Sand mouth material for blast furnace and preparation method for sand mouth material

A reclaimed sand and blast furnace technology, which is applied in the field of refractory materials for slag ditch repair and its preparation, and blast furnace iron gate, can solve the problems of short service life, high production cost, low compressive and flexural strength, etc., and reduce production cost , the effect of reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0022] The present invention is described in detail below:

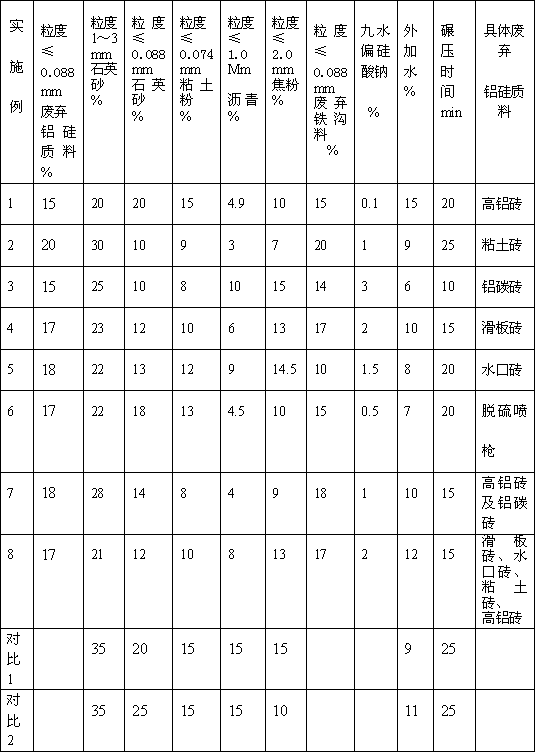

[0023] Table 1 is a list of the selected components and wt% values of the various embodiments of the present invention and comparative examples.

[0024] Table 2 is a list of performance results of each embodiment of the present invention and comparative examples after testing.

[0025] Table 2 adopts the following process steps:

[0026] 1) Add 15-20% of waste silicon-aluminum raw materials with a particle size of ≤0.088mm, 20-30% of quartz sand with a particle size of 1-3mm, 10-20% of quartz sand with a particle size of ≤0.088mm, and clay powder with a particle size of ≤0.074mm8 ~15%, 3~10% of asphalt with a particle size of ≤1.0mm, 7~15% of coke powder with a particle size of ≤2.0mm, 10~20% of waste iron trench material fine powder with a particle size of ≤0.088mm, sodium metasilicate nonahydrate: 0.1-3% of the raw materials are mixed until uniform;

[0027] 2) Add appropriate amount of water within the range...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com