Working lining for continuous cast steel tundish with environmental-friendly binder

An environmentally friendly, binder technology, applied in the field of working lining of continuous casting steel tundish, can solve the problems of carbon increase, production cost increase, environmental pollution, etc., to reduce cost and environmental pollution, eliminate carbon increase problem, solve low temperature Effects of strength and high temperature slag resistance issues

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

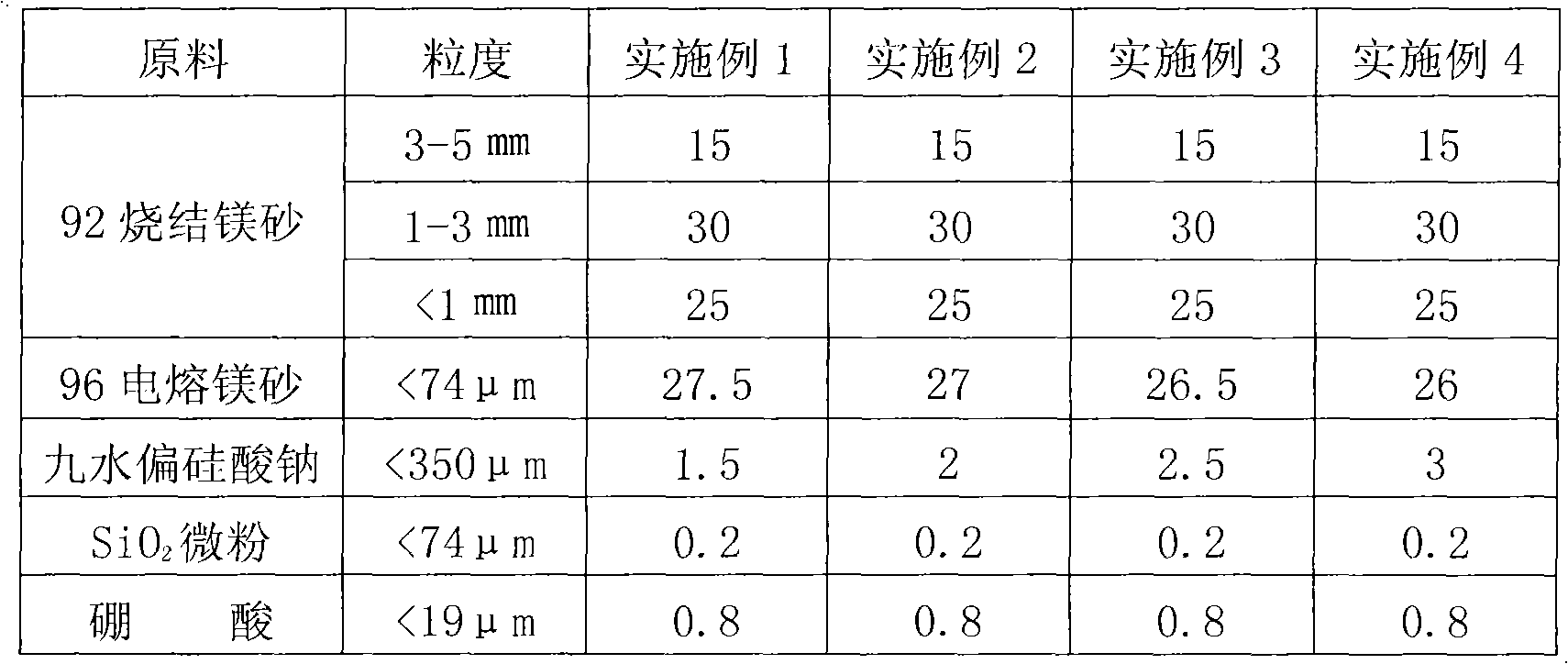

[0012] The aggregates used in the present invention are magnesia raw materials (92 sintered magnesia and 96 fused magnesia). The dry material binder of the tundish is a sodium borosilicate system, and the raw materials used are sodium metasilicate nonahydrate, SiO 2 Micronized and boric acid.

[0013] The raw material weight percentage content of 92 sintered magnesia is 70wt.% (3-5mm15wt.%, 1-3mm30wt.%, 2 The fine powder and boric acid are respectively 0.2wt.% and 0.8wt.%, and the addition amount of nonahydrate sodium metasilicate is 1.5-3wt.%.

[0014] The above raw materials are common commercially available products, 92 sintered magnesia and 96 fused magnesia are industrial pure, SiO 2 Micronized powder, boric acid and sodium metasilicate nonahydrate are chemically pure.

[0015] Concrete preparation steps are as follows:

[0016] (1) Raw materials with different particle sizes are first batched and mixed according to the ratio shown in Table 1. The instruments used incl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com