Patents

Literature

67results about How to "Easy to apply evenly" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

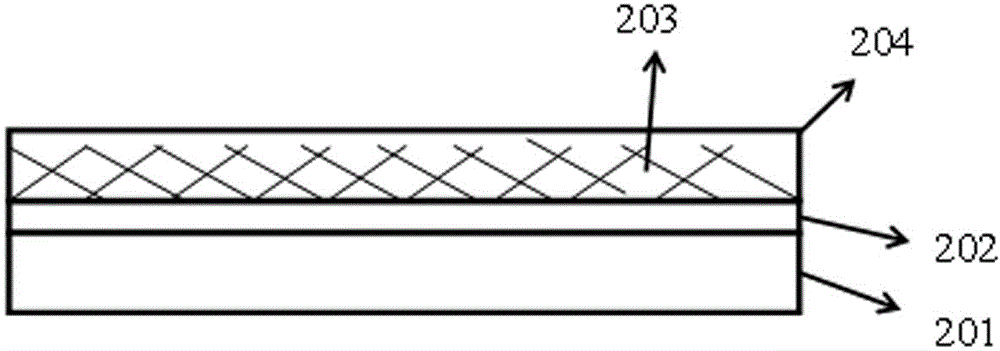

Low-haze transparent conductive film and preparation method thereof

ActiveCN104867540AEasy to apply evenlyChoose safety and environmental protectionConductive layers on insulating-supportsNon-conductive material with dispersed conductive materialHydrophilic coatingTransmittance

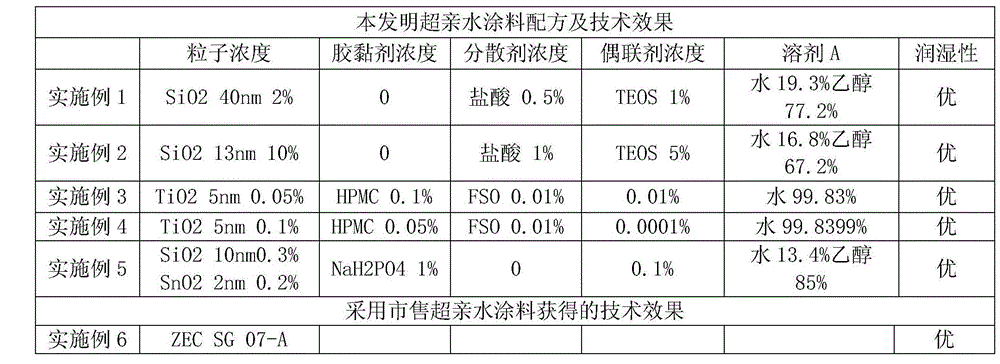

The invention provides a low-haze transparent conductive film and a preparation method thereof. The low-haze transparent conductive film comprises a transparent substrate layer, wherein the transparent substrate layer is coated with a super hydrophilic coating formed by a super hydrophilic coating material, the super hydrophilic layer is coated with a transparent conductive layer formed by a conductive ink composition, and the wetting angle of water at the surface of the super hydrophilic coating is less than or equal to 5 degrees. After the super hydrophilic coating is coated, the light transmittance of the substrate is improved, the haze is reduced, an adhesive force between the transparent conductive layer and the substrate is enhanced, and the oxygen permeability of the transparent substrate is also reduced at the same time. By adopting the technical scheme provided by the invention, the total haze of the ultimately acquired transparent conductive film is reduced by 40% compared with that before super hydrophilic processing under the condition of keeping the conductivity to be unchanged, the light transmittance is improved by 2-5%, the adhesive force is also obviously improved, and the appearance is more transparent.

Owner:JIANGSU NANOWELL ADVANCED MATERIALS SCI&TECH

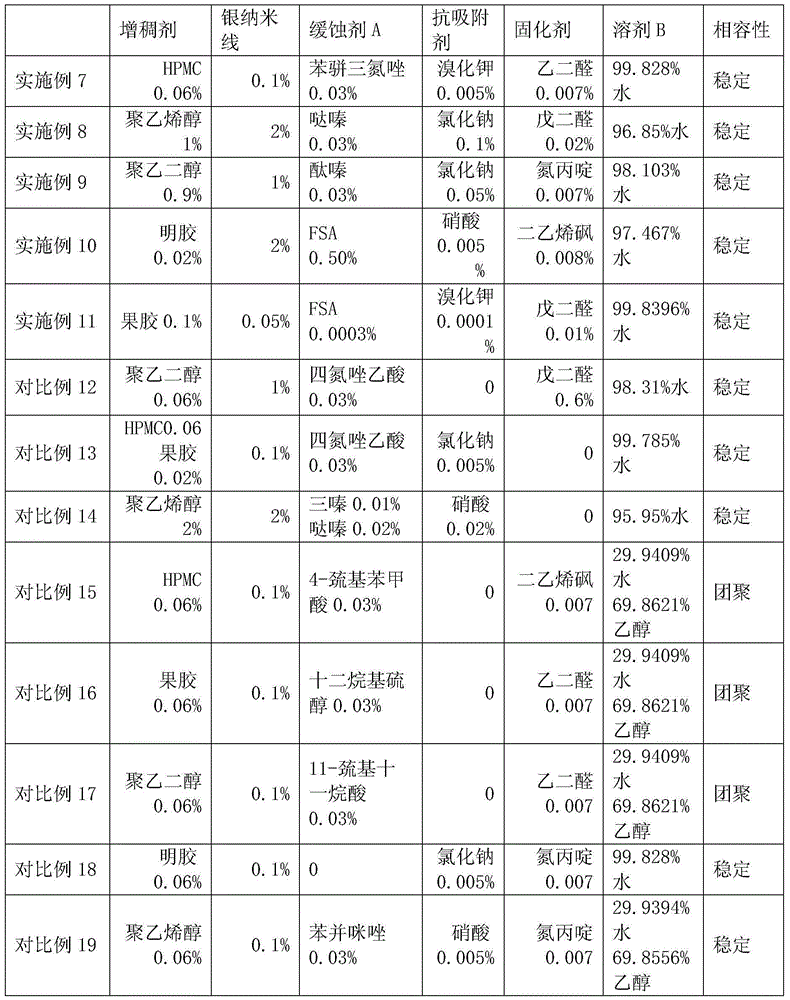

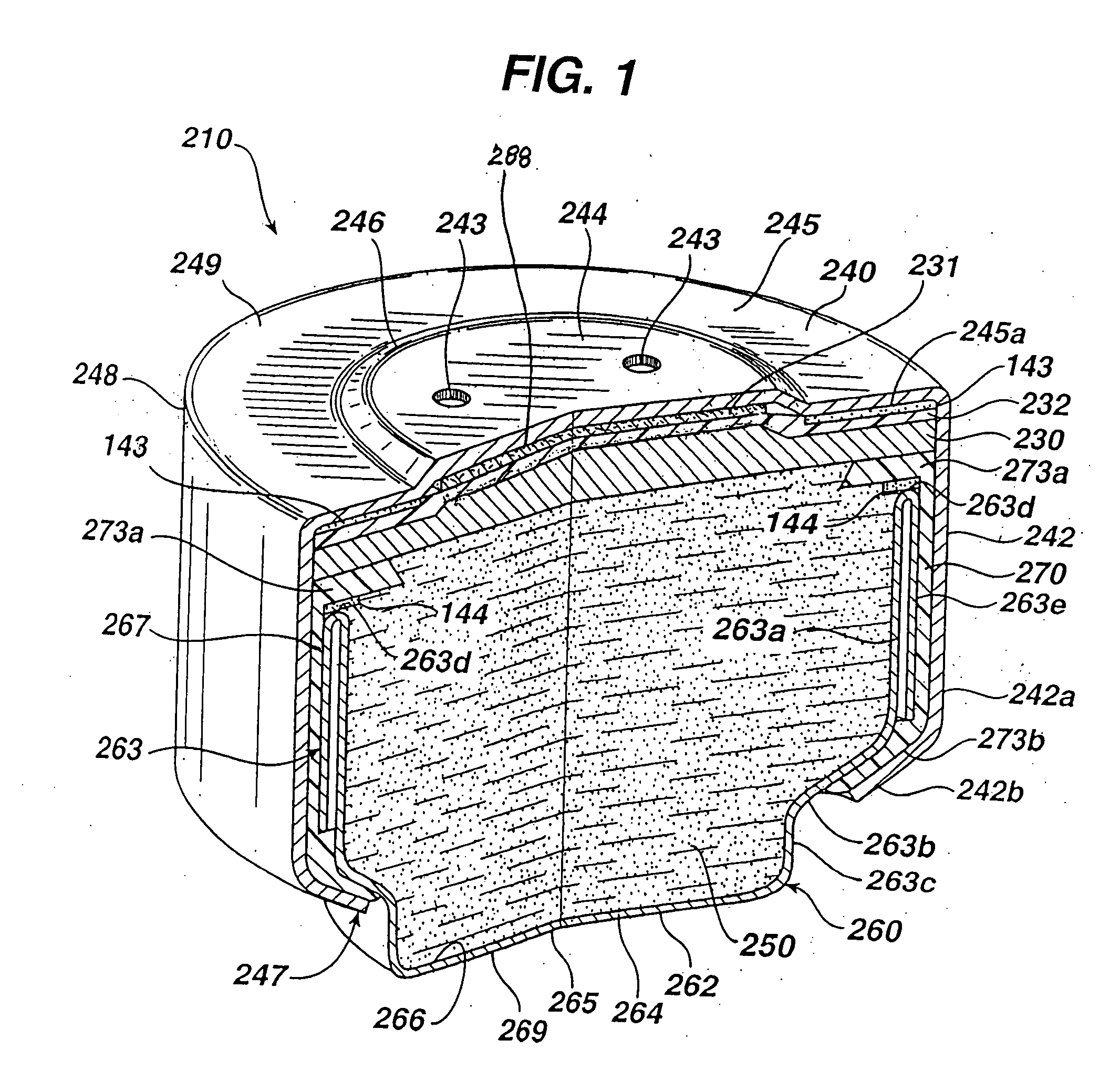

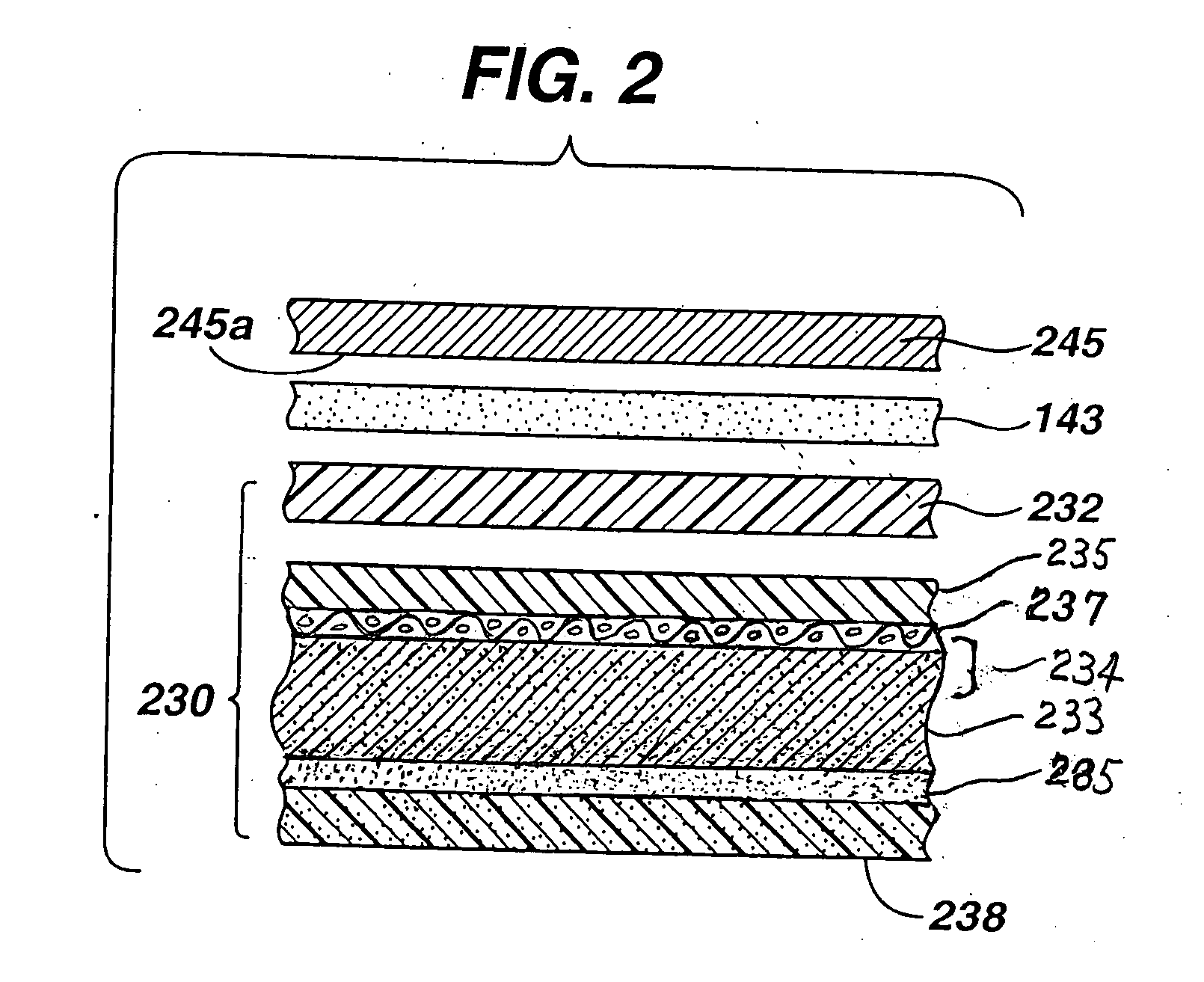

Zinc/air cell

InactiveUS20070224495A1Improve ionic conductivityResists deterioration in ionic conductivityFuel and primary cellsNon-aqueous electrolyte accumulator electrodesPolyvinyl alcoholButton battery

A zinc / air depolarized cell wherein the anode comprises zinc particles, aqueous alkaline electrolyte, and aqueous alkaline electrolyte within said anode casing; a cathode within said cathode casing; and an electrolyte permeable separator between said cathode and anode; and a glue comprising crosslinked polyvinylalcohol, preferably crosslinked with a boron containing compound, said glue located between the separator and a side of said cathode to adhesively bond the separator to the cathode. The cell may be in the form of a button cell. The glue provides a strong adhesive bond between the separator, desirably of microporous polypropylene, and the cathode. The glue promotes ionic conductivity at the separator / electrode interface even when the zinc / electrolyte ratio within the anode is elevated.

