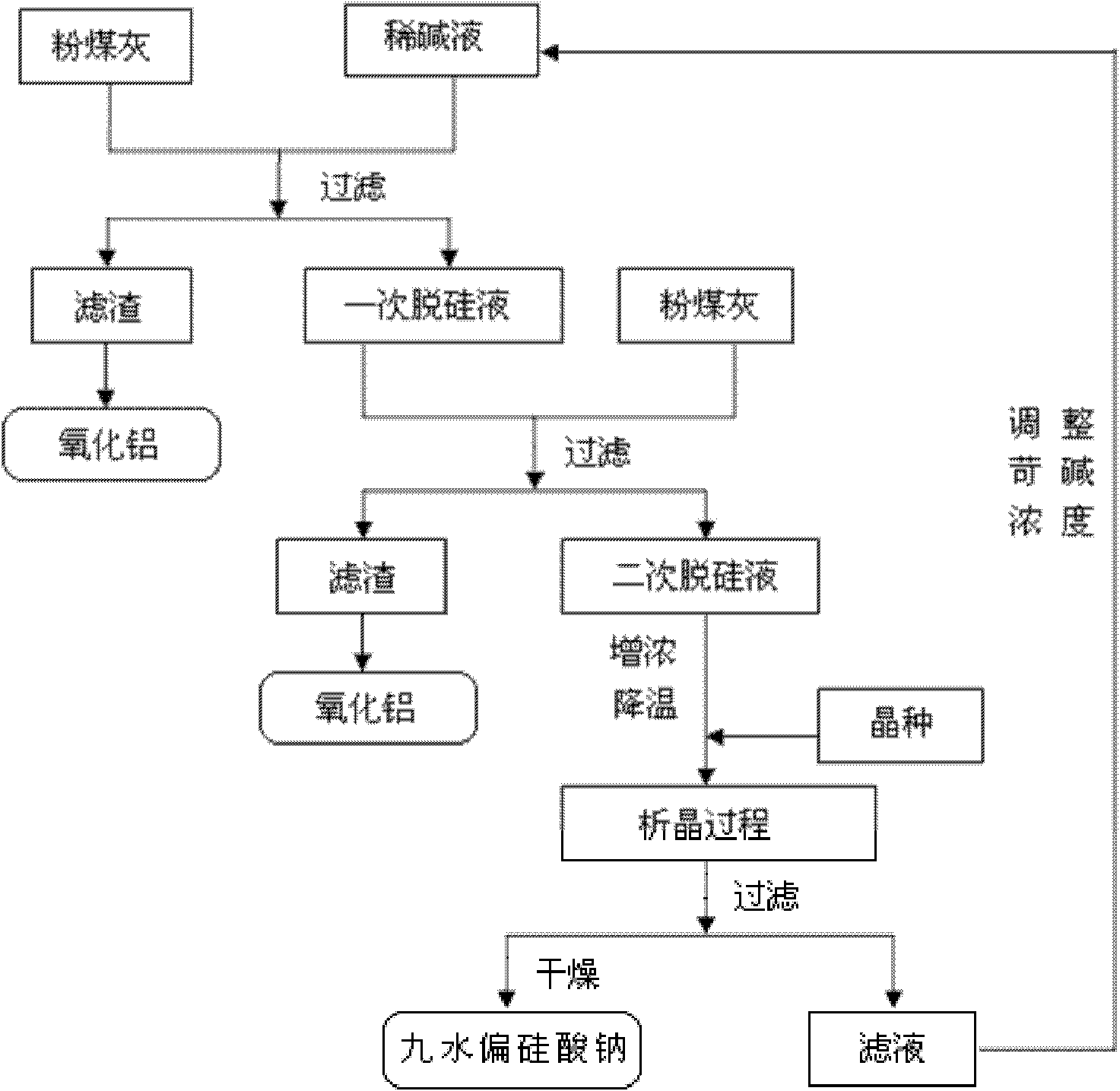

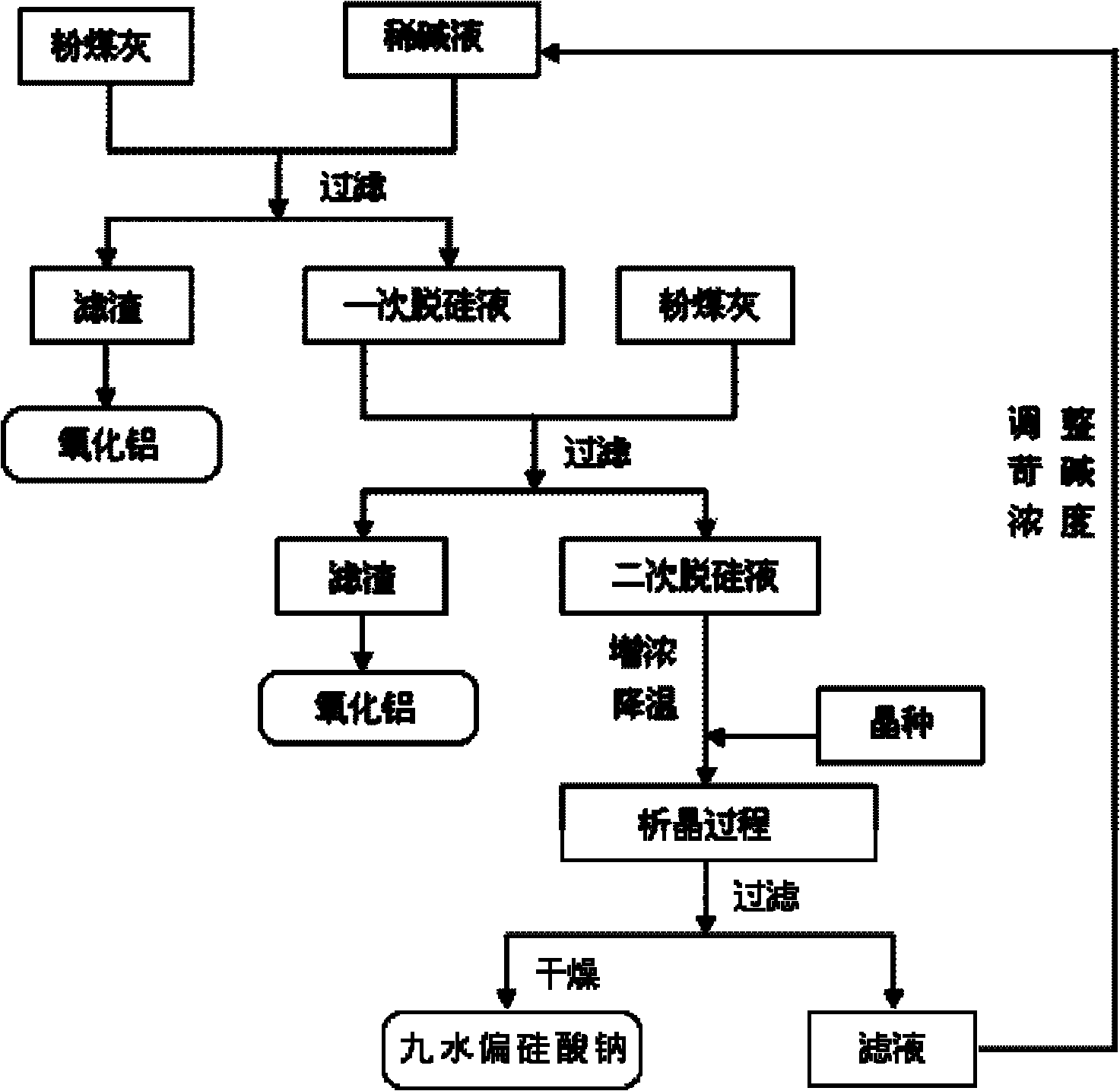

Method for manufacturing sodium metasilicate nonahydrate with fly ashes

ActiveCN102190310AWide variety of sourcesLow costSolid waste disposalAlkali metal silicatesFly ashSeed crystal

The invention discloses a method for manufacturing sodium metasilicate nonahydrate with fly ashes, comprising the steps of: adding fly ashes into a sodium hydroxide solution for desilication, then performing a solid-liquid separation, thus obtaining a first desiliconized liquid; adding fly ashes into the first desiliconized liquid for a second desilication, then performing a solid-liquid separation, thus obtaining a second desiliconized liquid; evaporating and thickening the second desiliconized liquid, and when the content of SiO2 accounts for 120-150g / L, stopping evaporating and thickening and starting cooling, then adding sodium metasilicate nonahydrate crystals into the second desiliconized liquid as a seed crystal, then precipitating crystals; performing a solid-liquid separation to the second desiliconized liquid from which the crystals are precipitated, so that a solid product can be obtained, then drying the solid product so as to obtain the product of sodium metasilicate nonahydrate. Adoption of the method provided in the invention overcomes lots of disadvantages of the prior art, and enjoys the advantages of easily available raw material, low cost, good product quality, improved production efficiency as well as easy industrialization promotion.

Owner:INNER MONGOLIA DATANG INT RENEWABLE RESOURCES DEV

Well cementation working solution prepared from red mud, slag and waste drilling fluids

InactiveCN108359435AHigh activityEnhanced pumpabilitySolid waste managementDrilling compositionSodium BentoniteRed mud

