TiO2 nanotube-based perovskite cell electrode preparation method

A perovskite battery and nanotube technology, which is applied in the direction of nanotechnology, nanotechnology, nanotechnology, etc. for materials and surface science, can solve the problem of uncontrollable oblique growth of ZnO nanowires and affecting perovskite thin film solar cells Photoelectric conversion efficiency, difficulties and other issues, to achieve the effect of enhancing the steric hindrance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

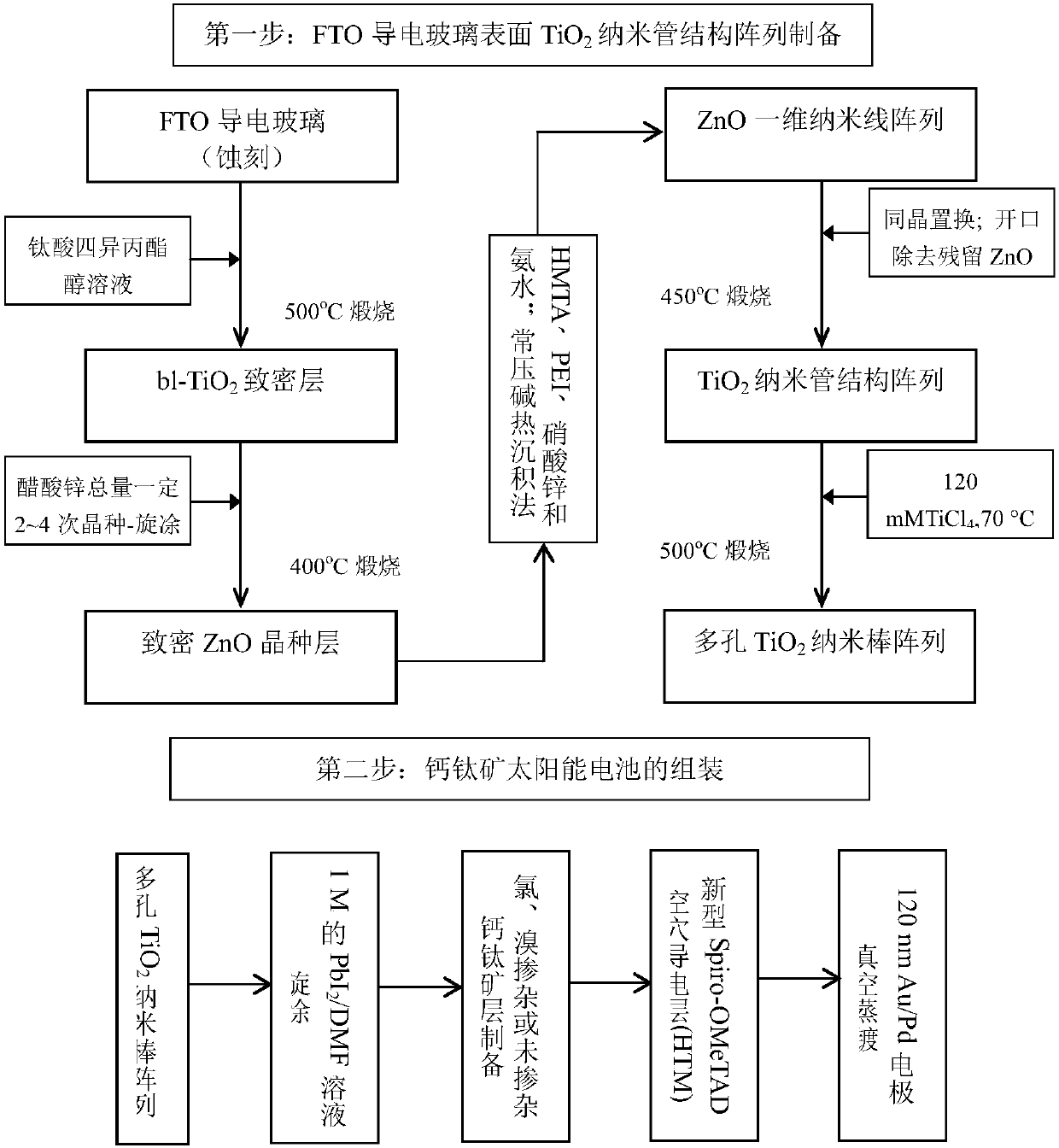

Method used

Image

Examples

preparation example Construction

[0080] First bl-TiO 2 The preparation of dense layer (all adopt identically in the following examples):

[0081] Pretreatment, cleaning the FTO conductive glass substrate, that is, ultrasonic treatment with methanol, ethanol, and deionized water respectively, and after drying, prepare bl-TiO 2 Floor.

[0082] Preparation of 0.1M and 0.2M titanium solutions: Weigh 4.86g and 9.72g of tetraisopropyl titanate respectively, and dissolve them in 100mL of n-butanol.