Owner:DURACELL U S OPERATIONS

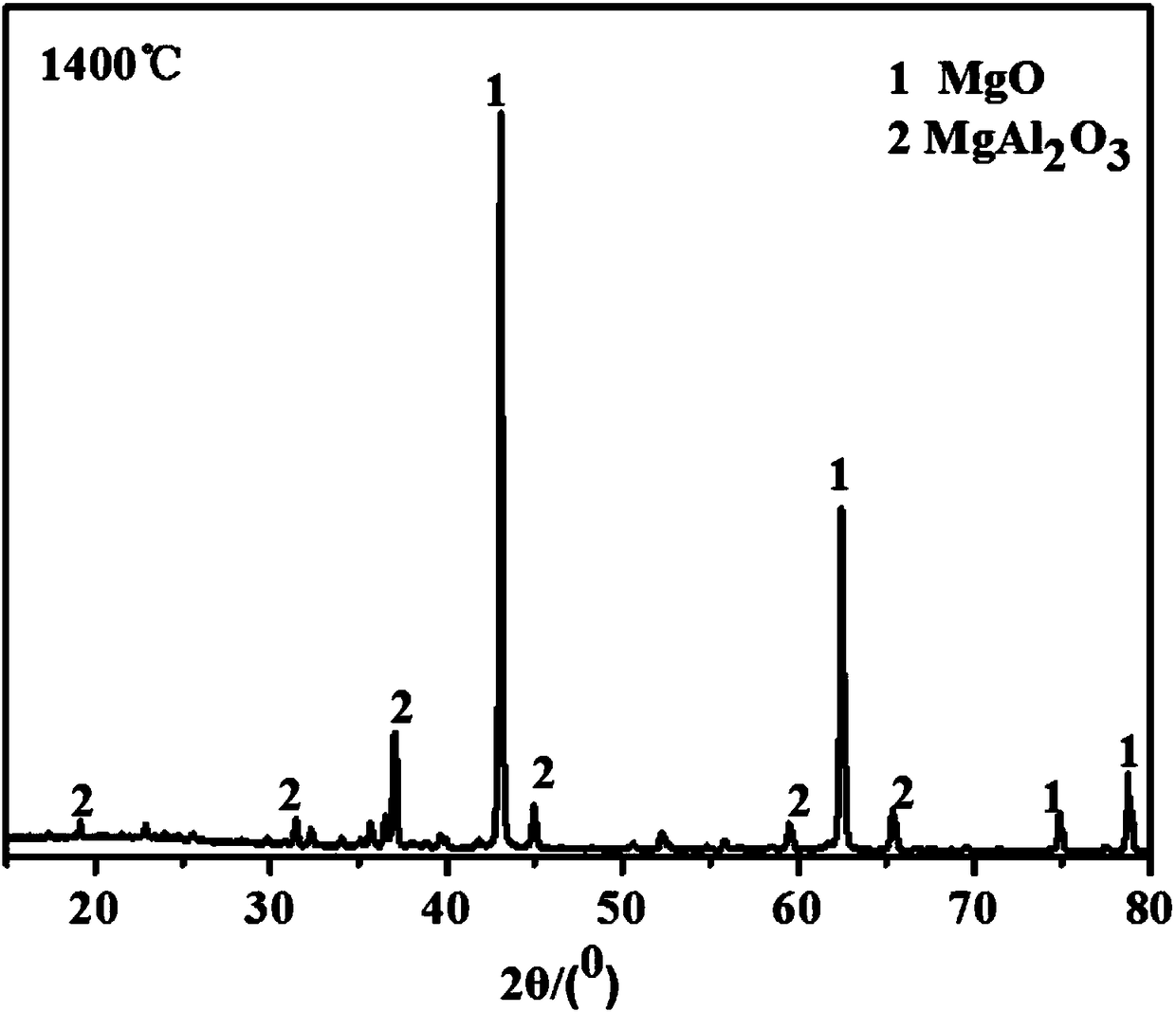

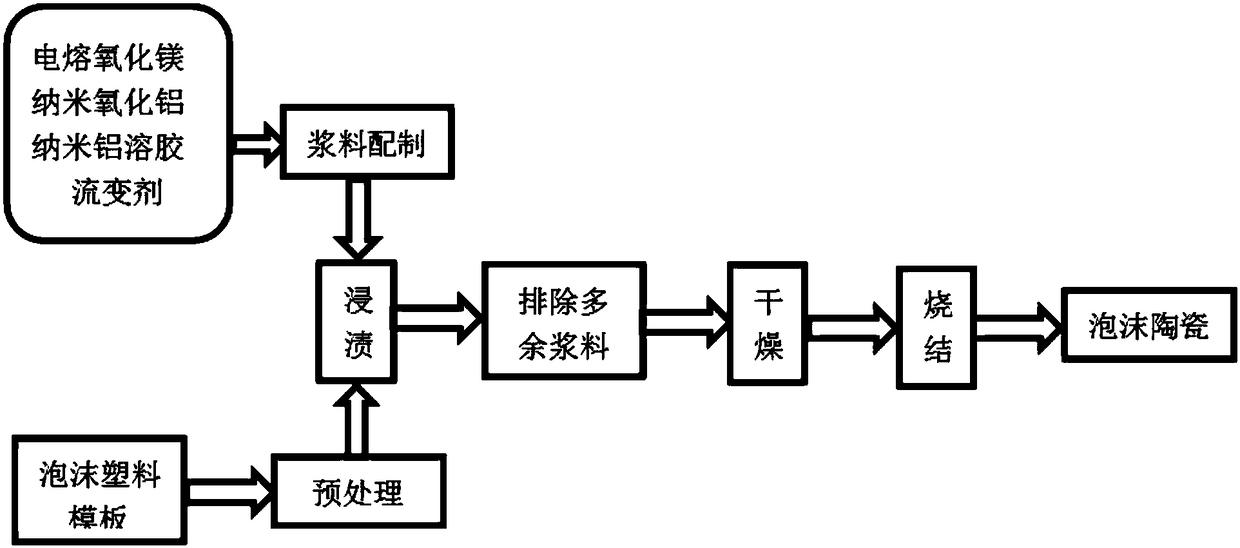

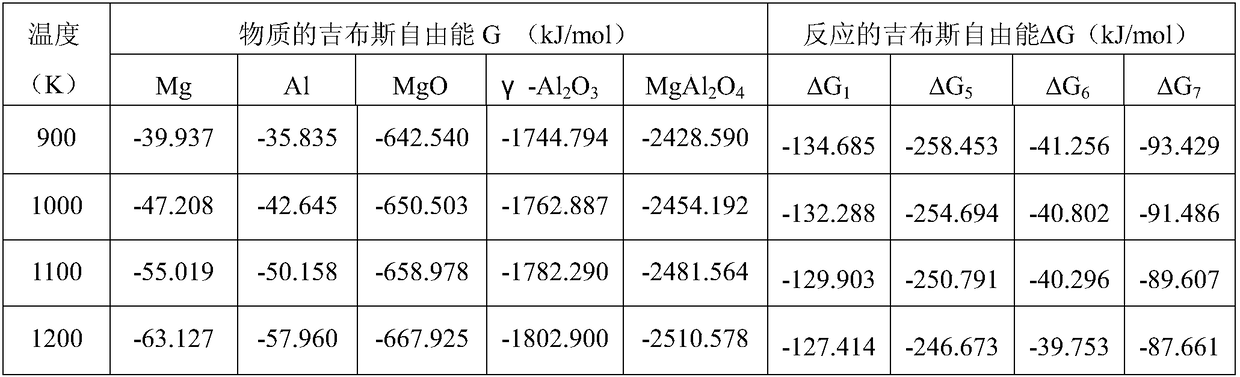

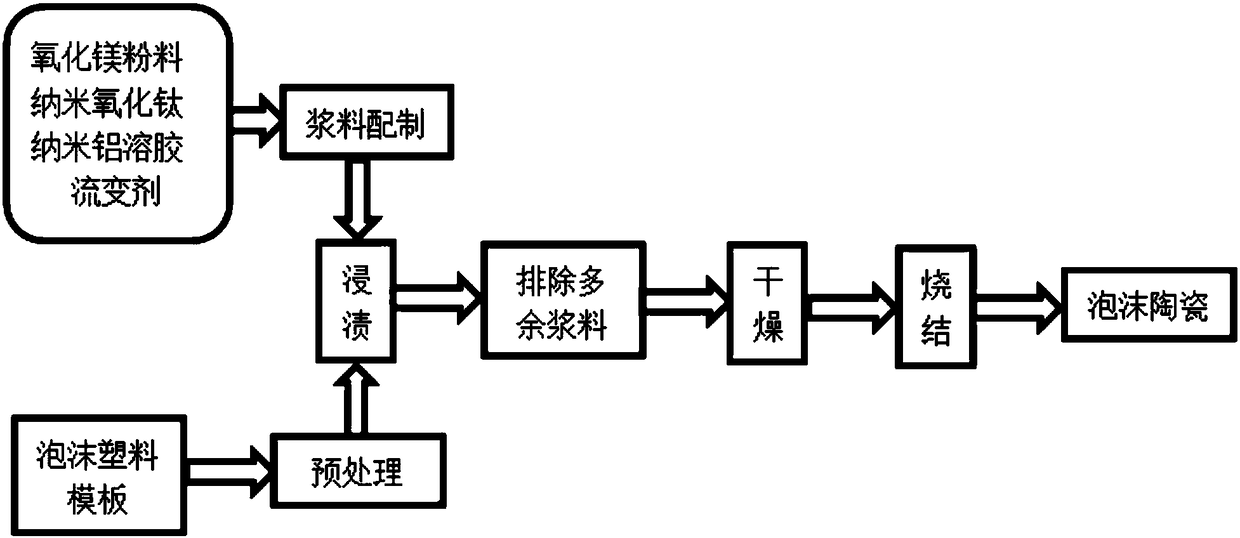

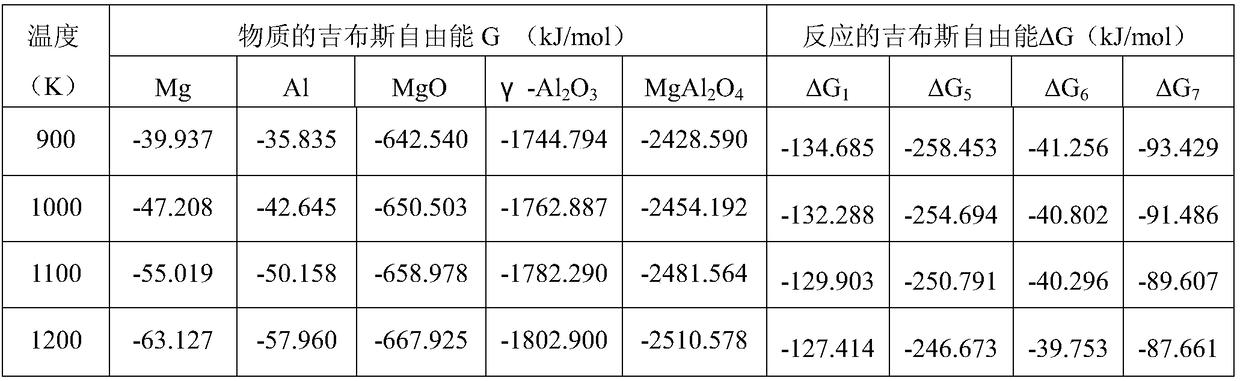

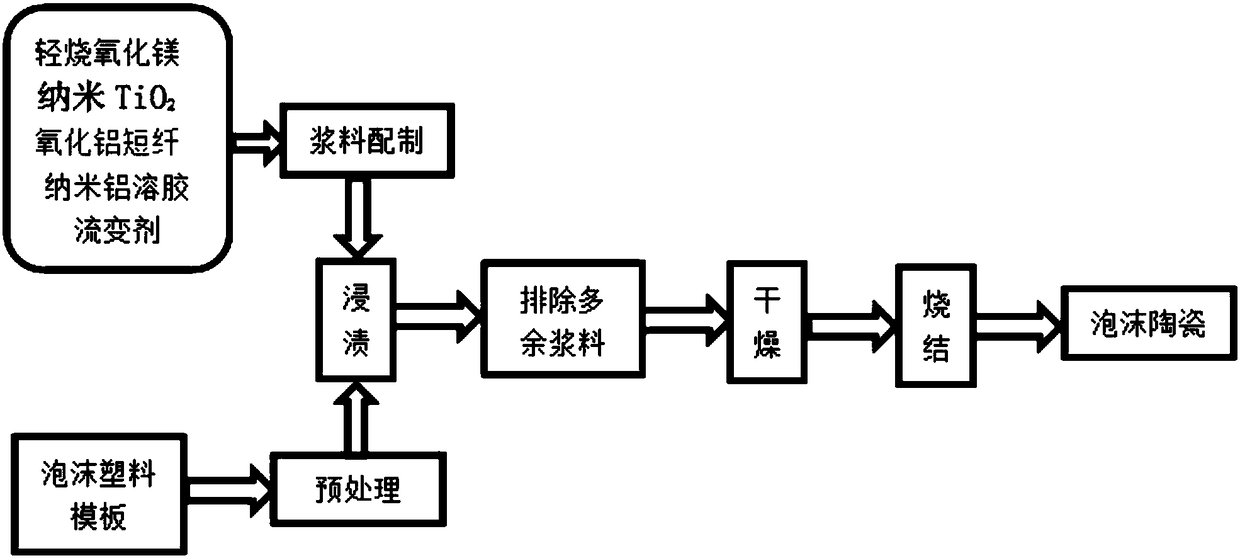

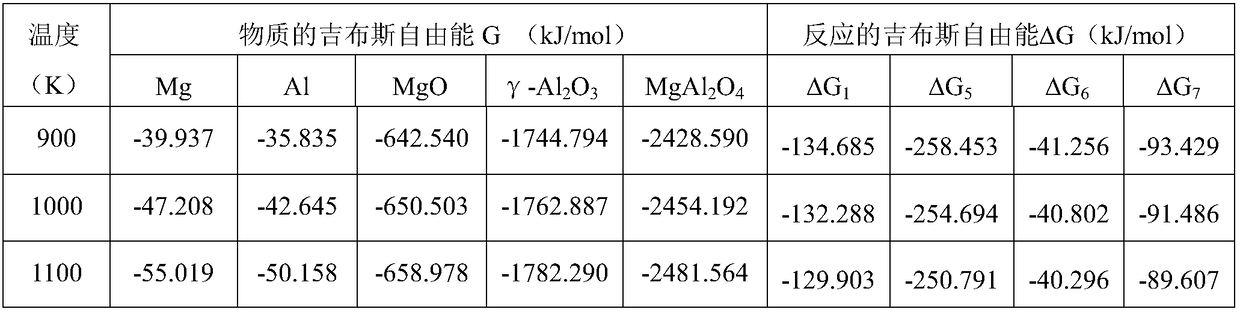

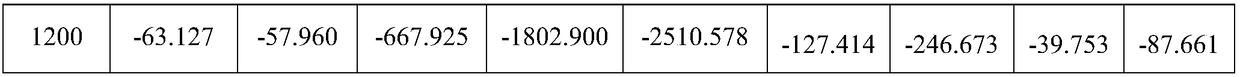

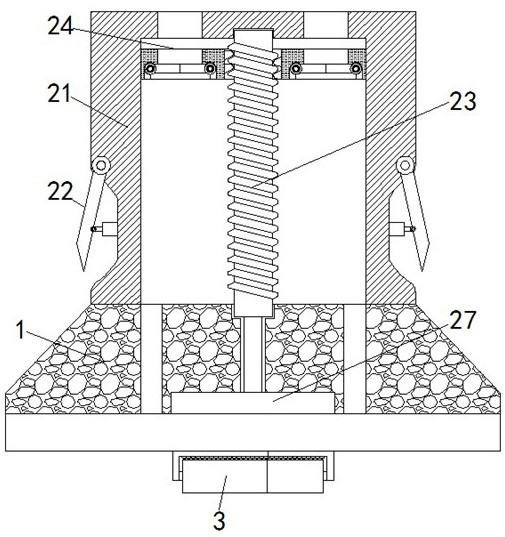

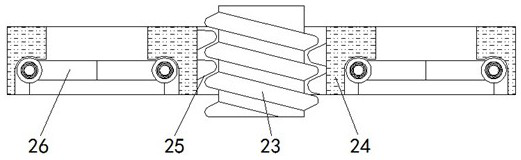

Magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter and preparation method thereof

ActiveCN108516803AAct as a binderAvoid damageFiltration separationCeramicwareOxide ceramicNano al2o3

The invention discloses a magnesium aluminate spinel enhanced magnesia-based foamed ceramic filter with capability of realizing sintering at low temperature, excellent chemical stability and excellentthermal shock resistant performance, and a preparation method thereof. The preparation method comprises the following steps that (1) 10 to 20 percent of nanometer alumina sol, 0.8 to 1.5 percent of rheological agents and the balance of magnesium oxide ceramic powder containing a nanometer aluminum oxide sintering aid are proportioned; deionized water is added; ball milling and uniform mixing areperformed; then, through vacuum exhaust, ceramic slurry with the solid content being 60 to 70 percent is prepared; (2) a polyurethane foamed plastic template is soaked into the ceramic slurry; the polyurethane foamed plastic template is extruded through a roller press for removing the redundant leaching hanging slurry; then, biscuit is prepared; then, the biscuit is heated to 80 to 120 DEG C for drying; (3) the dried biscuit is put into a sintering furnace; the temperature is raised to 1400 to 1600 DEG C; high-temperature sintering is performed; cooling is performed along with the furnace to room temperature; the magnesia-based foamed ceramic filter is obtained.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

Preparation method of antibacterial mould-proof plywood for decoration

ActiveCN107351197AInhibit residual mold activityGood flexibilityRadiation/waves wood treatmentNon-macromolecular adhesive additivesCelluloseHuman health

The invention mainly relates to the technical field of machining of artificial boards, and discloses a preparation method of antibacterial mould-proof plywood for decoration. The preparation method comprises drying, dipping, freezing, gluing, hot pressing and arrangement; the method is simple, safe and nontoxic; the obtained plywood for decoration reaches the mould inhibition rate of 76.3%, and contains no poisonous chemical reagent; the human health is guaranteed in the preparation and use process of the plywood; a veneer is firstly dried at low temperature, so that the water content is lower than the water content of a conventional veneer, the activity of the mould remained in the veneer is inhibited, the moulding is inhibited, the absorption of treatment solution in later treatment process is promoted, and the production efficiency is improved; and the dried veneer is put in sodium selenite solution for ultrasonic dipping, so that the sodium selenite solution is fully infiltrated in the veneer to inhibit growth of infectious microbes, the binding force of lignin to cellulose is reduced, the softness of the veneer is improved, breakage is prevented, and the machining performance and the use performance of the plywood are improved.