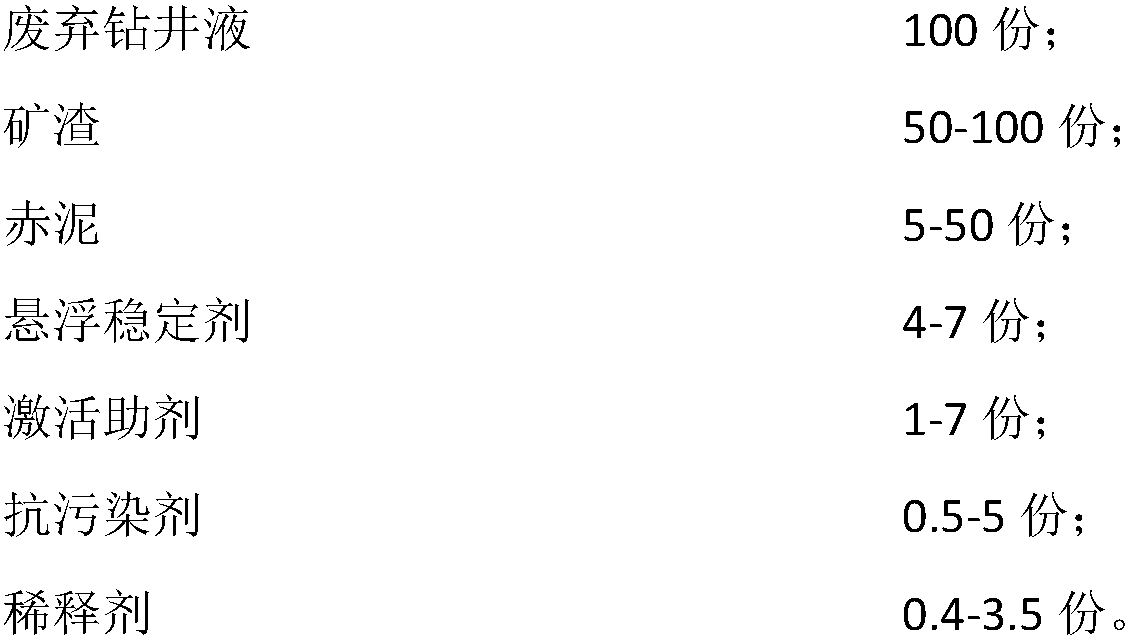

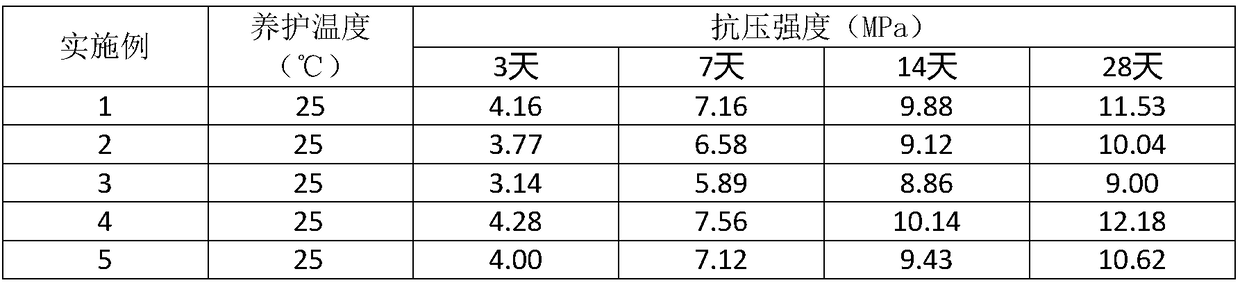

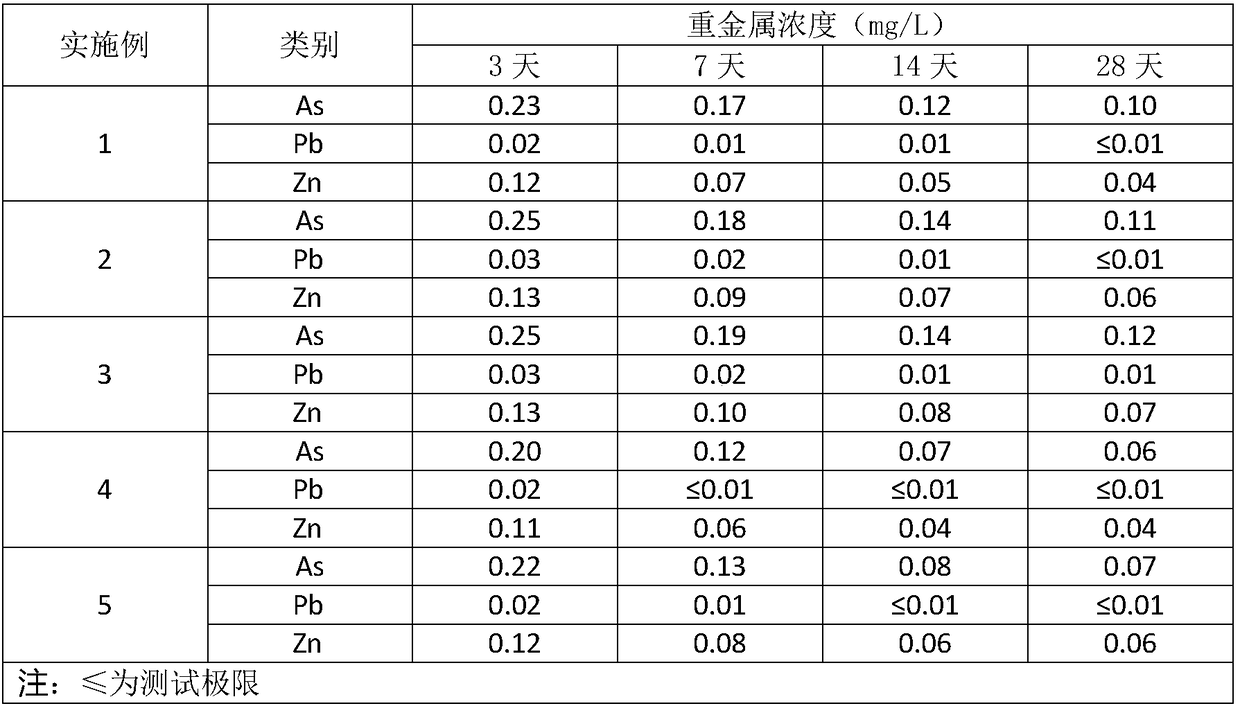

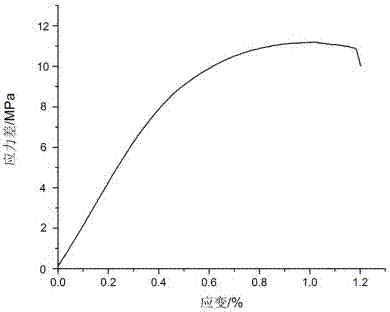

The invention discloses a well cementation working solution prepared from red mud, slag and waste drilling fluids. The working solution is prepared from components in parts by weight as follows: 100 parts of waste drilling fluids, 50-100 parts of slag, 5-50 parts of red mud, 4-7 parts of a suspension stabilizer, 1-7 parts of an activating aid, 0.5-5 parts of an anti-pollution agent and 0.4-3.5 parts of a diluent. The waste drilling fluids are waste waterborne drilling fluids, the slag is blast furnace slag or vanadium-titanium slag, the suspension stabilizer is sodium bentonite, carboxymethylcellulose or a mixture of sodium bentonite and carboxymethyl cellulose, the activating aid is sodium metasilicate nonahydrate, sodium carbonate or a mixture of sodium metasilicate nonahydrate and sodium carbonate, the anti-pollution agent is sodium salicylate, potassium citrate or a mixture of sodium salicylate and potassium citrate, and the diluent is sodium lignin sulfonate. The principle is reliable, the cost is low, recycling of multiple industrial wastes is realized, resources are saved, the environment is protected, the preparation technology is simple, the working solution is convenientto use on site and particularly applicable to cementation of oil and gas wells in low-abundance, low-pressure and easy-to-leak blocks, and good technical support can be provided for development of oil and gas resources of the blocks.

Owner:SOUTHWEST PETROLEUM UNIV +2

Multifunctional low-density curing working solution system

InactiveCN107987814AImprove toughnessHigh modulus of elasticityDrilling compositionSlagPotassium hydroxide

The invention discloses a multifunctional low-density curing working solution system which is prepared from the following components in parts by mass: 100 parts of waste drilling fluid, 30-70 parts ofa curing agent I, 10 parts of a curing agent II, 1-5 parts of a flexibilizer, 1-6 parts of an activating agent, 0.5-5 parts of a strength enhancer, 0.1-3 parts of an anti-pollution agent, 0.1-3 partsof diluent and 0.1-3 parts of a suspension stabilizer, wherein the curing agent I is blast furnace slag; the curing agent II is pumice powder; the flexibilizer is a mixture of modified basalt fibersand rubber latex; the activating agent is sodium hydroxide or potassium hydroxide; and the strength enhancer is sodium metasilicate nonahydrate, calcium sulfate, sodium carbonate or a mixture thereof.The multifunctional low-density curing working solution system disclosed by the invention has the characteristics of low temperature early strength, low elasticity modulus, high cementing between twointerfaces, excellent plugging effect and the like, is low in cost, environment-friendly and convenient in site construction and has wide market application prospects.

