Method for rapidly preparing efficient adsorbent with low cost by adopting organosilicone high-boiling residue

A high boiler, organosilicon technology, applied in chemical instruments and methods, inorganic chemistry, alkali metal compounds, etc., can solve problems such as safety hazards and environmental hazards, and achieve the effects of simple operation, short reaction period, and good decolorization.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0025] Distill industrial-grade organosilicon high boilers, and distill out fractions with a boiling range of 116°C ~ 125°C for use; weigh 3.9g of sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O), added to 26 mL of deionized water, stirred in a water bath at 50 °C for 20 min, and the solution was cooled for later use;

[0026] Mix 1 mL of organic silicon high boiler with a boiling range of 116°C to 125°C and 5 mL of absolute ethanol in a beaker, add a magnet to seal the beaker, stir thoroughly for 3 min, add the above sodium metasilicate solution drop by drop, and adjust The pH was 6. After the gel was formed, distilled water was added, soaked and aged in a water bath at 50 °C for 6 h, dried at 40 °C under normal pressure for 6 h, and finally cooled to room temperature to obtain a modified silicon-based adsorption material.

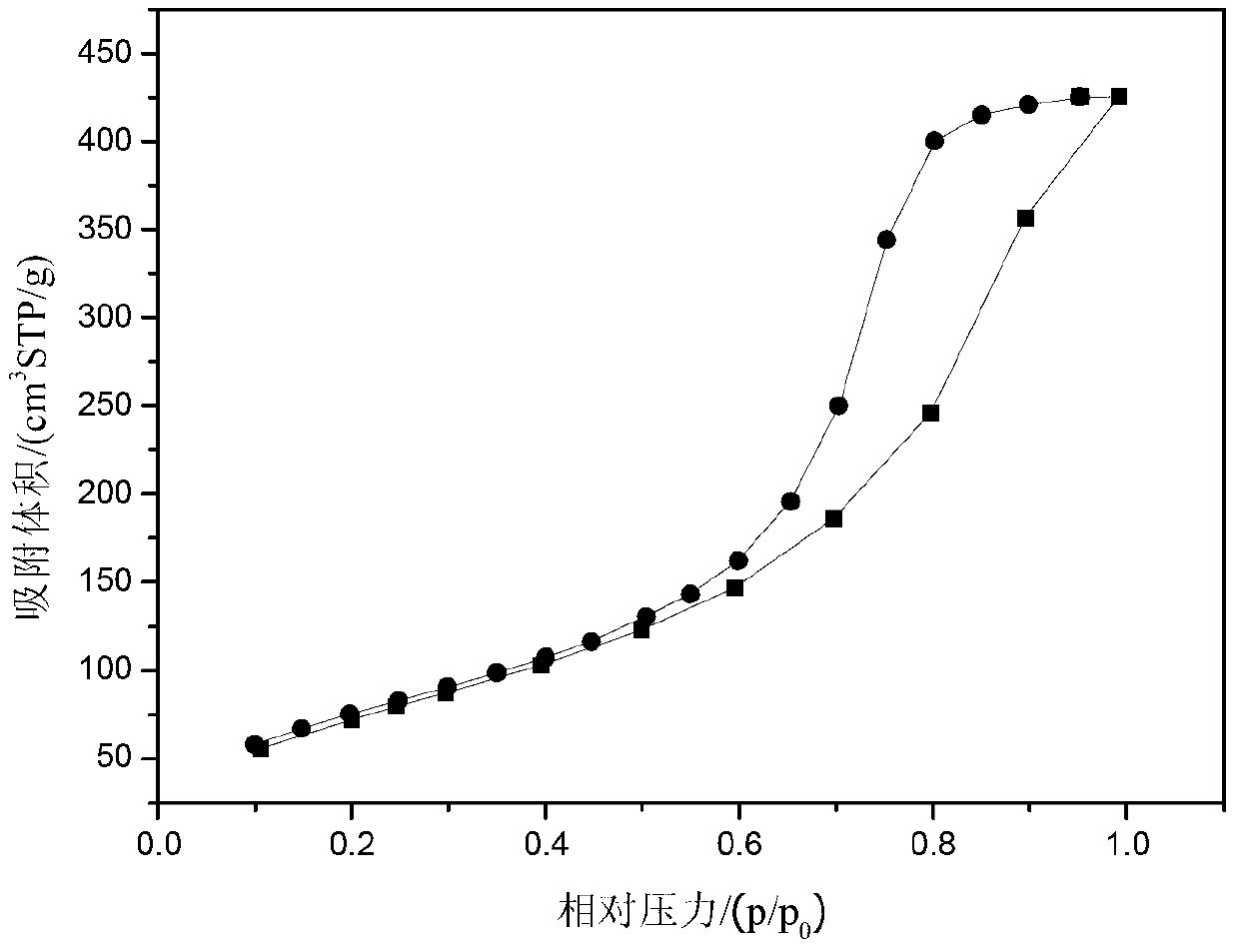

[0027] like figure 1 Shown is the silicon-based adsorbent nitrogen adsorption-desorption isotherm prepared by Example 1;