Owner:徐州市嘉翔木业有限公司

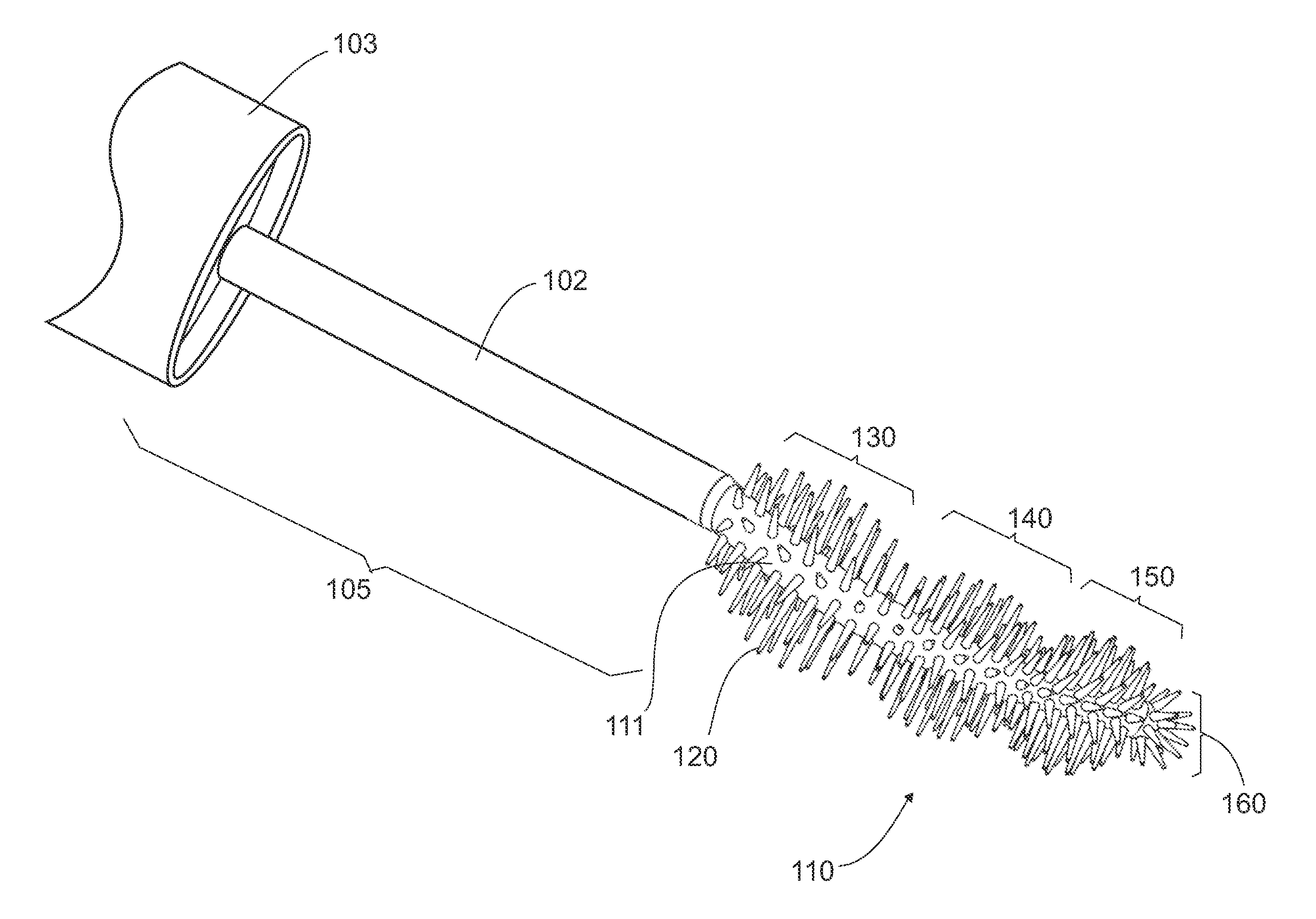

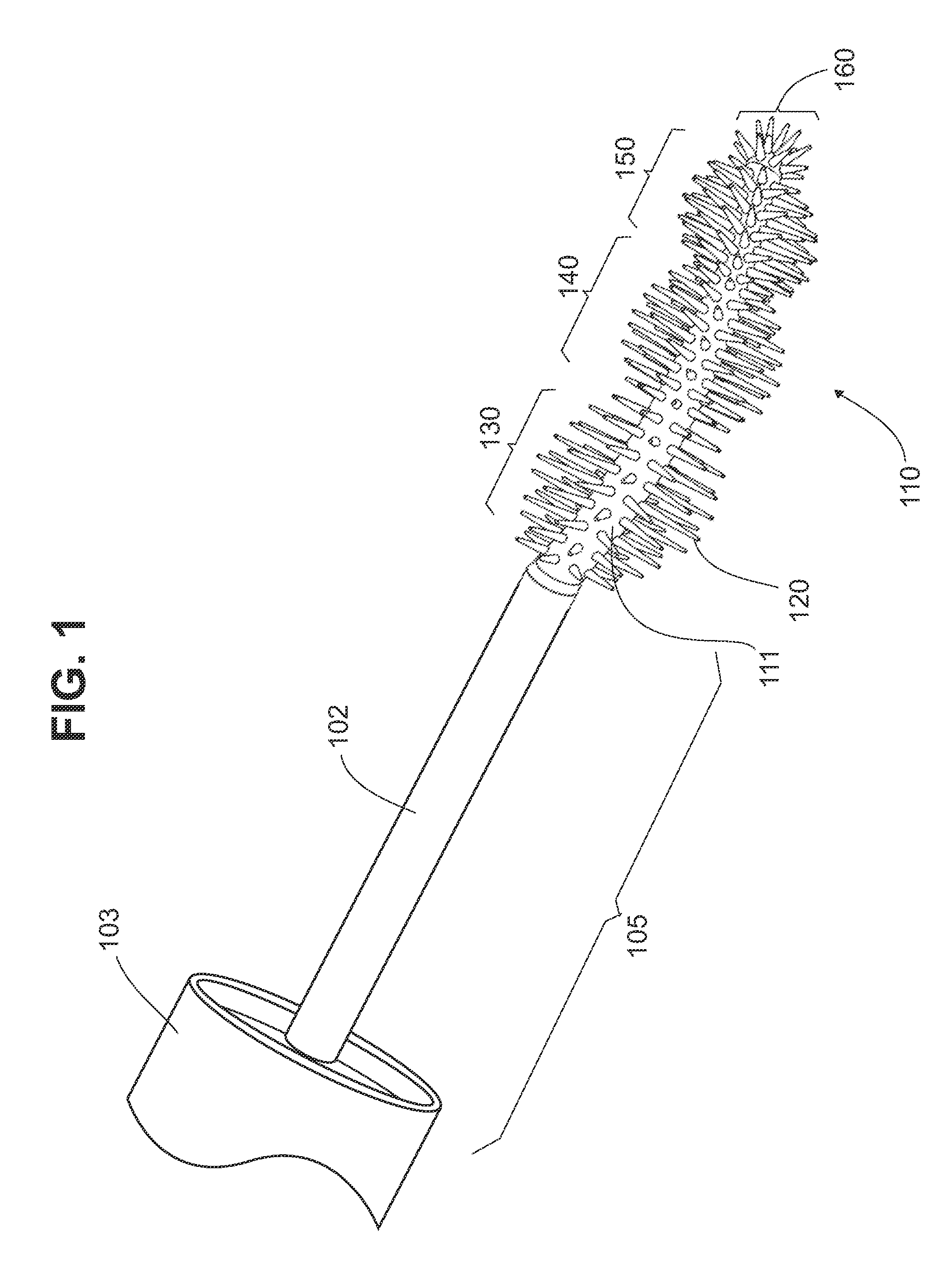

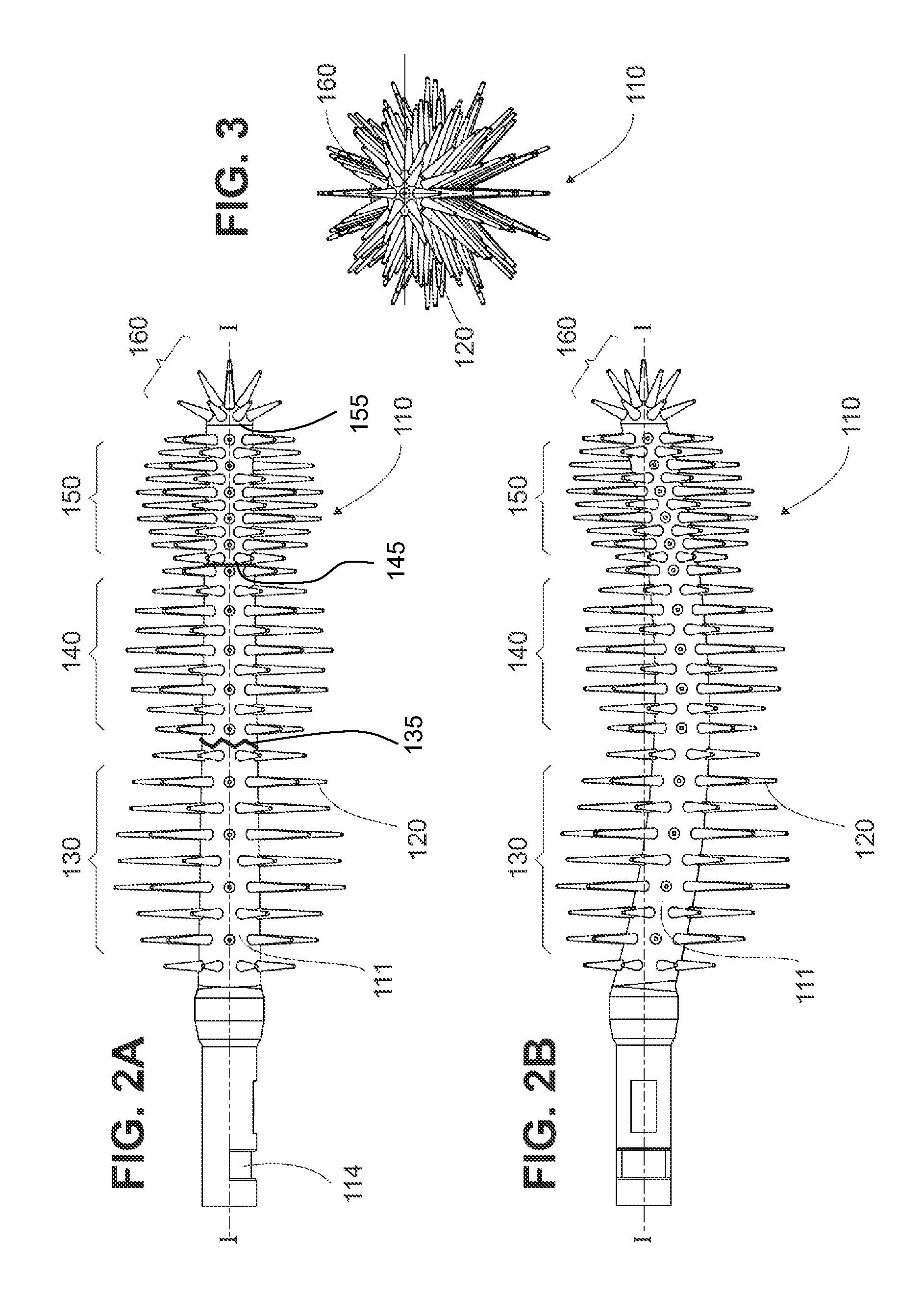

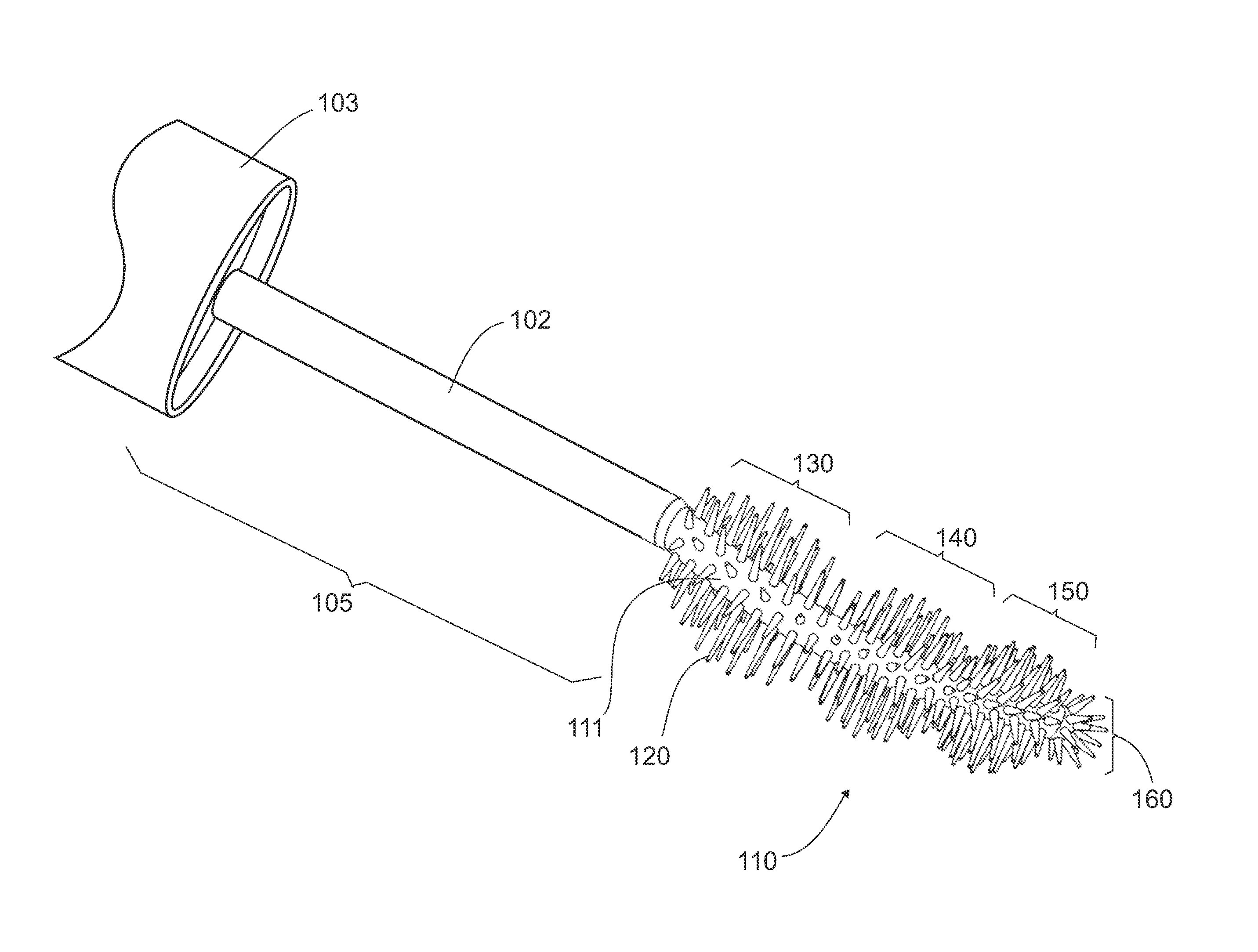

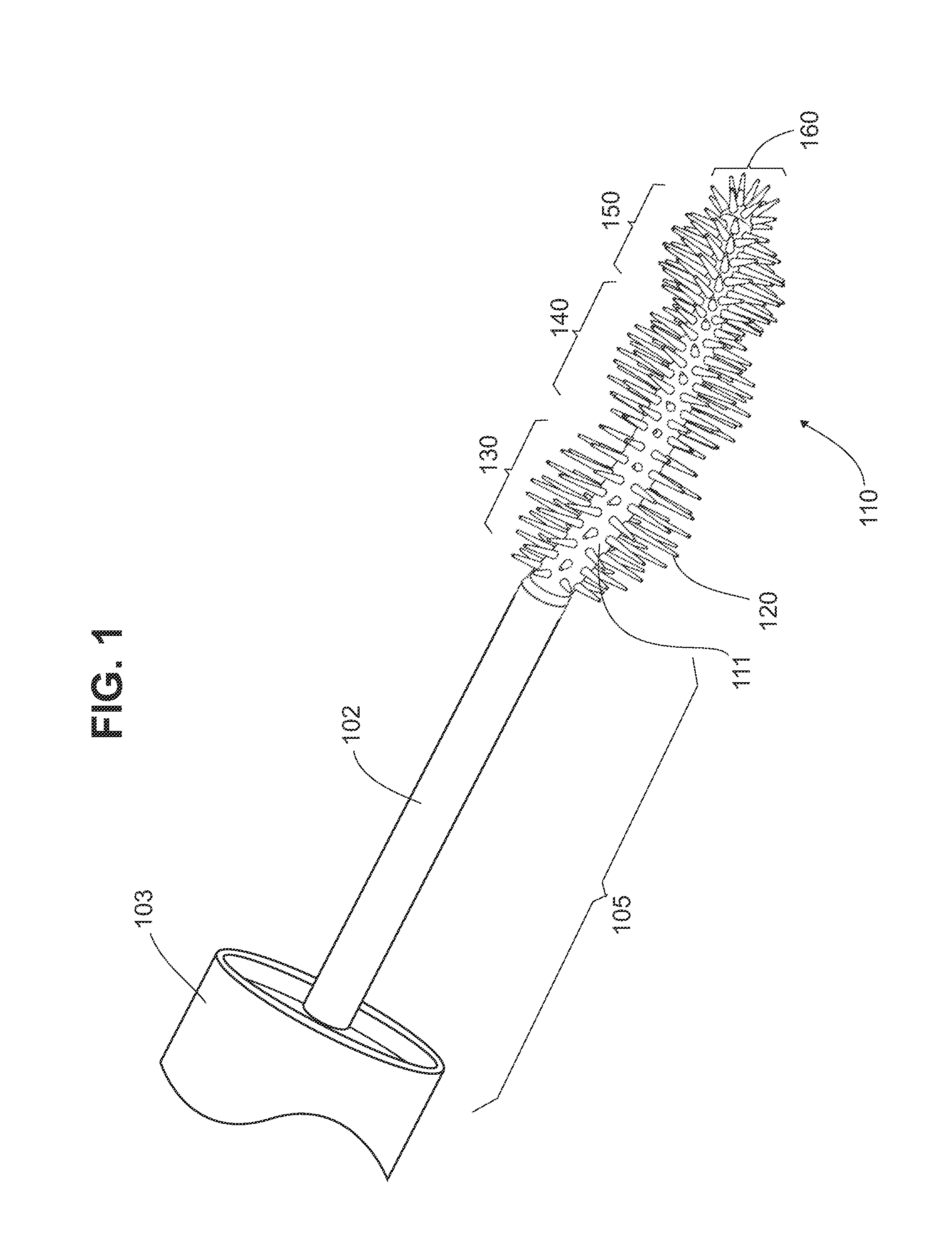

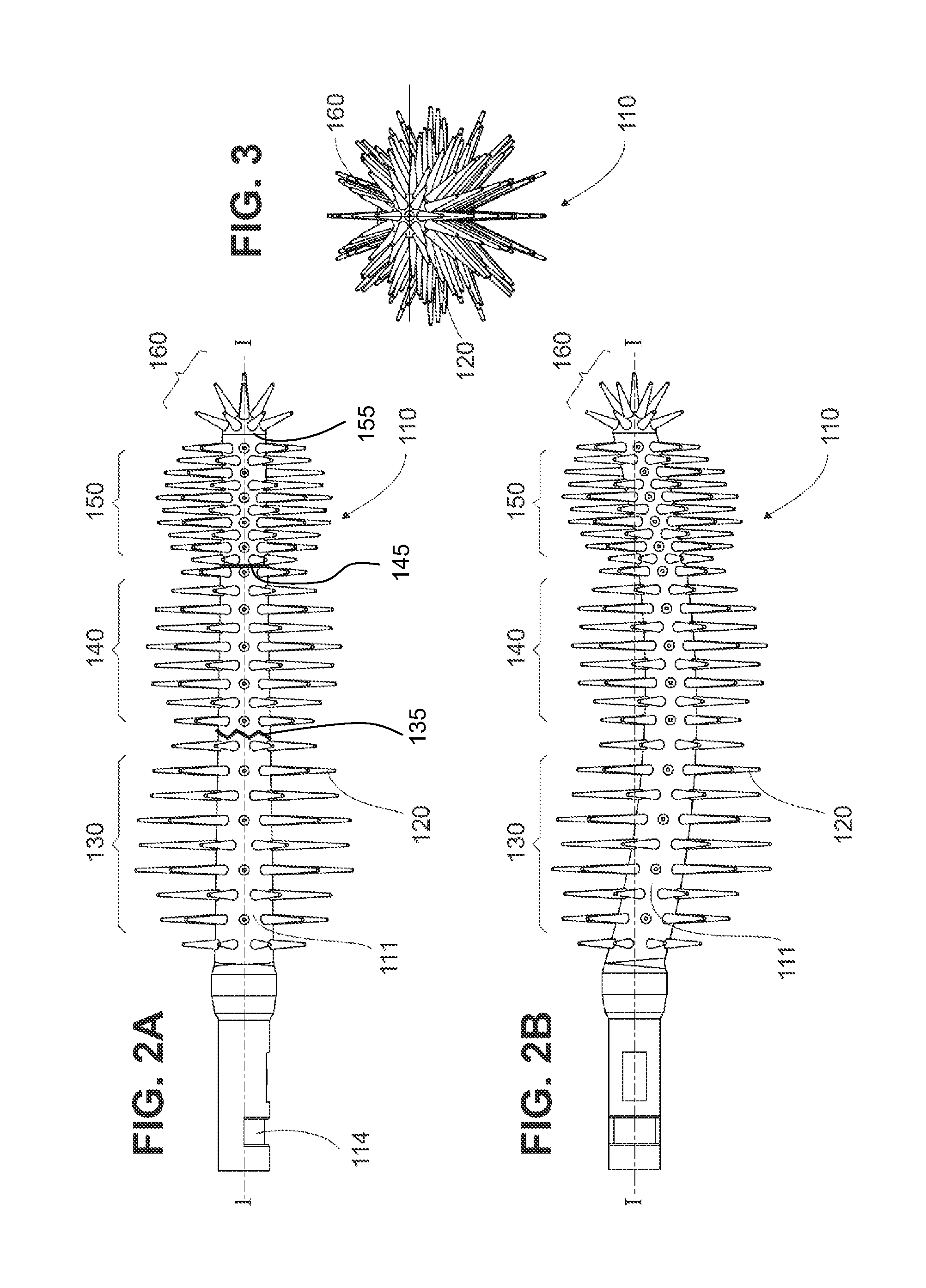

Cosmetic Applicator

An applicator is provided for applying a composition to a user's eyelashes. The applicator includes an applicator element having a large section, a medium section, and a small section, which are adapted to cover the outer, middle, and inner portions of a user's eyelashes, respectively, with a composition (e.g., mascara). The three sections of the applicator element include bristles sized and spaced in such a way as to facilitate even application of the composition without clumping.

Owner:AVON PROD INC

Nanometer strontium aluminate long-afterglow luminescent materials and preparation method thereof

InactiveCN101851506ASimple production processImprove efficiencyLuminescent compositionsGreen yellowNanometre

The invention discloses nanometer strontium aluminate long-afterglow luminescent materials and a preparation method thereof. The chemical formula of the luminescent materials is Sr(1-x)Al2O4:Eum2+,Dyn3+, wherein m plus n equals x; x is between 0.01 and 0.10; m is between 0.005 and 0.095; and n is between 0.005 and 0.095. Products in the invention have the advantages of pure phase, capability of emitting green-yellow light, few light scattering phenomenon, high nanometer fluorescence intensity, simple preparation and production process, high efficiency and low cost; all raw materials used in the invention are free from special requirements and rich in sources; all soluble salts can be alternately used; and the preparation process can be carried out flexibly and is easy for industrial application.

Owner:WENZHOU UNIVERSITY

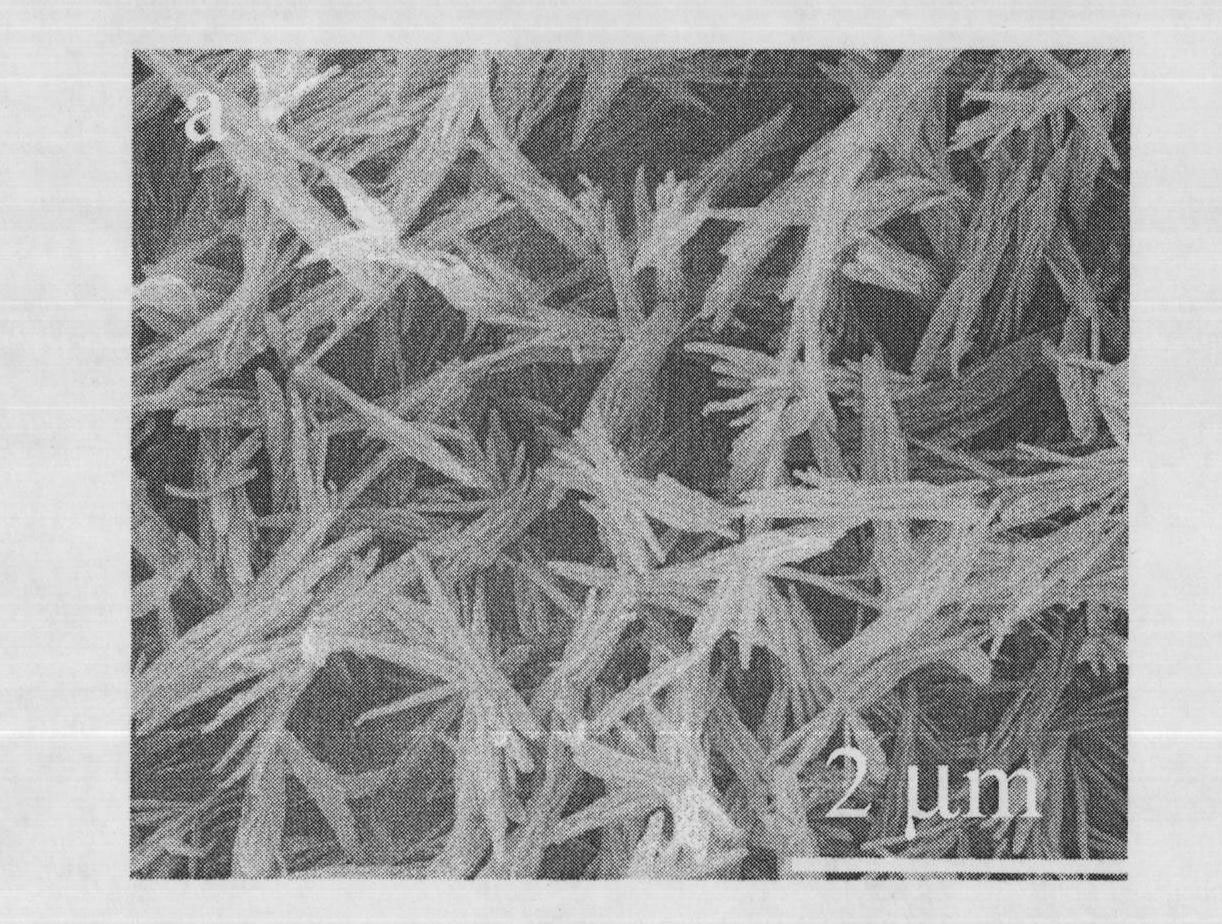

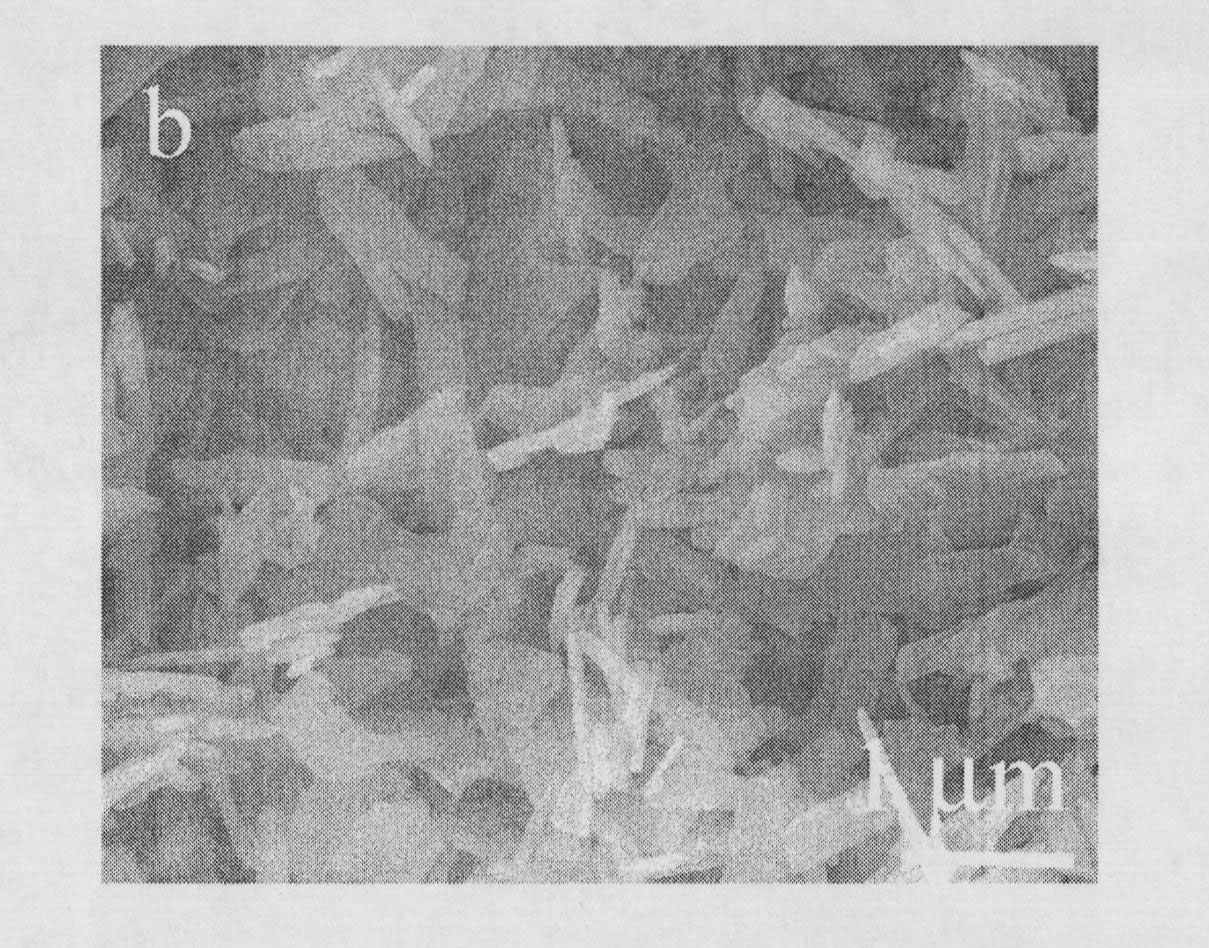

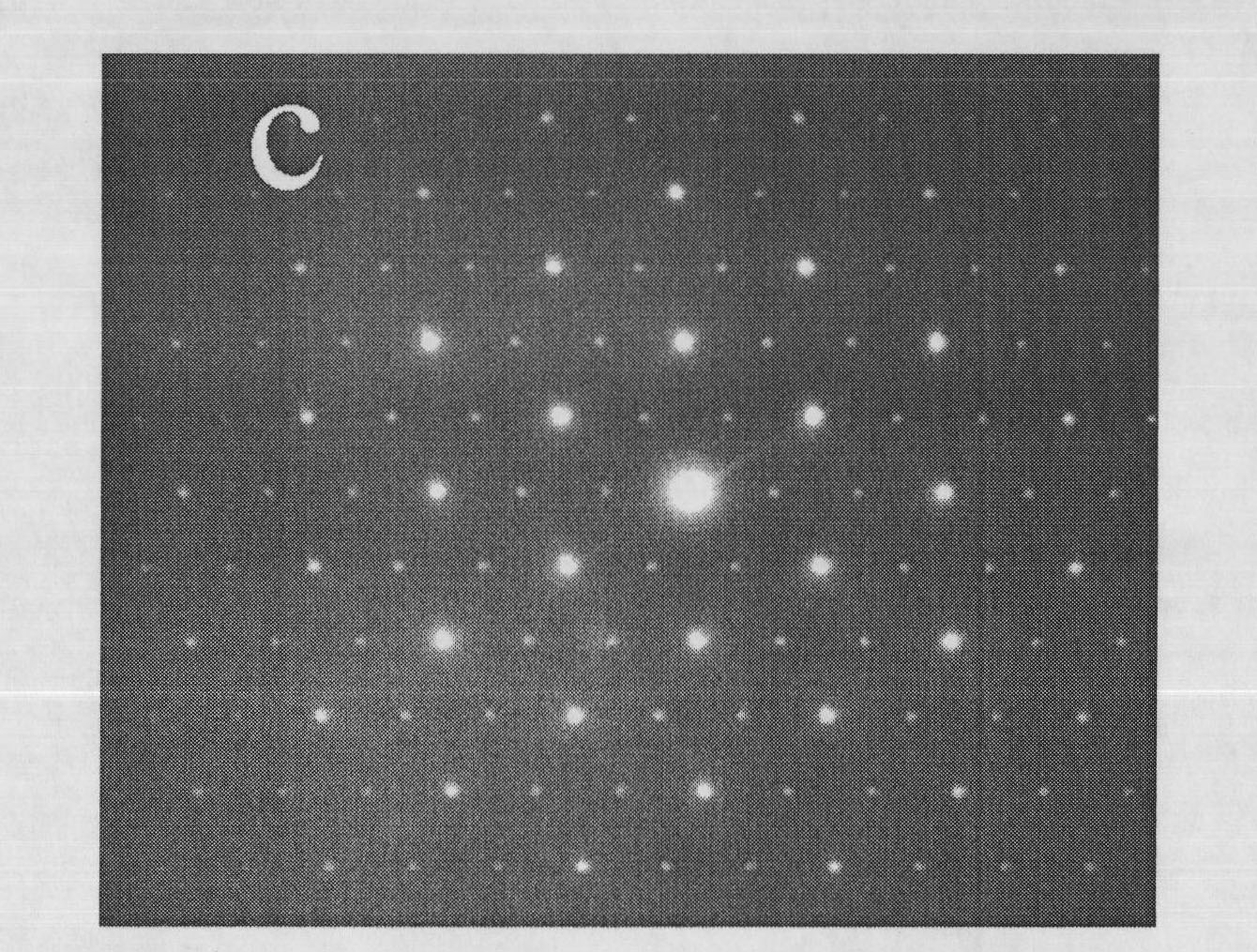

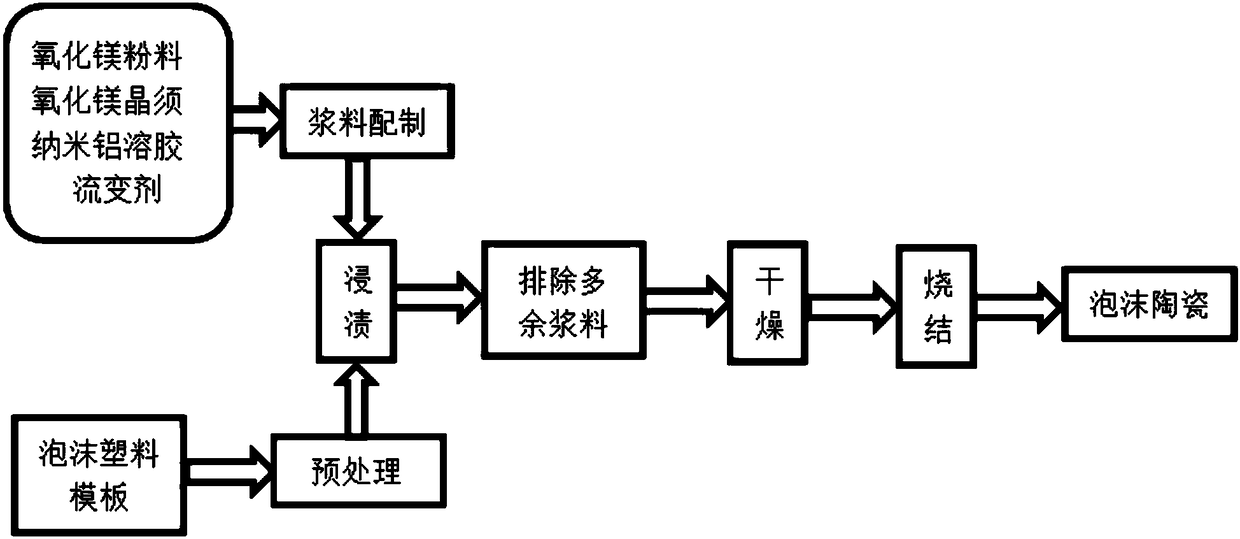

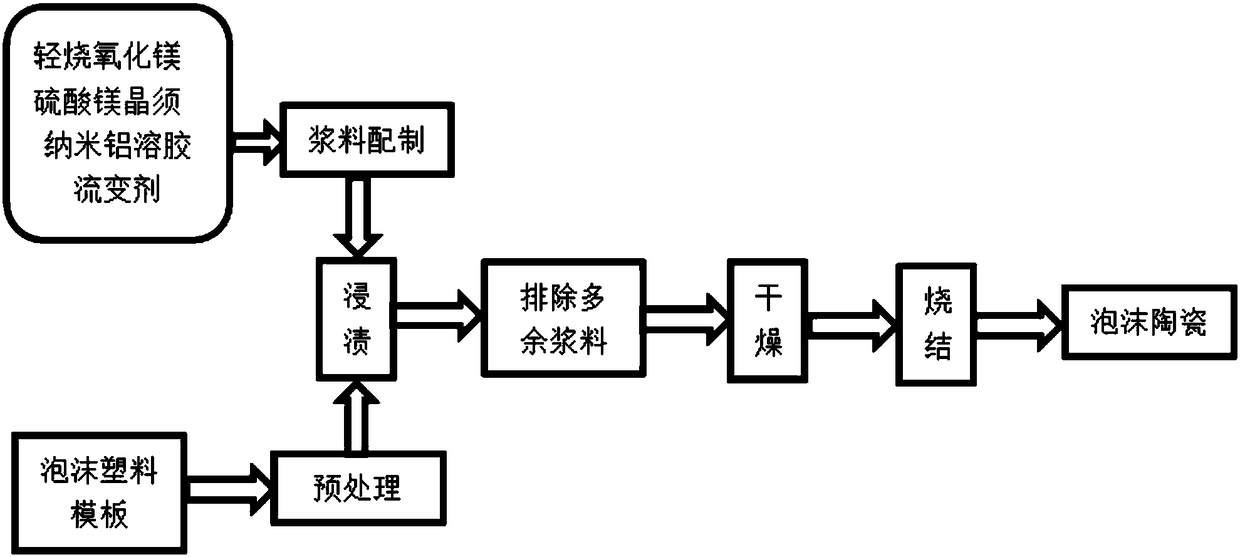

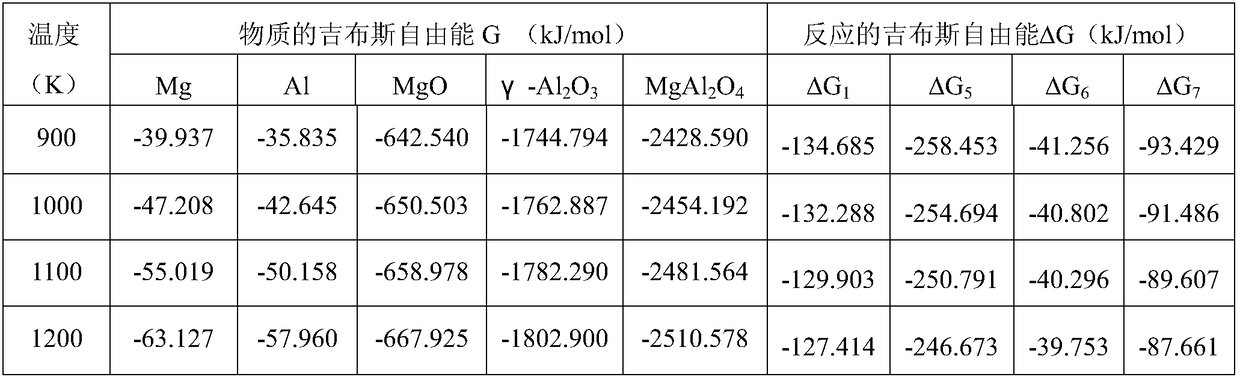

Magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

ActiveCN108484182AAvoid obstructionAct as a binderFiltration separationCeramicwareRoom temperatureSlurry

The invention discloses a magnesium oxide whisker in-situ synthesis magnesium aluminate spinel enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheological agent, and the balance of magnesia ceramics powder containing magnesium oxide whisker, adding deionized water, ball-milling, uniformly mixing, and preparing ceramic slurry of which the solid content is 60%-70% through vacuum exhaust; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, heating the biscuit to 80-120 DEG C, and drying; and (3) placing the dried biscuit in a sintering furnace, warming to 1400-1600 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