Owner:SOUTHWEST PETROLEUM UNIV

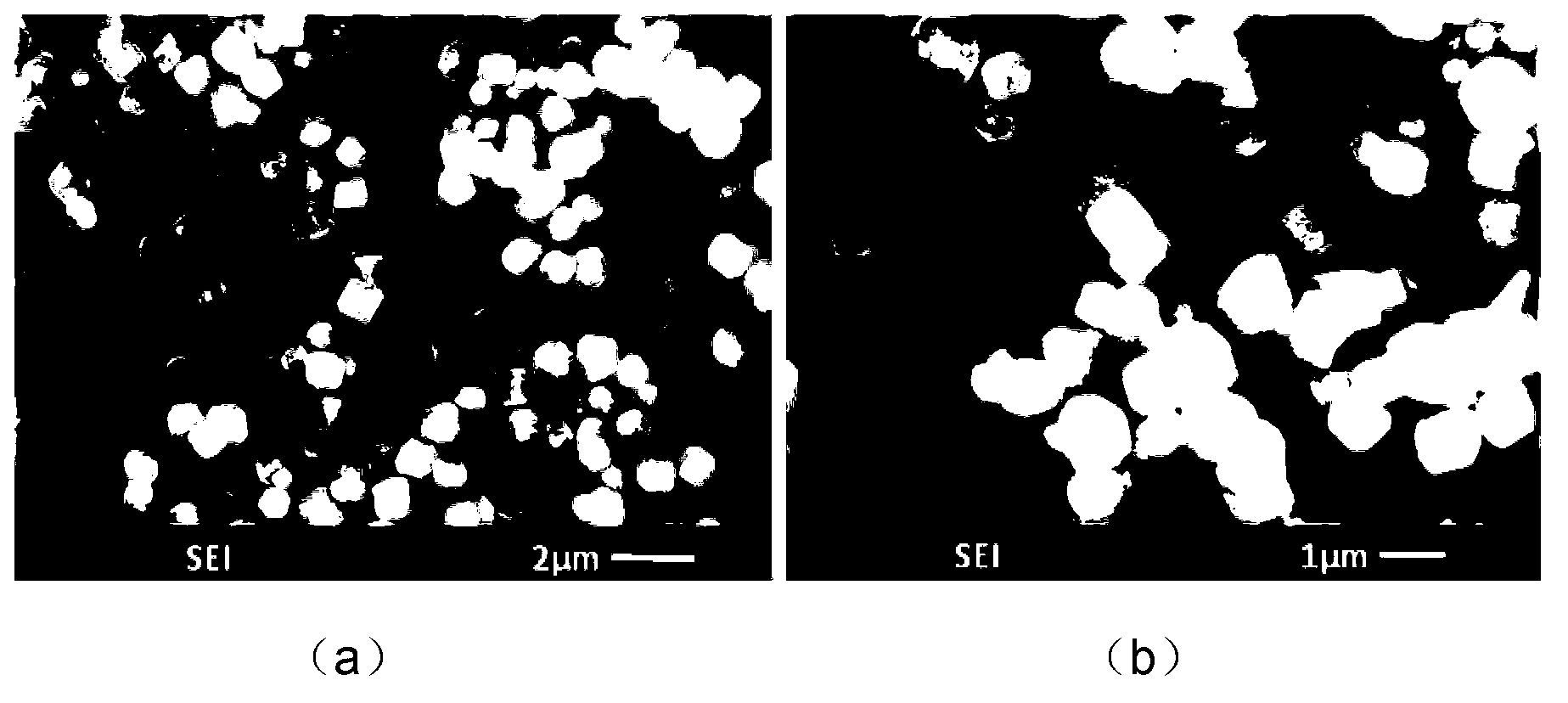

Preparation method of sodium metasilicate nonahydrate

InactiveCN101837985AHigh reactivityReduce caustic soda consumptionAlkali metal silicatesRoom temperatureSilicon dioxide

The invention discloses a preparation method of sodium metasilicate nonahydrate, which comprises the following steps of: cleaning an drying waste glass; grinding the waste glass into glass powder of over 200 meshes; mixing 15-30 percent NaOH solution with the waste glass powder in a mass ratio of 4-7:1; heating the mixture to the temperature of between 90 and 100 DEG C; performing a reaction for 50 to 150 minutes with continuous stirring; when a reaction product is cooled to the temperature of between 50 and 60 DEG C, adding sodium metasilicate nonahydrate which is 0.5 to 1 percent of the total mass of the reaction product into the reaction product while stirring, and simultaneously adding lauryl sodium sulfate which is 0.1 to 0.5 percent of the total mass of the reaction product into the reaction product; naturally cooling the mixture to the room temperature; performing crystallization on the mixture for 18 to 68 hours; and baking the mixture after crystallization for 200 to 300 minutes at the temperature of between 25 and 30 DEG C. The preparation method can fully use silicon dioxide and sodium oxide namely the main components in the waste glass, reduce the used amount of sodium hydroxide in production, and reduce the reaction time, the production energy consumption and the production cost.

Owner:NANCHANG UNIV

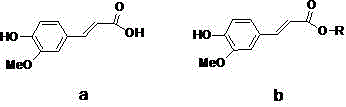

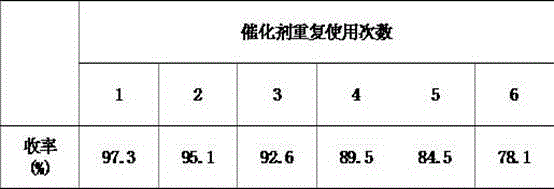

Method for synthesis of ferulic acid ester by solid acid catalysis

InactiveCN104311413ASimple preparation processReduce production processPhysical/chemical process catalystsOrganic compound preparationSolid acidSodium bisulfate

The invention discloses a method for synthesis of ferulic acid ester by solid acid catalysis, and relates to a method for synthesis of the ferulic acid ester, and the method is as follows: a, preparation of silica powder, to be more specific, taking sodium metasilicate nonahydrate to prepare into aqueous solution, starting to stir, heating, adding dropwise ethyl acetate, after gel is formed, performing low temperature vacuum drying to obtain white silica powder; b, catalyst preparation, to be more specific, putting the silica powder prepared by the step a into a muffle furnace for activation, mixing into aqueous solution of sodium bisulfate, soaking, filtering by suction, washing with distilled water until the filtrate is colorless, processing by low-temperature vacuum drying for standby use; c, catalyzed synthesis of the ferulic acid ester, to be more specific, adding ferulic acid, alcohol and a catalyst into a three necked flask equipped with a stirrer, a thermometer, a reflux condenser and a water separator, stirring, heating for reflux until no water is separated out in the water separator; and d, drying and recovery. The process is simple, cheap, non-toxic, non-corrosive and environmentally friendly, catalytic activity is high, catalytic reaction products are easy to separate and can be repeatedly used.

Owner:SHENYANG INSTITUTE OF CHEMICAL TECHNOLOGY

Method for rapidly preparing efficient adsorbent with low cost by adopting organosilicone high-boiling residue

InactiveCN103272564ASolve pollutionSignificant conservation benefitOther chemical processesAlkali metal oxides/hydroxidesHydration reactionSodium metasilicate

The invention discloses a method for rapidly preparing an efficient adsorbent with low cost by adopting organosilicone high-boiling residue. The invention belongs to the technical field of preparation of new materials and in particular relates to a method for rapidly preparing an efficient adsorbent with low cost by adopting organosilicone high-boiling residue. The method for rapidly preparing the efficient adsorbent comprises the following steps of: weighing right amount of sodium metasilicate nonahydrate (Na2SiO3.9H2O), adding the sodium metasilicate nonahydrate into deionized water, and stirring for spare use; treating industrial grade organic silicon byproduct, namely high-boiling residue, taking right amount of high-boiling residue and absolute ethyl alcohol, mixing high-boiling residue with absolute ethyl alcohol in a beaker, adding magnetons, sealing the beaker, fully stirring, dropwise adding the sodium metasilicate solution, regulating pH and standing to form gel, and washing and drying to obtain a modified silicon substrate adsorbing material. The method for rapidly preparing the efficient adsorbent has the advantages of simple process, low cost, easy operation and short reaction period and is applicable to industrial production.

