Primary crystallization hydrothermal preparation method of A-type and X-type molecular sieves containing pure Na ions

A molecular sieve and deionized water technology, applied in the direction of A-type crystalline aluminosilicate zeolite, crystalline aluminosilicate zeolite, octahedral crystalline aluminosilicate zeolite, etc., can solve the problems of complicated and time-consuming processes, and achieve low production cost, It is convenient for industrial production and the effect of simple synthesis process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

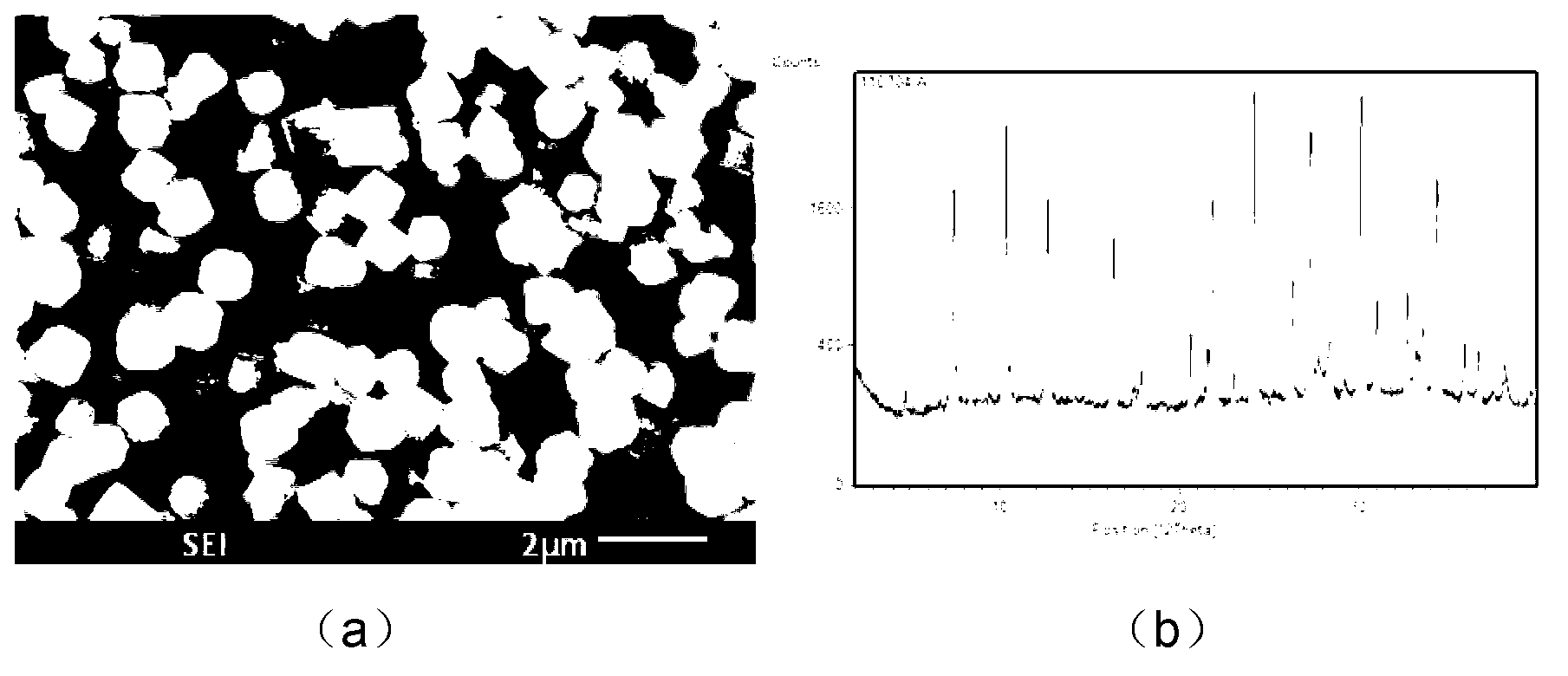

[0035] Preparation of NaA type molecular sieve (0.7 micron):

[0036] 1.5 g NaAlO 2 Add it into 10 ml of deionized water, stir to dissolve it evenly, add 1.875 g of NaOH and continue to stir for 30 minutes, and let it stand for a while; an aluminum source solution is obtained.

[0037] 1.5 g Na 2 SiO 3 9H 2 O was added to 10 ml of deionized water, stirred and dissolved until uniform to obtain a silicon source solution.

[0038] Then slowly add the aluminum source solution that has been left still to the stirring silicon source solution, continue stirring for 30 minutes, put it into a polytetrafluoroethylene-lined stainless steel reaction kettle, crystallize at 100°C for 5 hours, filter and dry Dry to obtain NaA type molecular sieve (0.7 micron). The obtained samples were uniform in size and well crystallized (attached figure 1 ), the yield is 70-75%, Si / Al=1:1, and the pore size is 0.4nm.