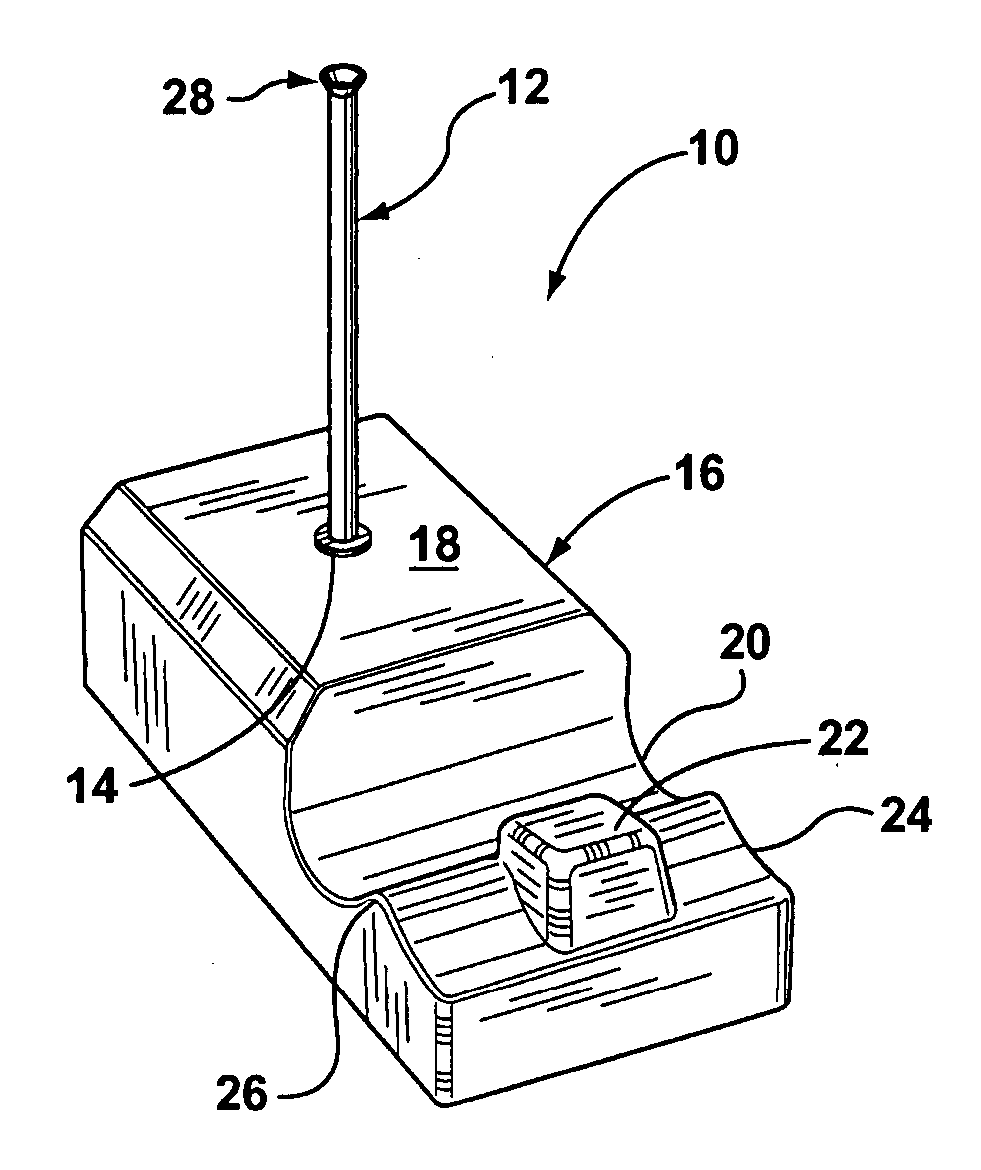

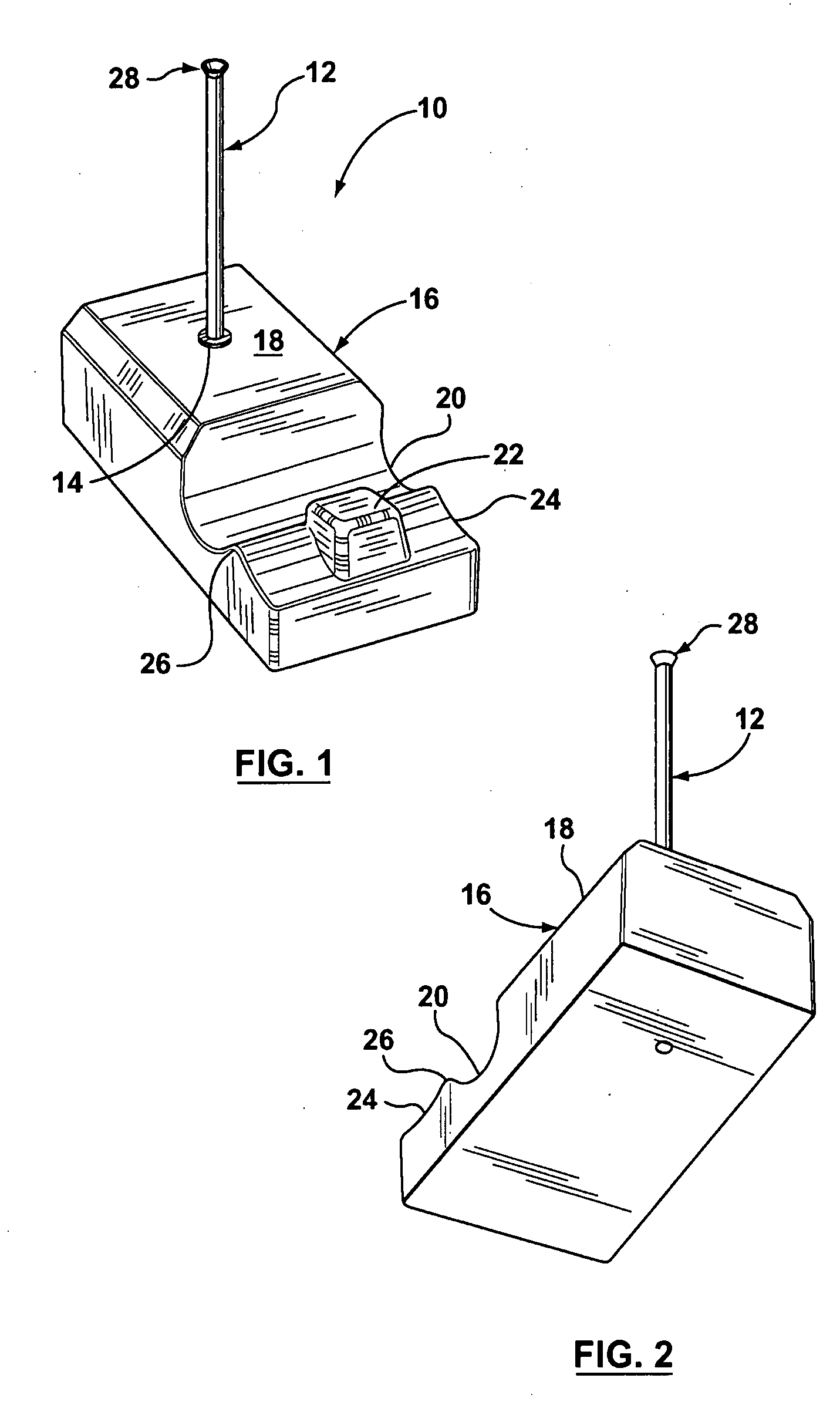

Dental holder

InactiveUS20080008982A1Shorten the timeEasy to prepareDental implantsArtificial teethDenturesProsthesis

An apparatus for holding a dental prosthesis during preparation of the dental prosthesis, the apparatus comprising: at least one base, the at least one base having an upper surface, at least one pin, and the at least one pin comprising a first end and a second end, the at least one pin further comprising a flared portion at the first end, and the first end extending beyond the upper surface of the at least one base, and the second end extending through and into the upper surface of the base. The use of an apparatus for holding a dental prosthesis during preparation of the prosthesis and for holding the dental prosthesis during firing without having to transfer the prosthesis to a second tray for firing. A method for preparing a dental prosthesis, the method comprising the steps of: a) mounting a substructure on an apparatus comprising at least one base, the at least one base having an upper surface, at least one pin, and the at least one pin comprising a first end and a second end, the at least one pin further comprising a flared portion at the first end, and the first end extending beyond the upper surface of the at least one base, and the second end extending through and into the upper surface of the base, b) applying at least one layer of ceramic to prepare a dental prosthesis, and c) firing the prosthesis mounted on the apparatus in a furnace.

Owner:MURSIC JONATHAN CARL

Basic magnesium sulfate whisker in-situ synthesized magnesium-aluminum spinel reinforced magnesium oxide based foamed ceramic filter and preparation method thereof

ActiveCN108530094ASimple processLow costProcess efficiency improvementCeramicwareOxide ceramicSlurry

The invention discloses a basic magnesium sulfate whisker in-situ synthesized magnesium-aluminum spinel reinforced magnesium oxide based foamed ceramic filter that can realize sintering at lower temperature and has excellent chemical stability and thermal shock resistance and a preparation method thereof. The preparation method comprises the steps of: (1) by mass percentage, blending 15%-25% of nano-aluminum sol, 0.8%-1.5% of a rheological agent, and the balance magnesium oxide ceramic powder containing basic magnesium sulfate whisker, adding anhydrous ethanol, performing ball-milling and uniform mixing to obtain a ceramic slurry with a solid content of 60%-70%; (2) immersing a polyurethane foam plastic template into the ceramic slurry, extruding the polyurethane foam plastic template by aroller press to remove redundant hung slurry for making a green body, then removing an ethanol solvent in a 40DEG C-50DEG C ventilation room, and drying the green body; and (3) putting the dried green body into a sintering furnace, performing heating to 1350DEG C-1550DEG C for high temperature sintering, and conducting furnace cooling to room temperature, thus obtaining the magnesium oxide basedfoamed ceramic filter.

Owner:FENGYANG L S NET FORMING CO LTD +1

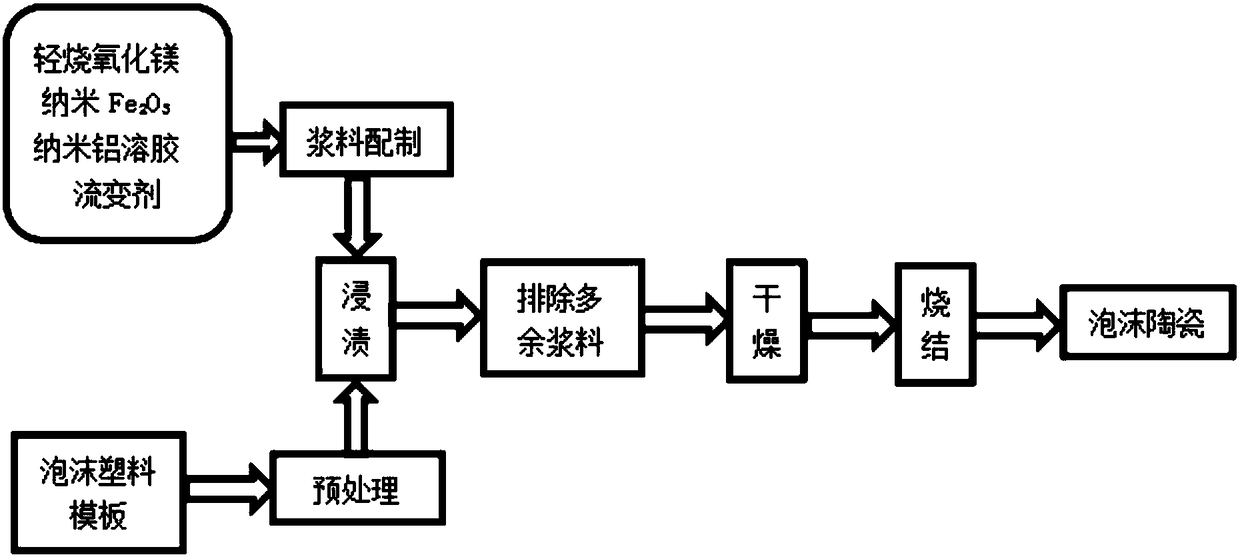

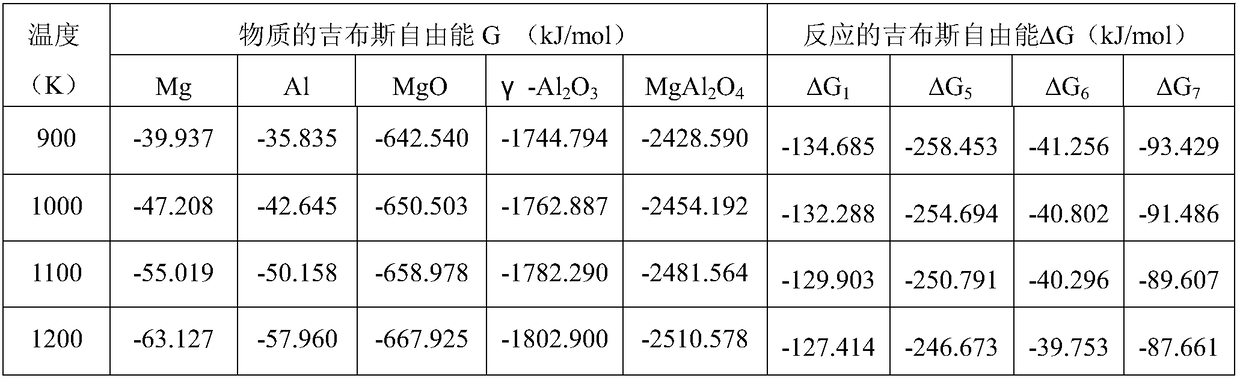

MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter and preparation method thereof

The invention discloses a MA-MF composite spinel reinforced magnesium oxide based foam ceramic filter capable of realizing low temperature sintering and excellent chemical stability and thermal shockresistance and a preparation method thereof, the preparation method comprises the following steps: (1) proportioning 15% to 25% by mass of nano-aluminum sol, 0.8% to 1.5% by mass of a rheological agent, and balance of magnesium oxide ceramic powder containing a nano-ferric oxide sintering aid, and adding anhydrous ethanol for even mixing by ball milling to obtain ceramic slurry having a solid content of 60% to 70%; (2) immersing a polyurethane foam plastic template into the ceramic slurry, extruding the polyurethane foam plastic template by a roll press to remove excess immersing slurry to obtain a green body, and removing an ethanol solvent in a ventilating chamber at 40 DEG C to 50 DEG C to dry the green body; and (3) putting the dried green body in a sintering furnace, heating to 1350 to 1550 DEG C for high temperature sintering, and cooling in the furnace to room temperature to obtain the magnesium oxide based ceramic foam filter.

Owner:NANJING UNIV OF AERONAUTICS & ASTRONAUTICS

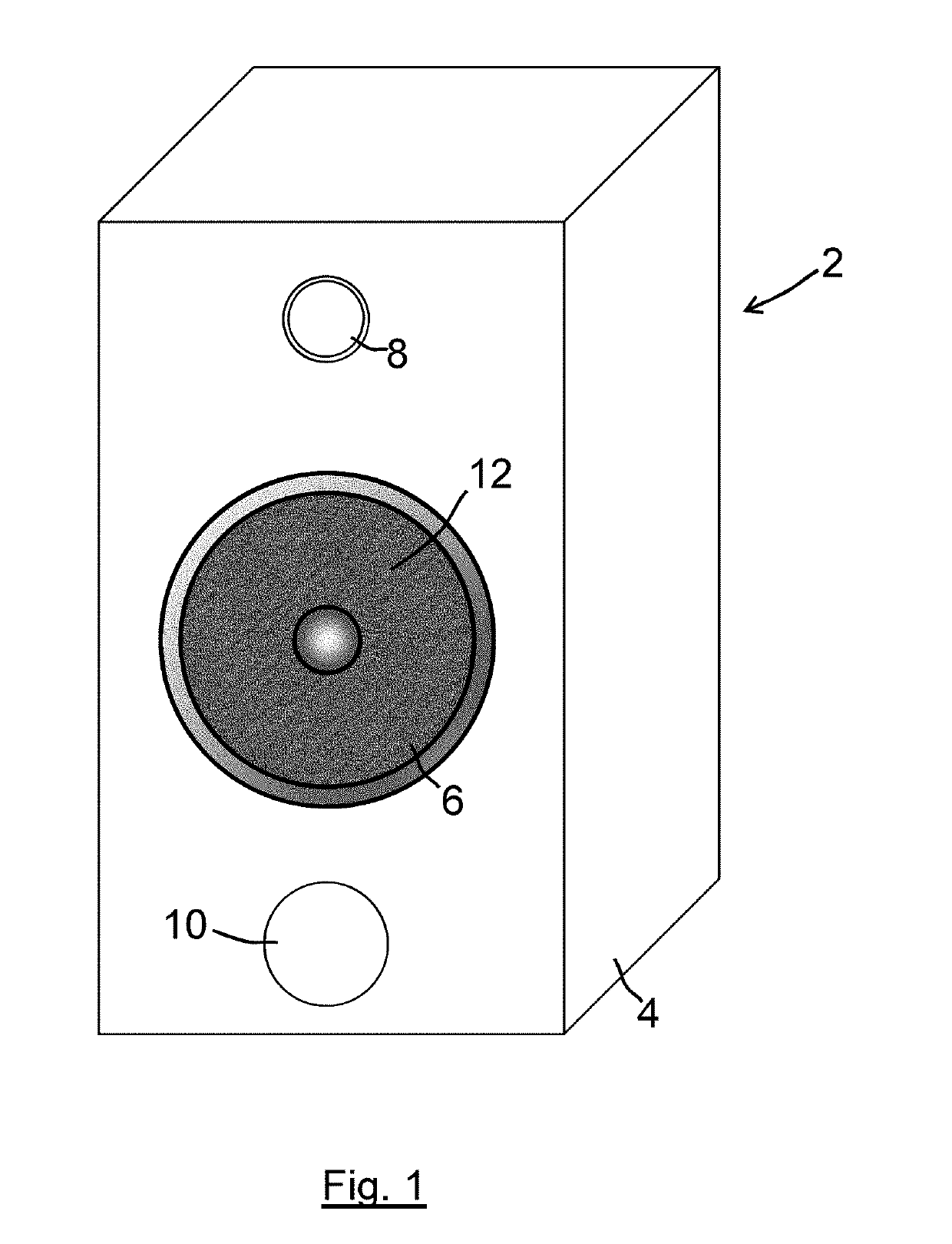

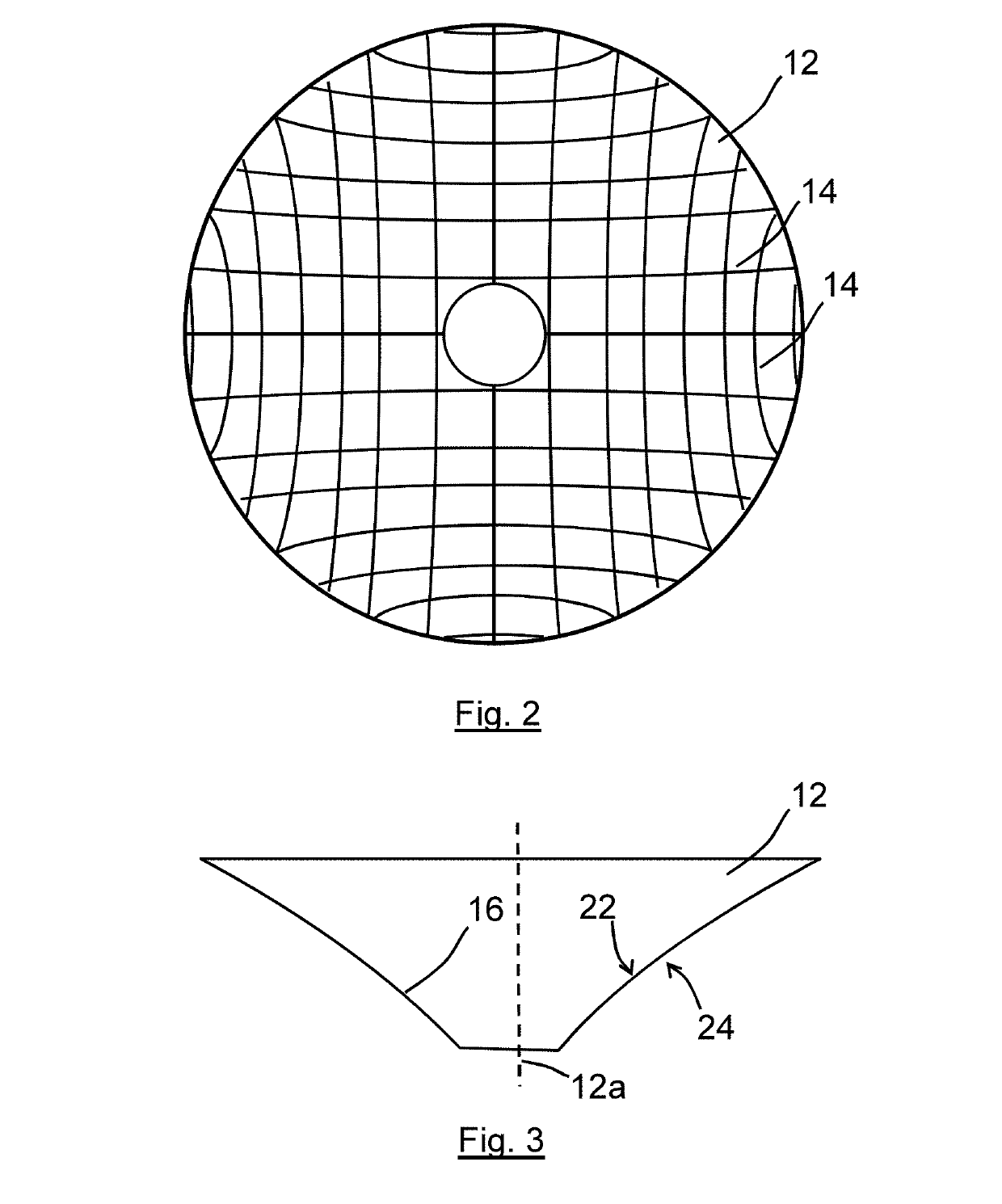

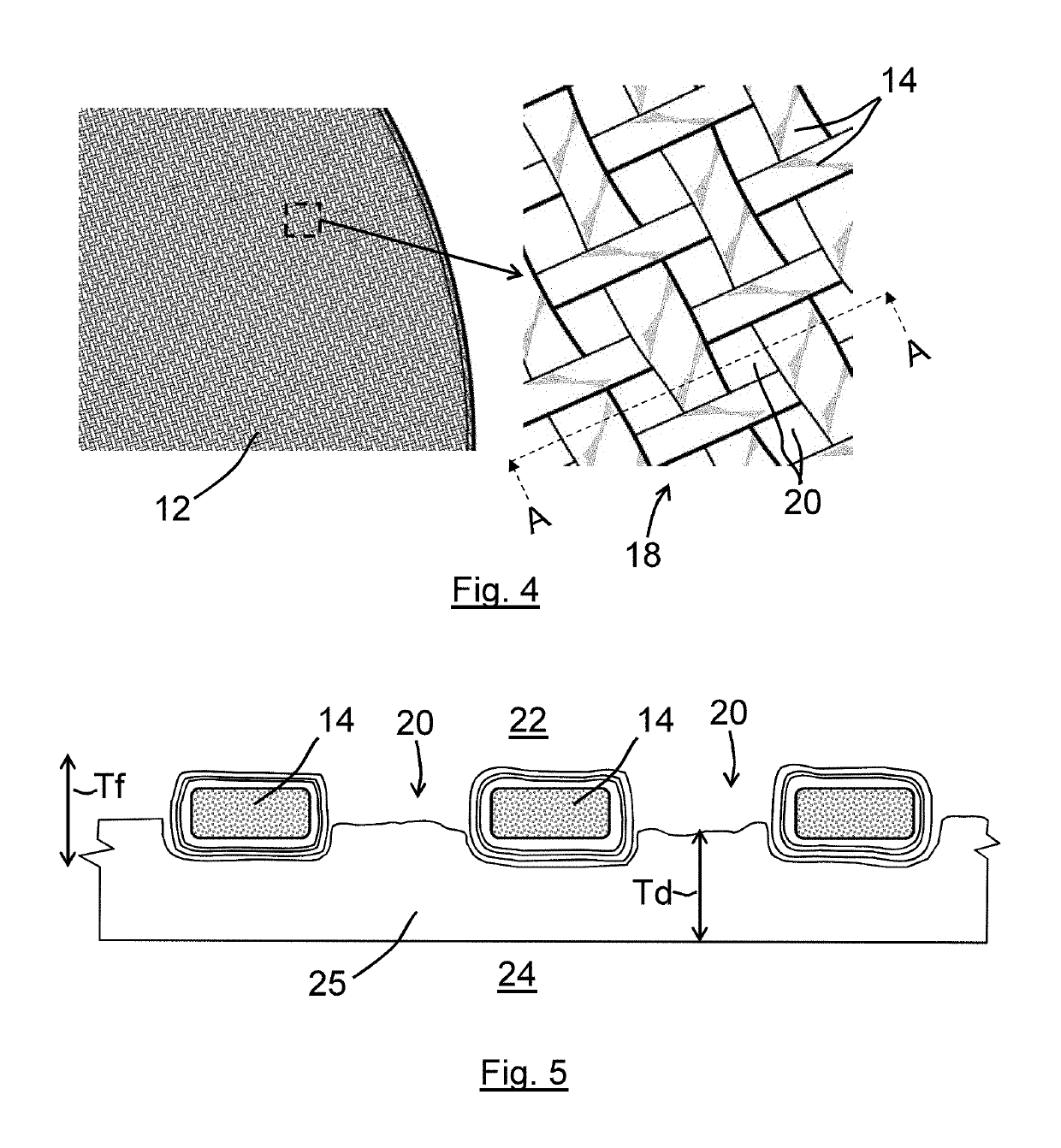

Loudspeaker Diaphragm

ActiveUS20190297424A1Minimise acoustic radiationDistinctive and attractive appearanceFibre diaphragmsPolymeric diaphragmsGlass fiberFiber

A loudspeaker diaphragm (12) comprising a woven fibre body supports damping material (25), for example PVA polymer, on a rearward-facing surface (24). The woven fibre body may be formed of lengths (14) non-metallic fibre material (for example glass fibre) coating with a thin metal coating (32). The mass of the layer of damping material (25) may be less than the mass of the woven fibre body. An attractive sparkly looking loudspeaker diaphragm (12) may thus be provided which damps undesirable vibration whilst providing a flatter frequency-response curve (50).