Owner:JIANGSU UNIV +1

Preparation method for purple archaistic ceramic pigment

The invention discloses a preparation method for purple archaistic ceramic pigment. The preparation method comprises the following steps: with Na2SiO3.9H2O (sodium metasilicate nonahydrate) as a silicon source and Cu(NO3)2 (cupric nitrate) and Ba(NO3)2 (barium nitrate) as a copper source and a barium source respectively, carrying out batching according to the chemical structural formula of Chinese purple and preparing a barium copper silicate performed polymer under magnetic stirring at a constant temperature; after dehydration and drying, carrying out a hydrothermal autoclave reaction at 160 to 180 DEG C so as to prepare a barium copper silicate pre-crystal; and carrying out crystallization sintering at a low temperature of 650 to 750 DEG C so as to obtain the Chinese purple archaistic ceramic pigment with a brilliant color and high purity and in good crystallization state.

Owner:SHAANXI UNIV OF SCI & TECH

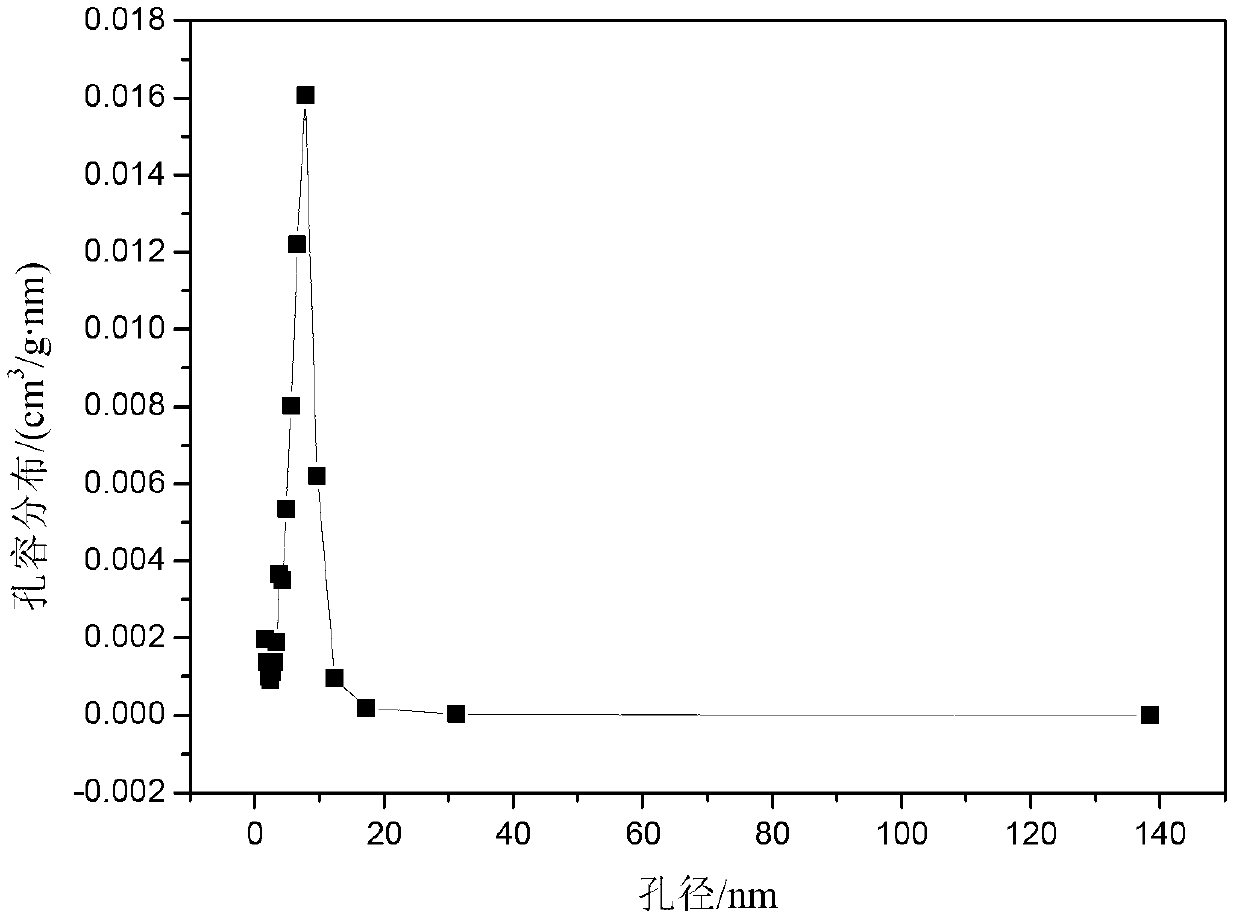

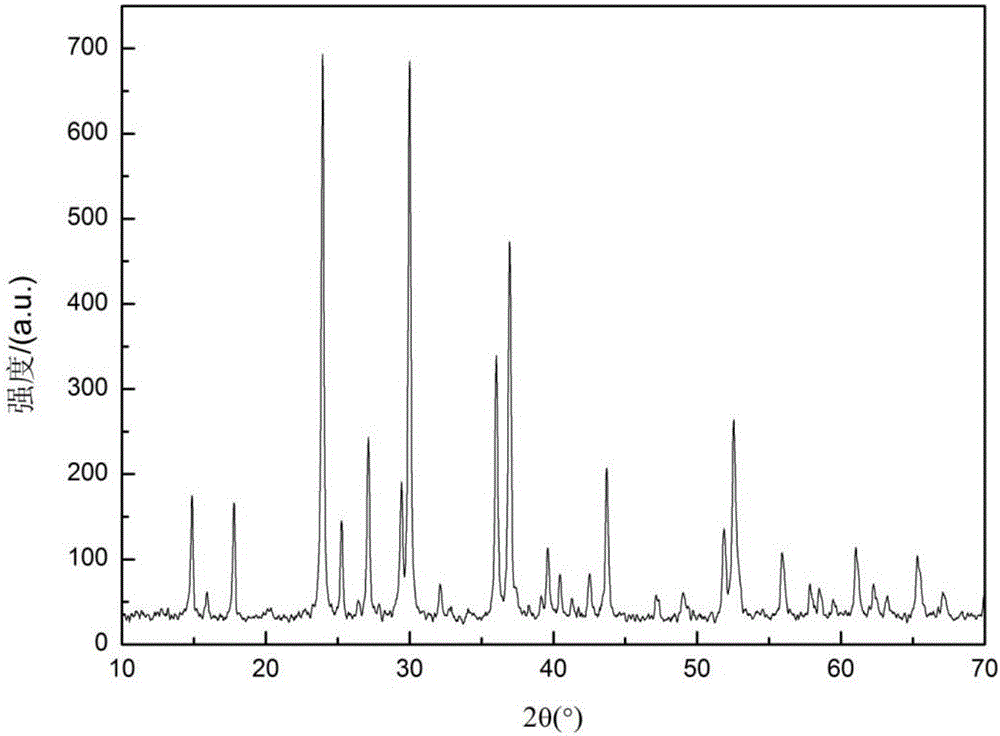

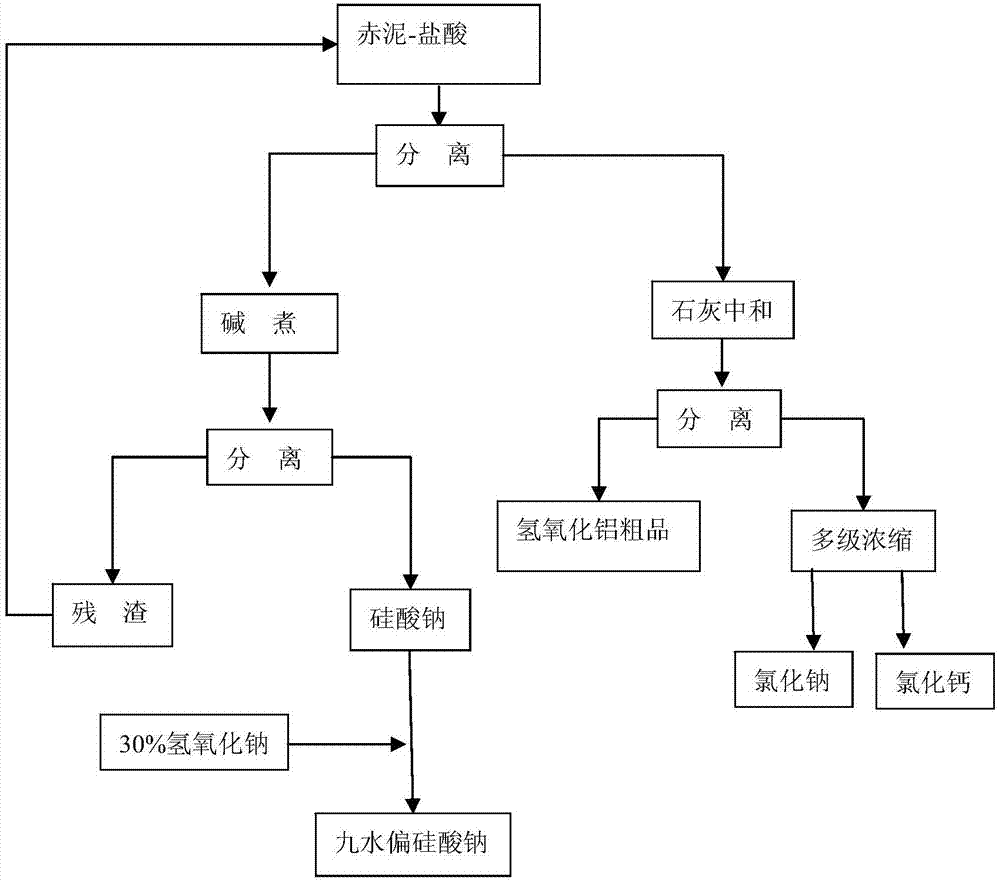

Novel red mud comprehensive utilization method

InactiveCN107162029ANothing producedEasy to achieve occupancyCalcium/strontium/barium chloridesAlkali metal silicatesRed mudSilicon dioxide

The invention discloses a novel red mud comprehensive utilization method which includes the steps: a drying and crushing red mud, uniformly mixing the red mud with hydrochloric acid, performing boiling reaction for 1-3 hours under normal pressure and filtering mixture to obtain first filtrate and first filter residues; b adding calcium hydroxide solution into the first filtrate, adjusting the first filtrate to be neutral, then filtering the first filtrate to obtain aluminum hydroxide coarse residues and second filtrate, and concentrating and crystallizing the second filtrate to successively