Multifunctional low-density curing working solution system

A working fluid, low-density technology, applied in chemical instruments and methods, drilling compositions, etc., can solve the problems of drilling fluid pollution, poor deformation ability, low compressive strength, etc. Broad market application prospects and the effect of convenient on-site construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

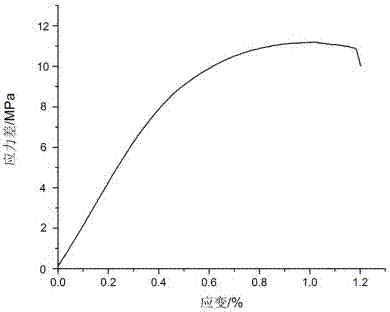

[0026] Embodiment 1 (blank sample)

[0027] Recipe: waste drilling fluid (1.05g / cm 3 ) 100 parts, curing agent I 40 parts, activator 3 parts, strength increasing agent 3 parts, anti-pollution agent 0.3 parts, diluent 0.3 parts, suspension stabilizer 0.1 parts.

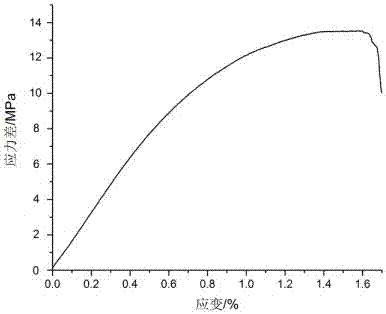

Embodiment 2

[0029] Recipe: waste drilling fluid (1.05g / cm 3 ) 100 parts, curing agent Ⅰ 30 parts, curing agent Ⅱ 10 parts, toughening agent 2 parts, activator 3 parts, strength increasing agent 3 parts, anti-pollution agent 0.3 parts, diluent 0.3 parts, suspension stabilizer 0.1 parts.

Embodiment 3

[0031] Recipe: waste drilling fluid (1.15g / cm 3 ) 100 parts, curing agent Ⅰ 50 parts, curing agent Ⅱ 10 parts, toughening agent 2 parts, activator 2.5 parts, strength increasing agent 4 parts, anti-pollution agent 0.8 parts, thinner 0.6 parts, suspension stabilizer 0.2 parts.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com