Owner:B & W GRP LTD +1

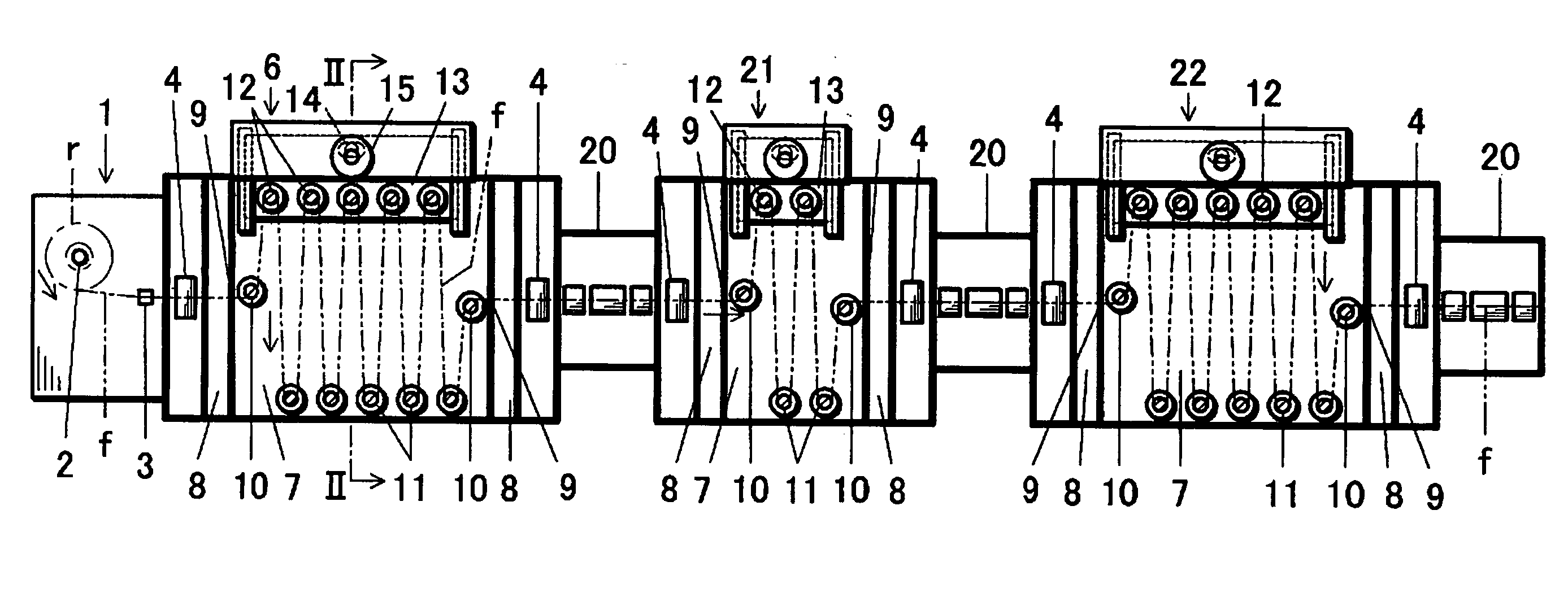

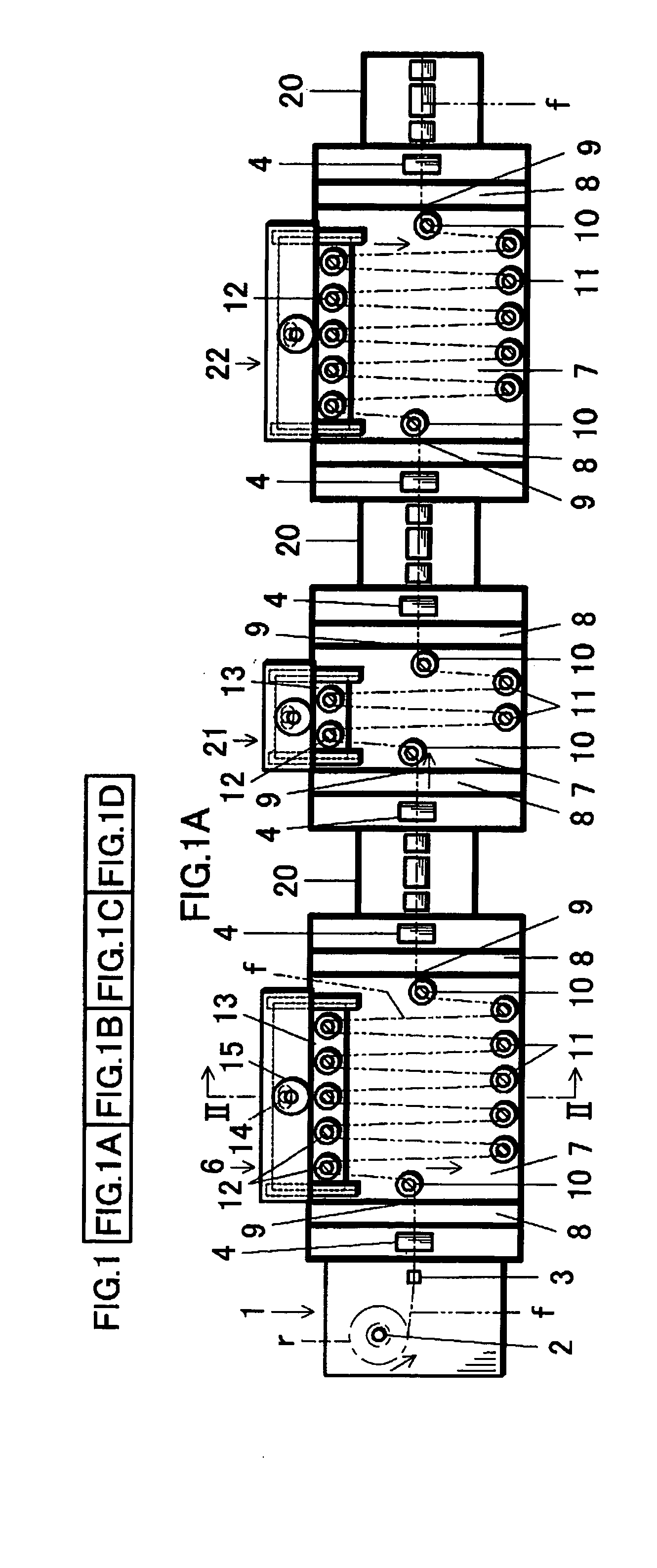

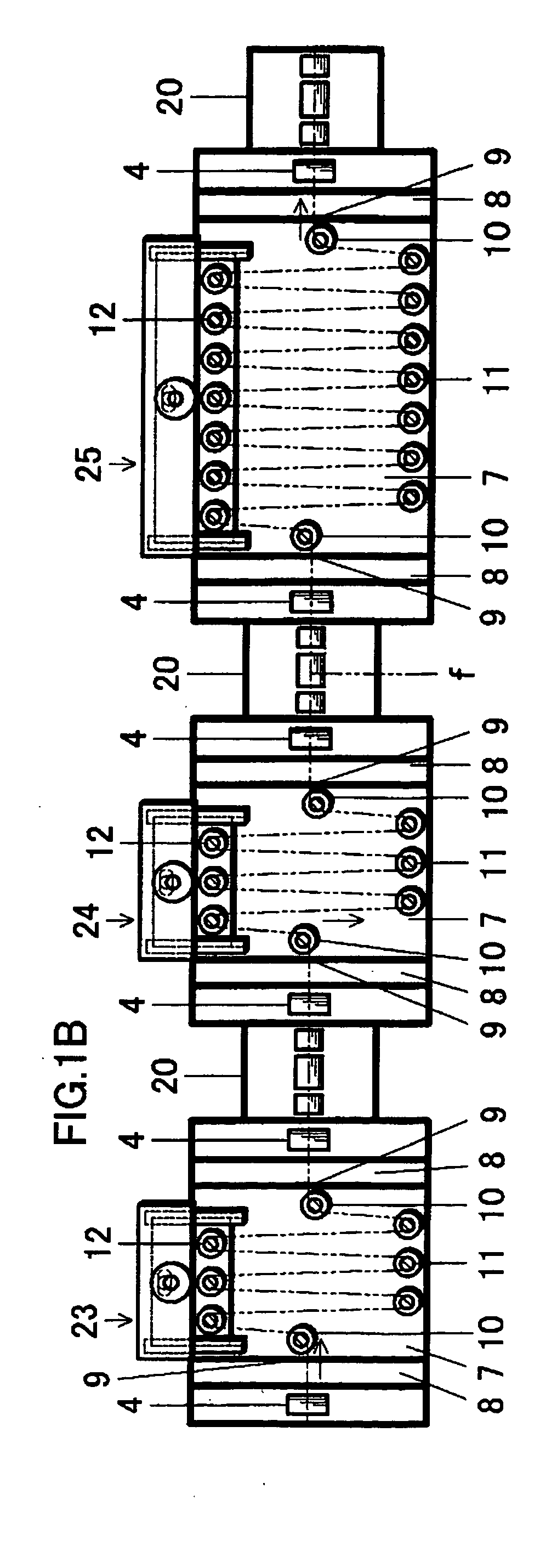

Continuous plating method of filament bundle and apparatus therefor

InactiveUS20050089639A1Efficient use ofManufactured continuously and efficientlyFibre treatmentPretreated surfacesEngineeringMechanical engineering

A filament bundle is rewound from a reel, and passes through various sorts of liquid in processing vessels to be used for plating. The filament bundle passes through a fixed guide roller and a movable guide roller while it travels within the liquid in the processing vessel. The movable guide roller is moved periodically, the filament bundle is stretched and slackened by turns, whenever the filament bundle is slackened or untied, the bundle is loosened. The filament bundle with each filament subjected to the plating is taken up to a take-up reel.

Owner:NAGOYA PLATING

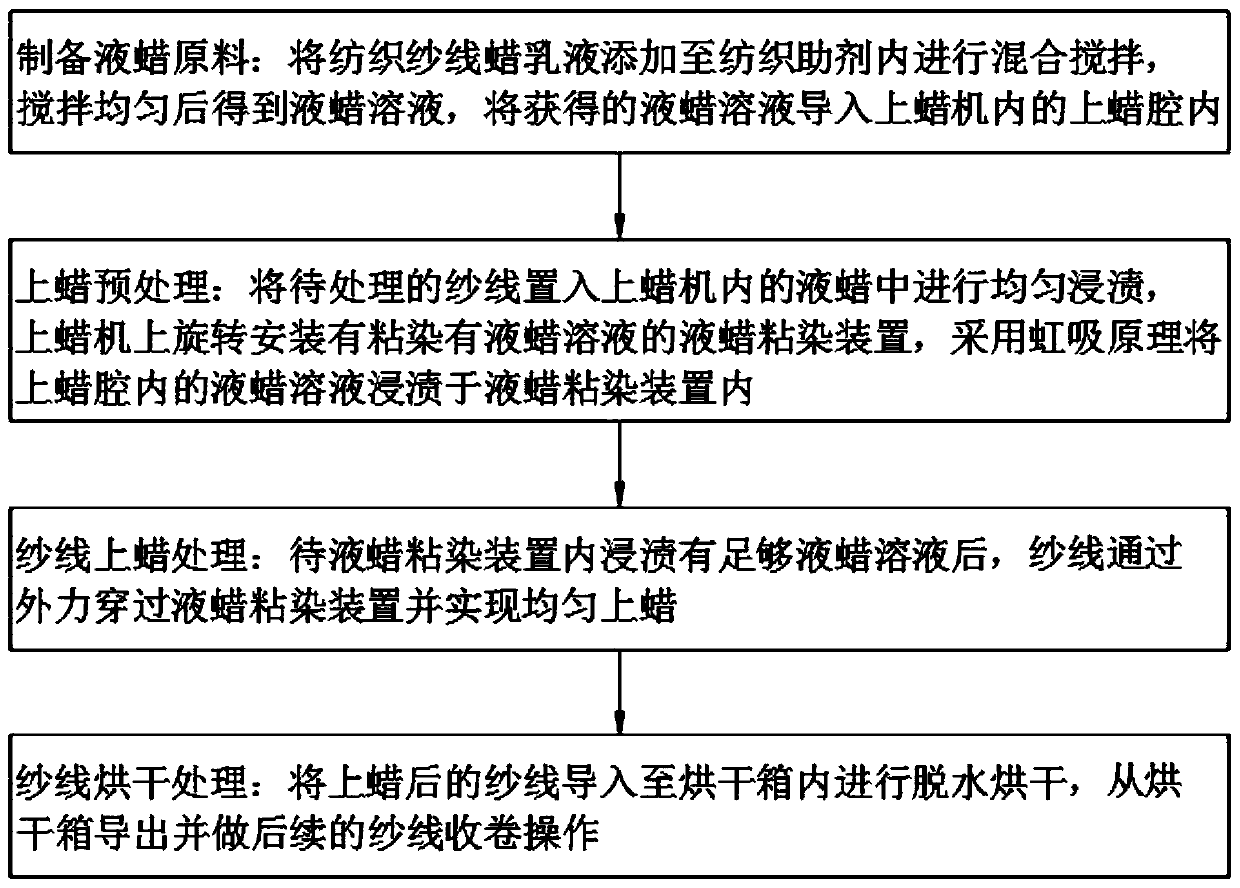

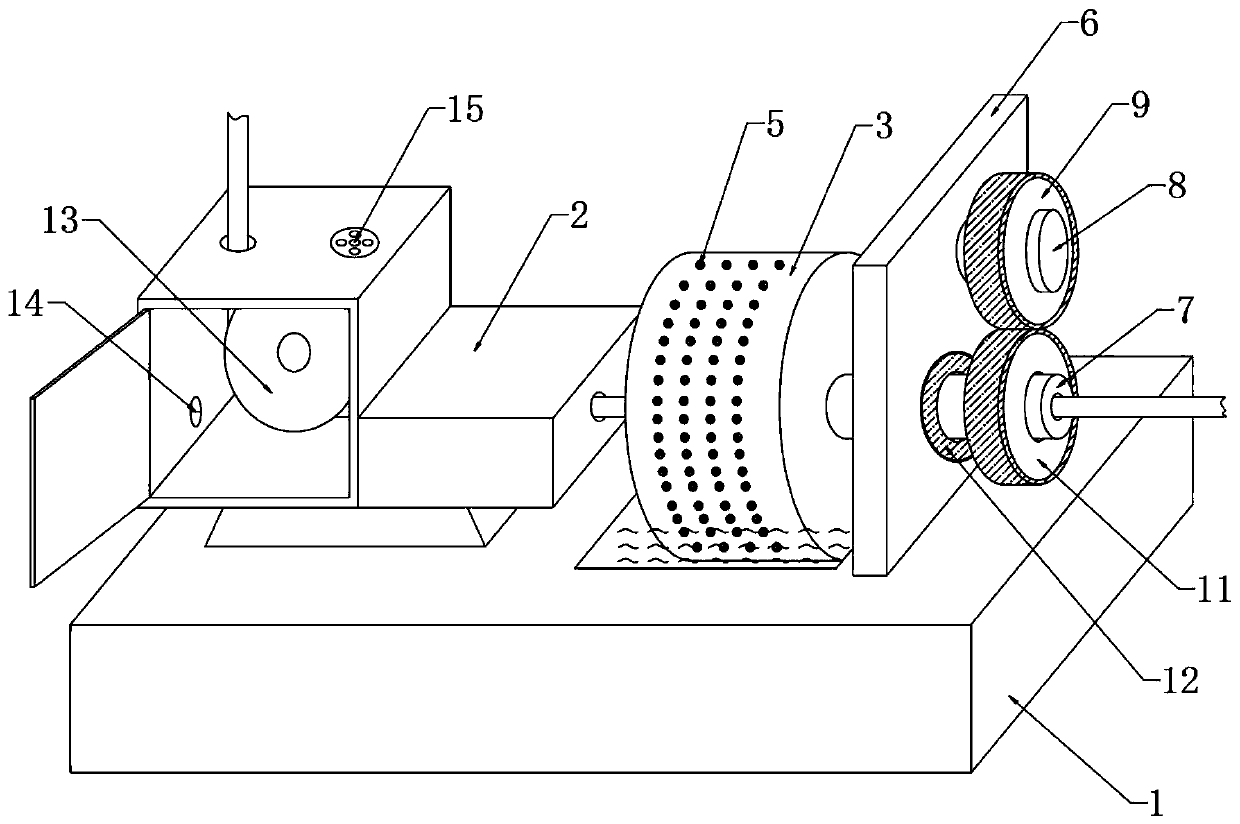

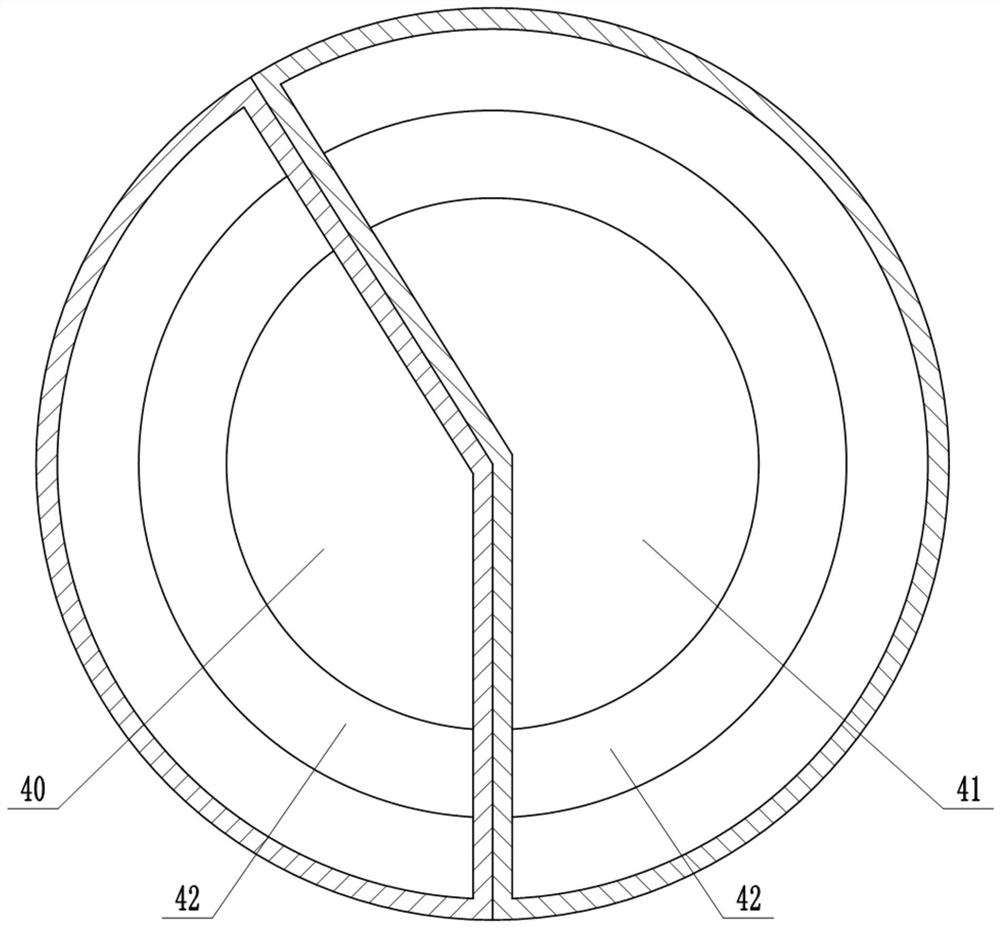

Comprehensive capillary permeation type yarn waxing process

ActiveCN111348490AUniform coatingImpregnation lasts evenlyFilament handlingPolymer scienceTextile yarn

The invention discloses a comprehensive capillary permeation type yarn waxing process, and belongs to the technical field of yarn processes. According to the comprehensive capillary permeation type yarn waxing process, a liquid wax raw material is prepared, wherein a textile yarn wax emulsion is added into a textile auxiliary agent, mixed and stirred the pH is adjusted to be 5-6.5, and a liquid wax solution is obtained after uniform stirring. The obtained liquid wax solution is guided into a waxing cavity in a waxing machine. A plurality of groups of cotton core strips are distributed on the periphery of an annular sponge waxing layer for yarns to pass through, and the annularly distributed cotton core strips are circularly impregnated in the liquid wax solution when rotating along with awaxing roller. According to the capillary permeation principle, the annular sponge waxing layer can be continuously and uniformly impregnated with the liquid wax solution in any direction. After a period of time, the annular sponge waxing layer is impregnated with enough liquid wax solution, and the yarns pass through the annular sponge waxing layer through external force pulling, so that the yarns are uniformly coated with the liquid wax solution, and the problem of poor waxing uniformity is effectively avoided.

Owner:NANTONG SUZHONG TEXTILE

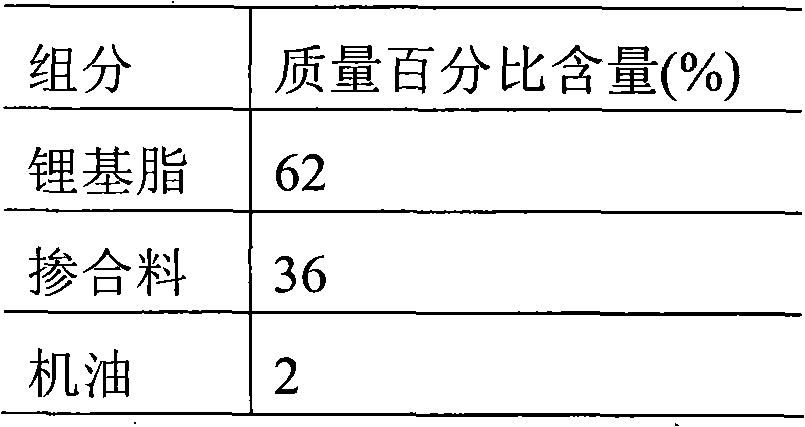

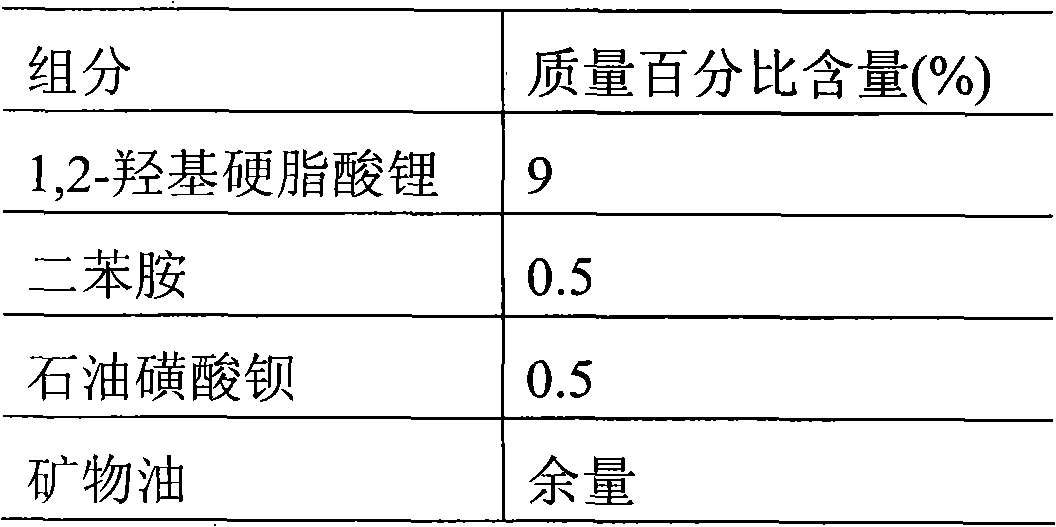

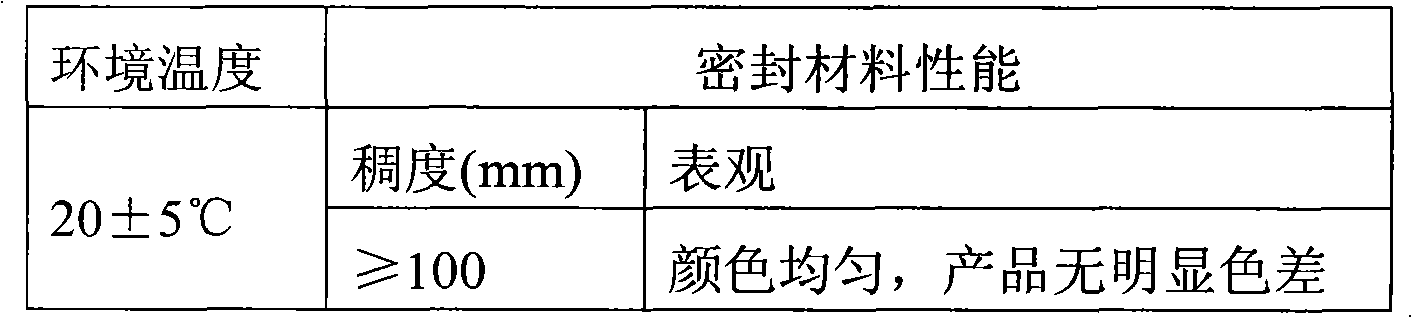

Concrete impermeable sealant

The invention relates to oil, grease or wax for post treatment of concrete, in particular to a concrete impermeable sealant. The concrete impermeable sealant is formed by stirring 62 to 67 mass percent of lithium-based grease, 31 to 36 mass percent of admixture and the balance of engine oil uniformly, wherein the lithium-based grease is formed by mixing and thickening 9 to 13 mass percent of 1,2-hydroxy lithium stearate, 0.5 mass percent of diphenylamine, 0.5 mass percent of petroleum barium sulfonate and the balance of mineral oil; and the admixture is selected from fly ash, coal gangue powder and cement powder, and the granule diameter of the powder is less than 0.9 millimeter. The concrete impermeable sealant is convenient to manufacture and use, is simple in operation, time-saving and labor-saving, has good sealing property, has no harm to the human body, and is environmentally-friendly.