generate sodium chloride and calcium chloride; c washing the first filter residues to be neutral, adding sodium hydroxide solution, performing boiling reaction for 2-8 hours under the normal pressure, and performing filtering separation after reaction to obtain third filtrate and second filter residues; d adding sodium hydroxide solution into the third filtrate, adjusting the mole ratio of sodium oxide and silicon dioxide in mixed solution to be 1-3, transferring the mixed solution into a crystallizing pond and performing standing to obtain sodium metasilicate nonahydrate. The red mud is treated by acid and alkali to produce various products such as crude aluminum hydroxide, the sodium chloride, the calcium chloride and the sodium metasilicate nonahydrate, and the method is low in cost and less in energy consumption.

Owner:SHANDONG UNIV OF SCI & TECH

Foaming type kitchen heavy oil removal agent and preparation method thereof

ActiveCN106367223AEasy to cleanEasy to removeInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsPhosphateKitchen utensils

The invention belongs to the technical field of cleaning agents, and particularly relates to a foaming type kitchen heavy oil removal agent and a preparation method thereof. The foaming type kitchen heavy oil removal agent is prepared from sodium hydroxide, sodium carbonate, fatty alcohol-polyoxyethylene ether sodium sulfide, linear alkyl benzene sulphonic acid, triethanolamine, sodium metasilicate nonahydrate, fatty alcohol-polyoxyethylene ether, phosphate, essence, a pH regulator, a corrosion remover and the balance deionized water. The foaming type kitchen heavy oil removal agent is mild in character and safe and non-toxic to human bodies, does not stimulate skin in the cleaning process, is high in dirt removability, capable of rapidly, easily and conveniently removing oil dirt and low in corrosivity and does not damage kitchen utensils.

