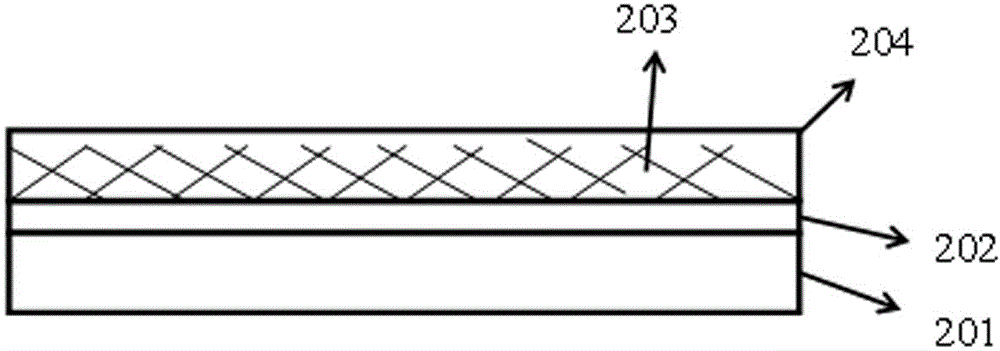

Low-haze transparent conductive film and preparation method thereof

A technology of transparent conductive film and transparent conductive layer, which is applied in the direction of cable/conductor manufacturing, conductive layer on insulating carrier, conductive material dispersed in non-conductive inorganic materials, etc. Layer and other problems, to achieve excellent weather resistance, improved adhesion, good solvent resistance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

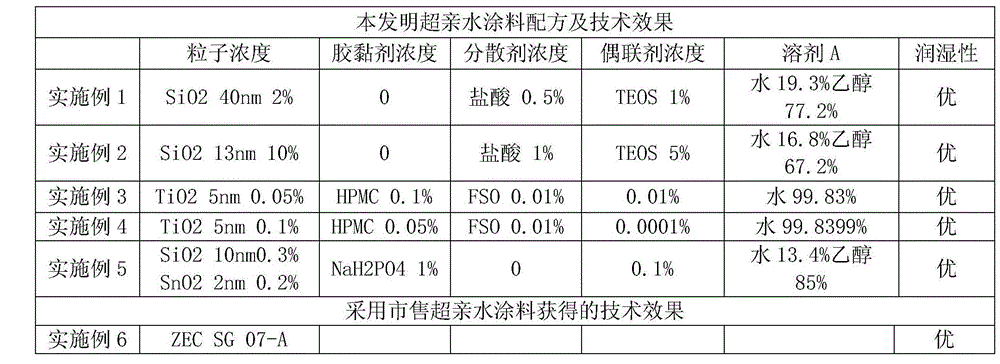

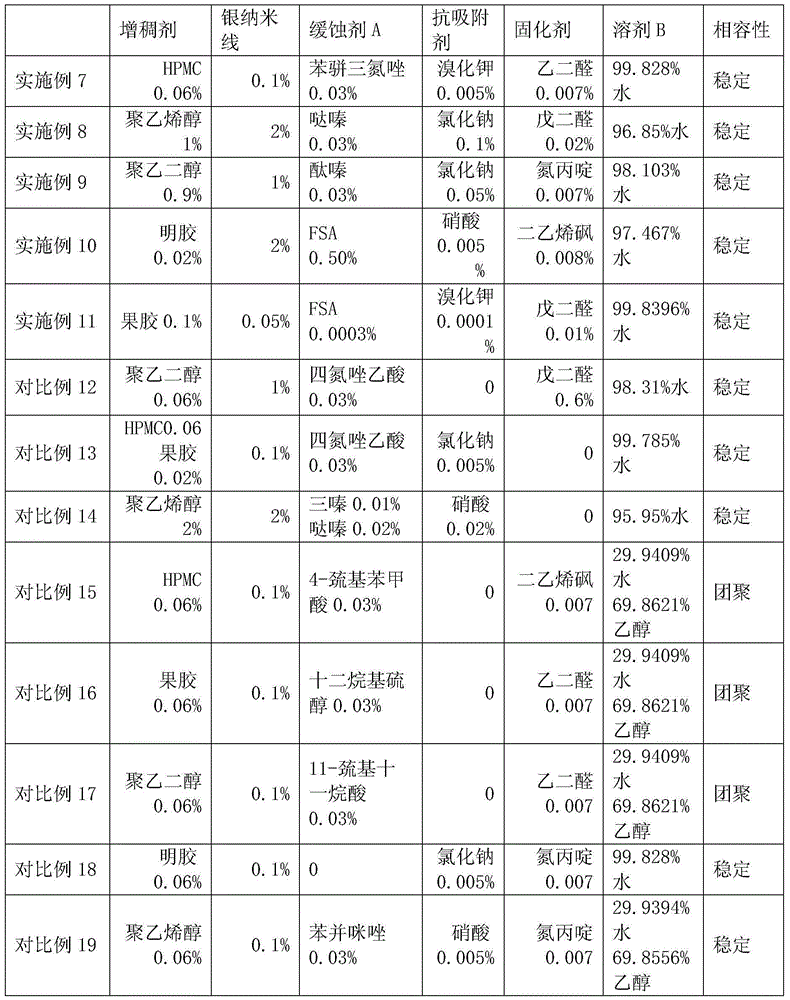

Embodiment 1

[0136] Weigh 10g of 20% mass concentration of 40nm SiO2 nanoparticle aqueous solution, 1.4g of 35.5% mass concentration of hydrochloric acid aqueous solution, 1gTEOS, add 8.4g of water to dilute, stir well, add 77.2g of ethanol, stir well, and configure it as a coating solution. Use OPS-10 wire rod to get 10μm thick wet film on PET surface, bake at 120℃ for 10 minutes. Get the pretreated PET film, which is denoted as sample1.

Embodiment 2

[0138] Weigh 20g of 50% mass concentration of 13nm SiO2 nanoparticle aqueous solution, 2.8g of 35.5% mass concentration of hydrochloric acid aqueous solution, 5g of TEOS, stir evenly, add 67.2g of ethanol, stir evenly, and configure it as a coating solution. Use OPS-10 wire rod to get 10μm thick wet film on PET surface, bake at 120℃ for 10 minutes. Obtain the pretreated PET film, denoted as sample2.

Embodiment 3

[0140] Weigh 0.25g of 20% mass concentration 4nmTiO2 nanoparticle aqueous solution, 10g of 1% mass concentration of HPMC aqueous solution, 1g of 1% FSO aqueous solution, 1g of 1% titanate aqueous solution, add 86g of water to dilute, stir evenly, and configure it as a coating solution. Use OPS-10 wire rod to get 10μm thick wet film on PET surface, bake at 120°C for 10 minutes, and irradiate with 400w UV for 10 seconds. Get the pretreated PET film, which is denoted as sample3.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com