Method for preparing silicon-based aerogel with different contact angles by drying with low cost under normal pressure

A technology of atmospheric drying and airgel, applied in the direction of silicon oxide, silicon dioxide, etc., which can solve the problems of low safety factor, high energy consumption, restrictions on industrial production and practical application, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

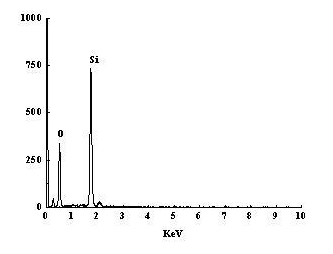

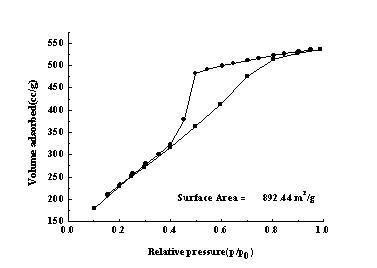

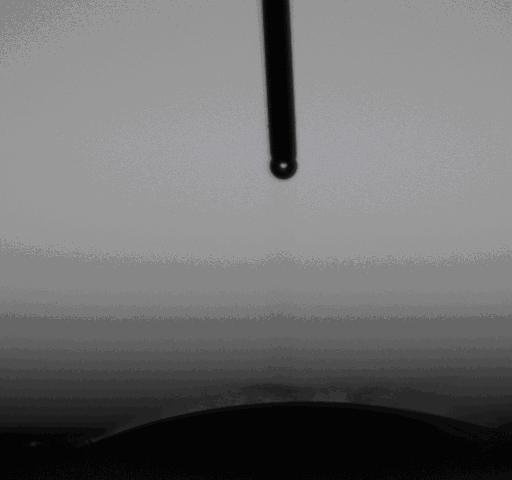

[0016] Weigh 3.8 g of sodium metasilicate nonahydrate, add it to 20 ml of deionized water, and stir in a 60 ℃ water bath for 20 min. After the solution is cooled, add 4 ml of glacial acetic acid solution dropwise. Show acidity, stand in a 60 ℃ water bath, gelatinize after a few hours to obtain a silica wet gel, aged for 2 days; add deionized water in a 60 ℃ water bath for immersion and cleaning for 24 h; add 15-25 ml absolute ethanol, exchange the water in the gel twice within 48 hours (soak the gel with ethanol and replace it once in 24 hours), and then use 15-25 ml of n-hexane to exchange the ethanol in the gel twice within 48 hours. Wet gels were immersed in n-hexane / trimethylchlorosilane solutions with different ratios (the molar ratio of silicon content in wet gel to trimethylchlorosilane was Si : TMCS = 1:1), and the surface modification was carried out at 50 °C. After 24 hours, add 15-25 ml of n-hexane to exchange the unreacted modifier twice within 24 hours, seal the b...

example 2

[0018] Weigh 3.8 g of sodium metasilicate nonahydrate, add it to 20 ml of deionized water, and stir in a 60 ℃ water bath for 20 min. After the solution is cooled, add 4 ml of glacial acetic acid solution dropwise. Show acidity, stand in a 60 ℃ water bath, gelatinize after a few hours to obtain a silica wet gel, aged for 2 days; add deionized water in a 60 ℃ water bath for immersion and cleaning for 24 h; add 15-25 ml absolute ethanol, exchange the water in the gel twice within 48 hours (soak the gel with ethanol and replace it once in 24 hours), and then use 15-25 ml of n-hexane to exchange the ethanol in the gel twice within 48 hours. Wet gels were immersed in n-hexane / trimethylchlorosilane solutions with different ratios (the molar ratio of silicon content in wet gel to trimethylchlorosilane was Si : TMCS = 1:2), and the surface modification was carried out at 50 °C. After 24 hours, add 15-25 ml of n-hexane to exchange the unreacted modifier twice within 24 hours, seal the b...

example 3

[0020] Weigh 3.8 g of sodium metasilicate nonahydrate, add it to 20 ml of deionized water, and stir in a 60 ℃ water bath for 20 min. After the solution is cooled, add 4 ml of glacial acetic acid solution dropwise. Show acidity, stand in a 60 ℃ water bath, gelatinize after a few hours to obtain a silica wet gel, aged for 2 days; add deionized water in a 60 ℃ water bath for immersion and cleaning for 24 h; add 15-25 ml absolute ethanol, exchange the water in the gel twice within 48 hours (soak the gel with ethanol and replace it once in 24 hours), and then use 15-25 ml of n-hexane to exchange the ethanol in the gel twice within 48 hours. Wet gels were immersed in n-hexane / trimethylchlorosilane solutions with different ratios (the molar ratio of silicon content in wet gel to trimethylchlorosilane was Si : TMCS = 1:6), and surface modification was carried out at 50 °C. After 24 hours, add 15-25 ml of n-hexane to exchange the unreacted modifier twice within 24 hours, seal the beake...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

| contact angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com