Owner:壹田(广州)生活健康用品有限公司

Cold-rolled oil sludge degreaser and use method thereof

ActiveCN105002001ALess quantityReduce disposal costsOrganic detergent compounding agentsSurface-active detergent compositionsOil and greaseUltra fine

The invention discloses a cold-rolled oil sludge degreaser and a use method thereof. The cold-rolled oil sludge degreaser comprises, by weight, 10-20% of a mixed surface active agent, 0-5% of EDTA, 0-5% of sodium metaaluminate, 0-5% of sodium metasilicate nonahydrate, 3-10% of sodium borate, 0-6% of sodium pyrophosphate and the balance of water. The method includes the steps that 1, the degreaser and cold-rolled oil sludge are fully and evenly mixed to form a mixed solution, and accordingly grease in the cold-rolled oil sludge is extracted through the degreaser, wherein the use amount of the cold-rolled oil sludge degreaser in per kilogram of cold-rolled oil sludge is 1.2-3L; 2, the mixed solution stands still for 1.5-2.5 h, then the mixed solution is filtered, the grease is filtered out, and super-fine iron is separated. By means of the degreaser, the grease in the cold-rolled oil sludge is washed, and micro-iron and nano-iron are separated out. Disposal cost of hazardous waste is reduced, ultra-fine iron products with high additional value are obtained, and the problem that ore grease degreasing efficiency in the cold-rolled oil sludge is low is solved.

Owner:武汉钢铁有限公司

Preparation method for sodium metasilicate nonahydrate liquid concrete accelerator

The invention discloses a preparation method for a sodium metasilicate nonahydrate liquid concrete accelerator, and belongs to the field of chemical building materials. The concrete accelerator is prepared by using sodium metasilicate nonahydrate, water, aluminum sulfate, sodium nitrite, potassium dichromate and triethanolamine as raw materials and through a method of mixing the raw materials at a specific temperature. The preparation method is simple in process, low in production cost and good in product quality. The sodium metasilicate nonahydrate liquid concrete accelerator is simple in usage method, is particularly suitable for being added in silicate concrete, and has the effects of making the concrete solidified rapidly and early strengthened. Besides, the sodium metasilicate nonahydrate liquid concrete accelerator is small in toxicity, and has no influence on physical health of operation staffs who are engaged in spraying the concrete.