Embodiment 2

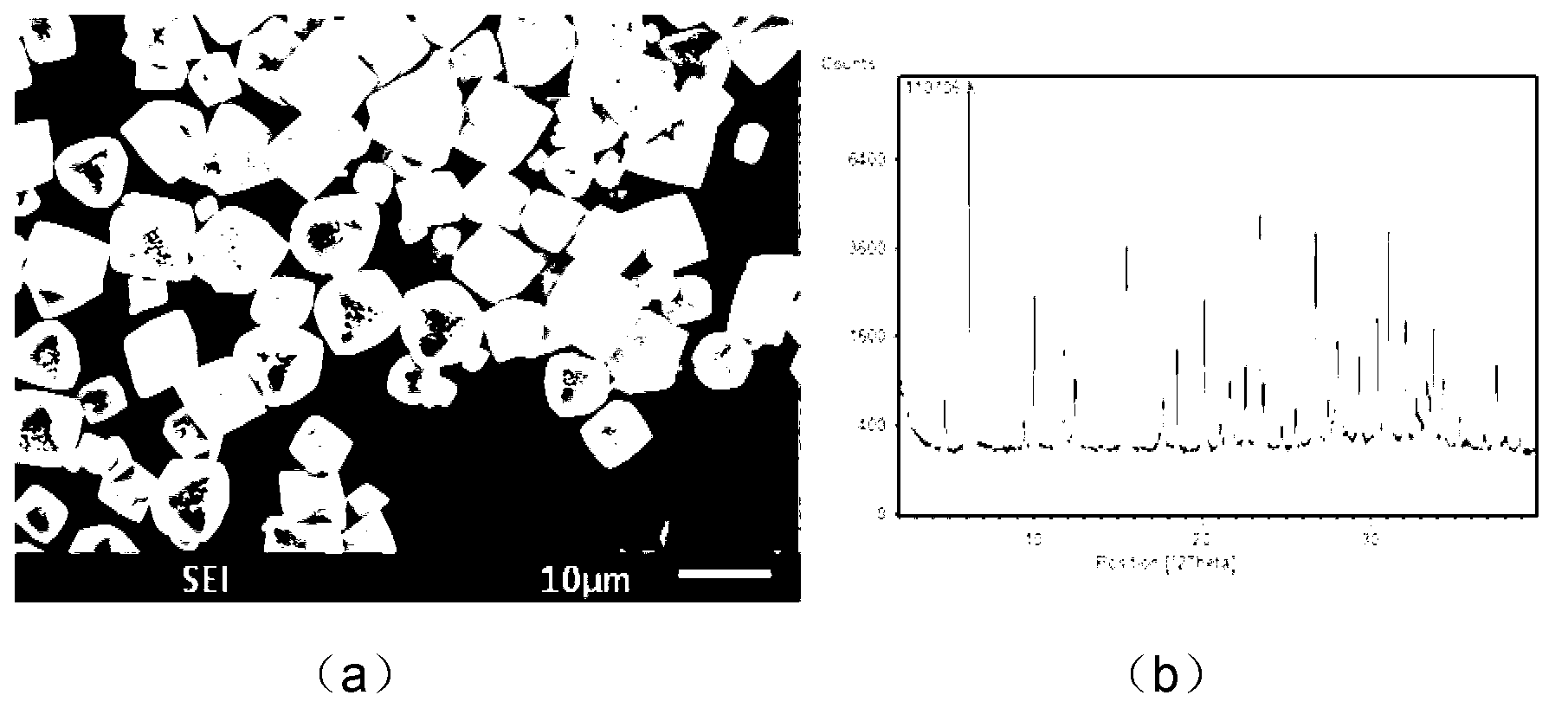

[0040] Preparation of NaX type molecular sieve (10 microns):

[0041]Add 0.3 g of NaOH to 6.5 ml of deionized water, stir well, then add 0.13 g of NaAlO 2 Continue to stir for 30 minutes, and let it stand for a while; an aluminum source solution is obtained.

[0042] 1.2 g Na 2 SiO 3 9H 2 O was added to 15 ml of deionized water and stirred until homogeneous to obtain a silicon source solution.

[0043] Then slowly add the aluminum source solution that has been standing still to the stirring silicon source solution, continue stirring for 30 minutes, put it into a stainless steel reaction kettle lined with polytetrafluoroethylene, crystallize at 100 ° C for 3 days, and filter and dry , to get NaX molecular sieve powder (10 microns) (attached figure 2 ), the yield is 70-75%, Si / Al=1:1.3, and the pore size is 1.0nm.