Owner:MCC TIANGONG GROUP

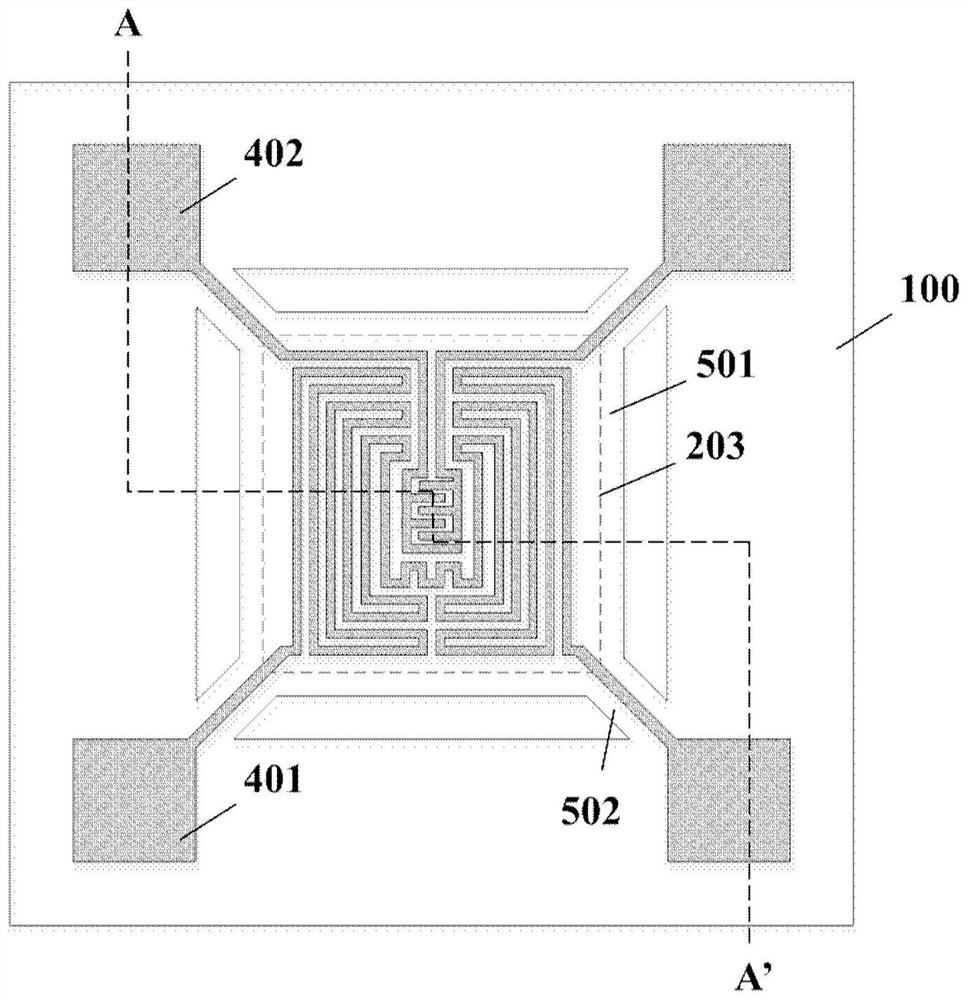

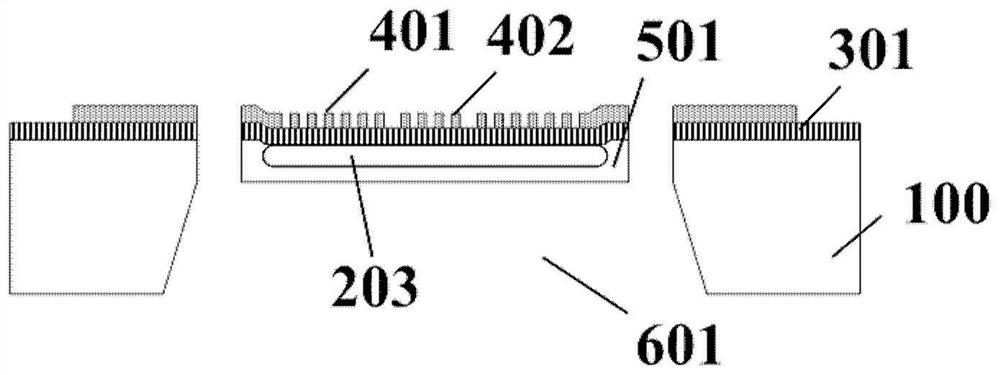

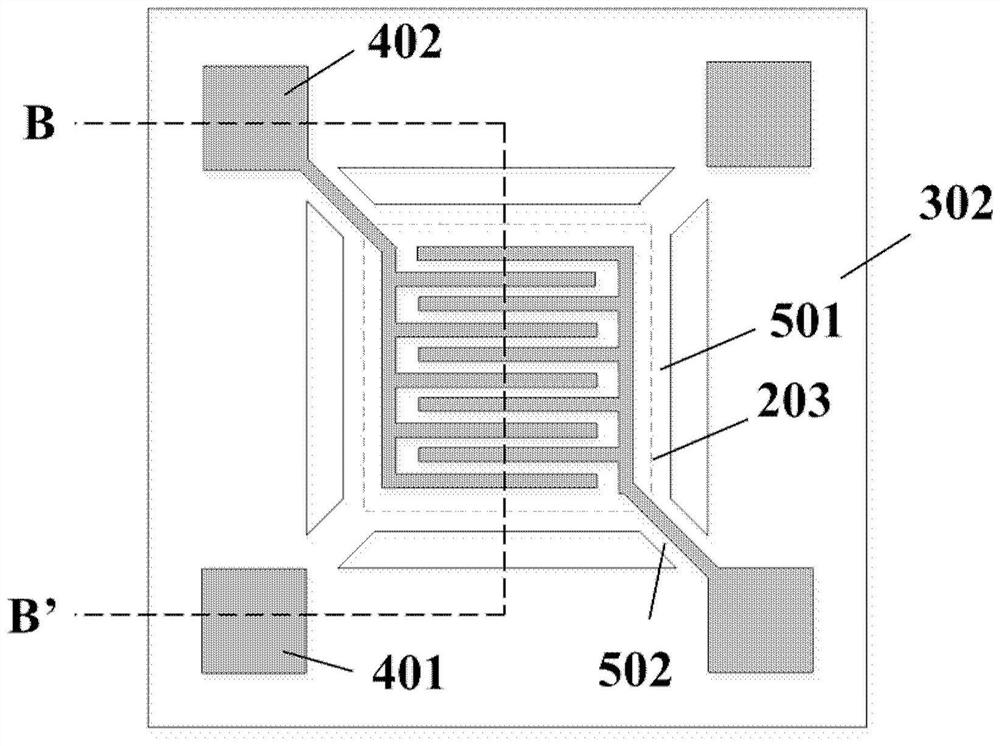

MEMS micro hot plate with vacuum thermal insulation layer and preparation method thereof

PendingCN113998663AReduce lossesReduce heat transferTelevision system detailsPiezoelectric/electrostriction/magnetostriction machinesThermal breakThermal insulation

The invention provides an MEMS micro hot plate with a vacuum thermal insulation layer and a preparation method thereof. The MEMS micro hot plate comprises: a silicon substrate; a vacuum thermal insulation layer formed on the surface of the silicon substrate through an SON process; an insulating layer formed on the silicon substrate and the vacuum thermal insulation layer; a heating electrode and a testing electrode formed on the insulating layer and positioned right above the vacuum thermal insulation layer; a heating platform formed by sequentially etching the insulating layer and the silicon substrate along the periphery of the vacuum thermal insulation layer and provided with a suspended beam supporting structure; and a thermal insulation groove formed by etching or corroding the insulating layer and positioned in an area right below the heating platform. According to the invention, by means of the micro hot plate, the thermal insulation layer can be in the vacuum state through the SON technology to form the vacuum thermal insulation layer, and compared with air thermal insulation, the vacuum thermal insulation layer has more advantages in the aspect of restraining heat loss of the heating platform, so that heat conduction to the outside when the micro hot plate works can be effectively reduced so as to reduce heat loss and improve the temperature uniformity of the micro hot plate.

Owner:INSTR TECH & ECONOMY INST P R CHINA

Micro-nano rhizoma bletillae skin care powder and processing method thereof

InactiveCN103142448AFast absorptionEasy to apply evenlyCosmetic preparationsBody powdersMicro nanoExodermis

The invention discloses a micro-nano hyacinth bletilla skin-care powder and a processing method thereof. The hyacinth bletilla skin-care powder prepared by the method of the invention is good in dispersibility, easy and uniform to smear, quick for skin absorption, applicable to whitening and moisturizing skin, making up and rendering, and convenient to use. The invention is implemented by the following technical scheme: cleaning hyacinth bletilla tubers, cooking or boiling the tubers in boiling water until no white core exists, drying the tubers in the sun, removing the outer skin, pulverizing the raw materials hyacinth bletilla, pearl powder, and borneol respectively with low-temperature pulverizing equipment according to the following proportion in parts by weight: 60-80 parts of hyacinth bletilla, 15-30 parts of pearl powder and 5-10 parts of borneol, to become powder with an average particle diameter of 0.2-0.6 microns, then completely mixing the same, drying the mixture with a low-temperature vacuum drying process in the prior art, then putting the dried mixture into a container for ultrasonic sterilization, and putting the treated mixed powder into a bag for sealing.

Owner:SICHUAN UNIV

Tungsten electrode argon arc welding active flux for increasing welding fusion depth

InactiveCN1276815CImprove molding qualityEasy to remove slagArc welding apparatusWelding/cutting media/materialsHigh intensityAlloy

An active welding flux of W-electrode argon arc welding for increasing the welded depth contains Cr2O3, TiO2 and metallic fluoride. It can increase the welded depth by more than 3 times. Its advantages are narrow width being affected by welding heat, high productivity and low cost.

Owner:国营七四一四厂

Cosmetic applicator

An applicator is provided for applying a composition to a user's eyelashes. The applicator includes an applicator element having a large section, a medium section, and a small section, which are adapted to cover the outer, middle, and inner portions of a user's eyelashes, respectively, with a composition (e.g., mascara). The three sections of the applicator element include bristles sized and spaced in such a way as to facilitate even application of the composition without clumping.

Owner:AVON PROD INC

Production process of solvent-free composite aluminum-plated bag

InactiveCN111959089AReduce the temperatureIncrease temperatureLiquid surface applicatorsLamination ancillary operationsAdhesive cementPolymer science

The invention belongs to the technical field of composite aluminum-plated bags, and particularly relates to a production process of a solvent-free composite aluminum-plated bag, which comprises the following processing steps: (1) mounting a printing film and an aluminum-plated film to be compounded on a solvent-free compounding machine; (2) blending a solvent-free two-component polyurethane adhesive; (3) debugging; (4) compounding: unwinding the aluminum-plated film, and controlling the tension to be 0.6-0.8 N / cm in the unwinding process; conveying the aluminum-plated film and the printing film coated with an adhesive solution to a composite roller, compounding the printing film and the aluminum-plated film under the pressure of 0.18 mpa / cm < 2 > to 0.23 mpa / cm < 2 >, wherein it is guaranteed that the temperature is controlled to be 35 DEG C to 40 DEG C while compositing is conducted; (5) cooling; (6) coiling: coiling the cooled film material into a coil under the tension of 1 to 1.4 N / cm; (7) drying and solidifying. The solvent-free composite aluminum-plated bag is produced by using the means of the scheme, and the produced composite aluminum-plated bag can meet the requirements in the aspects of sealing performance, high temperature resistance and the like.

Owner:重庆富美包装印务有限公司

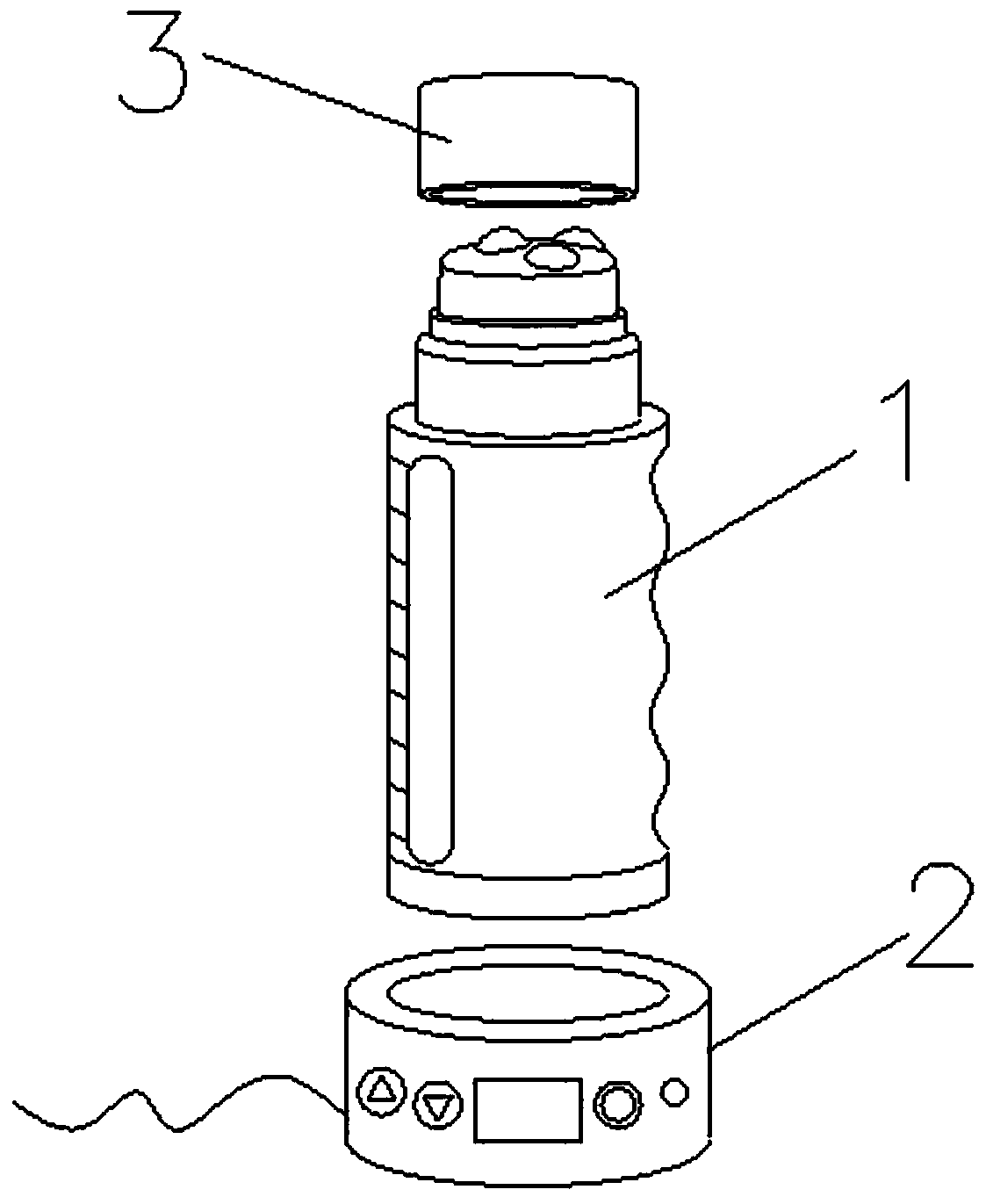

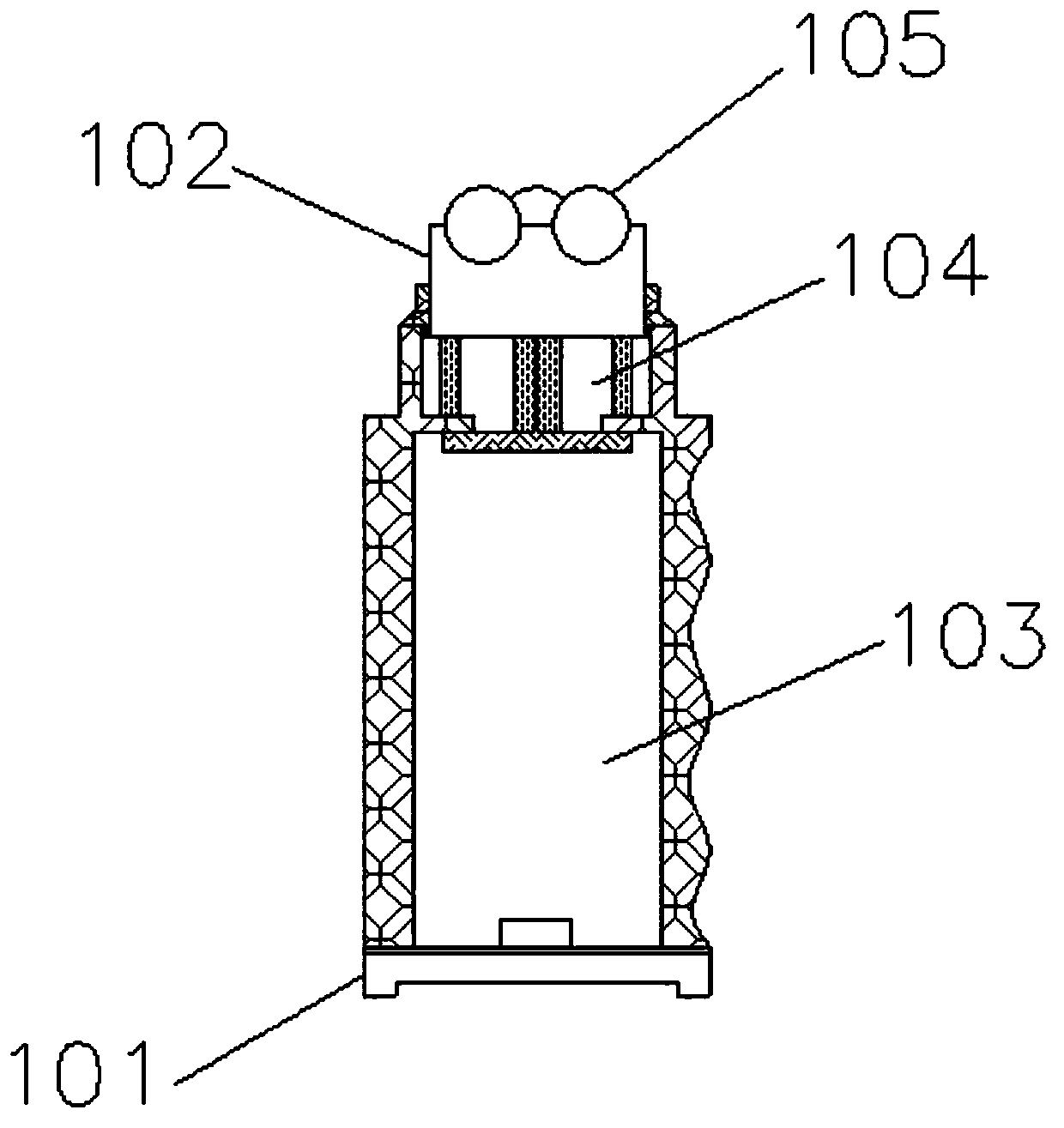

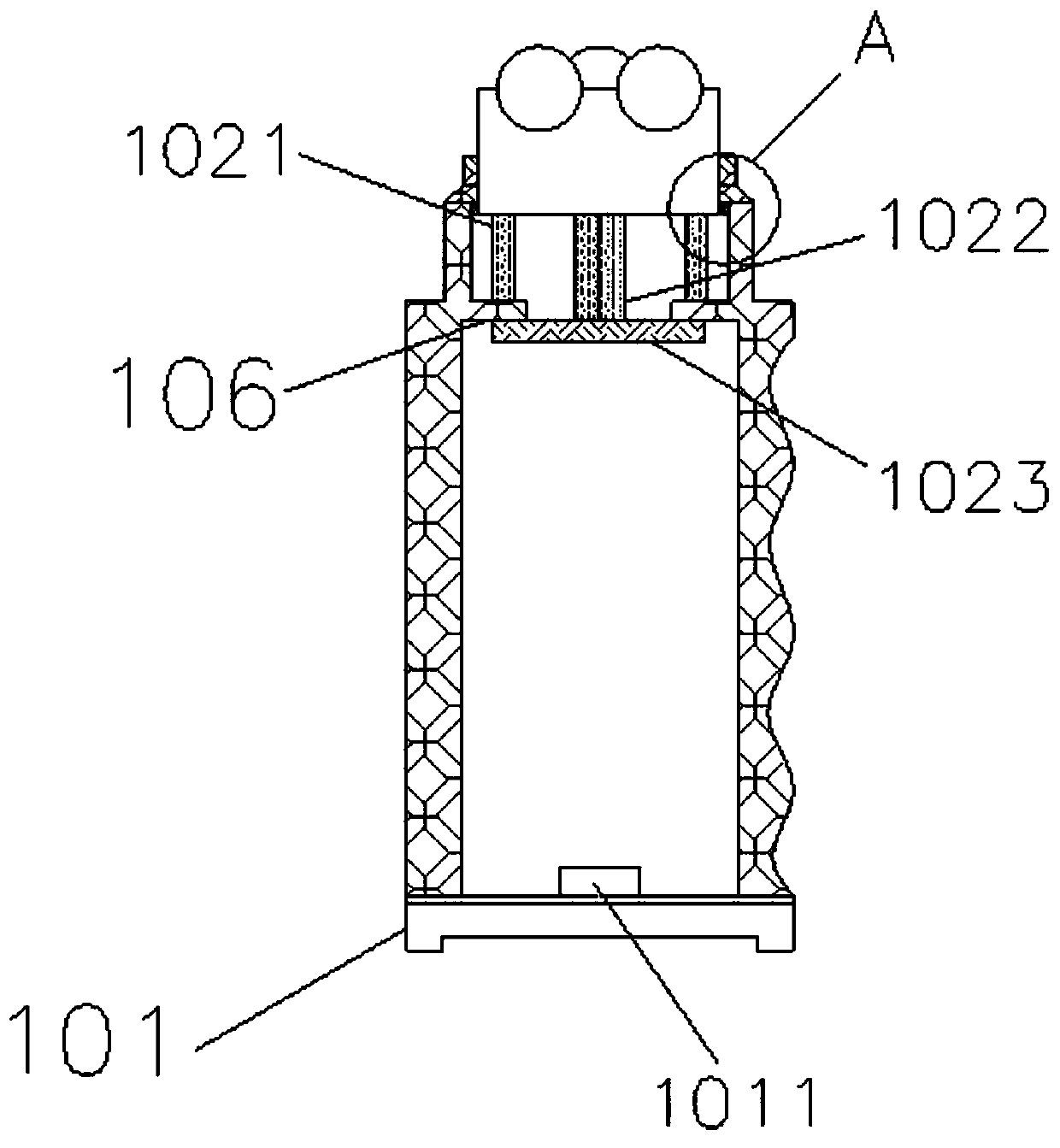

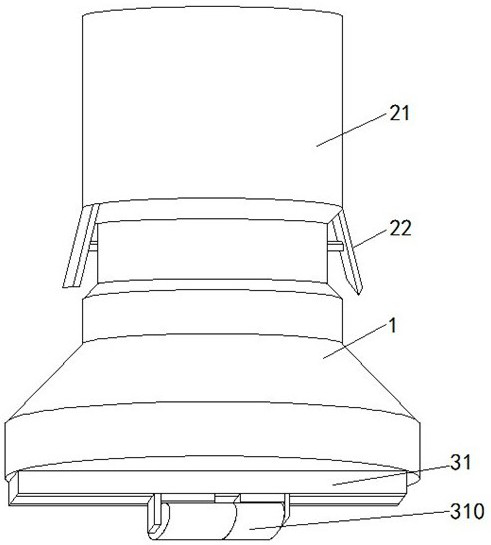

Coupling agent heating, extruding and applying device for ultrasonic medicine

InactiveCN110151220AAvoid stimulationEasy to squeeze and applyUltrasonic/sonic/infrasonic diagnosticsMedical devicesBiomedical engineeringMedical treatment

The invention discloses a coupling agent heating, extruding and applying device for ultrasonic medicine. The coupling agent heating, extruding and applying device for ultrasonic medicine comprises a device main body, a cover body and a heating pedestal; the device main body is used for accommodating the coupling agent and uniformly applying after extrusion; the heating pedestal heats the couplingagent in the device main body; the cover body covers the applying end of the device main body; and the coupling agent heating, extruding and applying device for ultrasonic medicine accurately controlsthe temperature of the applied coupling agent, facilitates extruding and applying, facilitates uniform application of the coupling agent, and is reasonable in structural design, accurate and efficient in operation and suitable for being popularized and applied in medical institutions.