Owner:张云侠

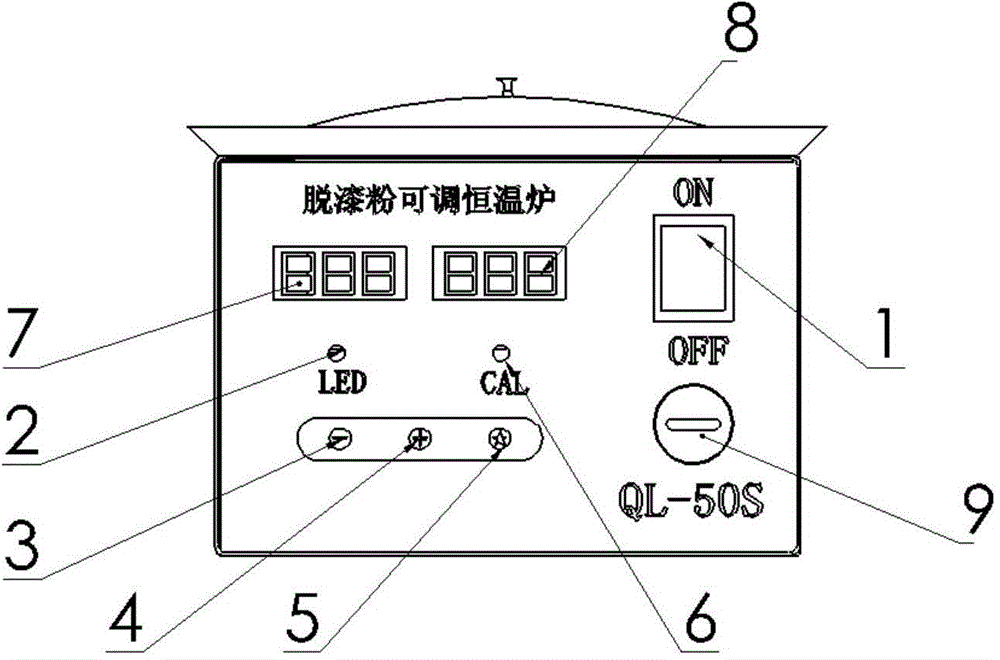

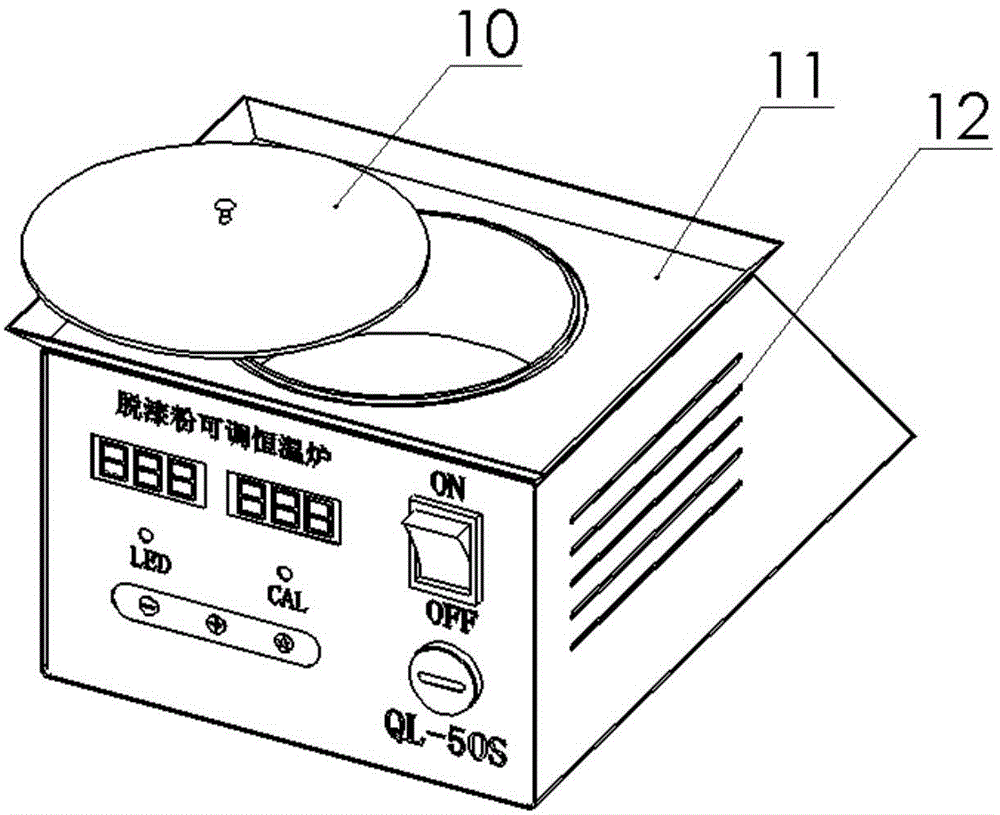

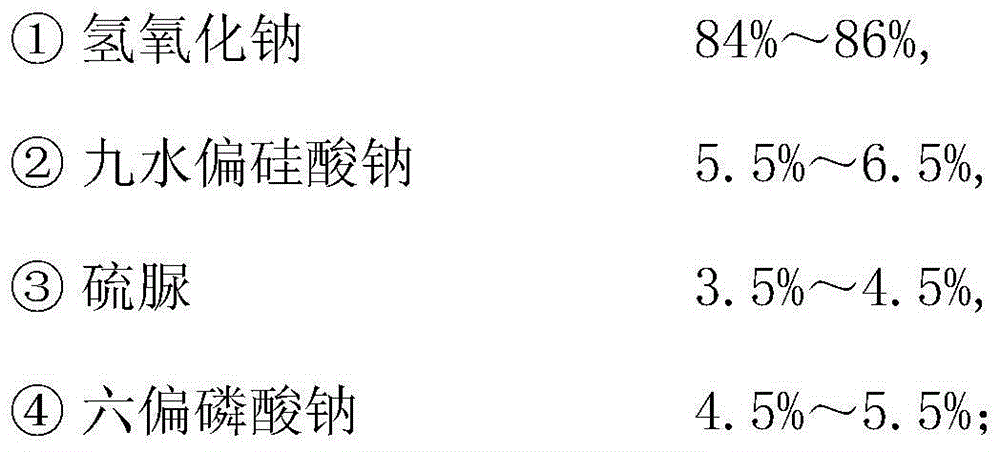

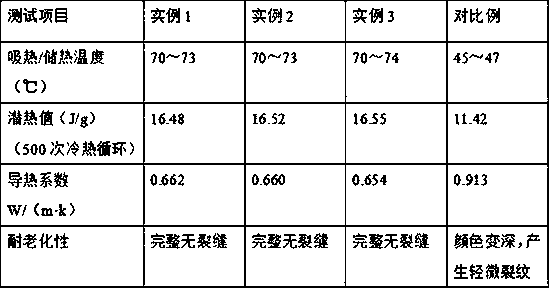

Enameled wire polyimide insulating layer nondestructive depainting powder and depainting method

ActiveCN104312257ADoes not affect solderabilityEasy to clean and removeLine/current collector detailsChemical paints/ink removersCopperSodium hydroxide

The invention relates to an enameled wire polyimide insulating layer nondestructive depainting powder and depainting method. The depainting powder is prepared by adopting the following raw materials by weight percent: 84 to 86 percent of sodium hydroxide, 5.5 to 6.5 percent of sodium metasilicate nonahydrate, 3.5 to 4.5 percent of thiourea and 4.5 to 5.5 percent of sodium hexametaphosphate. The depainting method comprises the following steps: heating the depainting powder in a special depainting furnace to form liquid, soaking an enameled wire head needing depainting into the molten liquid to be subjected to depainting, then taking out the enameled wire head, washing, rinsing and dehydrating the enameled wire head, so that a purpose for completing the quick nondestructive depainting of a lead-out end of the enameled wire can be achieved. The depainting powder formula is environmental friendly and safe, not only can the enameled wire copper material be prevented from being corroded, oxidized and decolored, but also is easy to wash and remove, and the soldability of the enameled wire copper material is not affected. By adopting the method, the traditional method for depainting the lead-out end of the enameled wire by virtue of a piece of abrasive paper can be changed, and the breaking potential safety hazard of a coil can be greatly eliminated.

Owner:SHAANXI QUNLI ELECTRIC

Method for preparing compound photothermal conversion phase change material

InactiveCN108517199ANot easy to seepImprove thermal conductivityHeat-exchange elementsCoatingsCarbon nanotubePolyethylene glycol

The invention relates to the technical field of semiconductor memory production, and concretely relates to a method for preparing a composite photothermal conversion phase change material. An oil-in-water emulsion is prepared from an emulsifier OP-10, liquid paraffin and hydrochloric acid, and is mixed and reacted with a sodium metasilicate nonahydrate solution to obtain a thermal phase change microcapsule material, thermal phase micro-capsules prepared from liquid paraffin are distributed in the pore structure to block outer holes and increase the pore closing rate, ferrous