Embodiment 3

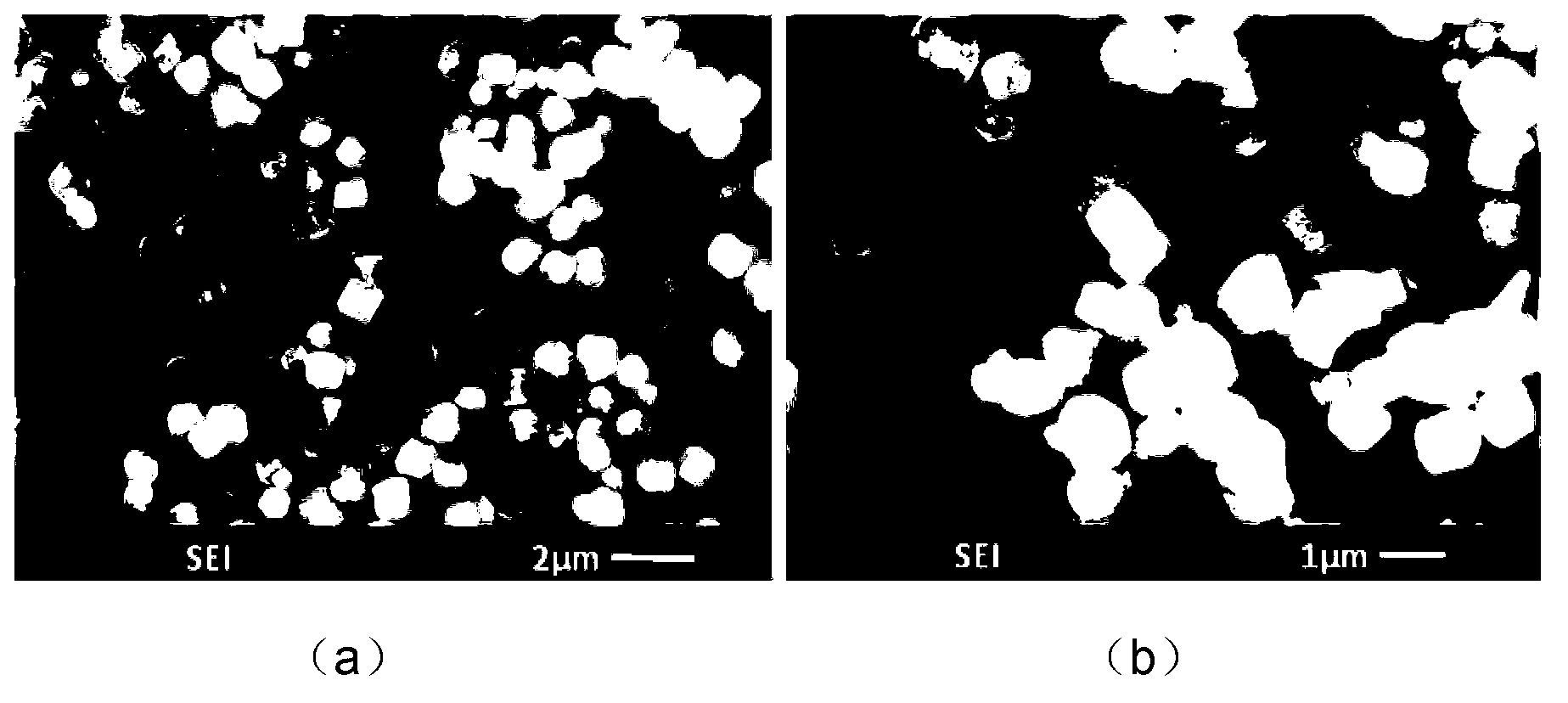

[0045] Preparation of NaA type molecular sieve (0.8 micron):

[0046] 0.75 g NaAlO 2 Add it into 10 ml of deionized water, stir to dissolve it evenly, add 0.94 g of NaOH and continue to stir for 30 minutes, and let it stand for a while; an aluminum source solution is obtained.

[0047] 0.75 g Na 2 SiO 3 9H 2 O was added to 10 ml of deionized water, stirred and dissolved until uniform to obtain a silicon source solution.

[0048] Then slowly add the aluminum source solution that has been left still to the stirring silicon source solution, continue stirring for 30 minutes, put it into a polytetrafluoroethylene-lined stainless steel reaction kettle, crystallize at 100°C for 1 hour, filter and dry Dry to obtain NaA-type molecular sieves (0.8 microns). The obtained samples were uniform in size and well crystallized (attached image 3 ), the yield is 70-75%, Si / Al=1:1, and the pore size is 0.4nm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com