[0083] Use a 20-200μL pipette gun to pipette 80μL of 0.1M titanium solution and spin-coat it on the front of the FTO conductive glass at a speed of 3000r / min for 30s and dry at 125°C for 5min. After the covered film is cooled to room temperature, follow the same steps as above The 0.2M titanium solution was repeatedly spin-coated twice, and finally the three-time spin-coated glass substrate was calcined in a tube furnace at 500°C for 30min. Take it out directly after calcination, and get the front side coated with Ti...

example (1

[0084] Example (1): The multi-step seed crystal Spin-coating method is adopted. In example (1) preparation of zinc oxide (ZnO) nanowire arrays: Use a 20-200 μL pipette gun to pipette 80 μL of 5 mM zinc acetate ethanol solution according to the first 20 μL, the second 20 μL, the third 20 μL and the fourth 20 μL spin-coated on FTO conductive glass bl-TiO 2 dense layer surface. The rotating speed is 3000r / min, and the spin coating time is 30s. Then calcined in a tube furnace at 400° C. for 30 minutes to obtain a flat and uniform ZnO seed crystal film. The following is divided into the following steps.

[0085] (a) Vertically aligned ZnO one-dimensional nanowires were grown by atmospheric pressure alkaline thermal deposition method in 90 °C water bath. Corrosion control inhibitor hexamethylenetetramine (HMTA): 11~14mM, template agent polyethyleneimine (PEI): 1.6~2.5mM, zinc source zinc nitrate: 22~28mM, alkali ammonia water: 0.22~0.28M. And use a special glass cover to press ...

example (2

[0106] Adopt multi-step seed crystal Spin-coating method. In the process of example (1) growing vertically aligned ZnO one-dimensional nanowires by the normal-pressure alkaline thermal deposition method, the chemical deposition time was controlled to be 20 minutes, and the rest were the same.

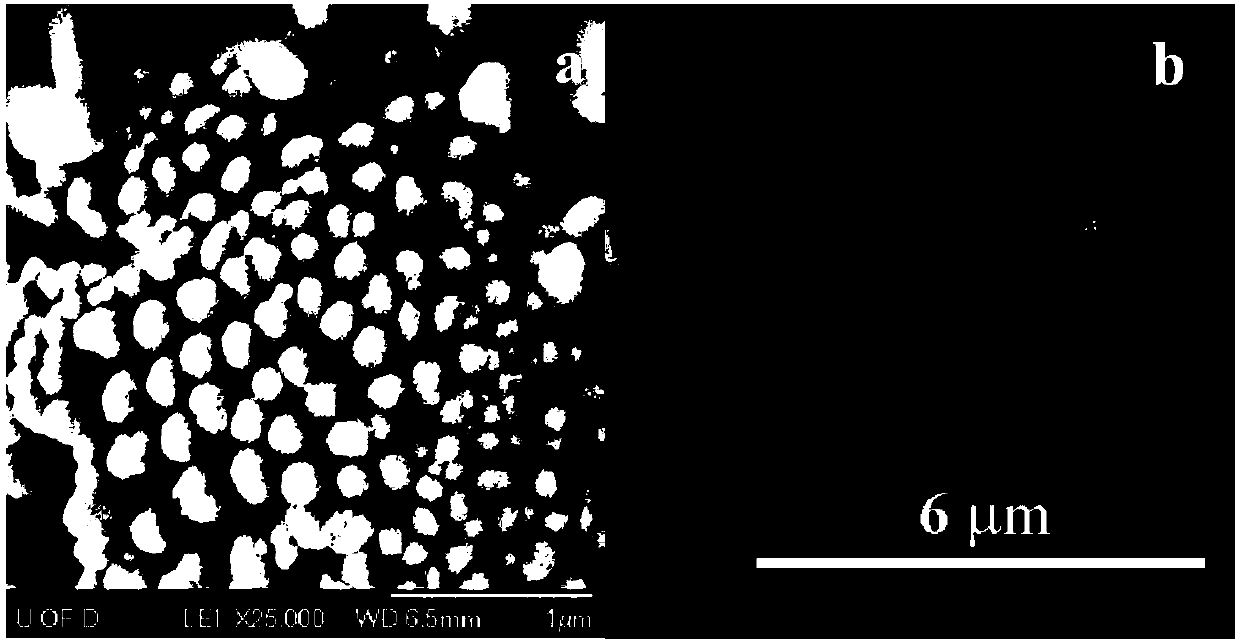

[0107] Image 6 For the multi-step seed crystal {20μL (1st time) + 20μL (2nd time) + 20μL (3rd time) + 20μL (4th time)} Spin-coating method nano ZnO wire distribution SEM image (a) and cross section Figure (b), the chemical deposition time is 20 minutes.

[0108] Image 6 a shows the vertical growth of ZnO nanowires with a diameter of 160-190 nm; Image 6 The cross-sectional view of b shows that the ZnO nanowire arrays grown vertically are closely arranged, and the ZnO nanowires are 1.7-1.8 μm long, which is longer than the 0.8-0.9 μm ZnO nanowires grown in 10 minutes. The distance between the obtained ZnO rods and rods is only about 50nm, indicating that the seed distribution is ve...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com