metal particles are attached to the surface of a phase change material to facilitate the energy storage and the energy release of the phase change material, polyethylene glycol used as a soft segment ad a dye moleculewith two reactive groups, used as a hard segment, undergo a stepwise polycondensation process to synthesize a polycondensed photothermal conversion organic shaped phase change energy storage material,the surface of a carbon nanotube material is modified with diazotized p-nitroaniline to improve the compatibility, and the high thermal conductivity and the high specific surface area of the carbon nanotube material make the distribution of a phase change substance in the phase change material uniform in order to facilitate energy storage and energy release.

Owner:王成

Boracic polysilicic acid containing aluminum sulfate and zinc sulfate and chitosan composite flocculant and preparation method thereof

InactiveCN107792923AImprove stabilityImprove stabilizerWater/sewage treatment by flocculation/precipitationZINC SULFATE HEPTAHYDRATEBorax

The invention discloses a boracic polysilicic acid containing aluminum sulfate and zinc sulfate and chitosan composite flocculant which is prepared from aluminum sulfate octadecahydrate, heptahydrate,sodium metasilicate nonahydrate, borax, chitosan and sulfuric acid by hybrid reaction. The molar ratio of aluminum to silicon is 0.3-0.5, the molar ratio of zinc to silicon is 0.2-0.4, the molar ratio of boron to silicon is 0.1-0.2, and the mass ratio of the chitosan to silicon is 0.04-0.15. The invention further discloses a preparation method of the boracic polysilicic acid containing aluminum sulfate and zinc sulfate and chitosan composite flocculant. The preparation method includes the steps: first, preparing polysilicic acid solution; second, preparing boracic polysilicic acid containingaluminum sulfate flocculant solution; third, preparing chitosan solution; fourth, preparing a boracic polysilicic acid containing aluminum sulfate and zinc sulfate and chitosan composite flocculant crude product; fifth, preparing the finished boracic polysilicic acid containing aluminum sulfate and zinc sulfate and chitosan composite flocculant. The composite flocculant prepared by the preparationmethod is low in cost, stable in performance, good in storage performance, convenient to use and more environmentally friendly as flocculation and algae removal are more efficient and thorough, and fewer metal ions remain in water.

Owner:HENAN VOCATIONAL COLLEGE OF WATER CONSERVANCY ANDENVIRONMENT

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com