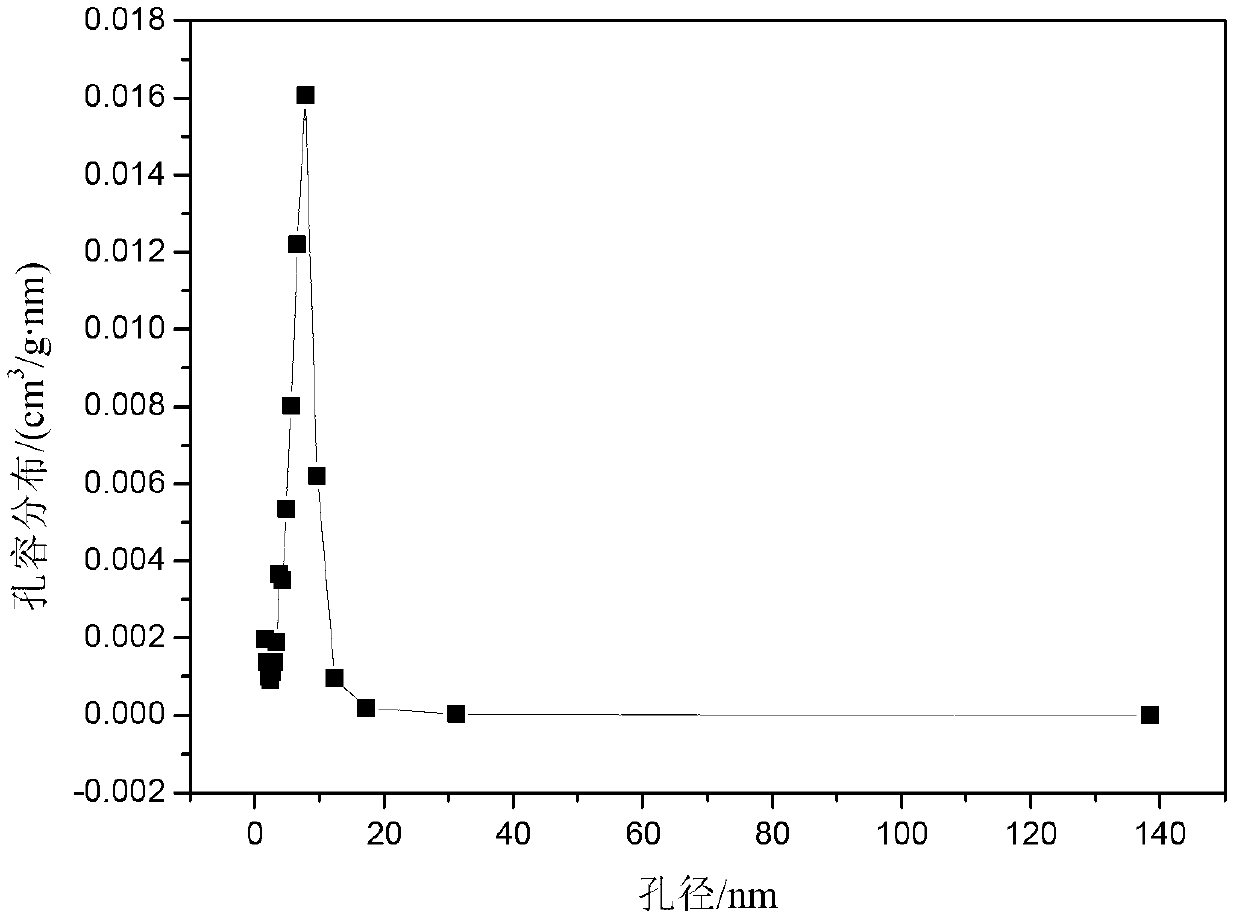

[0028] like figure 2...

Embodiment 2

[0031] Distill industrial-grade organosilicon high boilers, and distill out fractions with a boiling range of 126°C to 135°C for use; weigh 3.9 g of sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O), added to 26 mL of deionized water, stirred in a water bath at 50 °C for 20 min, and the solution was cooled for later use;

[0032] Mix 1 mL of organic silicon high boiler with a boiling range of 126°C to 135°C and 3 mL of absolute ethanol in a beaker, add a magnet to seal the beaker, stir thoroughly for 3 min, add the above sodium metasilicate solution drop by drop, adjust The pH was 8. After the gel was formed on standing, distilled water was added, soaked and aged in a water bath at 50 °C for 12 h, dried at 80 °C under normal pressure for 24 h, and finally cooled to room temperature to obtain a modified silicon-based adsorption material.

Embodiment 3

[0034] Distill industrial-grade organosilicon high boilers, and distill out fractions with a boiling range of 75°C to 155°C for use; weigh 3.9 g of sodium metasilicate nonahydrate (Na 2 SiO 3 9H 2 O), added to 23mL of deionized water, stirred in a water bath at 50°C for 20 min, and the solution was cooled for later use;

[0035] Mix 1 mL of organic silicon high boiler with a boiling range of 116°C to 125°C and 8 mL of absolute ethanol in a beaker, add a magnet to seal the beaker, stir thoroughly for 3 min, add the above sodium metasilicate solution drop by drop, and adjust The pH was 6. After the gel was formed, distilled water was added, soaked and aged in a water bath at 50 °C for 6 h, dried at 40 °C under normal pressure for 6 h, and finally cooled to room temperature to obtain a modified silicon-based adsorption material.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com