A production system for corex shaft furnace coated pellets

A production system and coating technology, which is applied in the field of pellet production equipment, can solve problems such as increased screw feeder workload, high-temperature extrusion force, and difficulty in unloading shaft furnaces, so as to improve the bonding firmness, High degree of automation, effect of suppressing sticking phenomenon

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

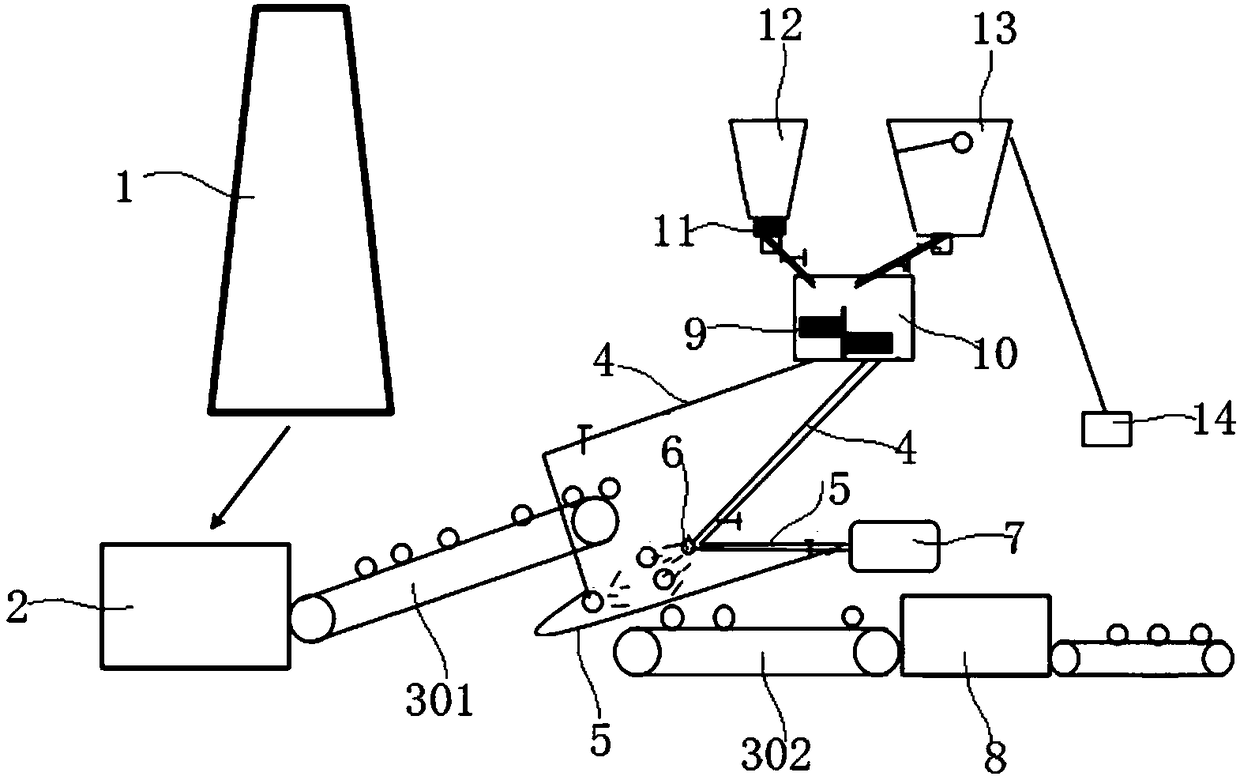

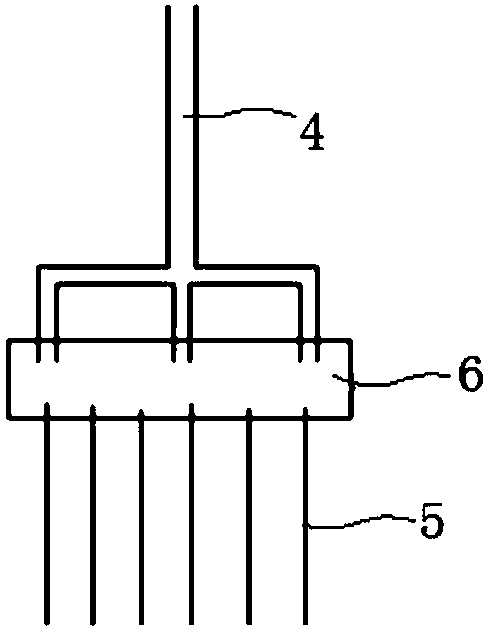

[0037] Such as figure 1 Shown, the production system of a kind of COREX shaft furnace coated pellet of the present embodiment, this production system comprises roasting furnace 1, conveying mechanism, spraying mechanism and mixing tank 10, wherein, described roasting furnace 1 and ring cooling Zone 2 is conveyed and connected, and the oxidized pellets to be coated in the annular cooling zone 2 are transported by the conveying mechanism. The oxidized pellets obtained after roasting in the roasting furnace 1 are cooled to 100°C in the annular cooling zone 2, and 8- After the qualified particle size of 16mm is transported by the conveying mechanism, the spraying mechanism is located above the conveying mechanism, and the coating mixture in the mixing tank 10 is sprayed to the surface of the oxidized pellets to be coated by the spraying mechanism, so that it can be oxidized A layer of uniform coating is prepared on the surface of the pellets, and the combination between the coating a...

Embodiment 2

[0039] Such as figure 1 Shown, the production system of a kind of COREX shaft furnace coated pellet of the present embodiment, this production system comprises roasting furnace 1, conveying mechanism, spraying mechanism and mixing tank 10, wherein, described roasting furnace 1 and ring cooling Zone 2 is conveyed and connected, and the oxidized pellets to be coated in the ring cooling zone 2 are transported through the conveying mechanism. The spraying mechanism is located above the conveying mechanism, and the paint mixture in the mixing tank 10 is sprayed to the to-be-treated pellet by the spraying mechanism. Coat the surface of the oxidized pellets. The coating in the mixing tank 10 is made of light burnt dolomite, Ca(OH) 2 , anthracite and water mixture, so as to ensure that the cohesion between pellets in the COREX shaft furnace can be effectively suppressed while maintaining a high metallization rate to prevent the reduction of the metallization rate, and the coating mat...

Embodiment 3

[0061] The structure of a production system of a COREX shaft furnace coated pellet of the present embodiment is the same as in Example 1, and the specific steps of using this system to produce coated pellets are:

[0062] (1) Preheat the raw pellets at 900°C for 15 minutes, then place them in the roaster 1 for roasting to form the finished product of oxidized pellets (the main components of the oxidized pellets after roasting are the same as in Example 1), and control the roaster The calcination temperature of 1 is 1280°C, the calcination time is 15min, and the heating rate is 10°C. The main components of the oxidized pellets obtained after calcination are close to those of Example 1.

[0063] (2) The 500g calcined pellets are transported by the conveying mechanism. When the oxidized pellets are transferred from the primary conveying device 301 to the secondary conveying device 302, the coating mixture in the mixing tank 10 is sprayed to the The surface of the pellets, which i...

PUM

| Property | Measurement | Unit |

|---|---|---|

| strength | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com