Owner:JILIN UNIV

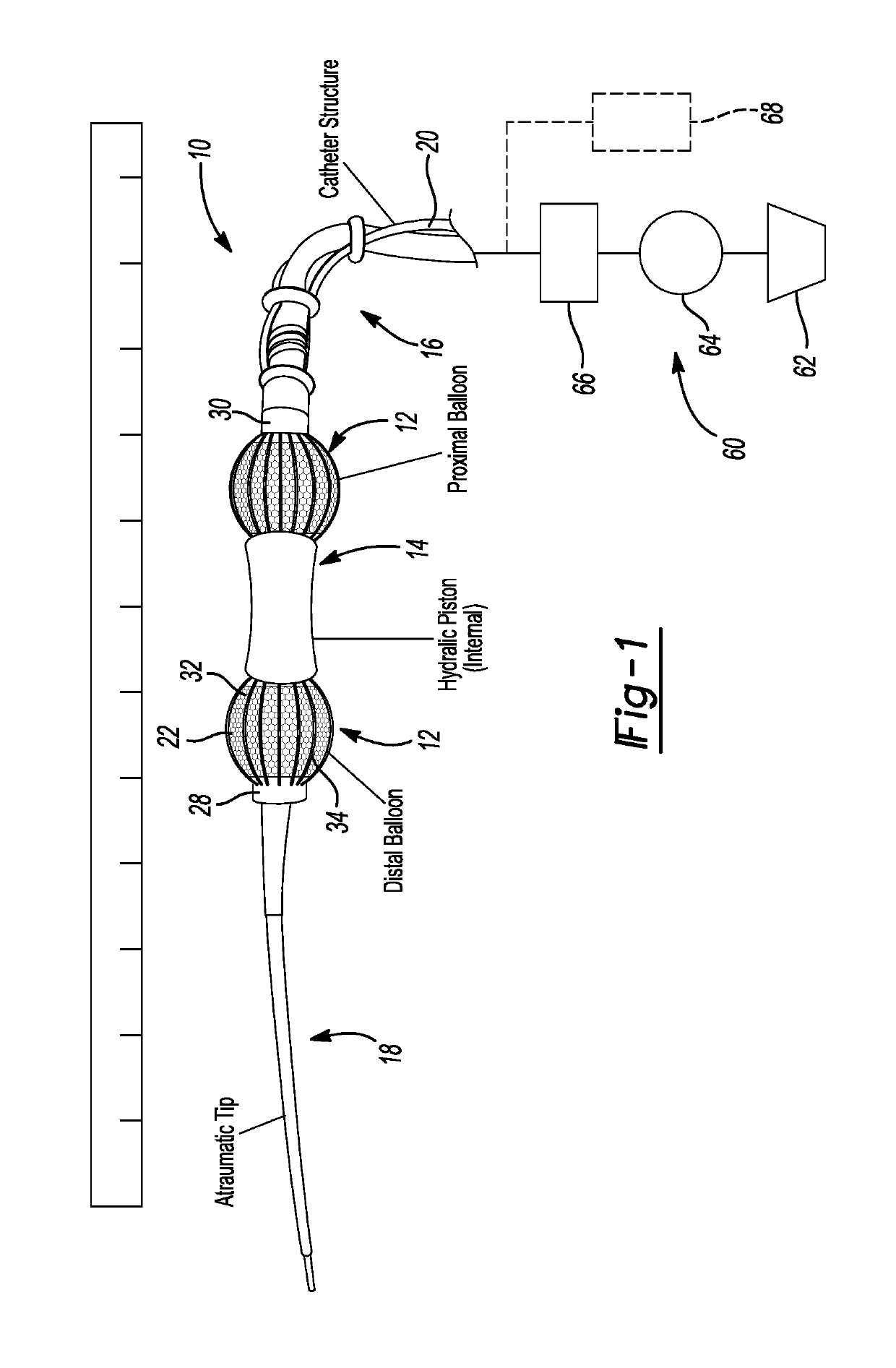

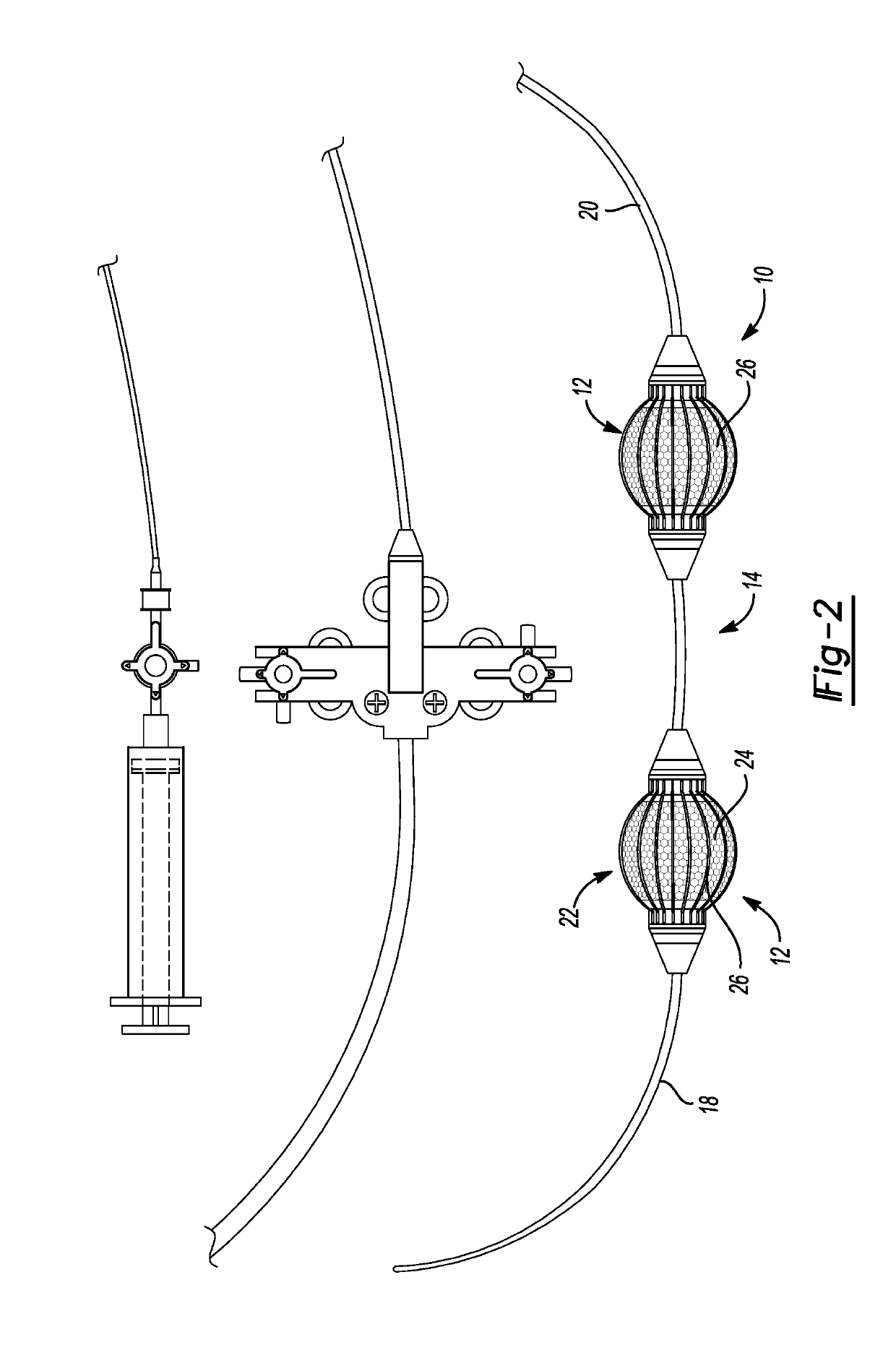

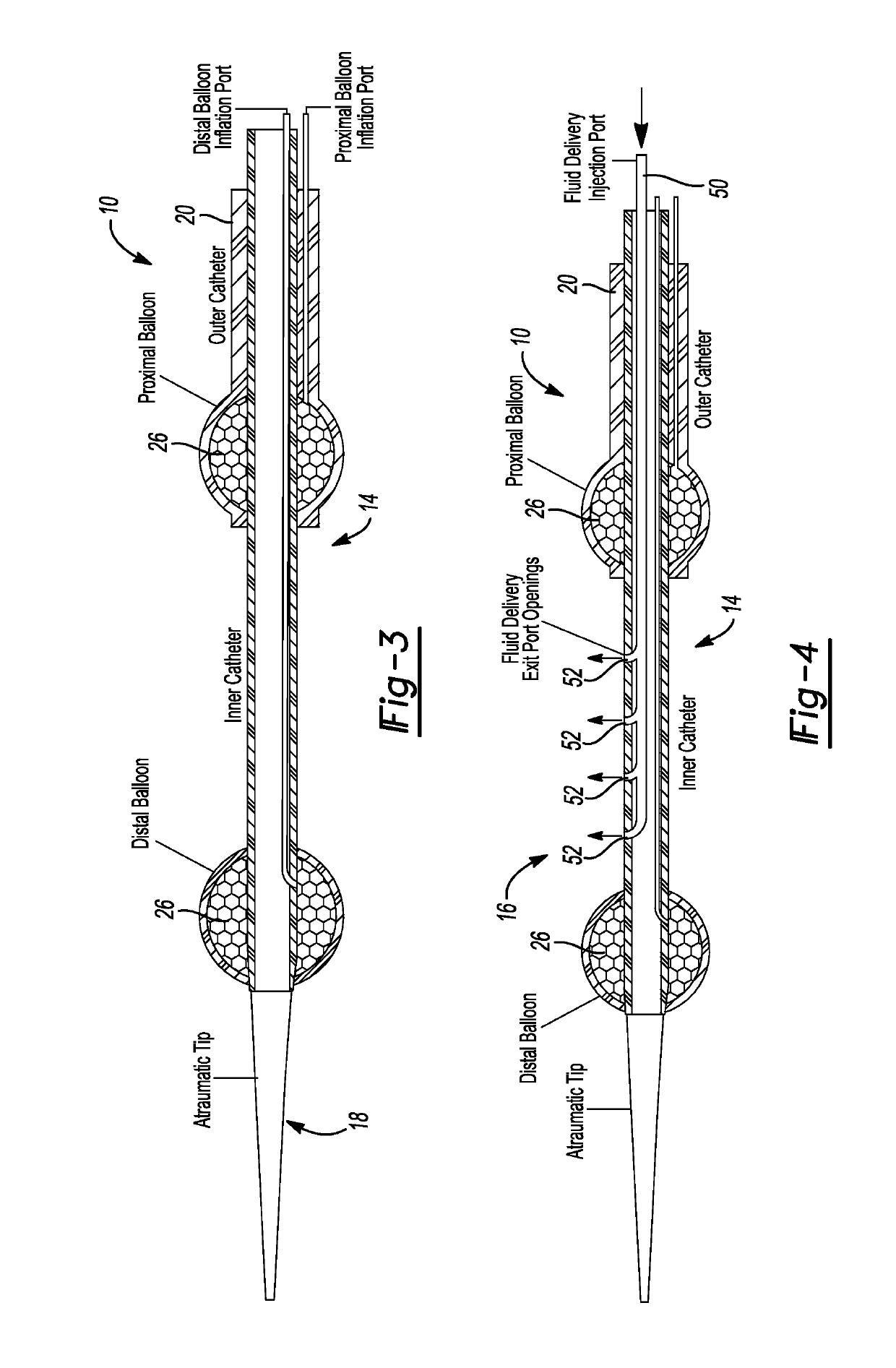

Mechanotransductive bowel extender device having local delivery of medically relevant liquids

ActiveUS20190125474A1Easy to apply evenlyPromote absorptionBalloon catheterAnaesthesiaMechanotransductionSmall intestine

A mechanotransductive bowel extender device that can be used to correct short bowel syndrome by applying tension to the bowel tissue which, via the process of mechanotransduction, grows in length in response to the applied tension. Such a device is placed within the small bowel and applies tension over a period of several days or weeks by attaching to the lumen of the bowel at two different locations and moving those two points apart, stretching the tissue between. The extender device further capable of localized application and / or evacuation of medically relevant liquid and other material within the bowel.

Owner:RGT UNIV OF MICHIGAN

Loudspeaker Diaphragm

ActiveUS20180184208A1Distinctive and attractive appearanceMinimum level of stiffness and structural supportFibre diaphragmsPolymeric diaphragmsThin metalFiber

A loudspeaker diaphragm (12) comprising a woven fibre body supports damping material (25), for example PVA polymer, on a rearward-facing surface (24). The woven fibre body may be formed of lengths (14) non-metallic fibre material (for example glass fibre) coating with a thin metal coating (32). The mass of the layer of damping material (25) may be significantly greater than the mass of the woven fibre body. An attractive sparkly looking loudspeaker diaphragm (12) may thus be provided which damps undesirable vibration whilst providing a flatter frequency-response curve (50).

Owner:EVA AUTOMATION INC +1

MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter and preparation method thereof

ActiveCN108439957AAvoid damageIncrease vacanciesSemi-permeable membranesMembrane filtersOxide ceramicSlurry

The invention discloses an MA-M2T spinel solid liquor enhanced magnesium oxide based foam ceramic filter which can realize sintering at the low temperature and has excellent chemical stability and thermal shock resistance and a preparation method of the foam ceramic filter. The preparation method comprises steps as follows: (1) 15%-25% of nano aluminum sol, 0.8%-1.5% of a rheological agent and thebalance of magnesium oxide ceramic powder containing a nano titania sintering aid are prepared in percentage by mass, deionized water is added, the mixture is subjected to ball milling and uniform mixing, and ceramic slurry with the solid content of 60%-70% is prepared through vacuum exhausting; (2) a polyurethane foam plastic template is soaked in the ceramic slurry and is extruded by a roller press to remove redundant soaked hanging slurry, a biscuit is prepared, and the biscuit is heated to 80-120 DEG C and dried; (3) the dried biscuit is put in a sintering furnace, heated to 1,400-1,600 DEG C for high-temperature sintering and cooled to the room temperature with the furnace, and the magnesium oxide based foam ceramic filter is obtained.

Owner:FENGYANG L S NET FORMING CO LTD +2

Aluminum oxide short-fiber enhanced magnesium-oxide-based foam ceramic filter and preparation method thereof

The invention discloses an aluminum oxide short-fiber enhanced magnesium-oxide-based foam ceramic filter with chemical stability and excellent thermal shock resistance capable of sintering in a low temperature and a preparation method thereof. The preparation method comprises the following steps: (1) according to a mass percent, compounding by 15%-25% of nano-aluminum sol, 0.8%-1.5% of rheologicalagent, and the balance of magnesia ceramics powder containing aluminum oxide short-fiber and nano-titania, adding absolute ethyl alcohol, ball-milling, and uniformly mixing to prepare ceramic slurryof which the solid content is 60%-70%; (2) immerging a polyurethane foamed plastic template in the ceramic slurry, extruding the polyurethane foamed plastic template through a roller press so as to remove redundant immerging slurry, preparing a biscuit, and removing an ethyl alcohol solvent in a ventilating chamber in 40-50 DEG C, and drying the biscuit; and (3) placing the dried biscuit in a sintering furnace, warming to 1350-1550 DEG C, and sintering in a high temperature, cooling to room temperature along with the furnace, to obtain the magnesium-oxide-based foam ceramic filter.

Owner:JIANGSU FAVOUR AUTOMOTIVE NEW STUFF SCI TECH +1

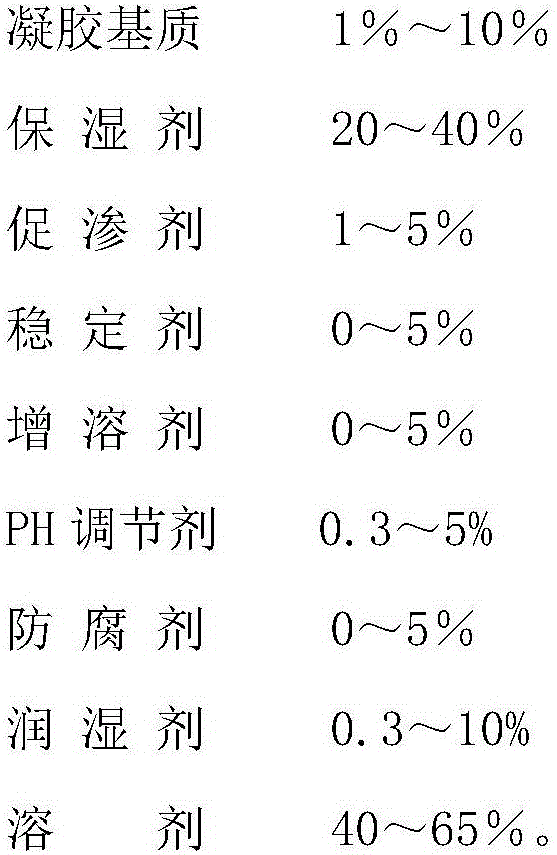

Antipyretic gel and roll-on device thereof

InactiveCN106691669AImprove complianceEfficient cold storage and coolingAntipyreticAerosol deliveryStored energyBall bearing

The invention discloses an antipyretic gel and roll-on device thereof. The antipyretic gel is prepared from, by mass, substrate gel 1-10%, moisturizer20-40%, penetration enhancers1-5%, stabilizer 0-5%, seltzer 0-5%, PH modifier0.3-5%, preservative 0-5%, wetting agent 0.3-10%, and solvent 40-65%. The antipyretic gel is made from stored energy high polymer material, soft and transparent, which has the advantages of cooling storage, lowing the temperature, being safe and non-stimulation, and no any side effects. The roll-on device thereof comprises a bottle body with an opening on the top, ball bearing components at the opening. The ball bearing components comprise a ball seat and a ball that can roll to insert the seat partly, a cover that connects to the cylinder thread and covers ball bearing components. The bottle is filled with antipyretic gel.

Owner:湖北兵兵药业(集团)有限公司

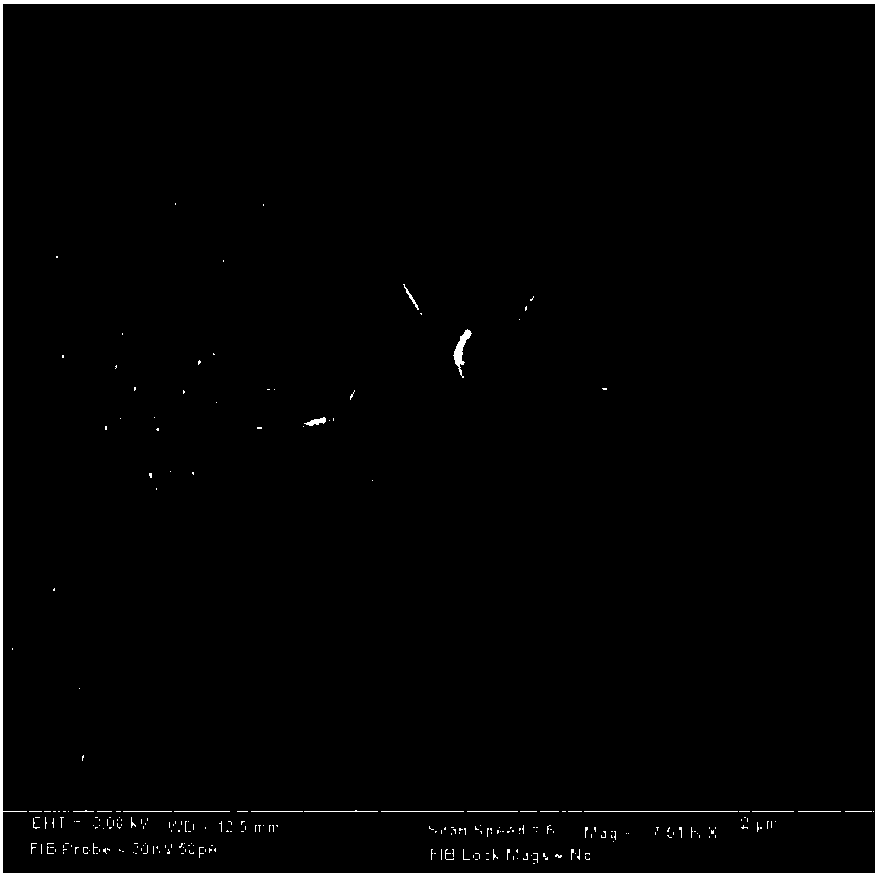

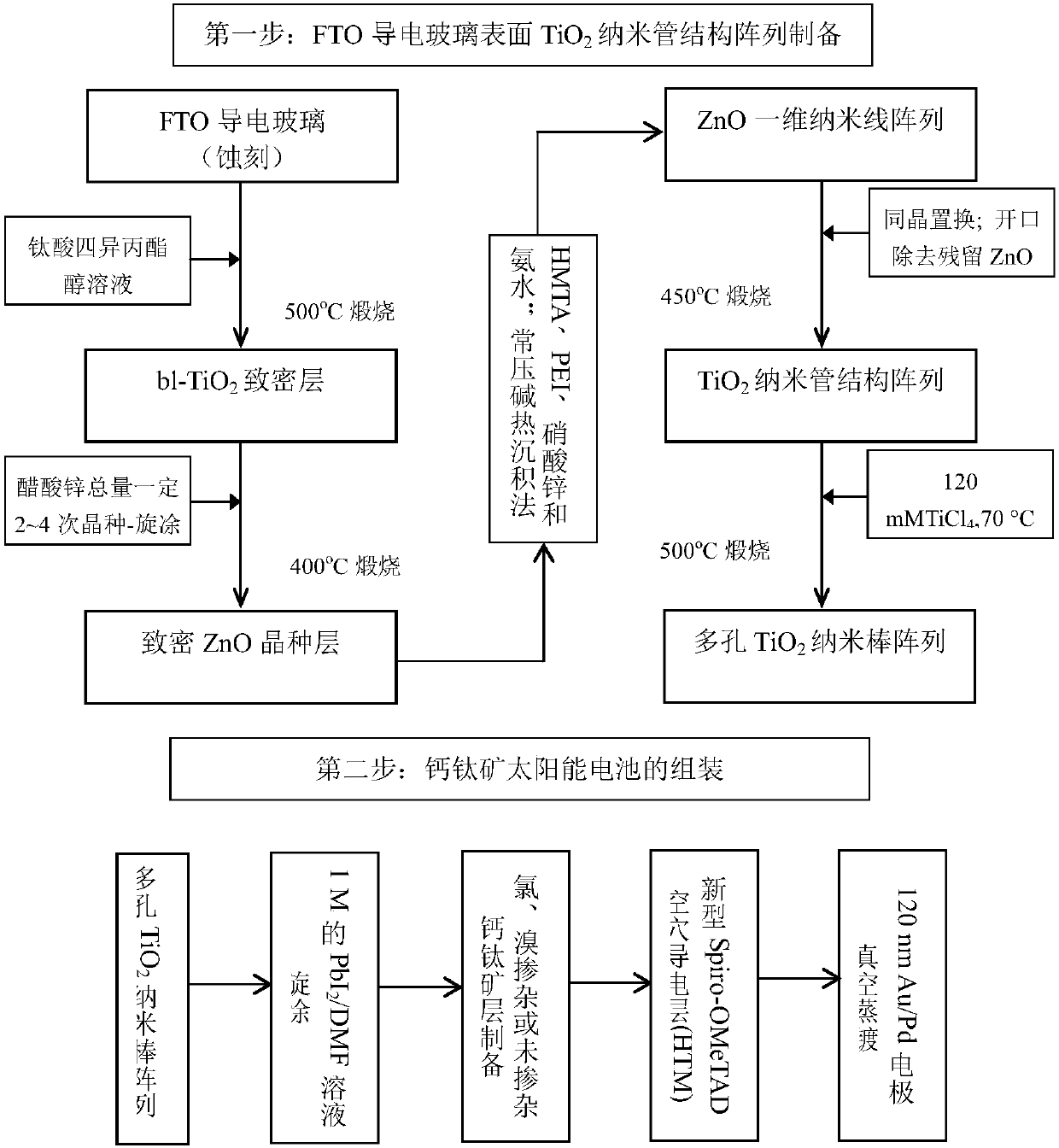

TiO2 nanotube-based perovskite cell electrode preparation method

ActiveCN110400875AIncreased steric hindranceImprove mobilityMaterial nanotechnologySolid-state devicesTio2 nanotubeIodide

The invention relates to a TiO2 nanotube-based perovskite cell electrode preparation method, which is characterized in that a spin coating method is adopted to perform two or four times of spin coating of a certain amount of a Zn(Ac)2 seed solution on the surface of FTO conductive glass plated with a TiO2 dense layer, and decomposition at 400 DEG C is carried out to generate a ZnO seed. Steric hindrance effects generated by the seed density are used to suppress oblique enhancement of nanowires, vertically-arranged ZnO nanowires grow by an atmospheric alkali thermal deposition method, isomorphous replacement between (NH4)2TiF6 and the ZnO nanowires is carried out, and a mesoporous TiO2 nanotube array is prepared. A CH3NH3PbI3 perovskite photosensitive layer is prepared by a two-step methodwith methylamine iodide as a raw material, a solid hole transport film with higher mobility is prepared through increasing the amount of doped lithium, the surface is plated with a gold film, and a counter electrode is formed. The photoelectric conversion efficiency is 11.8%, which provides the basis for practical deployment of high-efficiency and large-area perovskite solar cells.

