Method for manufacturing sodium metasilicate nonahydrate with fly ashes

A technology of sodium metasilicate nonahydrate and fly ash, which is applied in the field of resource utilization of fly ash, can solve the problems of large non-renewable mineral resources, destruction of ecological balance, difficult industrialization promotion, etc., and achieve the protection of ecological balance , low cost, scientific and reasonable method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

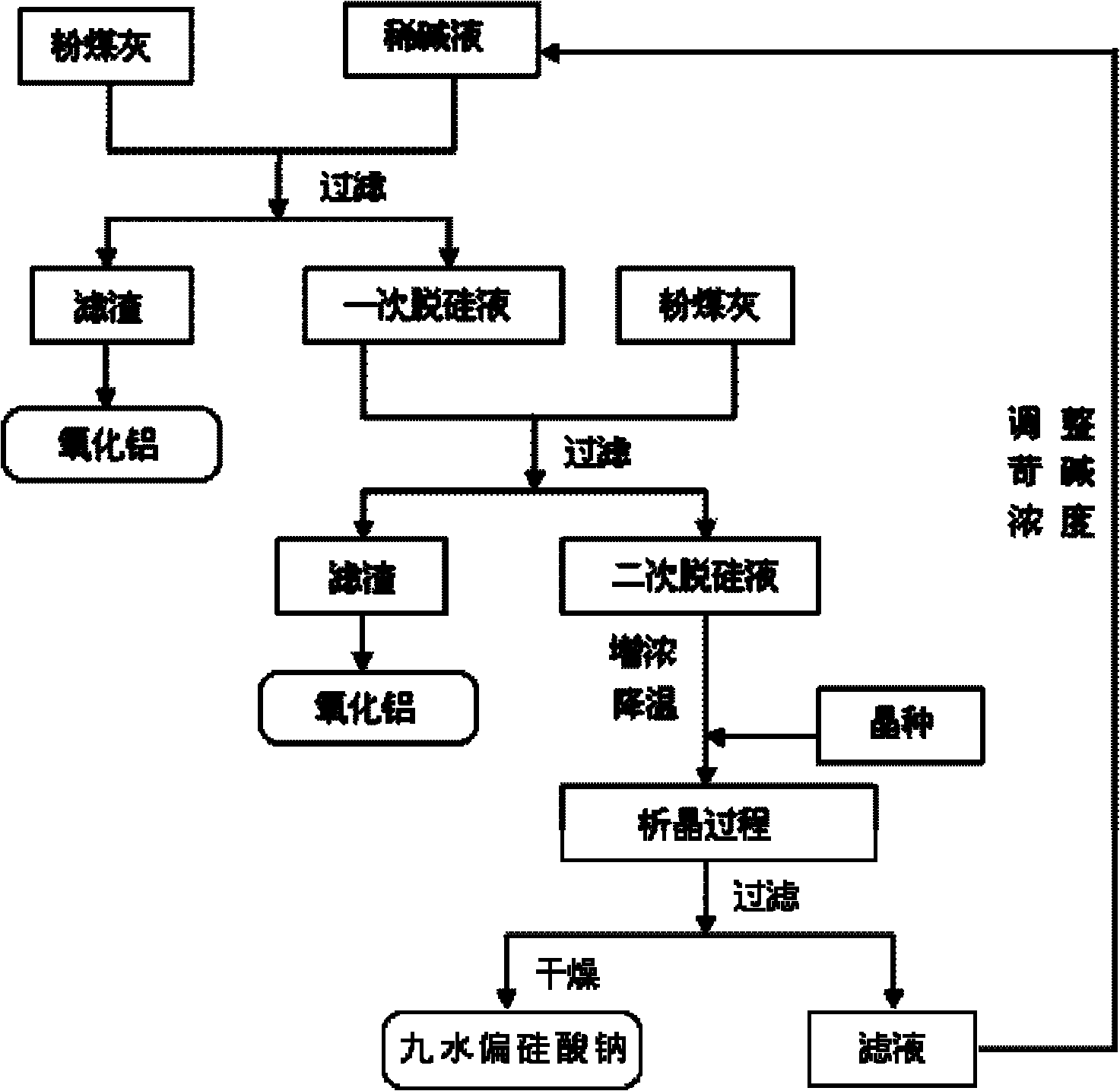

[0030] figure 1 It is a production process flow chart of the present invention. Such as figure 1 Visible, the method disclosed in the present embodiment utilizes fly ash to produce nonahydrate sodium metasilicate, comprises the steps:

[0031] 1) Dissolve 15g of NaOH in 85ml of water and raise the temperature to 120°C to prepare a sodium hydroxide solution, take 30g of fly ash and slowly add it to the sodium hydroxide solution, stirring while adding, when the fly ash and lye are mixed evenly, Insulate and react for 1.5 hours, then filter and separate the slurry, the obtained solid desiliconization slag is used to produce alumina, and the obtained filtrate is primary desiliconization liquid.

[0032] 2) Raise the temperature of the primary desiliconization solution to 125°C, then take 35g of fly ash and slowly put it into the primary desiliconization solution, stir while adding, after mixing evenly, keep it warm for 1.5h, then filter and separate the slurry, the obtained soli...

Embodiment 2

[0037] The disclosed method of utilizing fly ash to produce sodium metasilicate nonahydrate comprises the steps:

[0038] 1) Dissolve 12g of NaOH in 88ml of water and heat up to 110°C, then take 20g of fly ash and slowly add it to the sodium hydroxide solution, stirring while adding, when the fly ash and lye are mixed evenly, keep the temperature for 2 hours, and then The slurry is separated by filtration, and the obtained solid desiliconization slag is used to produce alumina, and the obtained filtrate is primary desiliconization liquid.

[0039] 2) Raise the temperature of the primary desiliconization solution to 115°C, then take 30g of fly ash and slowly put it into the primary desilication solution, stir while adding, after mixing evenly, keep it warm for 2 hours, then filter and separate the slurry to obtain solid desiliconization The slag is used to produce alumina, and the obtained filtrate is the secondary desiliconization liquid.

[0040] 3) Keep the secondary desili...

Embodiment 3

[0043] The disclosed method of utilizing fly ash to produce sodium metasilicate nonahydrate comprises the steps:

[0044] 1) Dissolve 18g of NaOH in 82ml of water and heat up to 130°C, then slowly add 40g of fly ash into the alkali solution, stirring while adding, when the fly ash and alkali are mixed evenly, keep the temperature for 1 hour, and then put The slurry is separated by filtration, and the obtained solid desiliconization slag is used to produce alumina, and the obtained filtrate is primary desiliconization liquid.

[0045] 2) Raise the temperature of the primary desiliconization solution to 135°C, then take 40g of fly ash and slowly put it into the primary desilication solution, stir while adding, after mixing evenly, keep it warm for 1 hour, then filter and separate the slurry to obtain solid desiliconization The slag is used to produce alumina, and the obtained filtrate is the secondary desiliconization liquid.

[0046] 3) Keep the secondary desiliconization solu...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com