Owner:EAST CHINA UNIV OF SCI & TECH

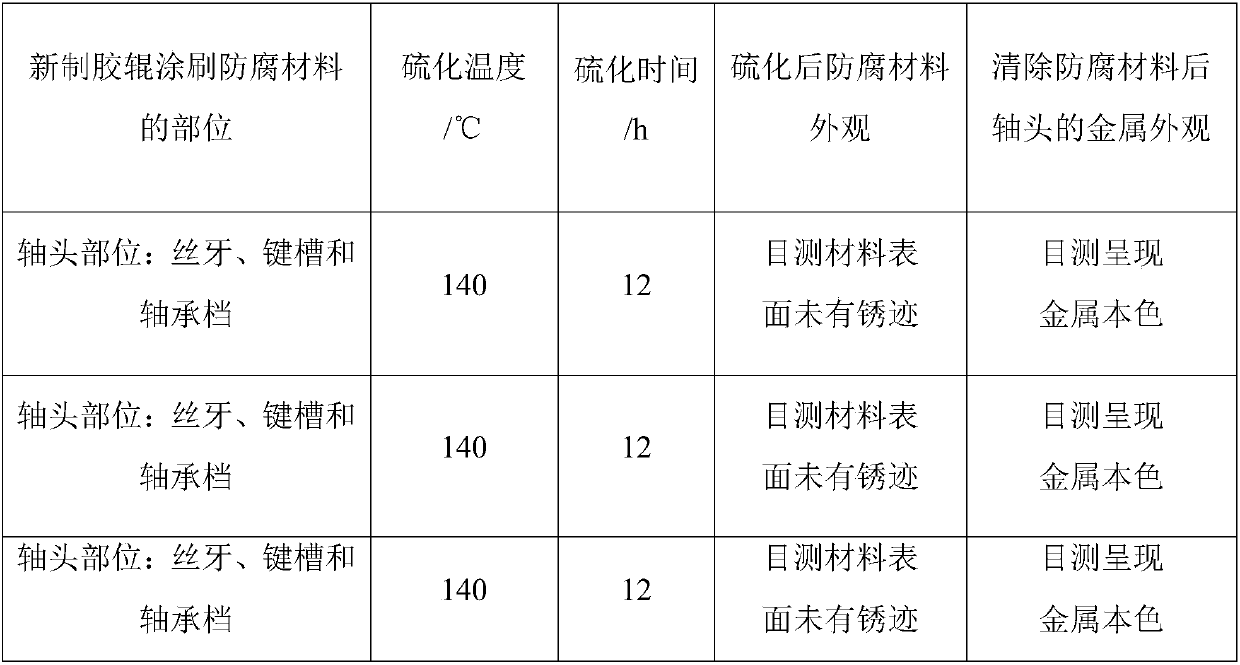

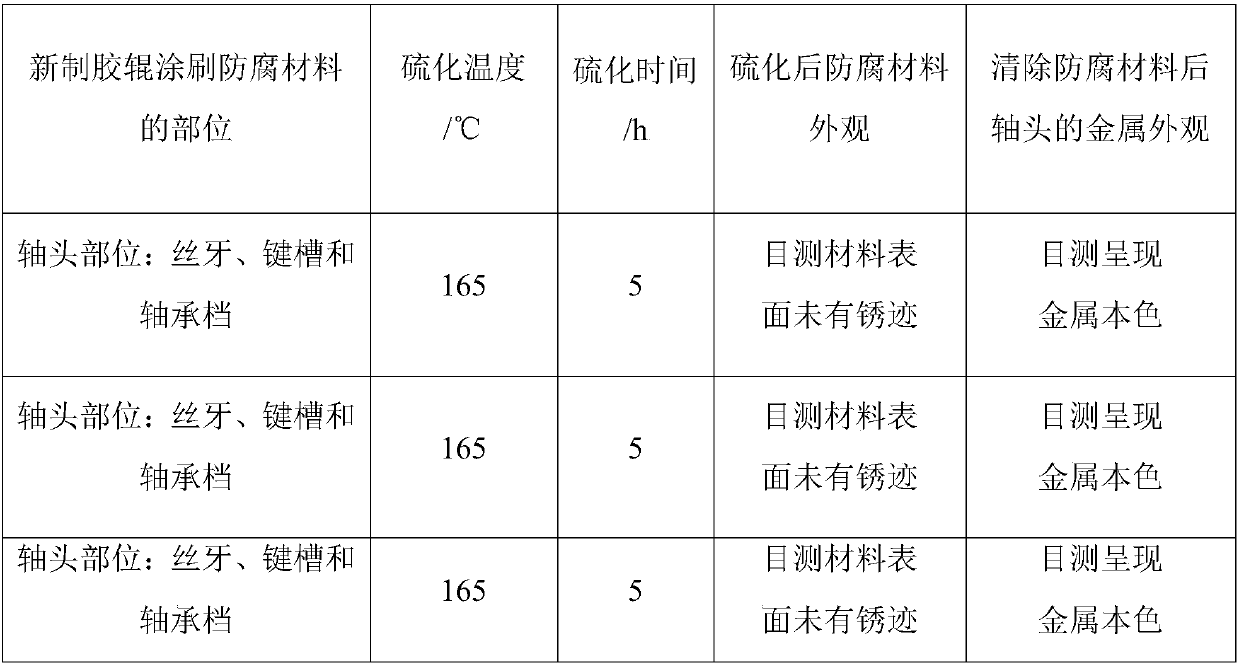

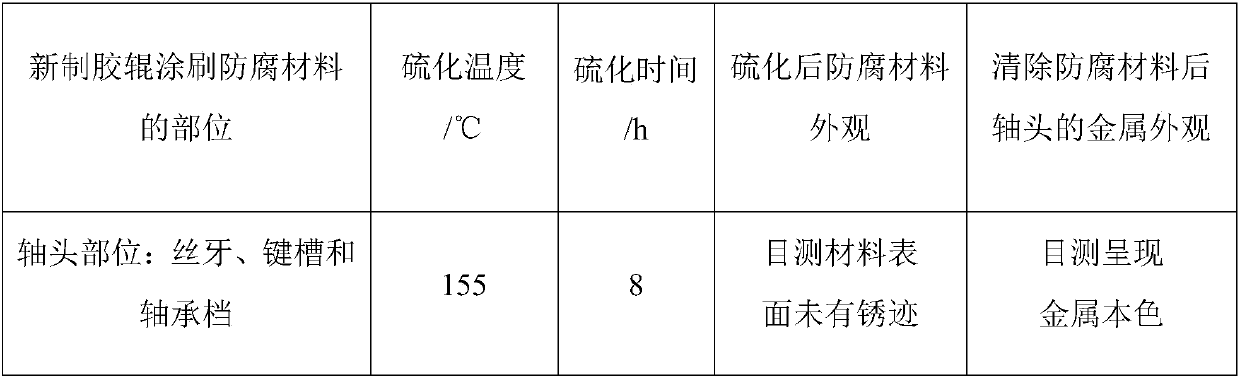

Rubber roller-vulcanized corrosion-resistant material and use method thereof

ActiveCN107903723AEasy to filmWide variety of sourcesFireproof paintsRubber derivative coatingsPolymer scienceVulcanization

The invention discloses a rubber roller-vulcanized corrosion-resistant material and a use method thereof and belongs to the field of material modification. The invention provides the rubber roller-vulcanized corrosion-resistant material which is prepared from the following raw materials in percentage by mass: 50-60 percent of silver powder paint, 30-40 percent of ethyl acetate and 10-20 percent ofpowdered zinc oxide; a preparation method of the rubber roller-vulcanized corrosion-resistant material comprises the following steps: (1) weighing the raw materials; and (2) uniformly stirring the raw materials till complete dissolution; and the use method of the rubber roll-vulcanized corrosion-resistant material comprises the following steps: (1) pretreatment; (2) brushing a rubber roller withthe corrosion-resistant material; and (3) vulcanization process treatment and corrosion-resistant material removal and recovery. The rubber roller-vulcanized corrosion-resistant material prepared by the preparation method disclosed by the invention can be prevented from rustiness due to high-temperature oxidation corrosion in the steam or hot air vulcanization process; and the vulcanized corrosion-resistant material is easily dissolved in the ethyl acetate as a cleaning solvent to be easily removed, and the removed corrosion-resistant material and the ethyl acetate as the cleaning solvent canalso be recycled.

Owner:南京金三力橡塑有限公司

Current collector for air electrode

PendingCN112072135AImprove breathabilitySmall apertureFuel and secondary cellsFuel cellsPtru catalystEngineering

The invention relates to a current collector for an air electrode. The current collector comprises foam carbon. As the slurry can be uniformly coated on the foam carbon, the amount of the carbon material, the catalyst and the like loaded on the current collector can be properly reduced, and the coating thickness can be reduced, so that the utilization rate of the catalyst and the like is greatly increased, the transportation of oxygen in the air electrode is facilitated, and finally, the purposes of improving the discharge capacity and reducing the discharge cost are achieved. Polarization isreduced and power characteristics are improved.

Owner:SHANGHAI INST OF MICROSYSTEM & INFORMATION TECH CHINESE ACAD OF SCI

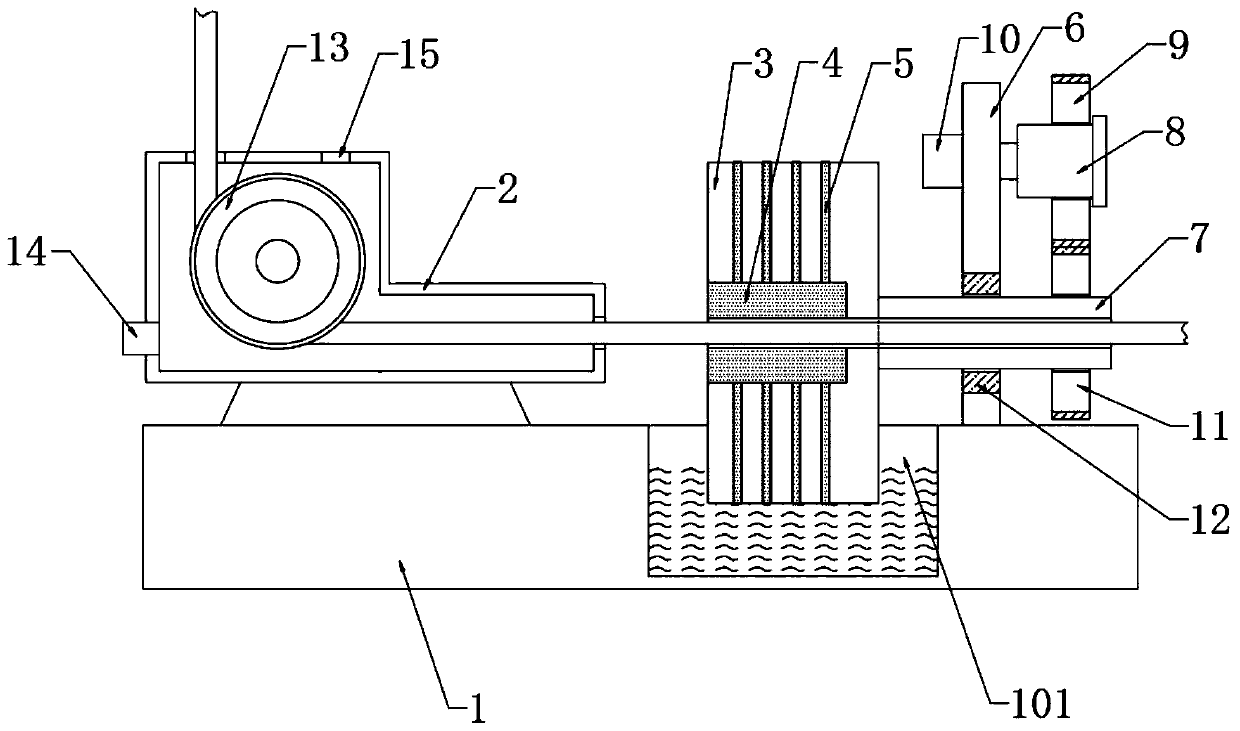

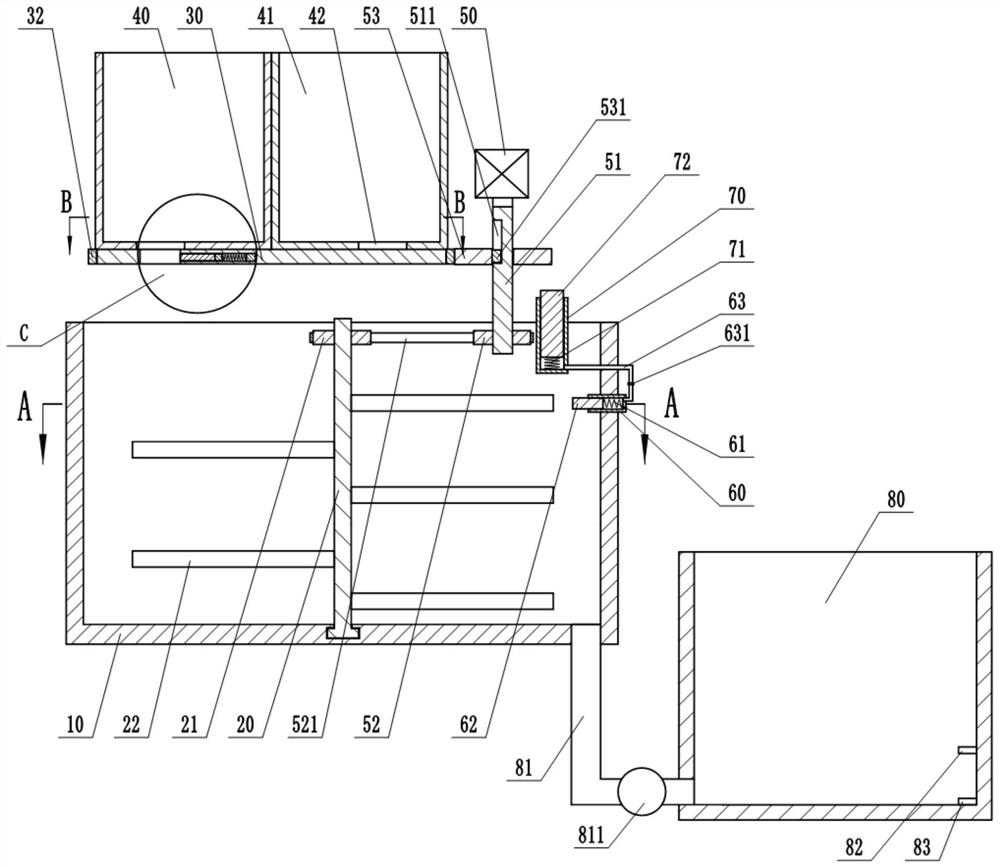

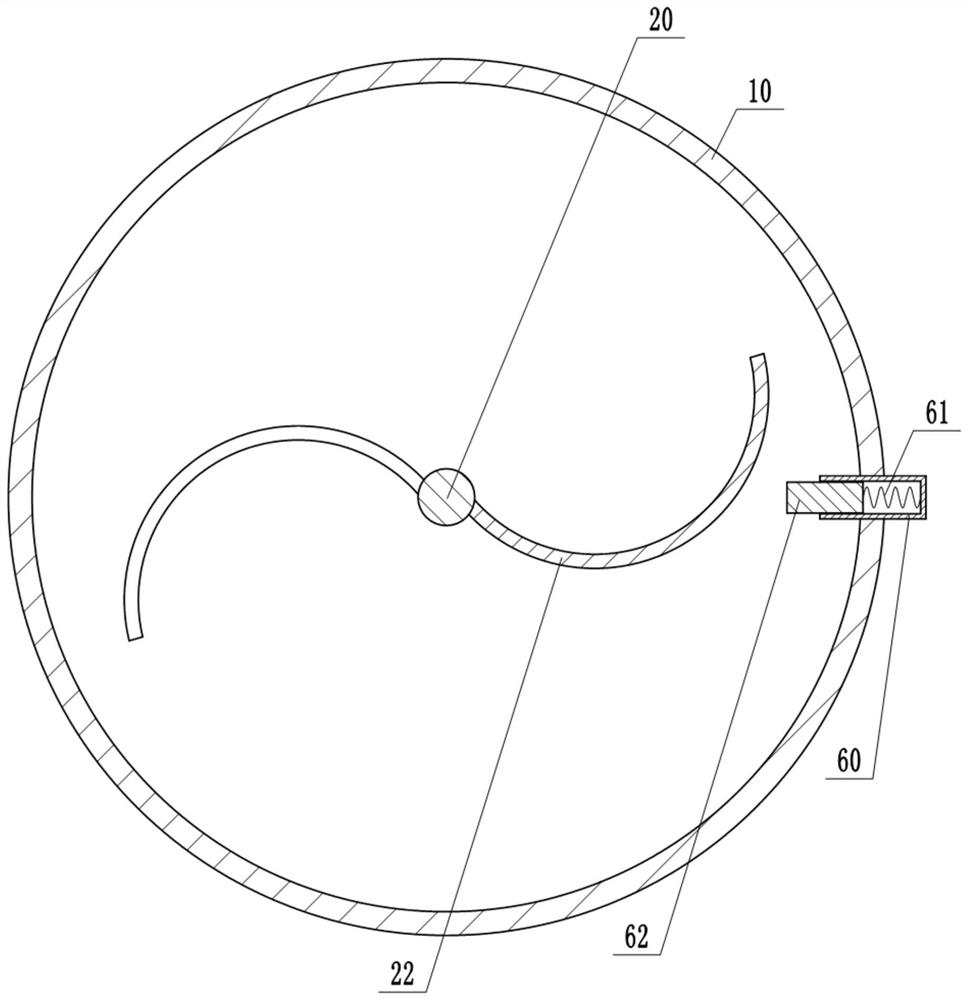

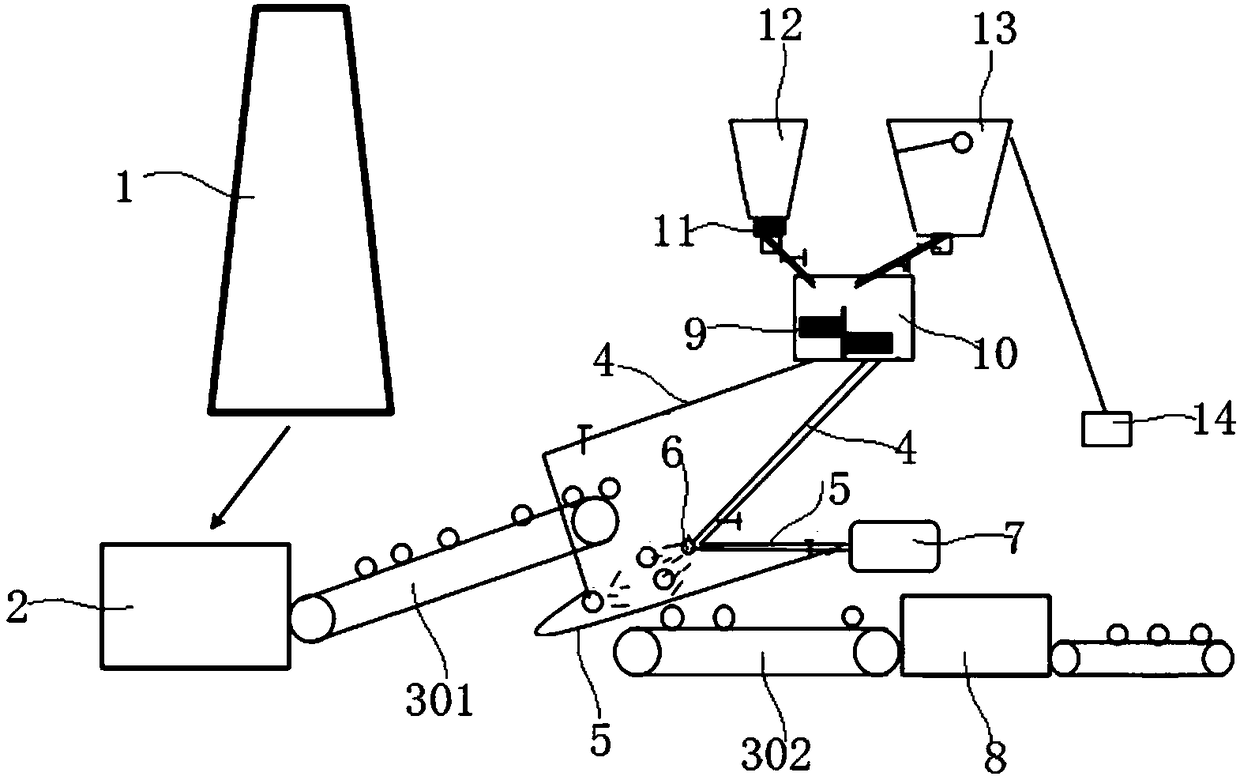

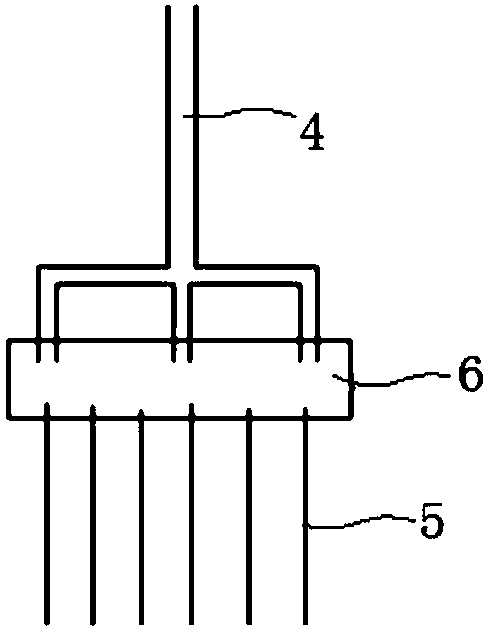

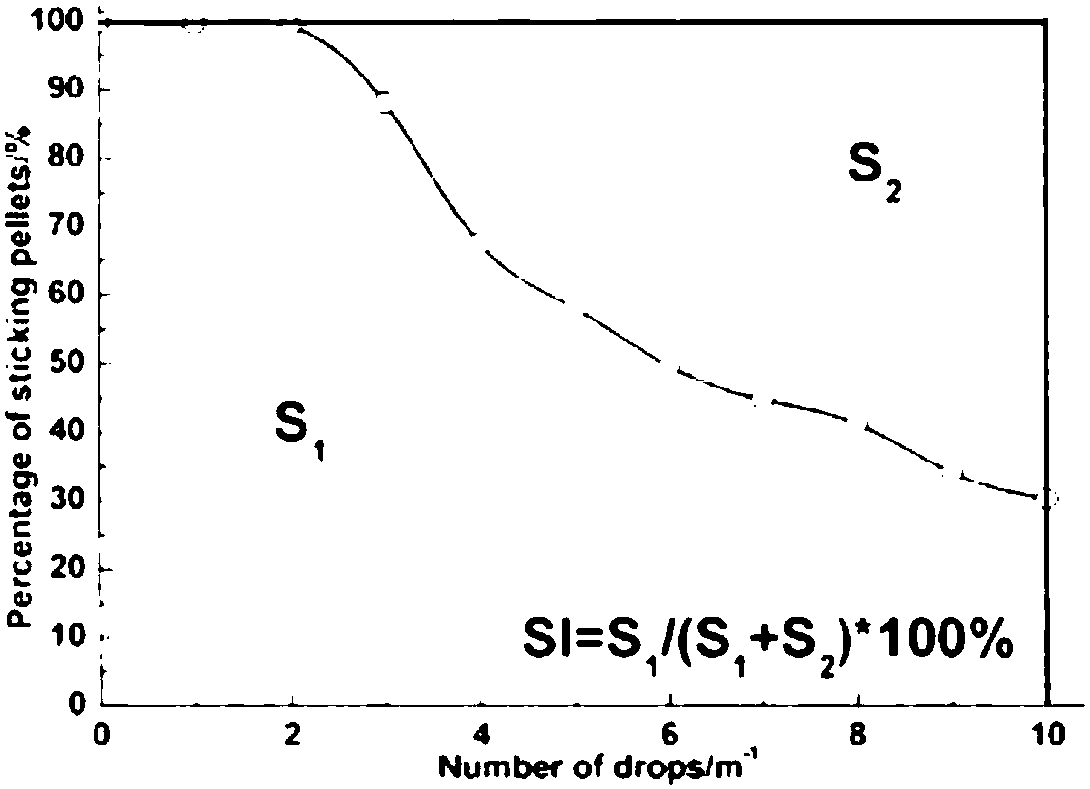

A production system for corex shaft furnace coated pellets

The invention discloses a production system for coated pellets of COREX shaft furnace and belongs to the technical field of pellet production equipment. The production system comprises a roasting furnace, a conveying mechanism, a spraying mechanism and a mixing tank, wherein the roasting furnace is connected to a circular cooling area in a conveying manner. Oxidized pellets to be coated in the circular cooling area are conveyed through the conveying mechanism. The spraying mechanism is positioned above the conveying mechanism. Through the spraying mechanism, a coating mixed liquor inside the mixing tank is sprayed onto the surface of the oxidized pellets to be coated. By the production system for production of the coated pellets, the caking problem of pellets in a COREX shaft furnace technology can be effectively improved, and the system is also beneficial to direct motion of a COREX pre-reduction shaft furnace and helps raise utilization efficiency of COREX shaft furnace equipment and reduce production cost of direct reduction iron. Caking index of reduced pellets is less than 25%.

Owner:ANHUI UNIVERSITY OF TECHNOLOGY

Medical cosmetology spray dressing smearing device convenient for uniform smearing

The invention provides a medical cosmetology spray dressing smearing device convenient for uniform smearing, and relates to the technical field of spray dressing smearing. The medical cosmetology spray dressing smearing device convenient for uniform smearing comprises a base plate, an extrusion mechanism is installed at the top of the base plate and comprises an extrusion pipe, an electric switch is hinged to the outer side of the extrusion pipe, an extrusion rod is inserted into the extrusion pipe, a baffle is hinged to the bottom of an extrusion plate, and a rotating disc is fixedly connected with the bottom of the extrusion rod. According to the medical cosmetology spray dressing smearing device convenient for uniform smearing, the rotating disc rotates by pressing an electric switch to swing, the electric switch changes the rotating speed of the rotating disc through different electric switch pressures and different swing angles, and therefore the smearing speed can be adjusted; and the medical cosmetology spray dressing smearing device is suitable for wounds with different severity degrees, smearing is comfortable, and through cooperative use of a smearing roller and the rotating disc, the effects of uniform smearing and convenient use are achieved.

Owner:王爱堂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com